Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

94 results about "Emulsion dispersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An emulsion dispersion is thermoplastics or elastomers suspended in a waterphase with help of emulsifiers.

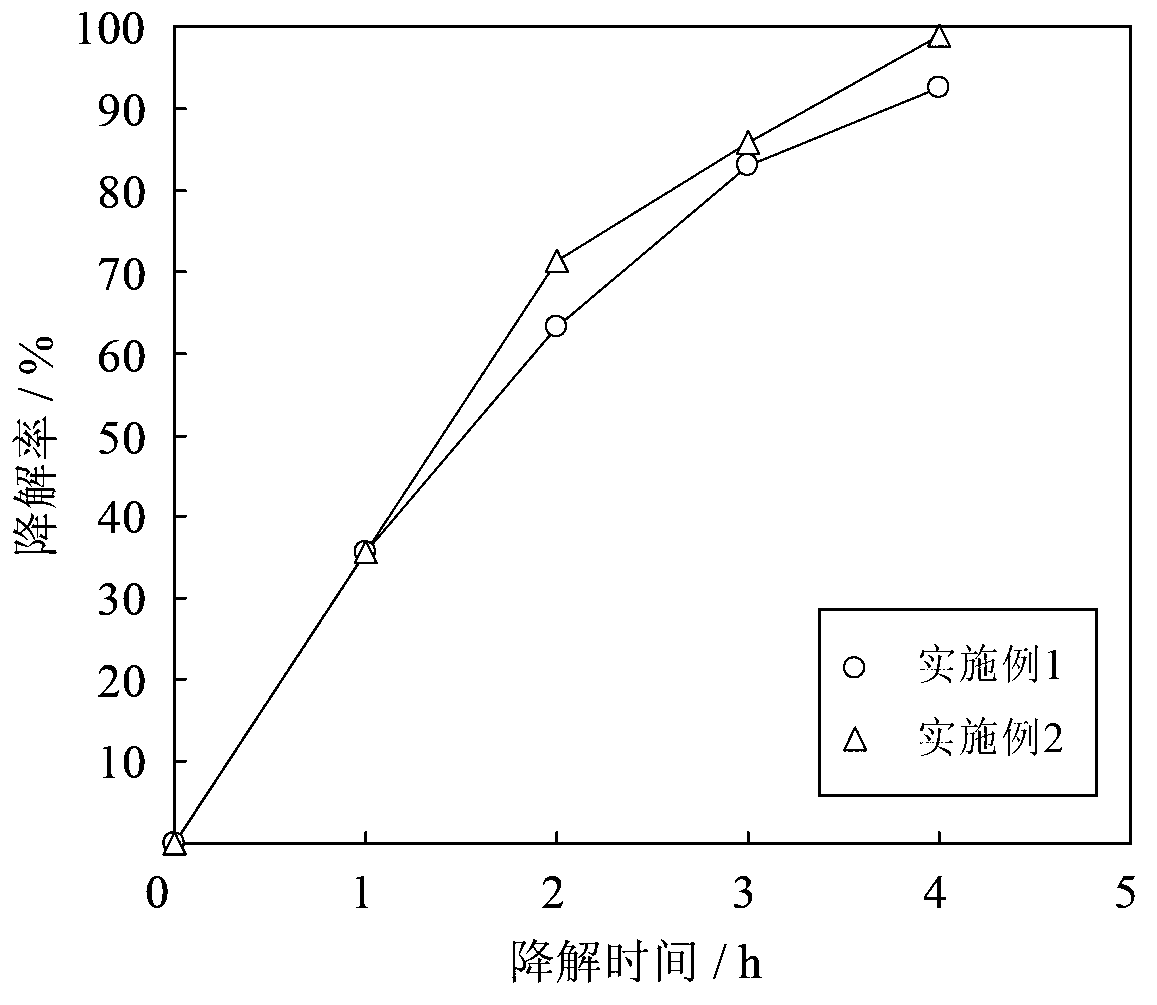

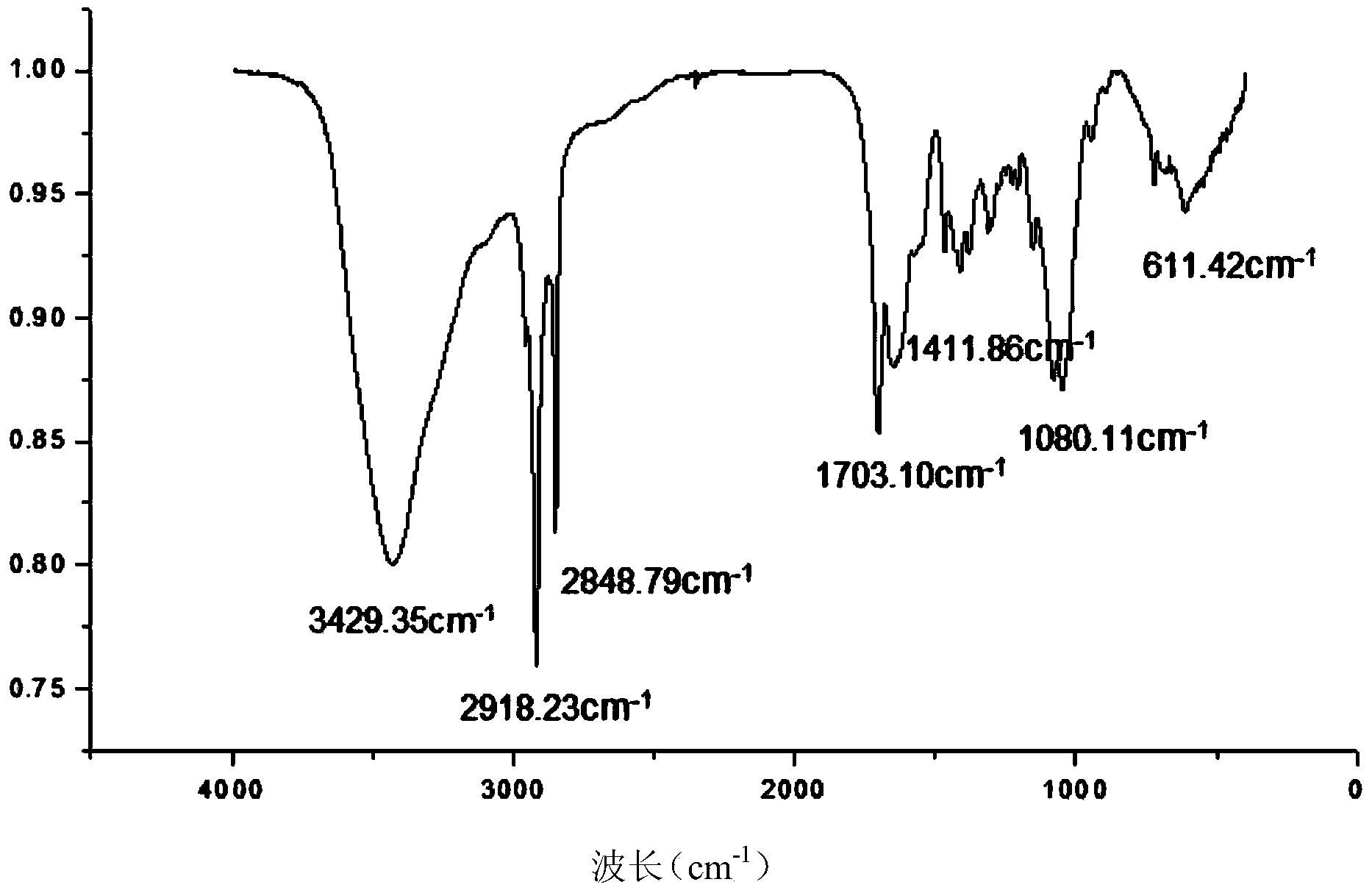

Preparation method of waterborne polyurethane capable of selfreparing

The invention relates to a preparation method of waterborne polyurethane capable of selfreparing. The preparation method includes the steps that hydrophilic chain extender is added to dihydric alcohol, heating for dehydration is conducted under a vacuum condition, the mixture is cooled to 70-85 DEG C, diisocyanate is added, stirring is conducted for a reaction, then the temperature is cooled to 50-55 DEG C, butanone is added, then a catalyst and the chain extender containing disulfide bonds are added, a reaction is conducted for 0.5-3 hours, then the temperature is cooled to 30-35 DEG C, neutralizer is added, then the mixture is cooled to 20-25 DEG C, distilled water is added, the mixture is stirred till emulsion and dispersion are achieved, ethidene diamine is added, chain extension is conducted for 0.5-1 hour, the butanone is removed, vacuum defomaing is conducted, and waterborne polyurethane capable of being self-repaired is obtained. The waterborne polyurethane prepared through the method can be self-repaired under the heating condition, the required condition is mild, the repairing effect is good, emulsion dispersion stability is good, operation is simple, and environmental friendliness is good.

Owner:DONGHUA UNIV

Preparation method for aired tobacco extracts and essential oil

InactiveCN102488318ASimple production process and equipmentImprove controllabilityTobacco preparationTobacco treatmentWaxAlcohol

The invention discloses a preparation method for aired tobacco extracts and essential oil. The preparation method includes extracting aroma components such as ester, wax compounds and the like in aired tobaccos by the aid of carbon dioxide supercritical fluid; adopting water as eluent to dynamically wash supercritical fluid extracts in a primary separating kettle so as to extract water soluble components; eluting the supercritical fluid extracts via ethanol in a secondary separating kettle to obtain alcohol soluble aired tobacco essential oil; and utilizing alcohol insoluble substances as cigarette aroma additives by an emulsion dispersion method. The preparation method can remarkably increase aired tobacco aroma component extracting efficiency and selectivity, aired tobacco aromatic characteristics of the extracts are remarkable, offensive and irritancy can be reduced, and sensory comfort can be improved.

Owner:CHINA TOBACCO ANHUI IND CO LTD

Acid soaping agent

ActiveCN101781613AImprove washing fastnessGood anti-staining effectSurface-active detergent compositionsHydrophilic monomerMaleopimaric acid

The invention discloses an addition agent acid soaping agent for dyeing. Although the conventional soaping agent composite has good soaping function, but cannot neutralize the alkaline substances which are remained on the cloth, and the cloth is washed by water for multiple times until the pH value of the cloth is close to neutral, the cloth can be used, so a great amount of water resource is wasted. Fatty alcohol polyethenoxy ether is firstly reacted with acrylic acid or maleic acid to generate a polymerization monomer with surface activity, then under the existence of the evocating agent, the polymerization monomer is polymerized with hydrophilic monomer to generate a macromolecular polymer having dispersion chelation performance, and the macromolecular polymer is compounded with the surface active agent to obtain the acid soaping agent. The prepared acid soaping agent integrates the neutralization process and the soaping process after the dyeing of the active dye, so the process flow is greatly shortened, the water is saved, the energy is saved, the emulsion dispersion chelation performance is excellent, the loose color on the texture can be easy to wash, and the staining prevention performance is excellent.

Owner:HANGZHOU TRANSFAR FINE CHEM CO LTD +2

Agricultural macromolecular surfactant and preparation method and application thereof

InactiveCN102308798ARealize intelligent controlRealize adjustableBiocideAnimal repellantsHydrophilic monomerPolymer science

The invention discloses an agricultural macromolecular surfactant and a preparation method and application thereof, belonging to the technical field of surfactants. According to the invention, the block-type macromolecular surfactant is prepared by performing solution or emulsion polymerization on hydrophilic monomer and lipophilic monomer in a manner of employing a reversible addition fragmentation chain free radical copolymerization technology under the action of an initiator and a chain transfer agent, wherein the polymerization temperature is 50-150 DEG C and the polymerization pressure is 0.1-10 MPa. The macromolecular surfactant is applied in environment-friendly pesticide preparations. Hydrophilic groups with high charge density are bonded with the two ends of the macromolecular surfactant, and a hydrophobic long carbon chain is bonded with the other end of the macromolecular surfactant. According to the invention, the molecular weight and the molecular chain segment sequence structure of the macromolecular compound are intelligently controlled, and the molecular weight distribution is narrow. When being used in a pesticide preparation, the surfactant disclosed by the invention has the advantages of small dosage and good emulsion dispersion stability.

Owner:YANGZHOU SPED CHEM

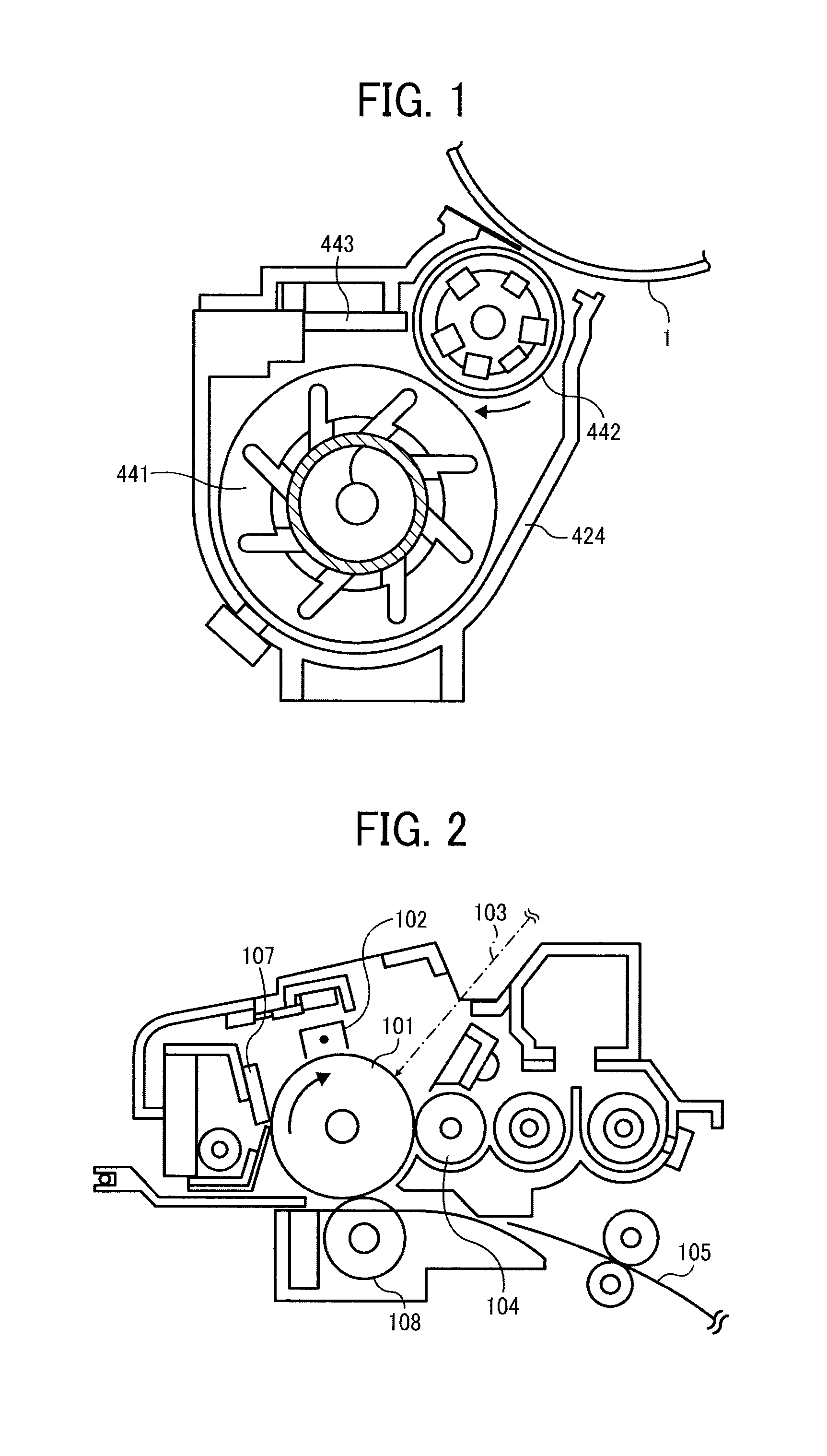

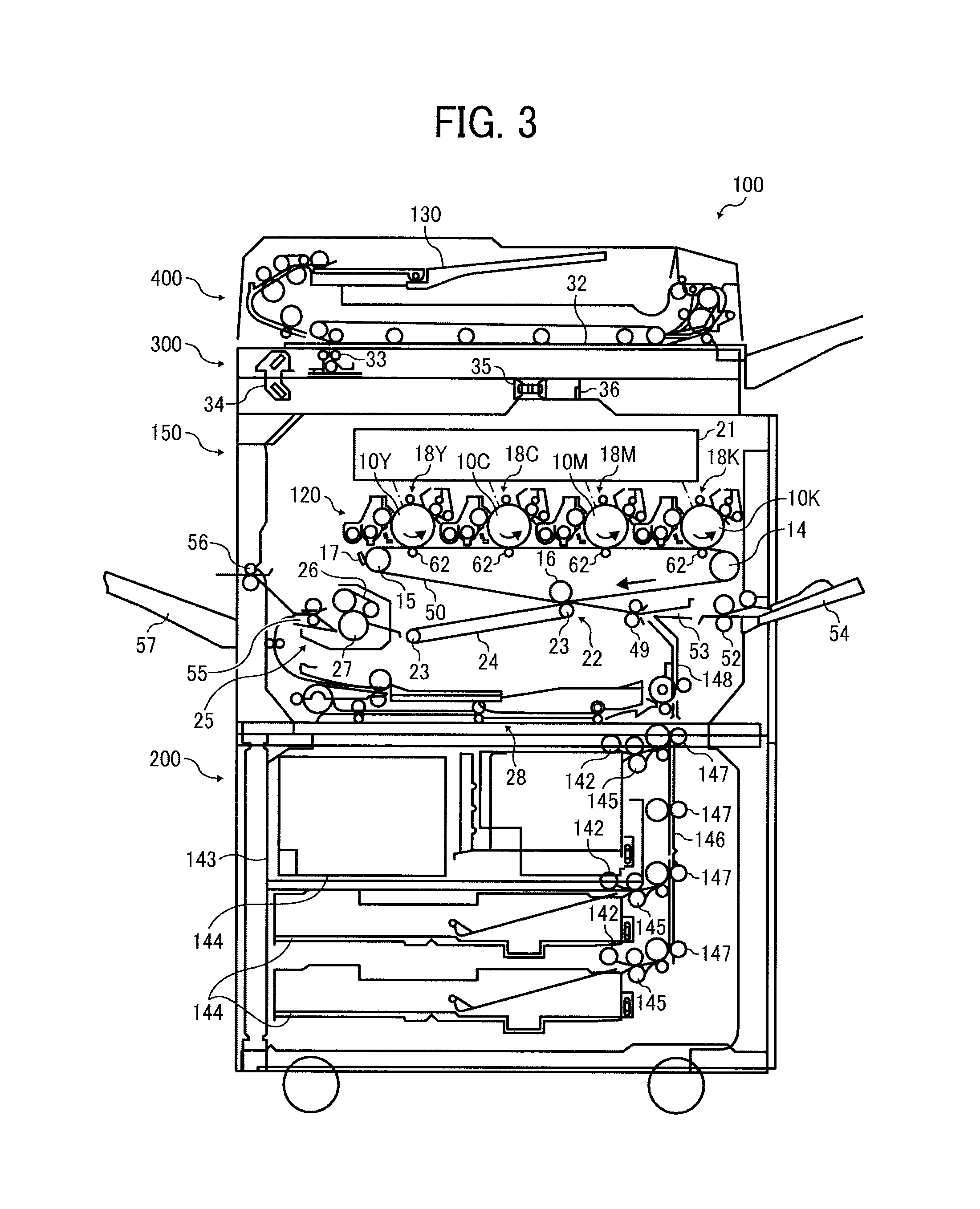

Toner for electrophotography, developer and method of preparing the toner

InactiveUS20130236826A1Improve low-temperature fixabilityAvoid it happening againDevelopersOrganic solventOil phase

A toner for electrophotography, which is prepared by a method including dissolving or dispersing a toner composition including at least a binder resin, or binder resin and a binder resin precursor as a resin component; and a colorant in an organic solvent to form an oil phase; emulsifying or dispersing the oil phase in an aqueous medium to form an emulsion dispersion comprising emulsified particles; converging the emulsified particles to granulate mother toner particles, including controlling a temperature of the emulsion dispersion to control a circularity of the mother toner particles; and removing the organic solvent, wherein the resin component includes a crystalline resin in an amount not less than 50% by weight, and the mother toner particles have an average circularity of from 0.940 to 0.980.

Owner:RICOH KK

Preparation method of sulfonate amphoteric polyurethane emulsion

The invention relates to a preparation method of sulfonate amphoteric polyurethane emulsion, comprising the following steps: adding oligomer polyalcohol subject to vacuum dehydration and isocyanate into a reactor under the protection of dry nitrogen, mechanically stirring the oligomer polyalcohol and the isocyanate to react for 2h at 85-100 DEG C, reducing the system temperature to 40-60 DEG C, adding a micro-molecule chain extender, a solvent, a catalyst stannous octoate (T-9) and dibutyltin dilaurate (T-12), and maintaining the temperature to react for 2h at 55-75 DEG C; reducing the systemtemperature below 60 DEG C, and adding a positive ion chain extender and the solvent to control the temperature between 40 DEG C and 60 DEG C to react for 1h; adding the sulfonate and the solvent; adding water to carry out emulsion dispersion until the content of an isocyanate group can not change in a generated prepolymer to be reacted; and decompressing, distilling and desolventizing to obtain the sulfonate amphoteric polyurethane emulsion. The prepared sulfonate amphoteric polyurethane emulsion has a certain acidity-alkalinity resistance and can be used as an excellent carrier of a biological macromolecule and a more ideal protein model compound.

Owner:ANHUI UNIVERSITY

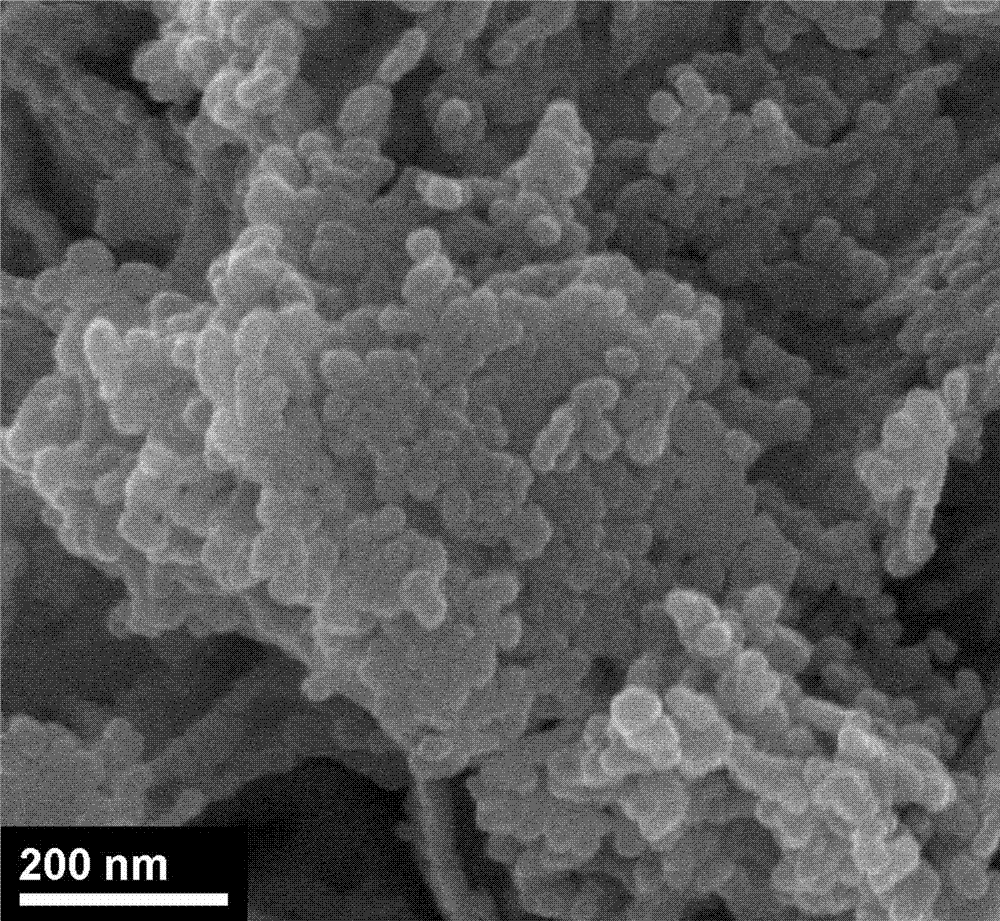

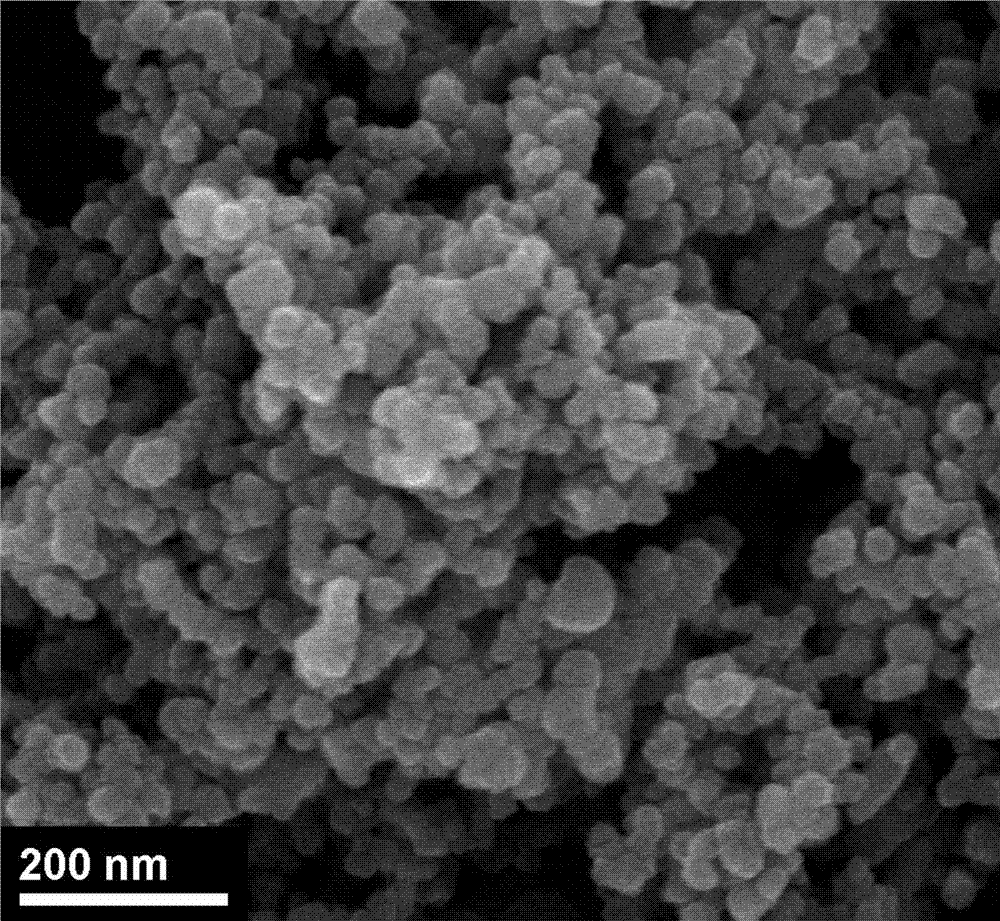

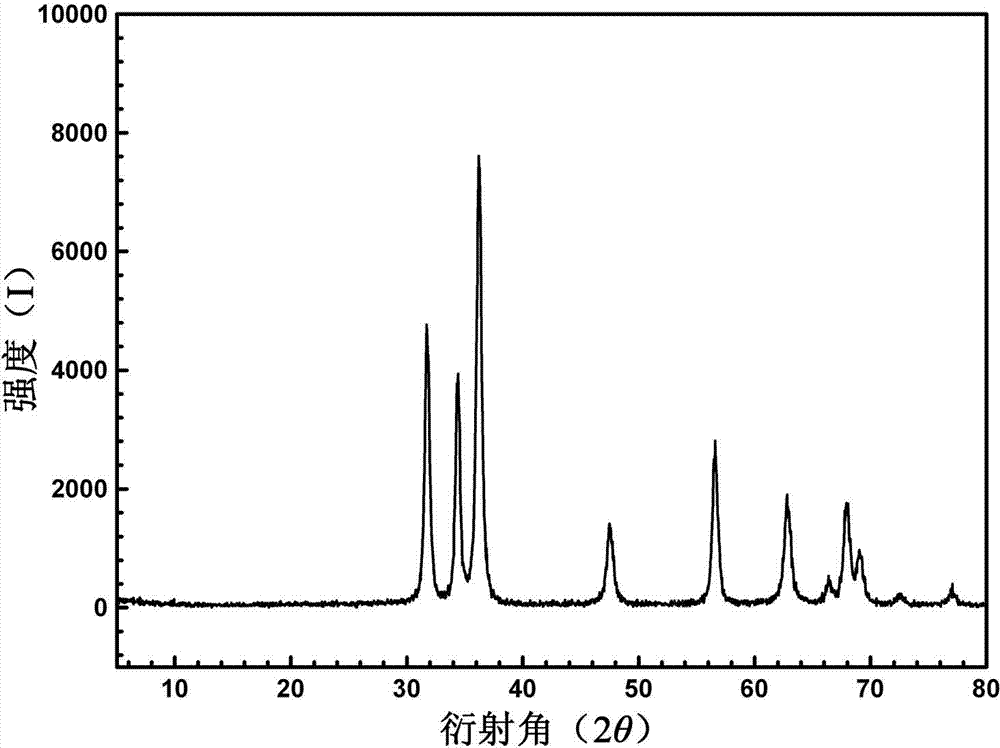

Preparation method of nanometer zinc oxide composite dispersion liquid

InactiveCN103693674AGood dispersionUniform and stable dispersionMaterial nanotechnologyZinc oxides/hydroxidesZno nanoparticlesOxide composite

The invention discloses a preparation method of a nanometer zinc oxide composite dispersion liquid. The method is characterized by comprising the following steps: mixing an oil phase component and an emulsifier according to certain proportion in an oil phase system; adding a dispersion stabilizing agent, a surfactant and a nano zinc oxide powder according to a certain ratio into water in a water dispersion system; and respectively uniformly mixing the two phases and heating to a certain temperature, rapidly stirring the two phases for homogeneous mixing, and cooling to room temperature to form a stable emulsion dispersion system. The nanometer zinc oxide composite dispersion liquid prepared by the above method, the particle size difference of zinc oxide particle and nano zinc oxide powder raw material is within 20%; in the dispersion liquid, nano zinc oxide particles are suspended in the liquid in a monodispersed form; and placing for more than 60 days, the nano zinc oxide composite dispersion liquid does not generate the phenomena of layering, demulsification or caking. Moreover, the preparation method has the advantages of simple operation, wide adjustable range of parameters, low energy consumption and short cycle, and is suitable for pilot plant test amplification and industrial large-scale production.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Waterborne polyurethane printing ink connecting material and preparation method thereof

The invention belongs to the technical field of waterborne printing ink and discloses a waterborne polyurethane printing ink connecting material and a preparation method thereof. The preparation method includes the steps that oligomer polyhydric alcohol and polyisocyanate react, then a hydrophilic chain extender and an alcohol micromolecular chain extender are sequentially added for a chain extending reaction, and after a reaction product is diluted and neutralized, an NCO-base-terminated polyurethane prepolymer is obtained; the polyurethane prepolymer is subjected to phase inversion emulsion dispersion in water, then an amine chain extender and a silane coupling agent are added for a rear chain extending and cross-linking reaction, and the waterborne polyurethane printing ink connecting material is obtained. The obtained product has excellent water resistance, heat stability and adhesion firmness, and is safe, free of toxins and suitable for printing thin films for food packaging.

Owner:SOUTH CHINA UNIV OF TECH

Hollow TiO2 microsphere synthesizing method

ActiveCN102701276AAccelerated settlementImprove light absorption efficiencyTitanium dioxideLiquid mediumMicrosphere

The invention discloses a hollow TiO2 microsphere synthesizing method, and belongs to the field of solar energy utilizing photovoltaic technology and photocatalysts. In the hollow TiO2 microsphere synthesizing method, through hydrothermal treatment, tetrabutyl titanate is directly taken as an oil phase and forms an emulsion dispersion system with water to obtain a TiO2 hollow spherical particle; a hollow characteristic is obtained through simple change in the mixing sequence of raw materials; the substantial part of the TiO2 hollow spherical particle has a three-dimensional interpenetrating network structure formed by a nano TiO2 crystal grain and a nano-sized space; the average diameter of the spherical particle is 0.5-1.5 microns and can be adjusted by changing the adding amount of a surfactant; the specific surface area of the spherical particle is 32-97 m2 / g; the apparent density of the spherical particle is 1.91 g / cm3. When the hollow spherical particle is used as an electrode material of a dye-sensitized TiO2 solar cell, the optical path can be elongated and the utilization efficiency of light energy can be improved; and when the hollow spherical particle is used as a photocatalyst, the photocatalytic activity is high and the hollow spherical particle is easily separated from a liquid medium.

Owner:溧阳常大技术转移中心有限公司

Thick oil activating agent and preparation method thereof

ActiveCN107383273AIncrease the viscosity of the aqueous phaseWith displacement functionDrilling compositionOil phaseReducer

The invention discloses a thick oil activating agent and a preparation method thereof. The thick oil activating agent is a polymer with the structure formula shown as a formula (1). In the formula (1), x, y, z, m and n are respectively mass percentage of the corresponding chain sections in the polymers; the m is between 0.75 and 0.85; the y is between 0.020 and 0.24; the x, the z, and the n are respectively between 0.001 and 0.01; the p is a natural number between 2 and 9. The activating polymer provided by the invention has the effects of enhancing the water phase viscosity and reducing the crude oil viscosity, and can be used as a displacing agent and a viscosity reducer to realize the integration of the displacing agent and the viscosity reducer. The activating polymer can enhance the water phase viscosity; the displacing function is realized; the emulsion dispersion of crude oil can be realized; the mixed phase flowability is enhanced; in addition, the dispersed crude oil and the non-contact crude oil continuously act; meanwhile, the water phase acts with both the mixed oil phase and the new oil in a continuously following way; more crude oil is continuously started. The activating polymer provided by the invention has low interface tension and has certain oil washing capability.

Owner:CHINA NAT OFFSHORE OIL CORP +1

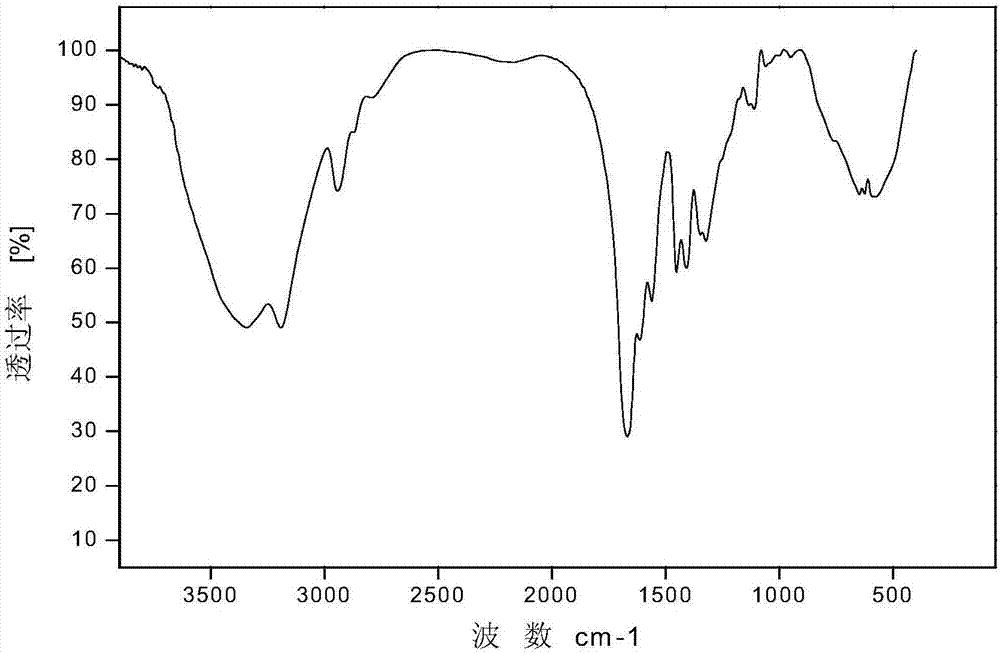

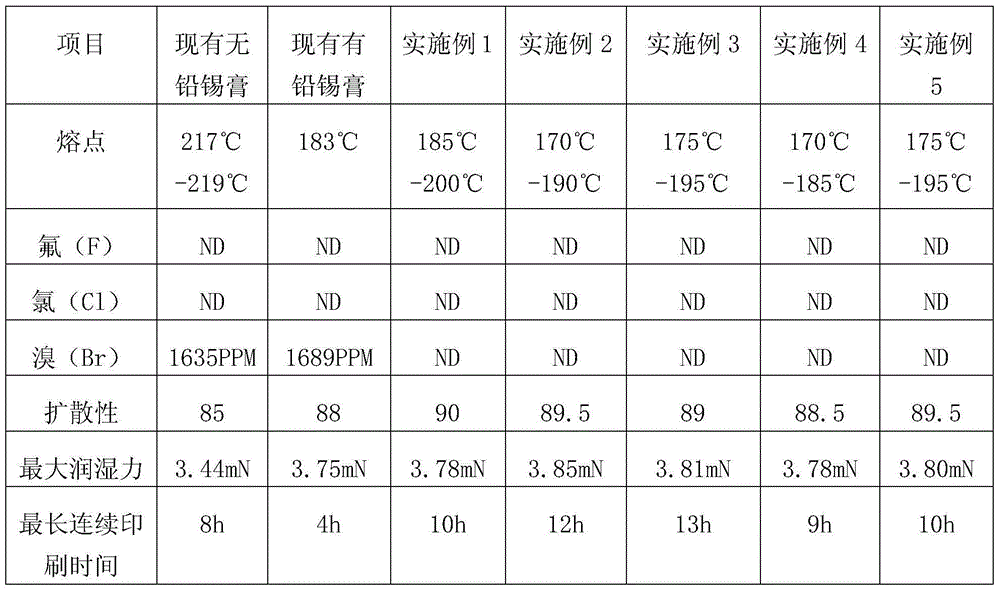

Lead-free halogen-free tin paste and production process thereof

InactiveCN104923952ALow melting pointLow soldering temperatureWelding/cutting media/materialsSoldering mediaOrganic acidSolvent

The invention relates to the technical field of electronic welding, in particular to lead-free halogen-free tin paste which comprises, in weight percent, 88%-90% of tin powder and 10%-12% of paste flux. The tin powder is made of alloys including 88-94.5% of Sn, 0.2-1.2% of Ag, 0.3-0.8% of Cu and 5-10% of Bi. The paste flux comprises rosin, solvents, corrosion inhibitors, activators, thixotropic agents and thickening agents, wherein the activators comprise organic acid and organic amine. The paste flux is prepared by an emulsion dispersion high-speed shearing process. A preparation method of the tin paste includes the steps: placing the tin powder and the paste flux into a sealed stirrer for stirring according to the proportion; pumping vacuum; releasing the vacuum; finishing preparation of the tin paste. The lead-free halogen-free tin paste is low in melting point, fine in weldability, full in welding spot and fine in reliability, achieves fine welding effects and meets environmental protection requirements, and the service life of the tin paste is prolonged.

Owner:广西南宁迈点装饰工程有限公司

Modified hyaluronic acid based macromolecule lipidosome and preparation method thereof

InactiveCN103505736AUniform particle sizeGood dispersionPharmaceutical non-active ingredientsLiposomal deliveryZeta potentialRotary evaporator

The invention relates to a modified hyaluronic acid based macromolecule lipidosome and a preparation method thereof. The grain size of the macromolecule lipidosome is 80-150 nm, and the Zeta potential is between minus 36 mV and minus 40 mV. The stearic acid modified hyaluronic acid is dissolved into dichloromethane to form an oil phase; the oil phase is subjected to ultrasonic operation at the power of 100-250 w, deionized water is added, then an ultrasonic generator is used for conducting ultrasonic dispersion to form a uniform emulsion disperse system; the emulsion is subjected to rotary evaporating on a rotary evaporator at the temperature of 25-50 DEG C and at the rotating speed of 20-100 r / min, and the macromolecule lipidosome is obtained after an organic solvent is completely volatilized. The grain size of the prepared macromolecule lipidosome is less than 150 nm and is uniform, and the dispersibility is good. The macromolecule lipidosome can freely move in blood so as to reduce the cytotoxic effect caused by positive electricity. The whole preparation process is simple and convenient, the preparation period is short, the yield is high, and the preparation method is applicable to batch production.

Owner:TIANJIN UNIV

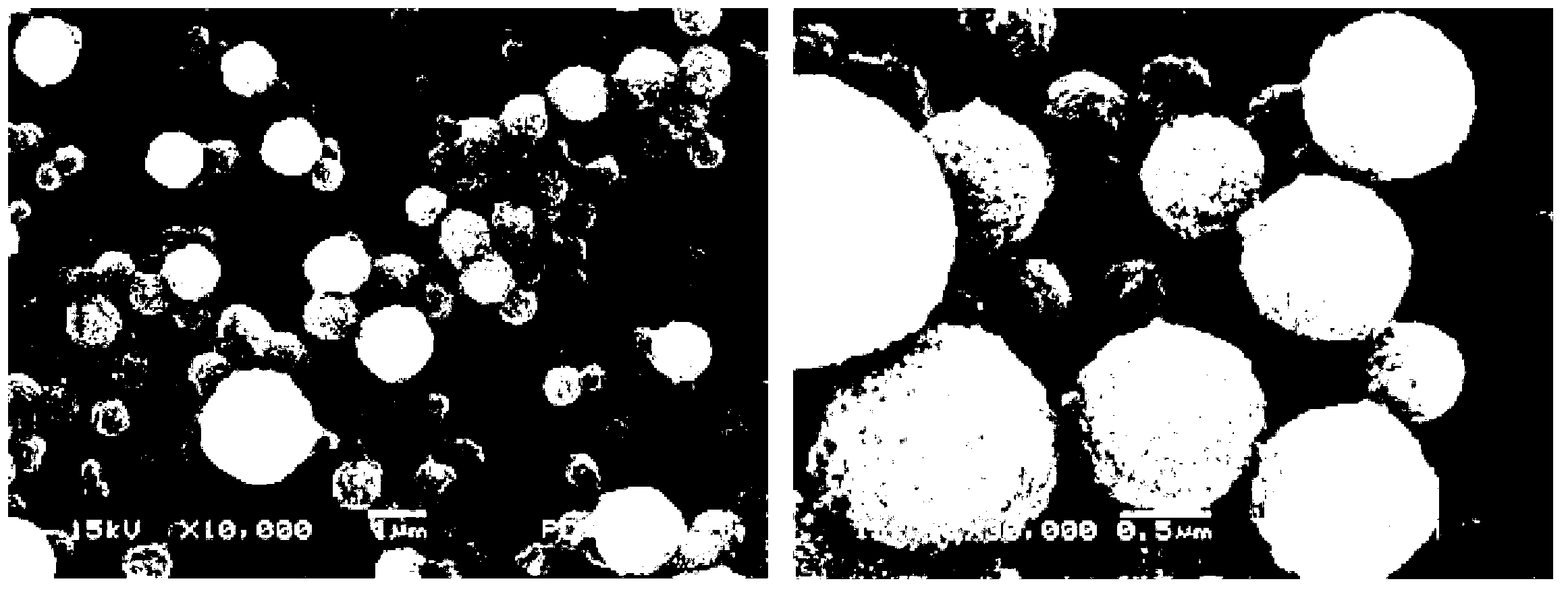

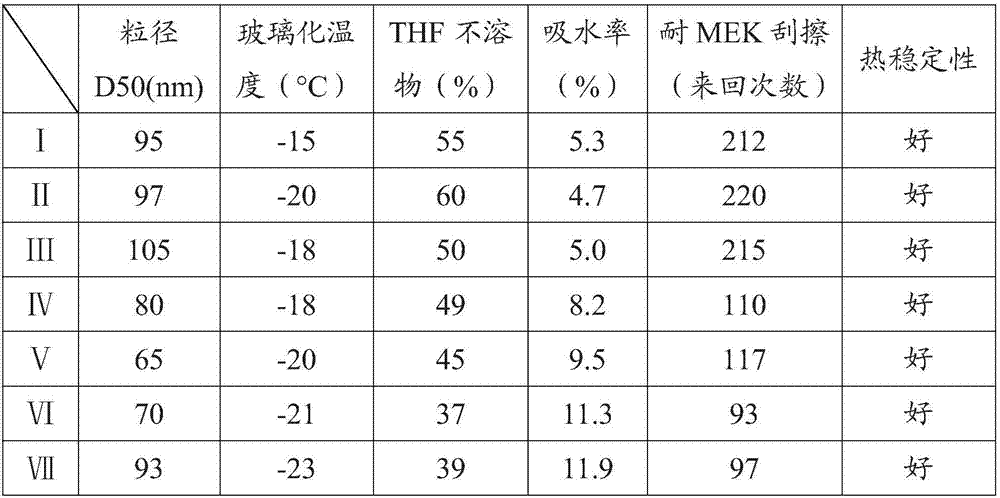

Composition of binder used for negative electrode of lithium ion secondary battery and preparation method thereof

ActiveCN107868160AExcellent battery characteristicsHas a rigid natureCell electrodesSecondary cellsLithiumMicroparticle

The invention relates to a composition of a binder used for a negative electrode of a lithium ion secondary battery and a preparation method thereof. The binder is a polymer microparticle emulsion binder, specifically a dispersion type polymer microparticle emulsion, wherein an emulsion dispersion is polymer microparticles; a dispersion medium is water; the dispersion polymer microparticles is a polymer which has a glass transition temperature of minus 50 to 50 DEG C and is copolymerized from a monomer containing conjugated diene, a monomer containing an aromatic vinyl group and an unsaturatedmonomer containing an epoxy group; and the polymer microparticle emulsion binder has a particle size of 50 to 300 nm, a gel content of 20 to 90% and a pH value of 4.0 to 7.0. The binder provided by the invention can be used for manufacturing of the negative electrode of the lithium ion secondary battery, and has an effect of binding an electrode active material, a conductive agent and a current collector.

Owner:NANJING TECH UNIV

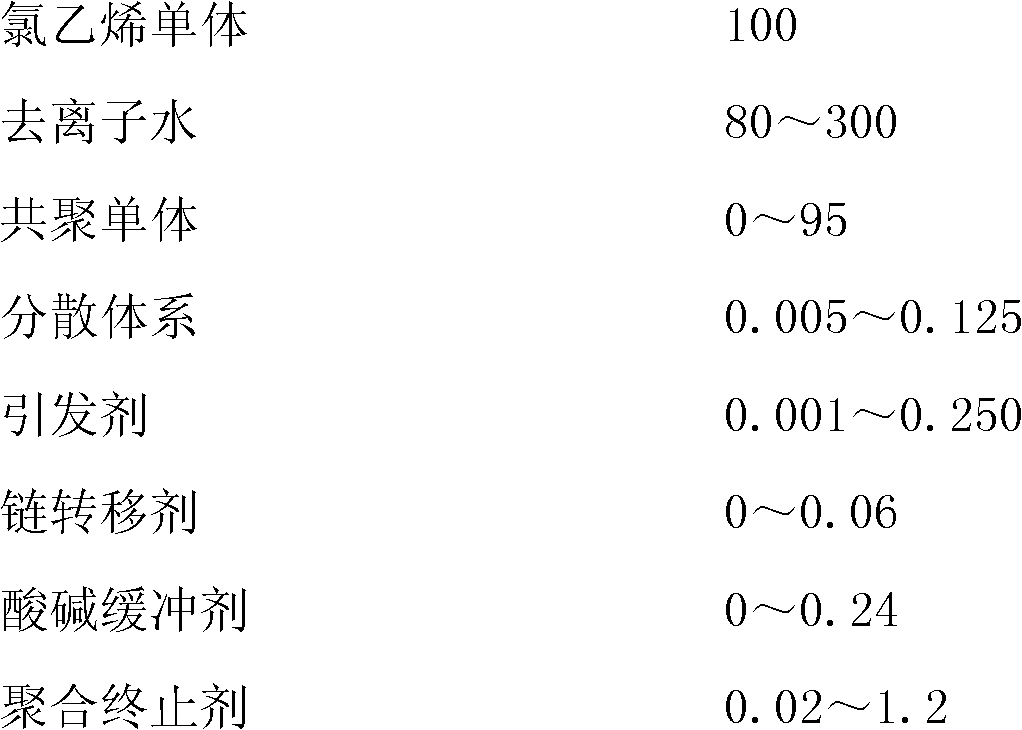

Chloroethylene suspension polymerization terminator and preparation method and use method thereof

The invention discloses a chloroethylene suspension polymerization terminator and a preparation method and a use method thereof, belonging to a terminator used in a chloroethylene polymerization process. The chloroethylene suspension polymerization terminator is characterized by being an aqueous emulsion dispersion liquid and consisting of the following raw materials in parts by weight: 100 parts of deionized water, 2-30 parts of organic tin thermal stabilizer, 0.3-4.5 parts of polyvinyl alcohol I, 0-3.1 parts of polyvinyl alcohol II, 0.2-4.5 parts of cellulose ether and 0.1-3.5 parts of chain terminator, wherein the deionized water is industrial secondary desalted water; the alcoholysis degree of the polyvinyl alcohol I is between 75-85 percent; the alcoholysis degree of the polyvinyl alcohol II is between 50-60 percent; and the cellulose ether is methyl cellulose (MC), hydroxyethylmethylcellulose (HEC) or hydroxypropyl methyl cellulose (HPMC). The invention provides a chloroethylene suspension polymerization terminator which can be used for effectively terminating a chloroethylene polymerization reaction and remarkably improving the aging whiteness and heat resistance of polymerized resin, and the preparation method and the use method thereof.

Owner:CHINA PETROLEUM & CHEM CORP

Method for preparing unsaturated fatty acid zinc salt reinforced natural rubber in in-situ reaction

The invention relates to a method for preparing unsaturated fatty acid zinc salt reinforced natural rubber in in-situ reaction. The method comprises the following specific steps: adding nano-zinc oxide, a proper amount of coupling agent, an anionic surfactant and emulsion hydroxyethyl methylacrylate rubber, and preparing nano-zinc oxide emulsion dispersion by adopting stirring and ultrasonic dispersion; stabilizing emulsion natural rubber by adopting a proper amount of nonionic surfactant, uniformly mixing the nano-zinc oxide emulsion dispersion in the emulsion natural rubber, and dropwise adding an unsaturated fatty acid and an initiation cross-linking agent, thereby obtaining an in-situ reaction unsaturated fatty acid zinc salt-natural rubber composite material in a rubber latex state; further solidifying, pressing, washing, drying and performing other standard China rubber conventional processing technologies on the composite material, thereby obtaining an unsaturated fatty acid zinc salt-natural rubber composite material in a dry glue state. The composite material prepared by the method is good in performance.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI +1

Touch oil and preparation method for touch membrane utilizing same

InactiveCN105925167AGood yellowing resistanceResponsivePretreated surfacesPolyurea/polyurethane coatingsPolyesterCross-link

The invention provides touch oil and a preparation method for a touch membrane utilizing the same. A preparation method for the touch oil comprises the following steps of: performing a polymerization reaction on mixed dihydric alcohol containing polyester diol and polyether glycol and isophorone diisocyanate; further reacting with a hydrophilic chain extender, a cross-linking agent and the like in the presence of a catalyst so as to form a polyurethane prepolymer; adding the prepolymer and deionized water into a dispersion machine, and performing emulsion dispersion; and mixing with a nano aluminum oxide aqueous solution, a flatting agent and ultraviolet absorbent, thereby obtaining the touch oil. The invention further provides a preparation method for a touch membrane utilizing the touch oil. The touch membrane is obtained in roller coating, a coating is sufficiently cured in a drying tunnel and is sufficiently crystallized in a third segment, so that the touch effect of the hot-pressed coating does not disappear. The touch method prepared by the preparation method can be applied to thermal gluing of an automotive trim plate, and has the advantages of good abrasive resistance, high light transmittance, no disappearing of touch feeling after hot-pressing, and the like. The method provided by the invention is capable of facilitating large-scale production and improving construction environments.

Owner:深圳市连创实业有限公司

Preparation method of waterborne polyurethane dispersoid

InactiveCN107011494ASmall water absorptionImprove water resistanceDyeing processPolyurethane dispersionPolymer science

The embodiment of the invention discloses a preparation method of a waterborne polyurethane dispersoid. The preparation method is used for obtaining the waterborne polyurethane dispersoid with low water-absorbing property, high water tolerance and chemical stability as well as excellent adhesive force and wet-dry rubbing fastness, so that the waterborne polyurethane dispersoid is applicable to the fields of leather, fabric printing, coating and the like, particularly digital ink jet printing. The method provided by the embodiment of the invention comprises the following steps: performing crosslinking on poly-dihydric alcohol, a diisocyanate monomer as well as first micromolecular polyhydric alcohol and / or an isocyanate polymer for the first time to obtain a prepolymer; adding a hydrophilic chain-extending agent into the prepolymer to form a hydrophilic prepolymer; and adding a neutralizing agent into the hydrophilic prepolymer to perform neutralization, adding deionized water to perform emulsion dispersion, adding second micromolecular polyhydric alcohol to perform crosslinking for the second time, and removing acetone to obtain the waterborne polyurethane dispersoid.

Owner:SHENZHEN RUNTIANZHI DIGITAL EQUIP

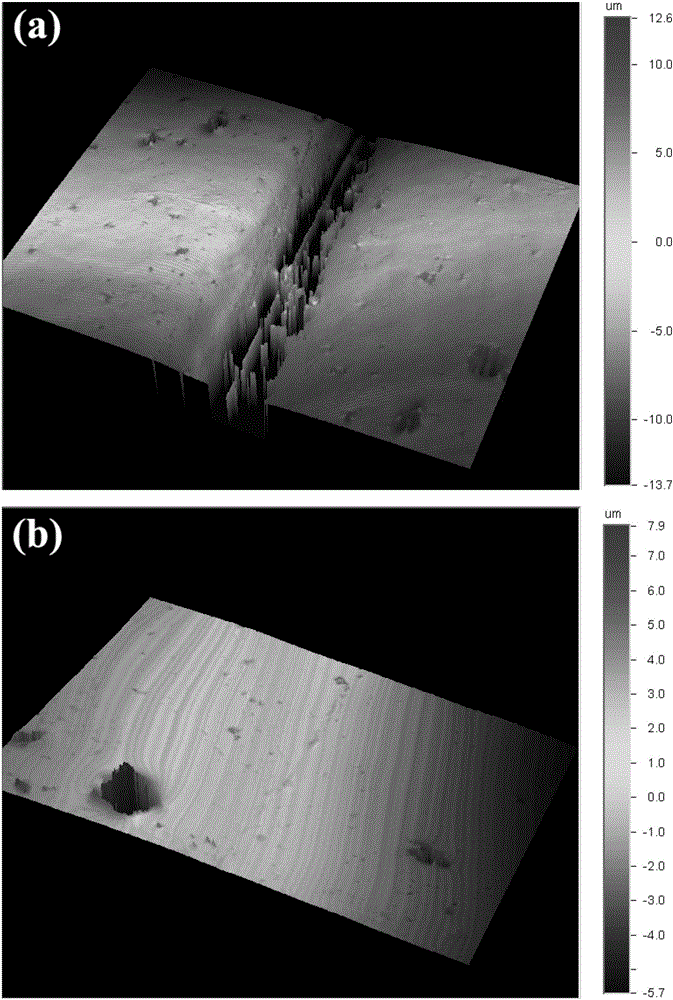

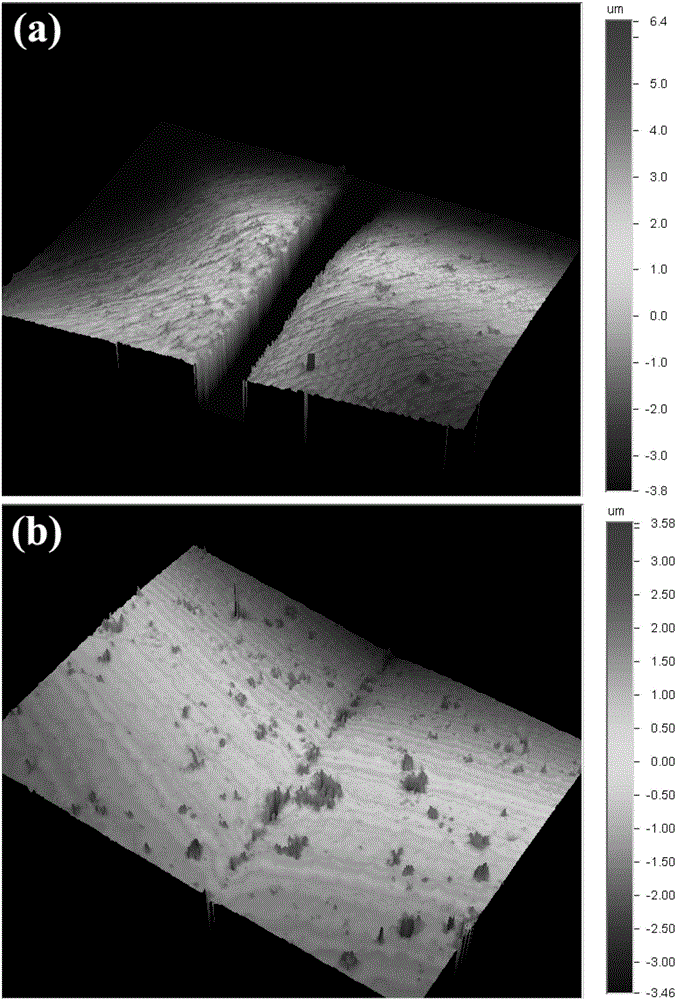

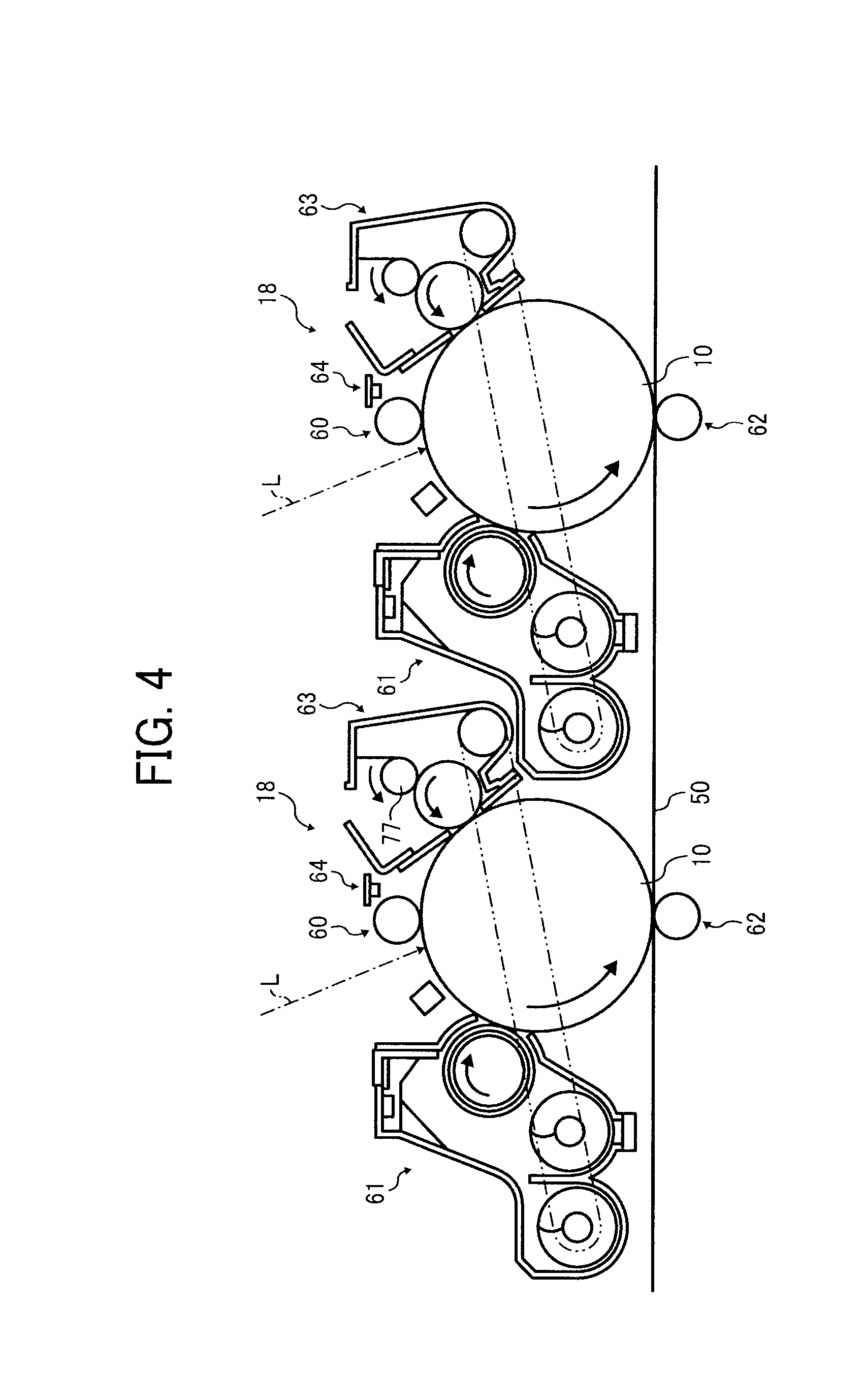

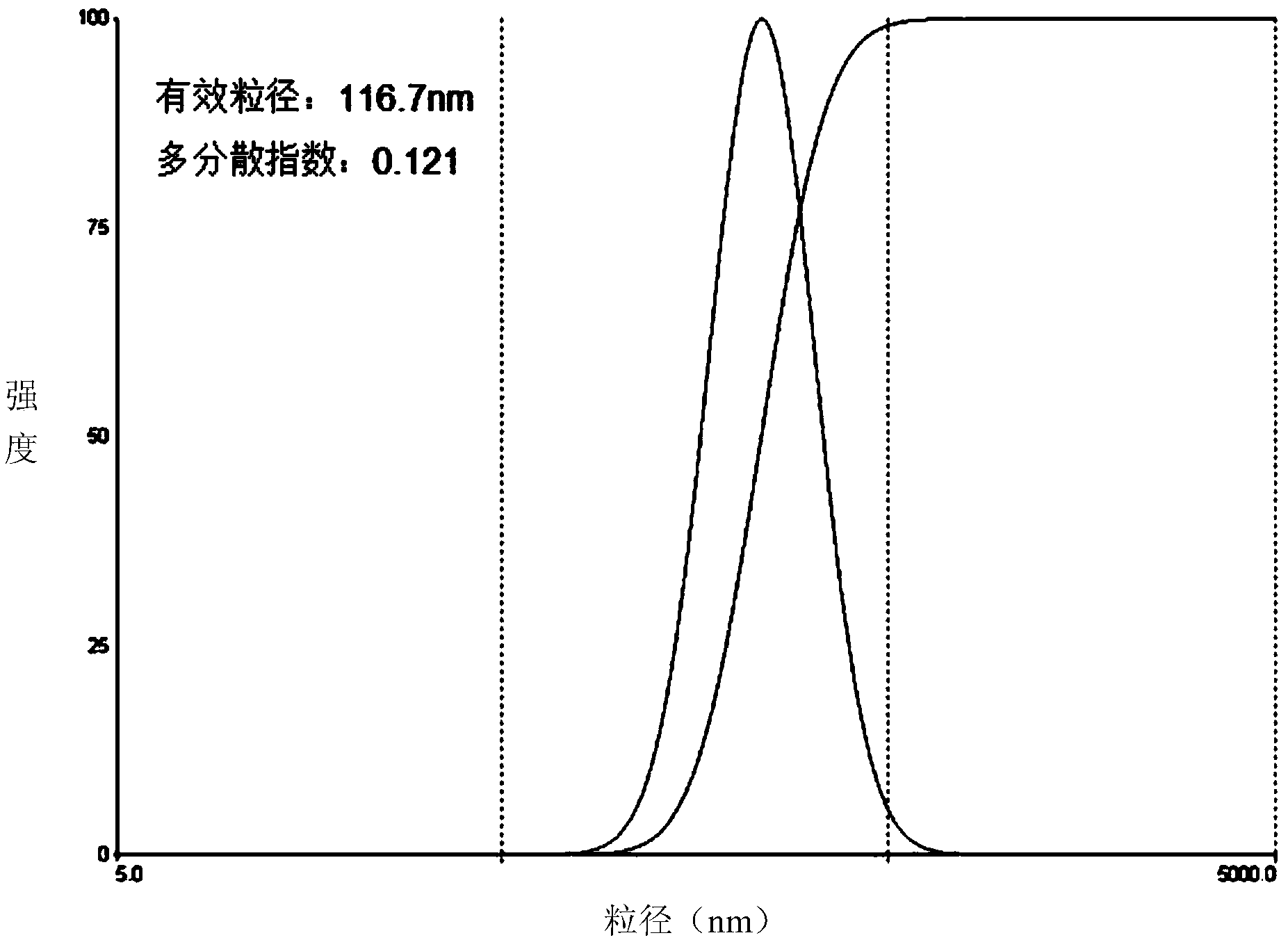

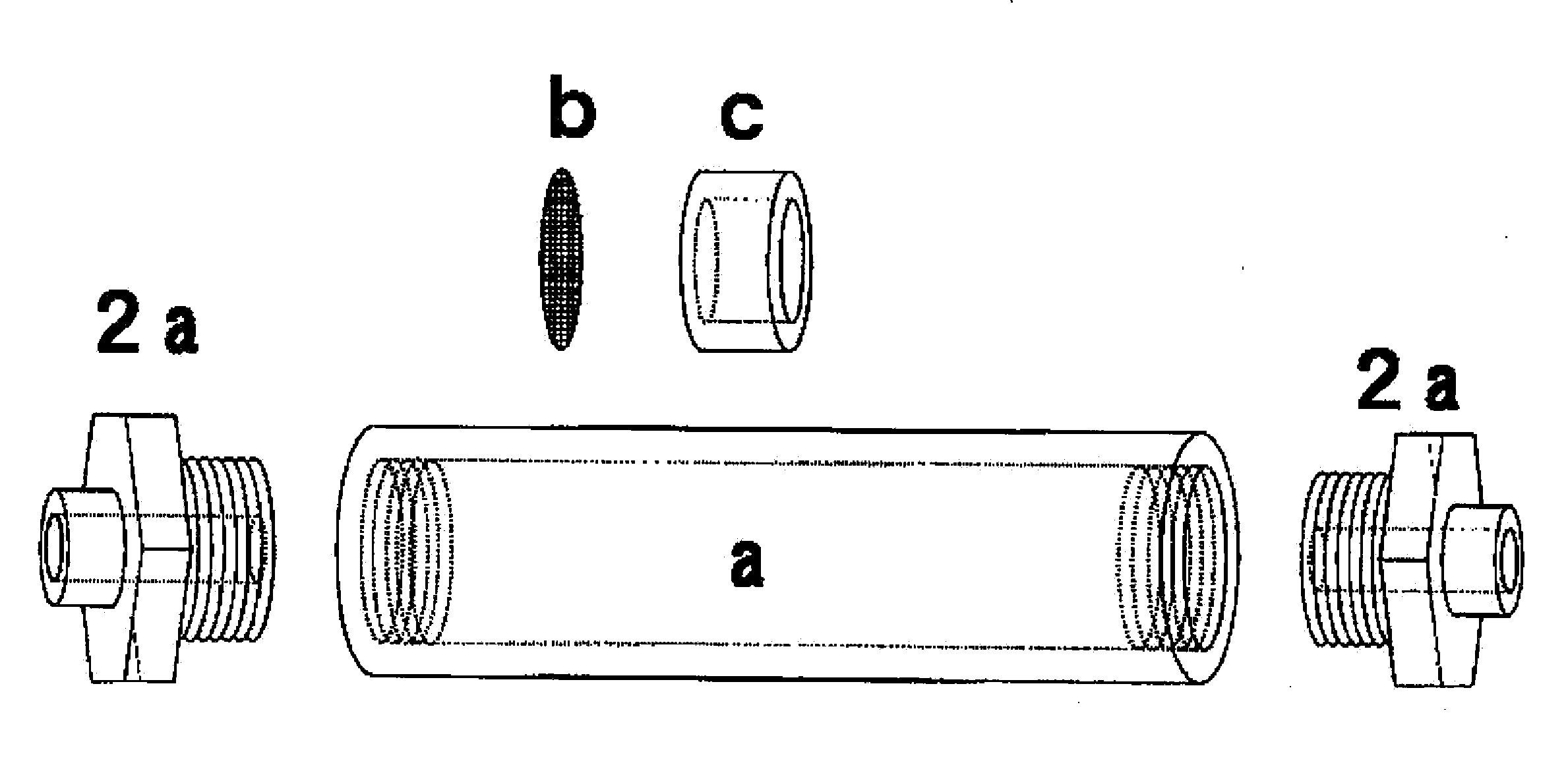

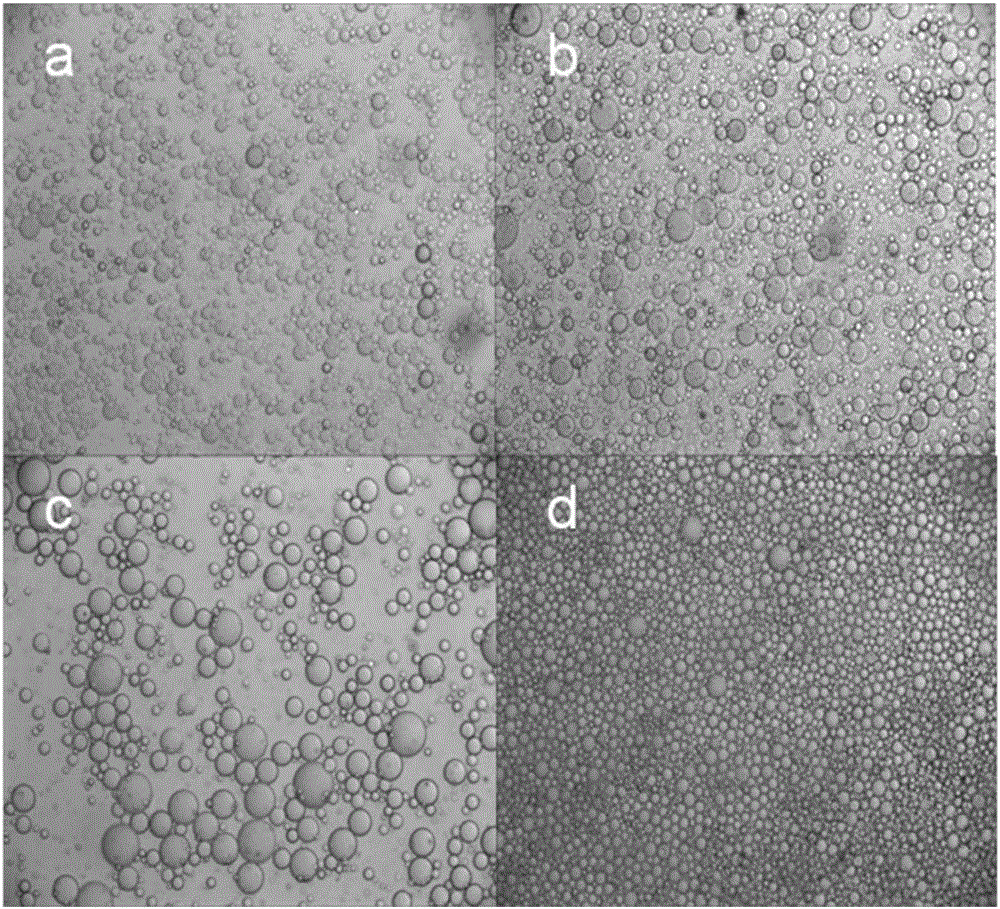

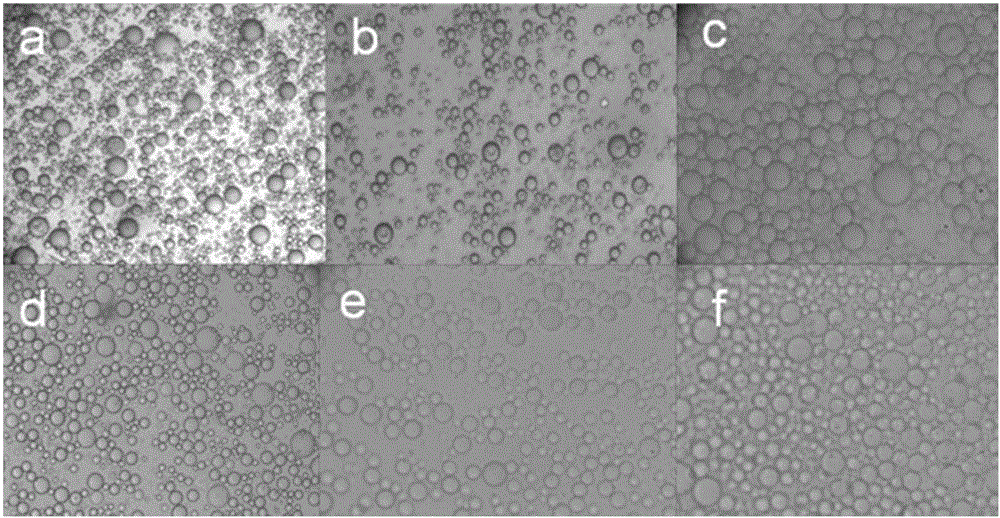

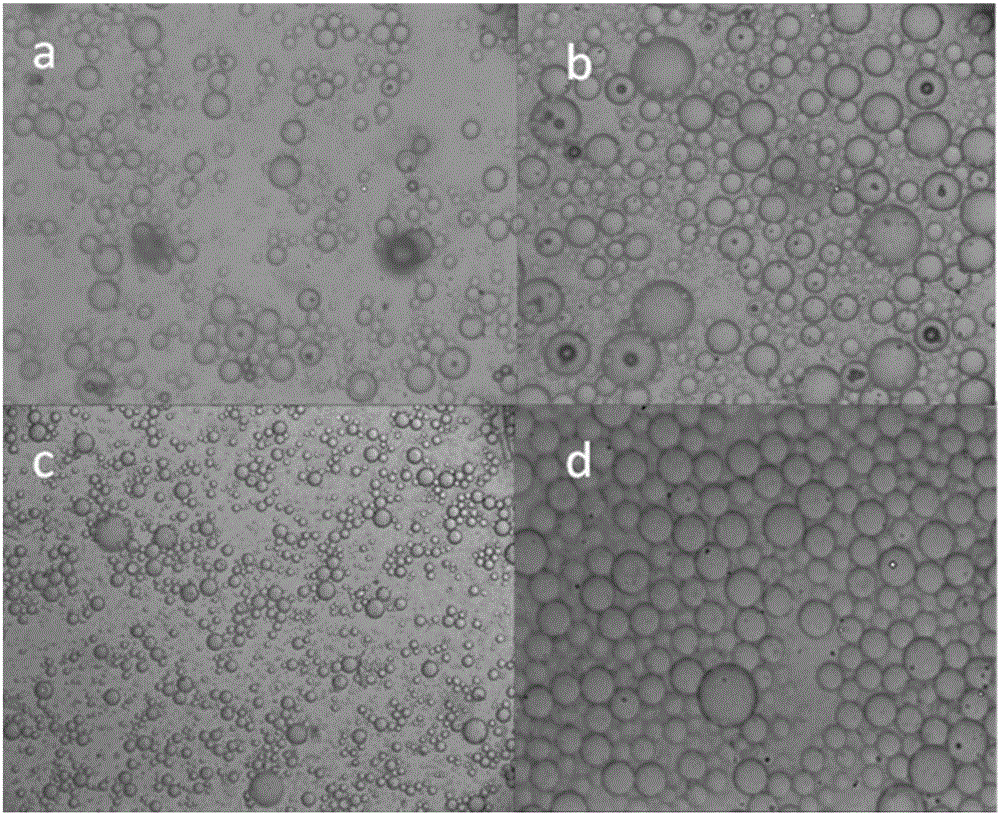

Method and apparatus for controlling particle diameter and particle diameter distribution of emulsion particles in emulsion

InactiveUS20110135933A1Easy to controlSimple structureLiquid surface applicatorsFlow mixersFeeding pumpsMaterials science

A method for controlling a particle diameter and a particle diameter distribution of emulsion particles during manufacturing of an emulsion dispersion is provided. The method includes causing two or more types of liquids substantially immiscible with each other to continuously and sequentially pass through net bodies. The net bodies are disposed in a cylindrical flow passage at intervals of 5 to 200 mm, and the number of the net bodies is more than 50 and 200 or less. Each of the net bodies is equivalent to a gauze having a mesh number of 35 mesh to 4000 mesh in accordance with an ASTM standard and has a surface that intersects the direction of the flow passage. An emulsification apparatus used for the method includes a feed pump for feeding two or more types of liquids substantially immiscible with each other; and a cylindrical flow passage to which the two or more types of liquids fed by the feed pump are delivered. A predetermined number of net bodies are disposed in the cylindrical flow passage at predetermined intervals, and each net body has a surface intersecting the direction of the flow passage.

Owner:NIPPON OIL CORP

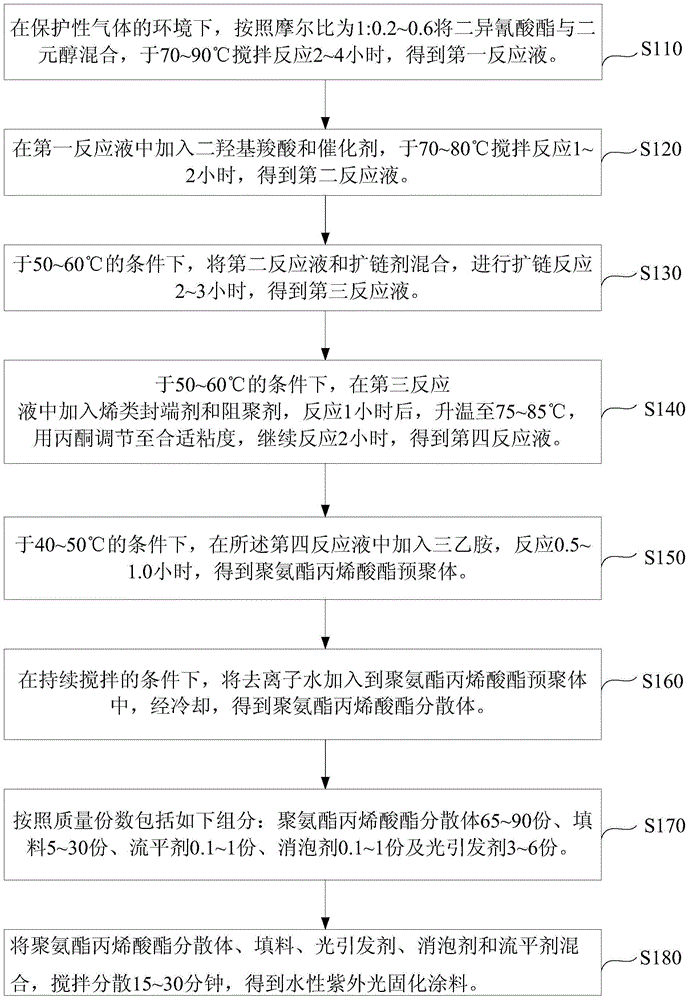

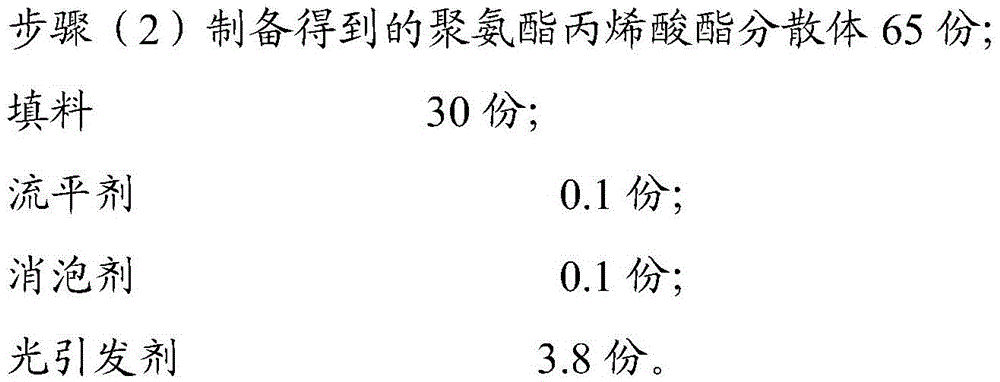

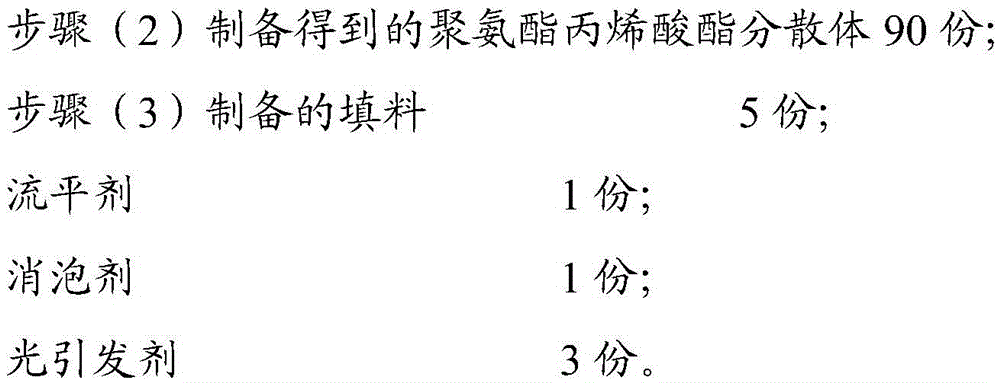

Water-based ultraviolet curing coating and preparation method thereof

ActiveCN105602439AEasy to operateEase of industrial productionPolyurea/polyurethane coatingsWater basedCarboxylic acid

The invention relates to a water-based ultraviolet curing coating and a preparation method thereof. The preparation method for the water-based ultraviolet curing coating comprises the following steps: mixing diisocyanate and diol and reacting to obtain a first reaction solution; adding dyhydroxyl carboxylate and a catalyst to the first reaction solution and reacting to obtain a second reaction solution, and mixing the second reaction solution and a chain extender and reacting to obtain a third reaction solution; adding an alkene end-capping agent and a polymerization inhibitor to the third mixed solution and reacting to obtain a fourth reaction solution, and adding triethylamine to the fourth reaction solution and reacting to obtain a urethane acrylate prepolymer; adding deionized water to the urethane acrylate prepolymer, carrying out emulsion dispersion to obtain an urethane acrylate dispersoid, mixing the urethane acrylate dispersoid, a photoinitiator, a defoaming agent and a leveling agent, and carrying out stirring dispersion for 15 to 30 minutes to obtain the water-based ultraviolet curing coating. The water-based ultraviolet curing coating prepared by the preparation method disclosed by the invention has relatively higher performances.

Owner:CHINA ACADEMY OF ENG PHYSICS FUNCTION MATERIAL RES INST

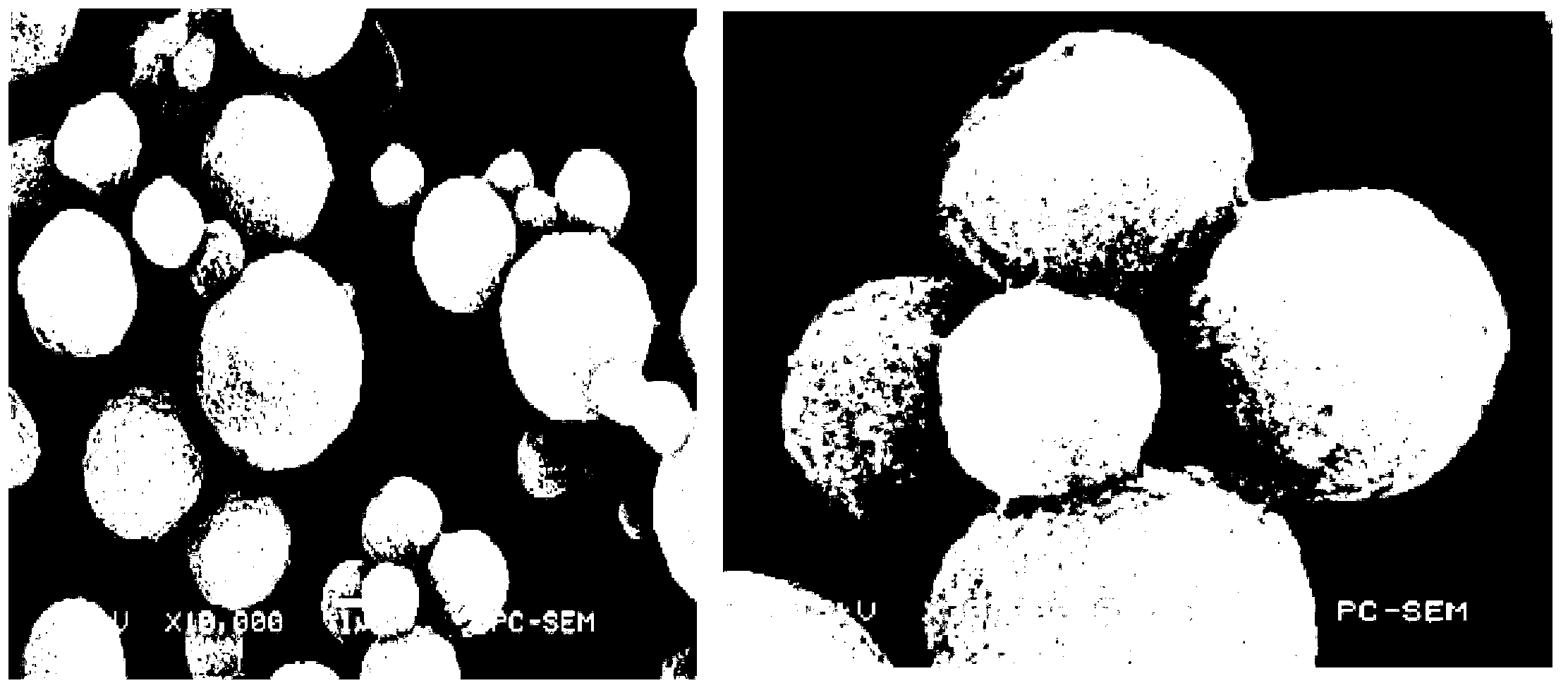

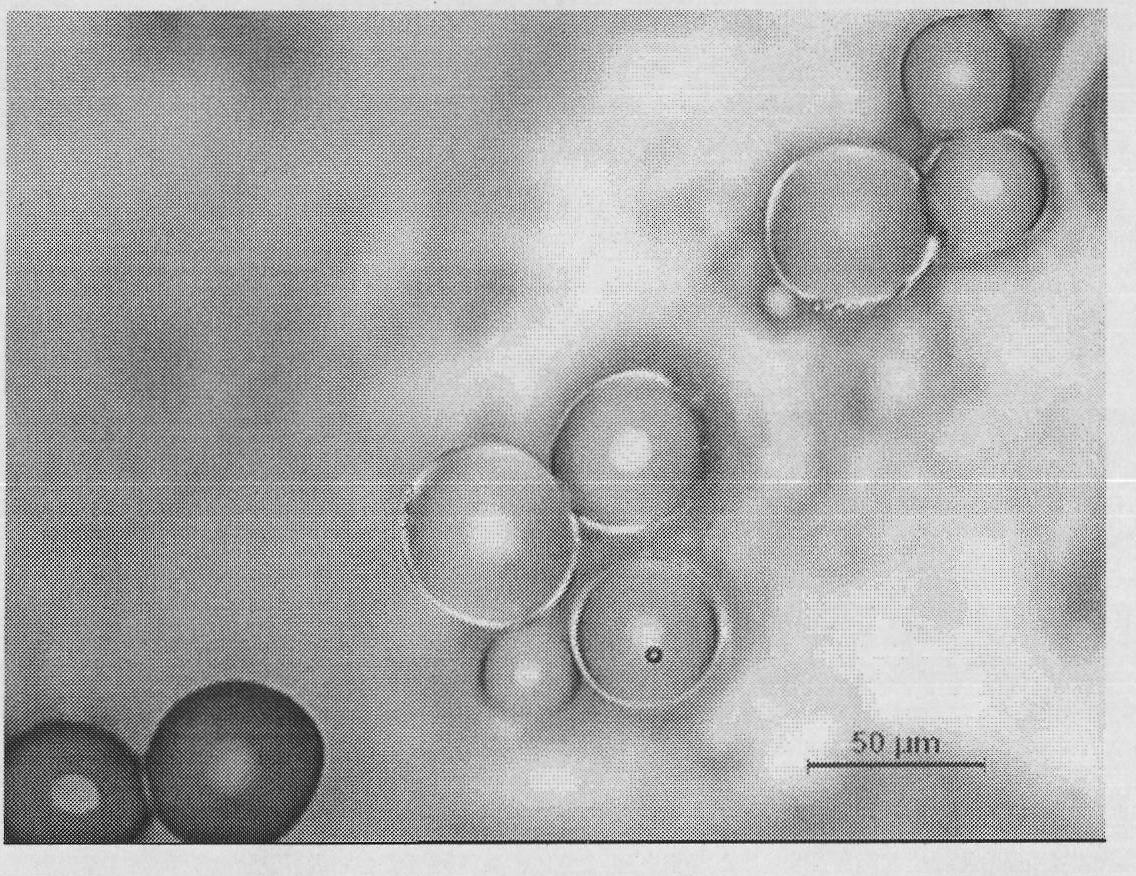

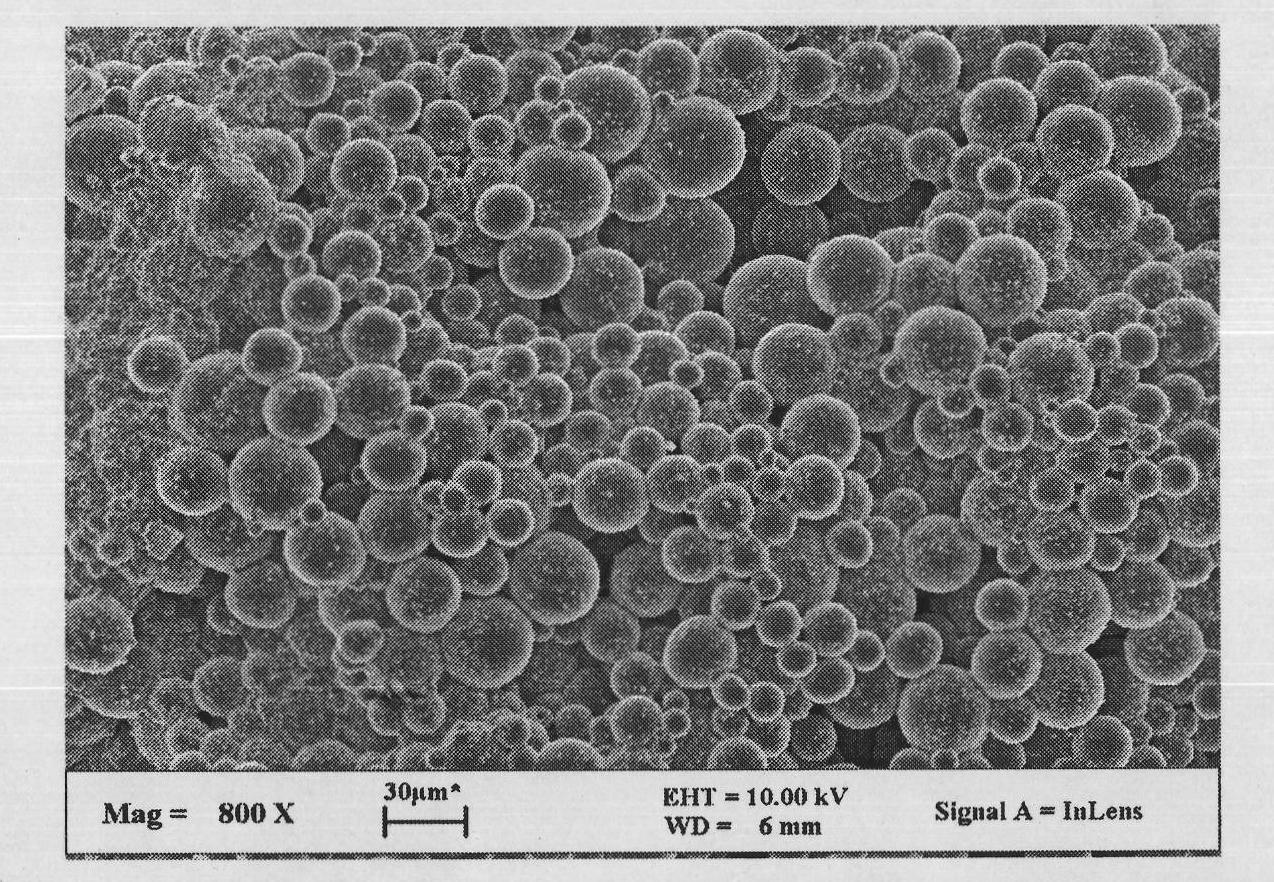

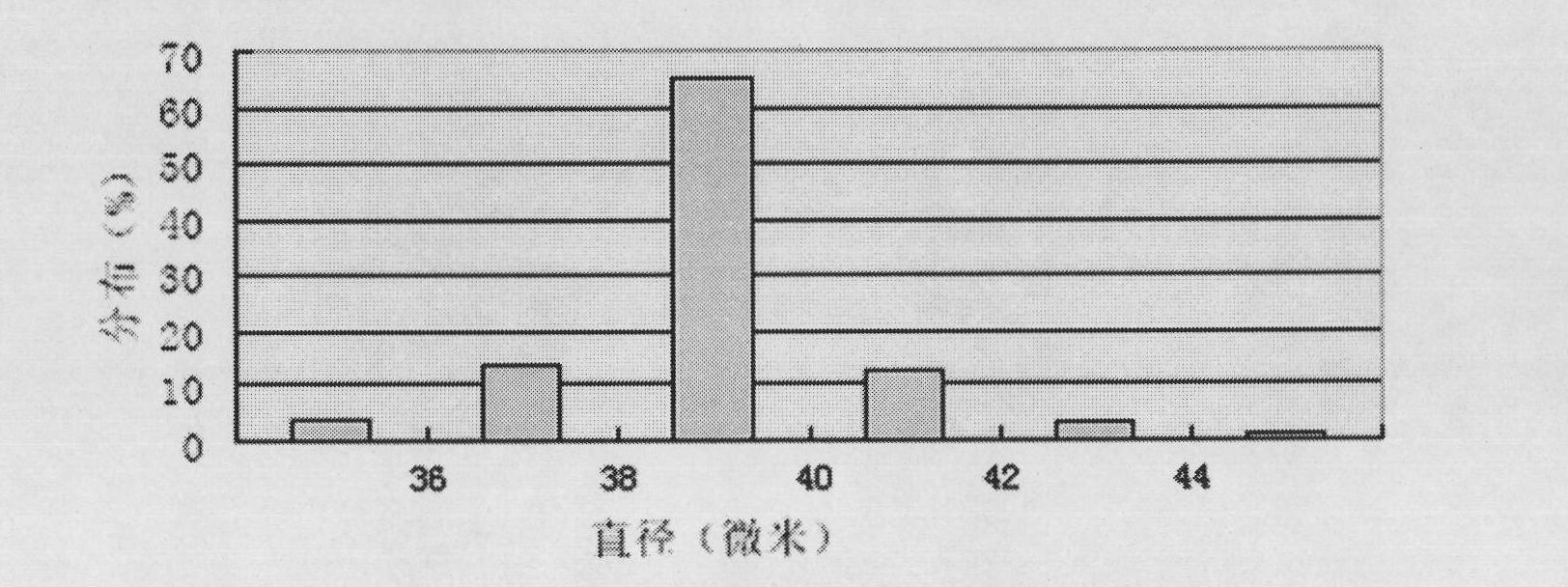

Preparation method of micron-sized polymethylmethacrylate microsphere

The invention provides a preparation method of a monodisperse micron-sized polymethylmethacrylate microsphere. The microsphere is prepared through emulsion dispersion and solvent evaporation with polymethylmethacrylate as a raw material and polyvinyl alcohol solution as a dispersion medium. The preparation method comprises the following steps: preparation of uniform and stable emulsion by adding PMMA solution into aqueous solution of polyvinyl alcohol at a certain flow rate under the high-speed stirring condition, ultrasonic dispersion, solvent evaporation, filtration, washing, vacuum drying and the like, so as to prepare a microsphere with a smooth surface, regular particles and no adhesion. The particle size of the microsphere is 10-100 Mum, and both the particle size and the particle size distribution can be controlled. Compared with the prior art, the invention has the advantages of simple operating process and mild implementation conditions, and provides a simple and feasible novel method for preparation of the micron-sized polymethylmethacrylate microsphere. The prepared micron-sized polymethylmethacrylate microsphere can be applied in the field of biomedical materials such as drug carriers, bone repair materials, plastic materials and the like.

Owner:SUMMIT GD BIOTECH

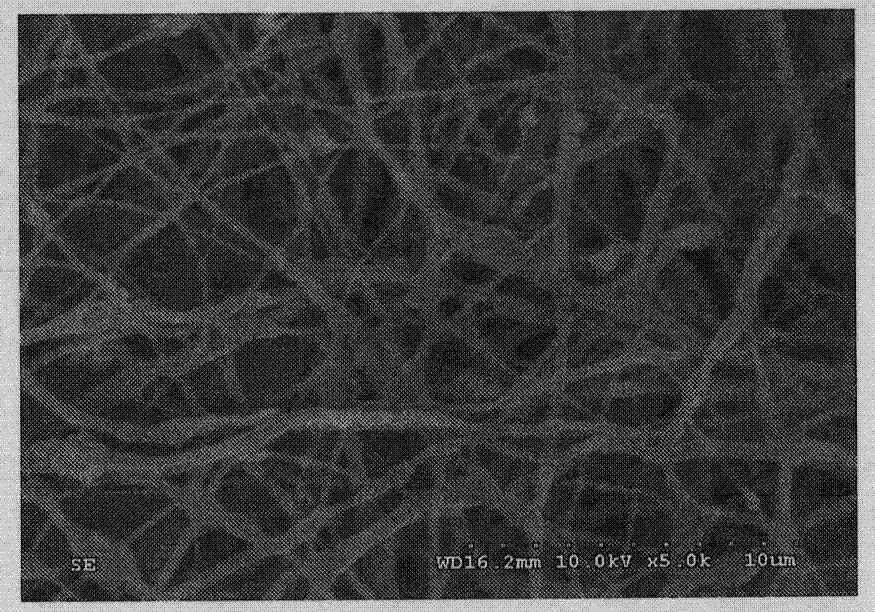

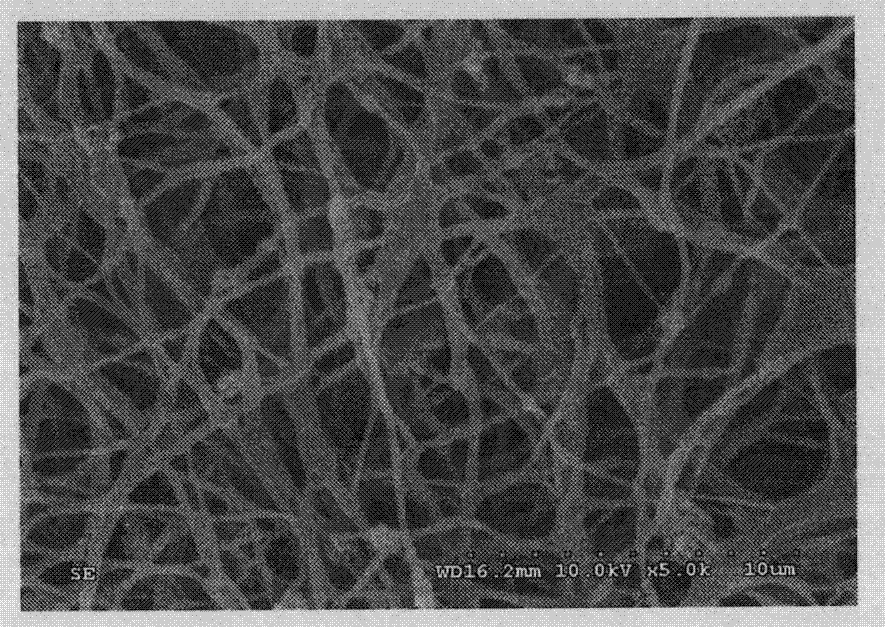

Method for preparing fibers in linear structure through pickering emulsion electrospinning

ActiveCN103757728ARaw materials are easy to getSimple processInorganic material artificial filamentsArtifical filament manufactureCypermethrinFiber

The invention discloses a method for preparing fibers in a linear structure through pickering emulsion electrospinning. The method comprises the steps of preparing pickering emulsion by using a sodium alginate derivative, nano-silica and cypermethrin, then preparing spinning emulsion dispersion liquid, carrying out high-voltage electrostatic spinning on the emulsion dispersion liquid, and collecting fibers with a slab or a roller, thus obtaining the micro-nano fibers in a linear structure. Compared with the prior art, the method has the beneficial effects that different morphologies of fibers in a linear structure are prepared by changing the ratio and spinning working parameters of the pickering emulsion dispersion liquid; by preparing the linear fibers by adopting the mode of pickering emulsion electrospinning, the preparation method is accessible in raw materials, simple in process and mild in conditions, is environment-friendly and safe, easily achieves mass production and has popularization and application values.

Owner:HAINAN UNIVERSITY

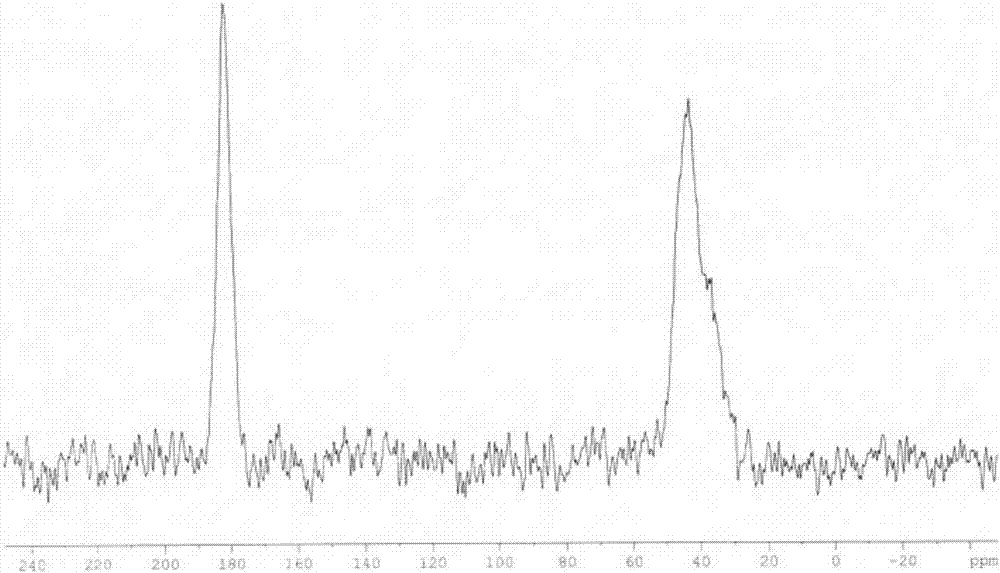

Preparation method of waterborne polyurethane

The invention provides a preparation method of waterborne polyurethane. The preparation method of the water polyurethane is characterized by comprising the first step of adding diisocyanate and chain extender into the polyether glycol or / and polyester dihydric alcohol, stirring and reacting for 1-4 hours at the temperature of 70-80 DEG C, reducing the temperature to 30-40 DEG C, adding the neutralizer for neutralizing, adjusting the viscosity with acetone and obtaining the prepolymer; and the second step of adding distilled water, stirring for emulsion dispersion, adding sulfoacid chain extender, stirring and reacting for 0.5-4 hours, conducting the reduced pressure distillation, removing acetone and obtaining the waterborne polyurethane. The prepared novel waterborne polyurethane is high in strength, good in stability of emulsion dispersion, simple in operation technology, friendly for environment and easy for large-scale production.

Owner:DONGHUA UNIV

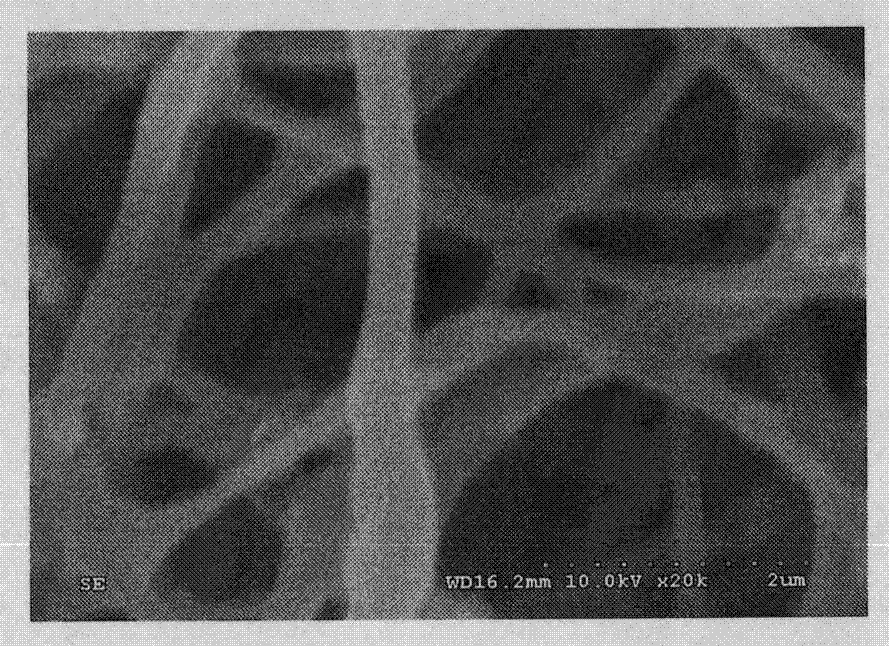

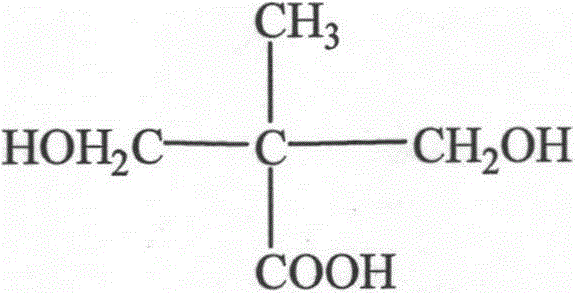

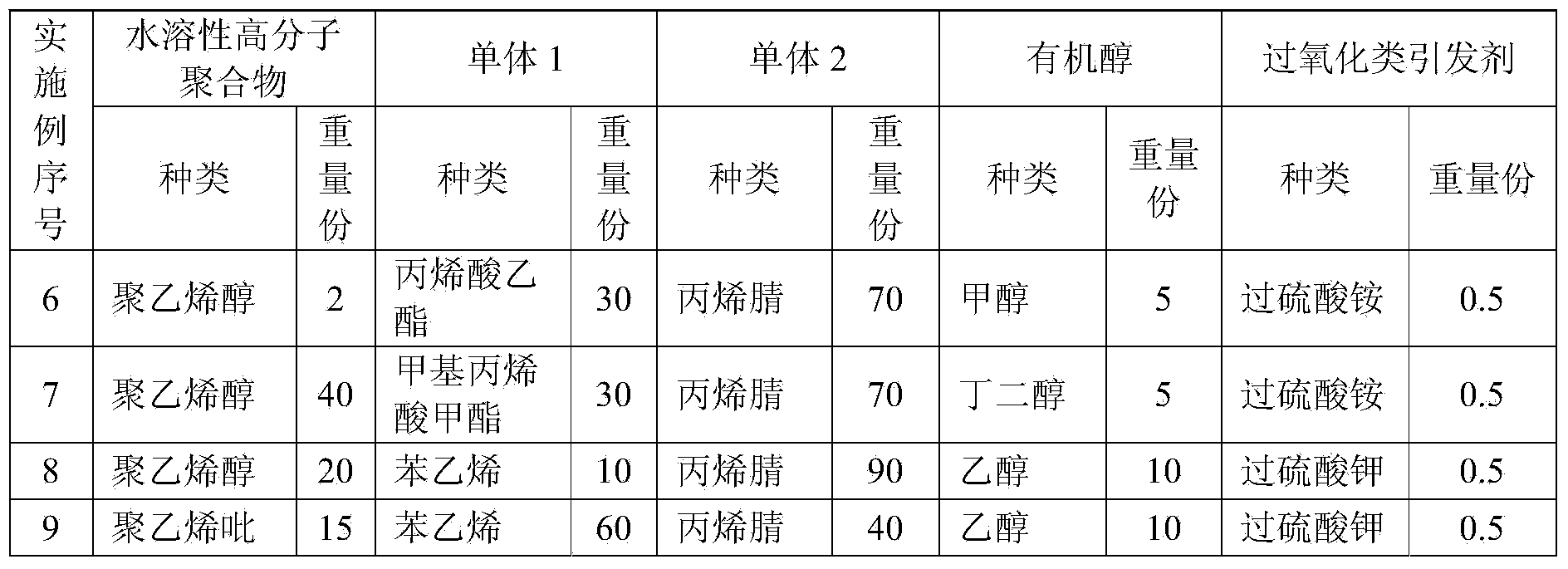

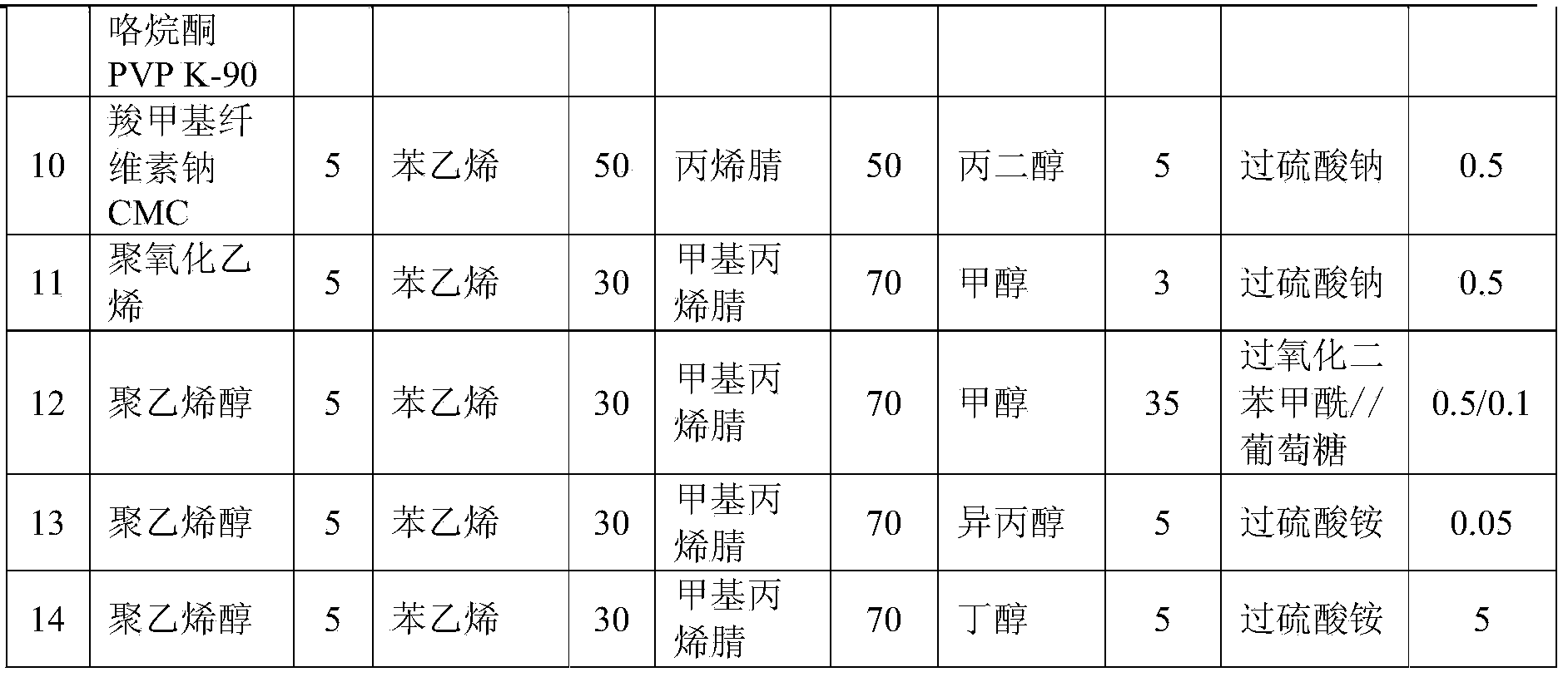

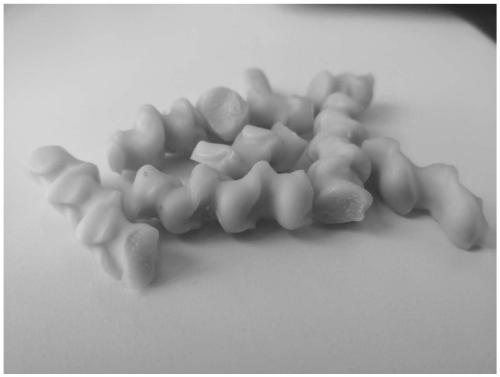

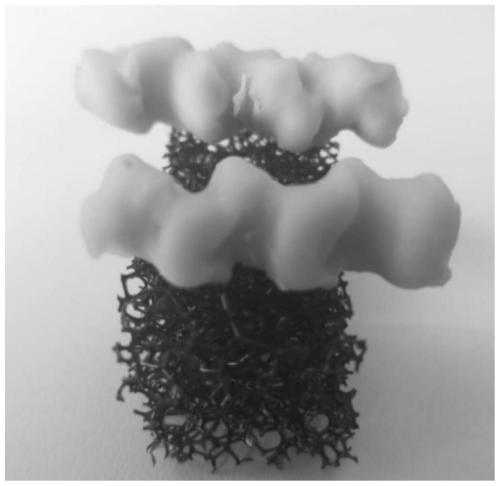

High-carbon-residue high-molecular emulsion microsphere and manufacturing method thereof

InactiveCN103467662AEffective isolation from direct contactGood compatibilityCell electrodesDispersion stabilityPolymer science

The invention relates to a high-carbon-residue high-molecular emulsion microsphere and a manufacturing method thereof. The outer side of the high-molecular emulsion microsphere is a water-soluble high-molecular polymer, and the inner side of the high-molecular emulsion microsphere contains acrylonitrile or methacrylonitrile of over 40 wt% and other organic elements of below 60 wt%. The high-molecular emulsion microsphere is obtained through the method including the steps that under the condition of dispersion stability of the water-soluble high-molecular polymer with over 1000 molecular weights, emulsion dispersoids manufactured from 40-90 wt% acrylonitrile monomers or methacrylonitrile monomers and 10-60 wt% another kind of or kinds of copolymerized unsaturated monomers are subjected to emulsion polymerization on the premise that peroxide initiators and organic alcohols exist, and then the high-molecular emulsion microsphere is synthesized. The high-molecular emulsion microsphere can be applied to surface modification of inorganic powder materials, especially the surface modification of lithium ion battery anode materials and lithium ion battery cathode materials.

Owner:南京毕汉特威高分子材料有限公司

Water-soluble metalworking fluid, metalworking liquid, and metalworking method

InactiveUS20150299599A1Easy to processHardly causes rotting deteriorationAdditivesMetal working apparatusMetalworking fluidSulfur

Provided are a water-soluble metalworking oil agent (cutting oil agent or grinding oil agent) and a metalworking liquid, each of which has excellent cutting machining performance or grinding machining performance of aluminum or aluminum alloys, hardly causes rotting deterioration, and has excellent emulsion dispersion stability and stability of undiluted liquid, by containing specified components (A) to (E) as essential components without containing a machinability-improving agent with a high environmental load, such as chlorine, sulfur, and phosphorus. Provided is also a metalworking method using the same.

Owner:IDEMITSU KOSAN CO LTD

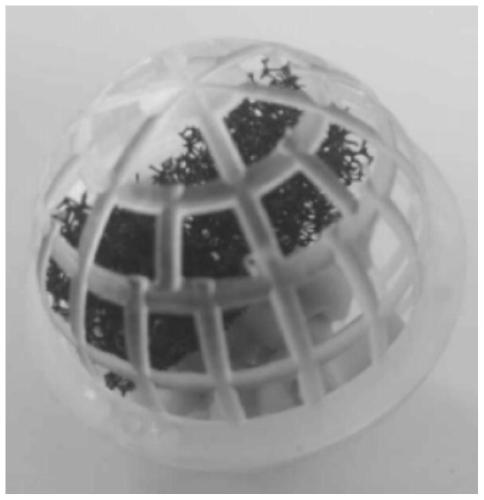

Denitrification filler, denitrification filler ball and application thereof

InactiveCN110078198AImprove nitrogen removal efficiencyEfficient decompositionWater treatment parameter controlWater contaminantsDecompositionPhosphate

The invention provides a denitrification filler and a denitrification filler ball. The denitrification filler is prepared by taking PHBV as a basal body and adding an iron powder, nitrifying bacteriaand denitrifying bacteria. A hydroxyl functional group is contained in PHBV, so that the biofilm culturing of active nitrifying bacteria is promoted; the active nitrifying bacteria forming a biological film also can be used for carrying out nitrification and denitrification by taking PHBV as a carbon source, so that nitrogenous substances in water are decomposed effectively; the addition of the carbon source is greatly reduced in sewage disposal, so that secondary pollution of a water body is avoided; moreover, the active nitrifying bacteria are used for decomposing PHBV according to the concentration of nitrogen in the water body to release corresponding carbon source, the extracellular decomposition of PHBV is nearly equal to nitric acid reducing action, and PHBV cannot release dissolvable organic carbon to pollute the water body; the iron powder is added into the system through emulsion dispersion, iron ions are released through the betatopic oxidization process of iron powder, andthe iron ions are combined with phosphate to realize dephosphorization. According to the denitrification filler ball provided by the invention, total nitrogen and total phosphorus in sewage are reduced effectively, the removal efficiency is high, and the program control is simple and convenient.

Owner:北京中水清源环境技术有限公司

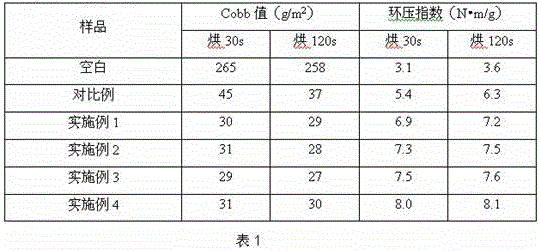

Surface sizing agent used for corrugated paper as well as preparation method and application thereof

ActiveCN106245431AReduce the Cobb valueIncreased ring compressive strengthWater-repelling agents additionPaper/cardboardAcetic acidPulp and paper industry

The invention provides a surface sizing agent used for corrugated paper as well as a preparation method and application thereof. The surface sizing agent used for corrugated paper is prepared by uniformly mixing a base material of the surface sizing agent used for corrugated paper and a cationic additive, wherein a preparation method of the base material of the surface sizing agent used for corrugated paper comprises the following steps of: adding cationic monomers, zircon salts, acrylate (methacrylate) monomers, styrene (methyl styrene), initiators, acetic acid and water to a reaction vessel to carry out free radical polymerization reaction, thus generating the base material of the surface sizing agent used for corrugated paper; a preparation method of the cationic additive comprises the following steps of: adding an alkyl ketene dimer to a water solution of cationic emulsifiers and fully stirring the materials to carry out emulsion dispersion, thus obtaining the cationic additive. The surface sizing agent prepared by the method provided by the invention not only can conduce to substantially reducing the Cobb value and can be rapidly cured and be basically cured immediately after coming off a machine but also can achieve the effect of substantially improving the ring crush strength of the corrugated paper under the condition that the dosage of the sizing agent is invariable.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

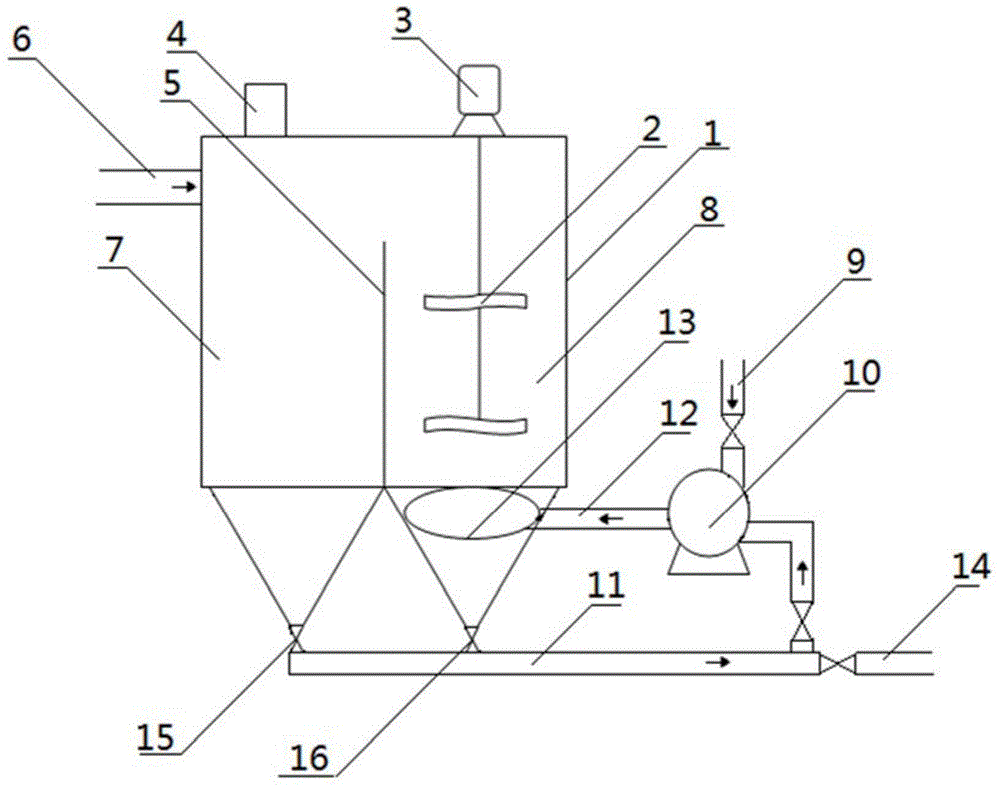

Carbonization reaction device and method for nano calcium carbonate production

ActiveCN104891545AAvoid backmixingGood for pulpingCalcium/strontium/barium carbonatesMaterial nanotechnologyRefluxCarbonization

The invention discloses a carbonization reaction device and a carbonization reaction method for nano calcium carbonate production. The carbonization reaction device comprises a Ca(OH)2 slurry feeding tube, a carbonization tower, a stirrer, an annular gas-liquid distributor, a CO2 gas inlet tube and an emulsion dispersing machine. The carbonization reaction method comprises the following steps: (1) feeding Ca(OH)2 slurry into a reflux area of the carbonization tower; (2) continuously feeding the Ca(IH)2 slurry into the emulsion dispersing machine to mix and react with a CO2 gas, and feeding the obtained product into the reaction area of the carbonization tower; (3) continuously circulating the mixed slurry between the carbonization tower and the emulsion dispersing machine for carbonization and emulsion dispersion; (4) adding a dispersing agent, continuously circulating the mixed slurry between the carbonization tower and the emulsion dispersing machine for secondary carbonization and emulsion dispersion; and (5) stopping introduction of CO2 for reaction and operation of the emulsion dispersing machine, thereby obtaining prepared nano calcium carbonate slurry. The carbonization reaction device and the carbonization reaction method for nano calcium carbonate production are rapid in carbonization reaction speed, high efficiency, good effect, small investment and low cost.

Owner:FUJIAN HONGFENG NANO TECH

Porous spherical silica chromatography filler and preparing method thereof

ActiveCN106215908ANarrow particle size distributionEasy to makeOther chemical processesMicrosphereSilica gel

The invention discloses porous spherical silica chromatography filler and a preparing method thereof. The method includes the steps that 1, absolute ethyl alcohol and a first component are mixed to obtain a mixed solution; 2, a hydrochloric acid water solution is added into the mixed solution and stirred, solvent is removed to obtain a polysiloxane prepolymer; 3, absolute ethyl alcohol and viscosity modifier are prepared into a continuous phase, the polysiloxane prepolymer is dispersed into the continuous phase to obtain an emulsion dispersing system; 4, strong ammonia water is added into the emulsion dispersing system and stirred for reaction, the mixture stands for ageing and is filtered to collect microspheres, and the microspheres are washed and dried to obtain spherical silica microspheres; 5, the spherical silica microspheres are dispersed in deionized water; 6, strong ammonia water is added into the spherical silica microsphere dispersion liquid and stirred, solid is collected, washed, dried and calcined to obtain the porous spherical silica chromatography filler. The filler is in a regular sphere shape and narrow in particle size distribution and can be used in normal-phase chromatography and other separating modes. The preparing method is simple and high in yield, and conditions are easy to control.

Owner:TIANJIN UNIV

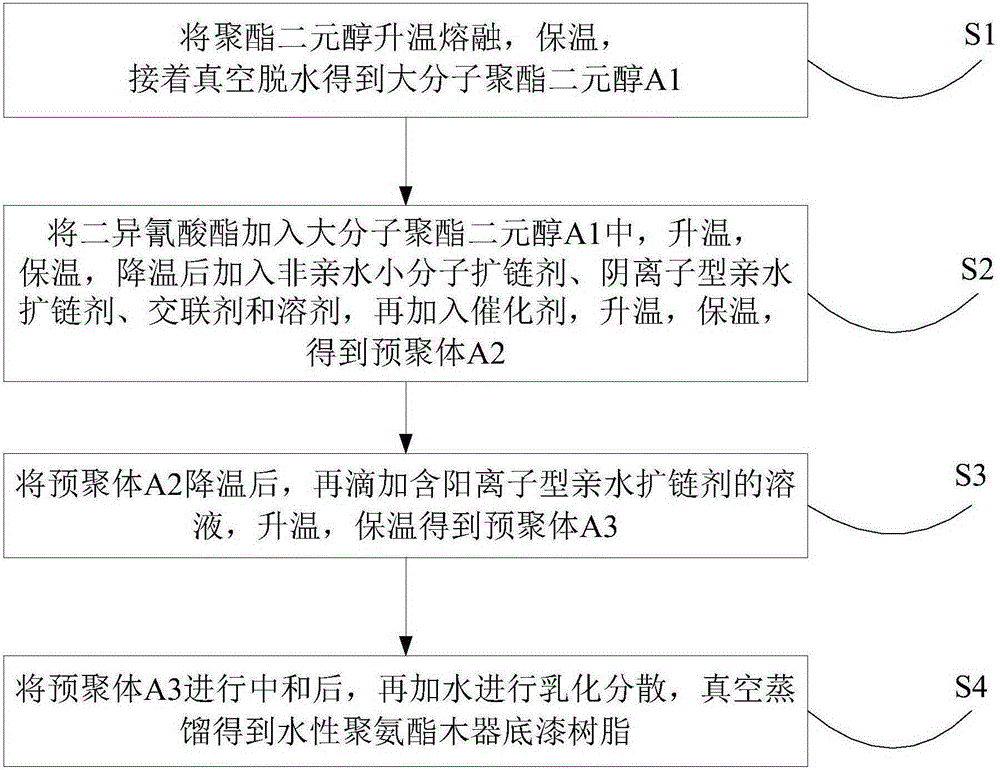

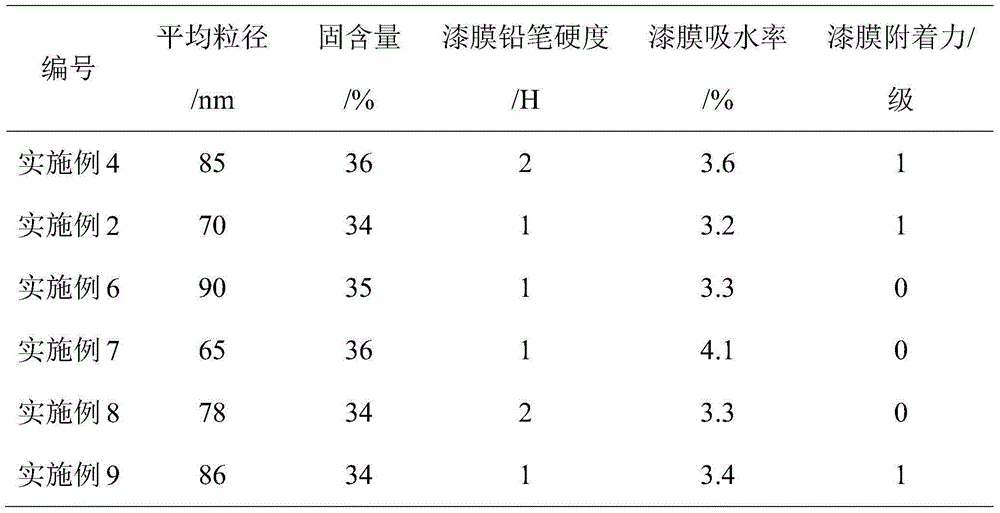

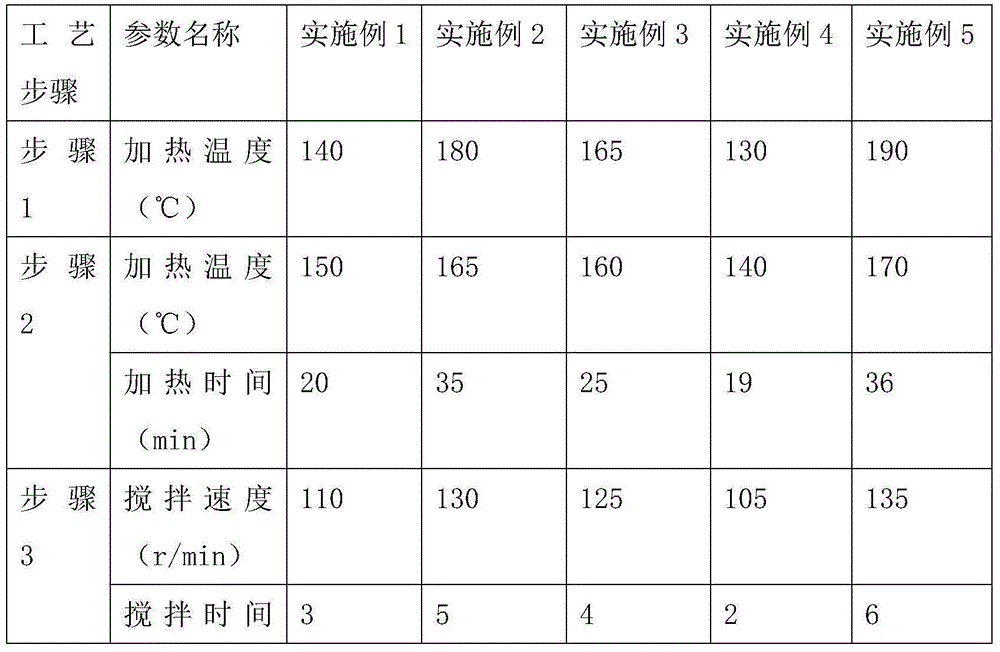

Waterborne polyurethane wood primer resin and preparation method thereof

InactiveCN105176363AHigh hardnessImprove water resistancePolyurea/polyurethane coatingsCross-linkPolyester

The invention discloses a waterborne polyurethane wood primer resin, wherein the soft section of the waterborne polyurethane wood primer resin is terephthalic anhydride polyester glycol, and the hard section of the waterborne polyurethane wood primer resin includes diisocyanate and a small molecule chain extender. The invention also discloses a preparation method of the waterborne polyurethane wood primer resin, which comprises the following steps: raising the temperature of polyester glycol for melting, insulating, and dehydrating in vacuum to obtain large molecule polyester glycol A1; adding diisocyanate into large molecule polyester glycol A1, raising the temperature, insulating, cooling, then adding a non-hydrophilic small molecule chain extender, an anionic hydrophilic chain extender, a cross-linking agent and a solvent, then adding a catalyst, raising the temperature, and insulating to obtain a prepolymer A2; cooling the prepolymer A2, then dropwise adding a solution containing a cationic hydrophilic chain extender, raising the temperature, and insulating to obtain a prepolymer A3; and neutralizing the prepolymer A3, adding water for emulsion dispersion, and carrying out vacuum distillation to obtain the waterborne polyurethane wood primer resin. The waterborne polyurethane wood primer resin has the advantages of simple method, high hardness and good adhesive force.

Owner:安徽思敬齐环保材料有限公司

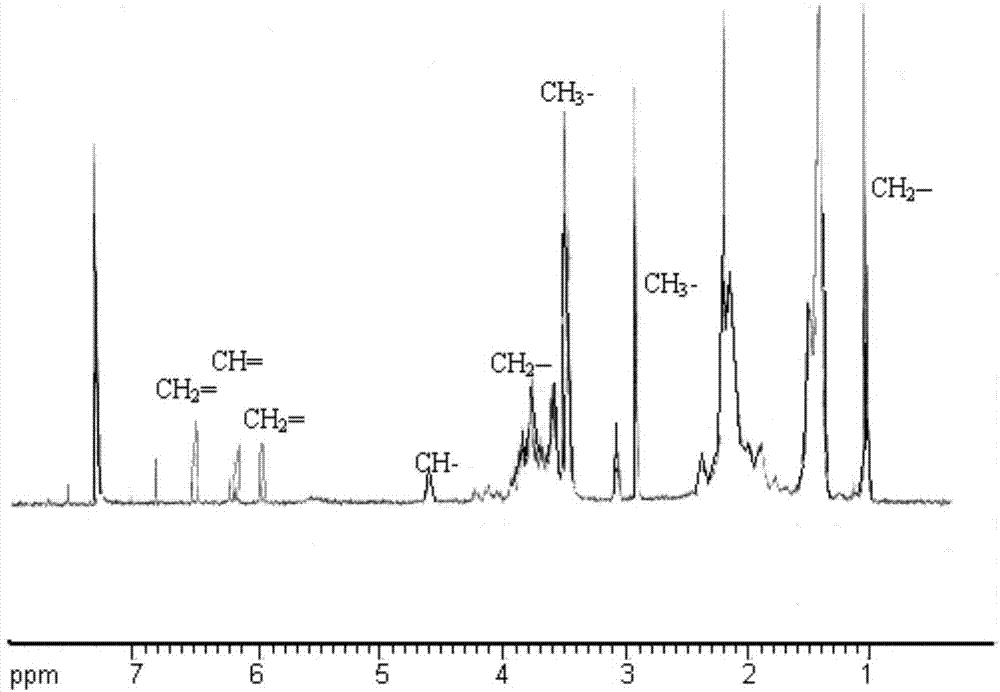

Preparation method for door sheet protective agent

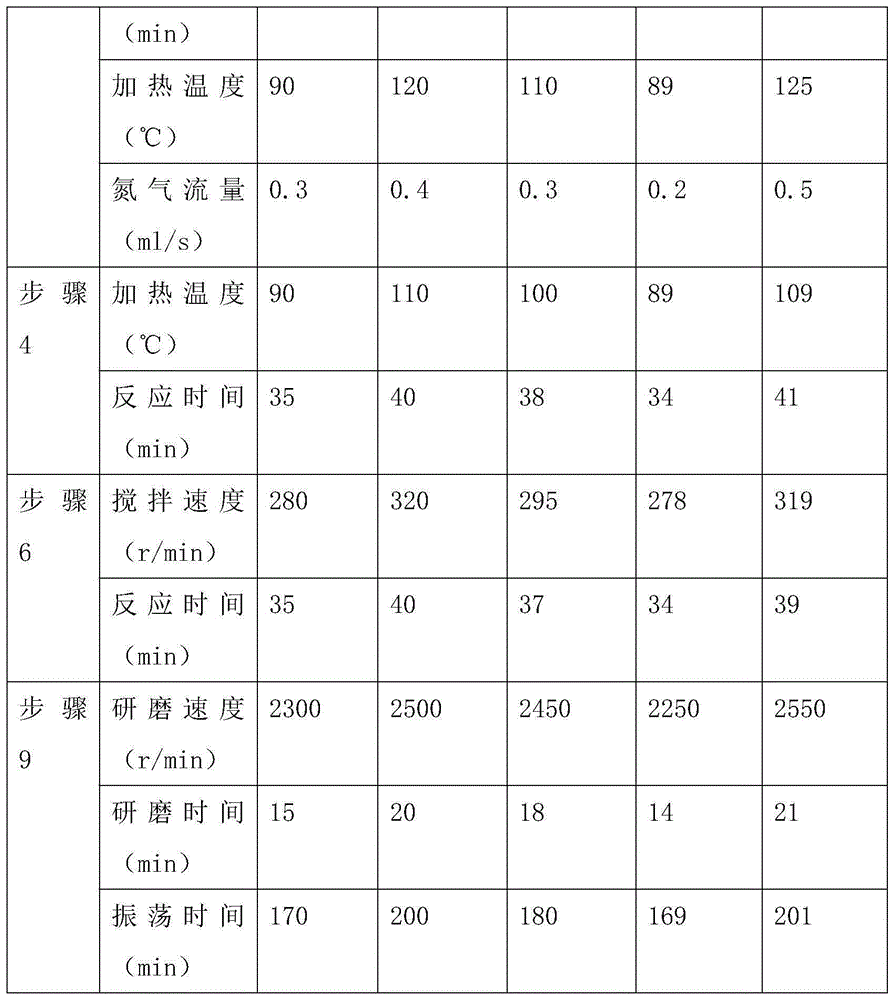

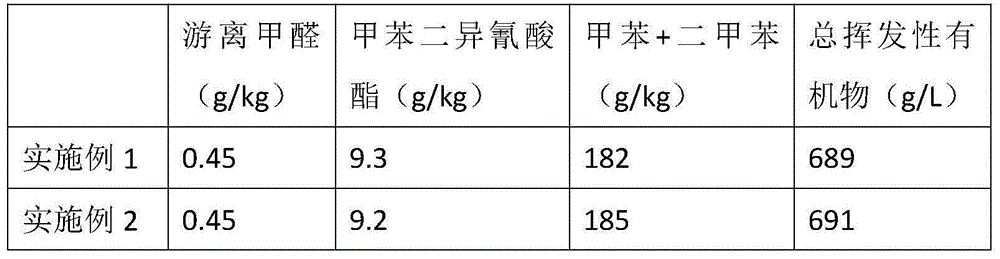

The invention discloses a preparation method for a door sheet protective agent. The preparation method comprises the following steps of completely reacting polyester polyol with poly(hexanediol adipate); uniformly stirring an obtained reaction product and isophorone diisocyanate, and introducing nitrogen to be reacted with the reaction product and the isophorone diisocyanate to generate isocyanate-terminated polyurethane; heating the polyurethane, hydroxyethyl methylacrylate and di-n-butyltin dilaurate to obtain a prepolymer with double bonds at both ends, and adding 2-methyl methacrylate for reaction to make the prepolymer contain both hydrophilic ion groups and unsaturated double bonds; adding 2-methyl methacrylate into the polyurethane prepolymer for viscosity reduction, performing neutralization with triethylamine, and adding an ethylene diamine solution at concentration of 3 percent for emulsion dispersion; performing oscillation dispersion on a polyacrylamide solution at concentration of 1.5 percent, polyoxyethylene ether and nanometer aluminum oxide, performing high-speed grinding with organic siloxane, and adding polyvinylpyrrolidone for oscillation dispersion. Therefore, the acid resistance, the alkali resistance and the stability of the protective agent are improved.

Owner:CHONGQING ZUOEN FURNITURE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com