Hollow TiO2 microsphere synthesizing method

A microsphere, hollow technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems such as the inability to significantly reduce the specific surface area, the difficulty of separating the medium liquid, etc., to improve the light absorption efficiency, improve the reuse rate, and reduce the cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Mix 5 mL of n-butyl titanate with 2 mL of acetylacetone, and stir for 0.5 h. The reaction is exothermic. The next step can only be performed when the temperature of the system returns to room temperature.

[0029] (2) Take 50 mL of an aqueous solution of 72 mg / L dodecylbenzenesulfonic acid and slowly add it to the above liquid while stirring to form a milky white dispersion system. Stirring was continued for 1 h.

[0030] (3) The above dispersion system was transferred to a reactor with a polytetrafluoroethylene inner cup, and reacted at a temperature of 150 °C for 24 h.

[0031] (4) After the reaction product was centrifuged, washed with water and ethanol, it was dried at 100°C for 2 h.

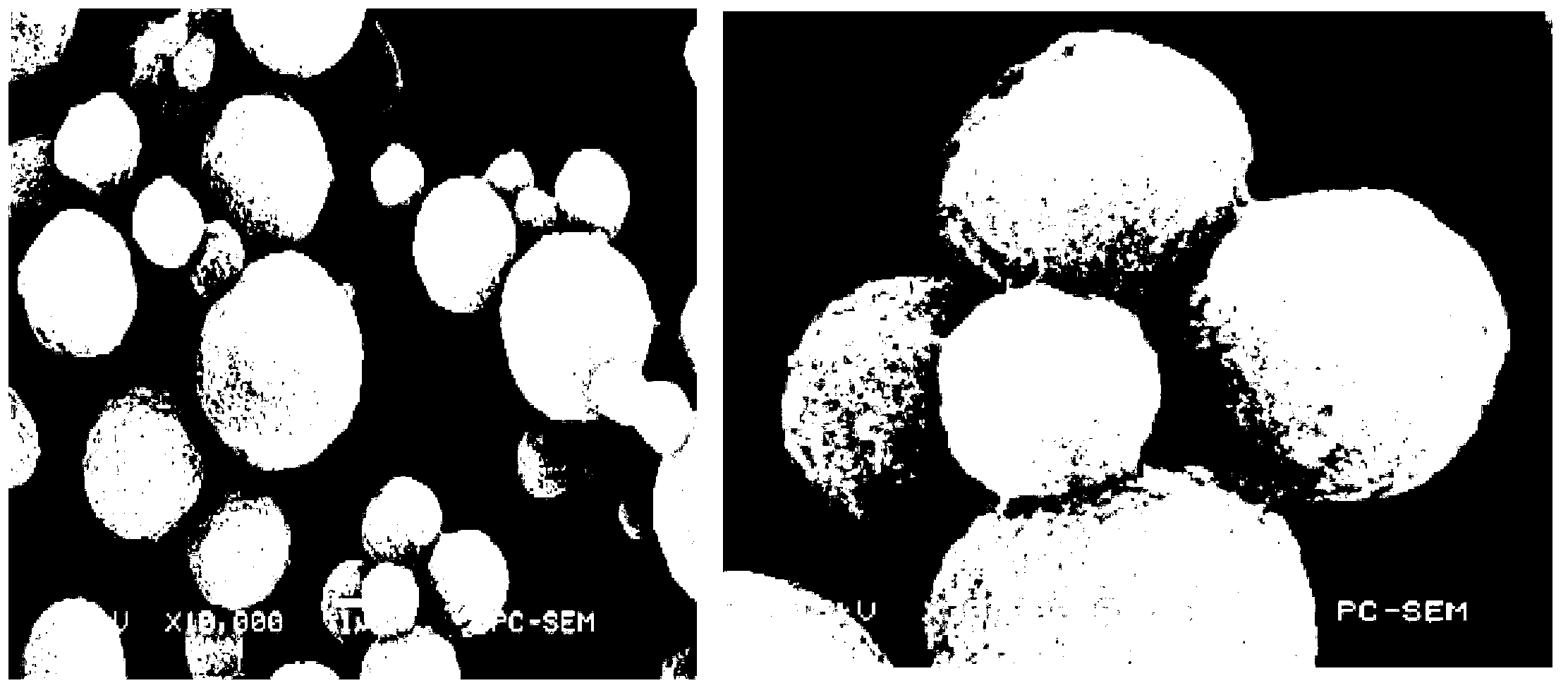

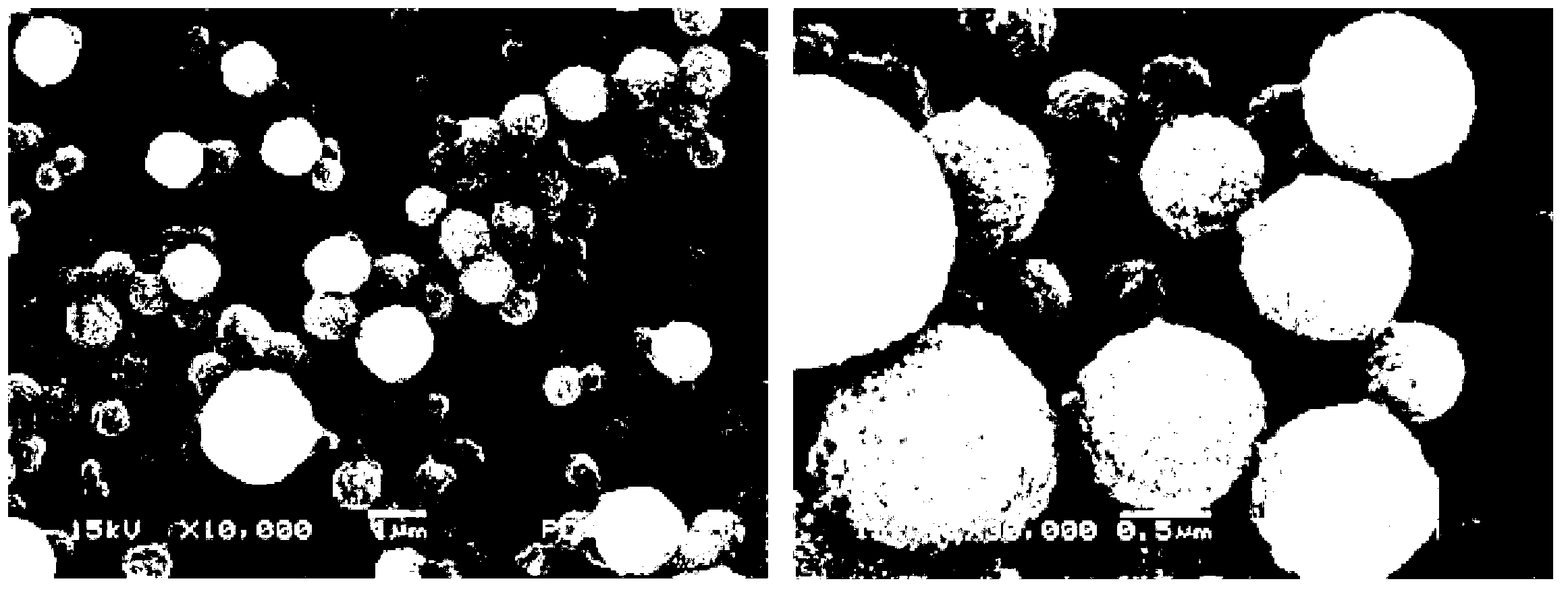

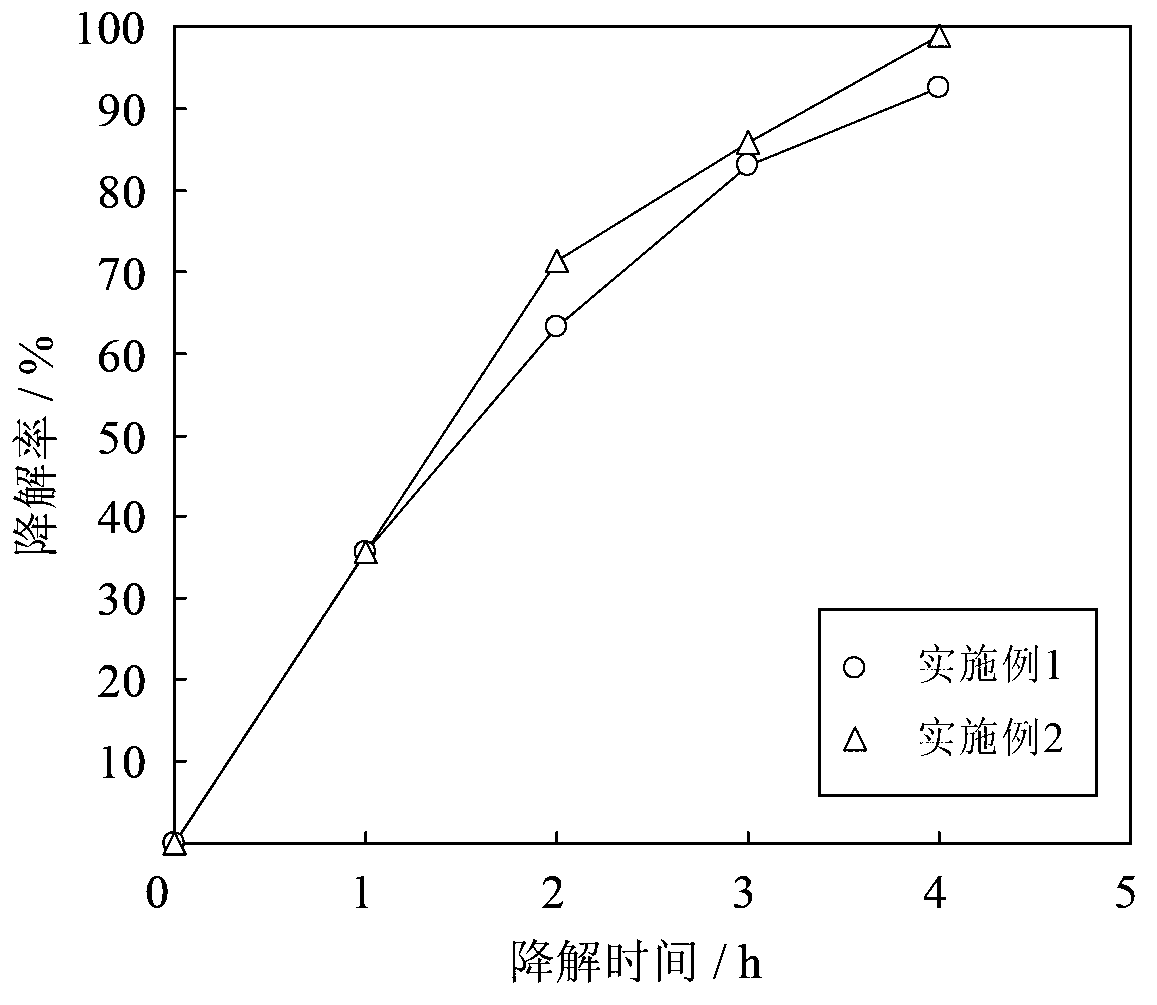

[0032] (5) Finally, the sample was heat-treated in a muffle furnace at 550 °C for 0.5 h to obtain TiO 2 microsphere catalyst. Its electron microscope pictures are as figure 1 . It can be seen that the appearance of the particles is spherical, and the surface is relatively ...

Embodiment 2

[0046] (1) Mix 5 mL of n-butyl titanate with 2 mL of acetylacetone, and stir for 0.5 h. The reaction is exothermic. The next step can only be performed when the temperature of the system returns to room temperature.

[0047] (2) Take 50 mL of an aqueous solution of 800 mg / L dodecylbenzenesulfonic acid and slowly add it to the above liquid while stirring to form a milky white dispersion system. Stirring was continued for 1 h.

[0048] (3) The above dispersion system was transferred to a reactor with a polytetrafluoroethylene inner cup, and reacted at a temperature of 150 °C for 24 h.

[0049] (4) After the reaction product was centrifuged, washed with water and ethanol, it was dried at 100°C for 2 h.

[0050] (5) Finally, the sample was heat-treated in a muffle furnace at 550 °C for 0.5 h to obtain TiO 2 microsphere catalyst. Its electron microscope pictures are as figure 2 . The shape of the particles is similar to the product obtained in Example 1, except for the sphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com