High-carbon-residue high-molecular emulsion microsphere and manufacturing method thereof

A polymer emulsion and water-soluble polymer technology, applied in electrical components, circuits, battery electrodes, etc., can solve the problems of large specific surface area, low carbon residue, and high impurities, and achieve the reduction of specific surface area and the amount of carbon residue Effect of high and low specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

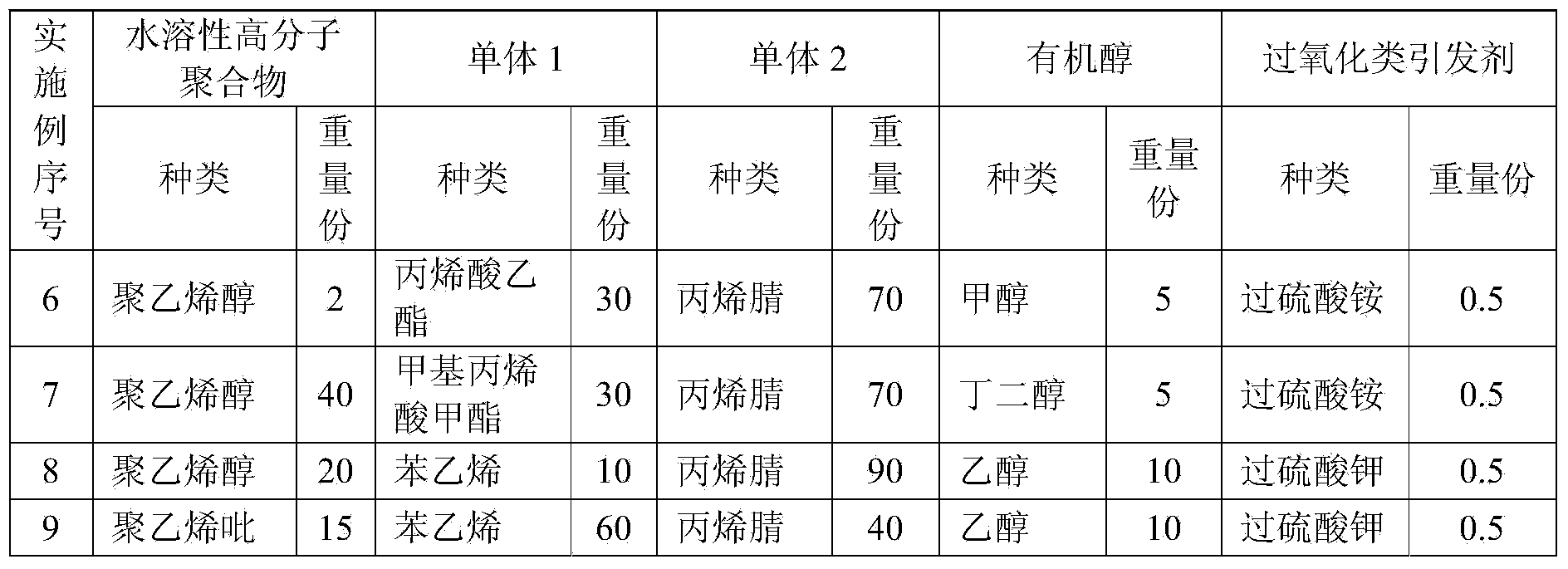

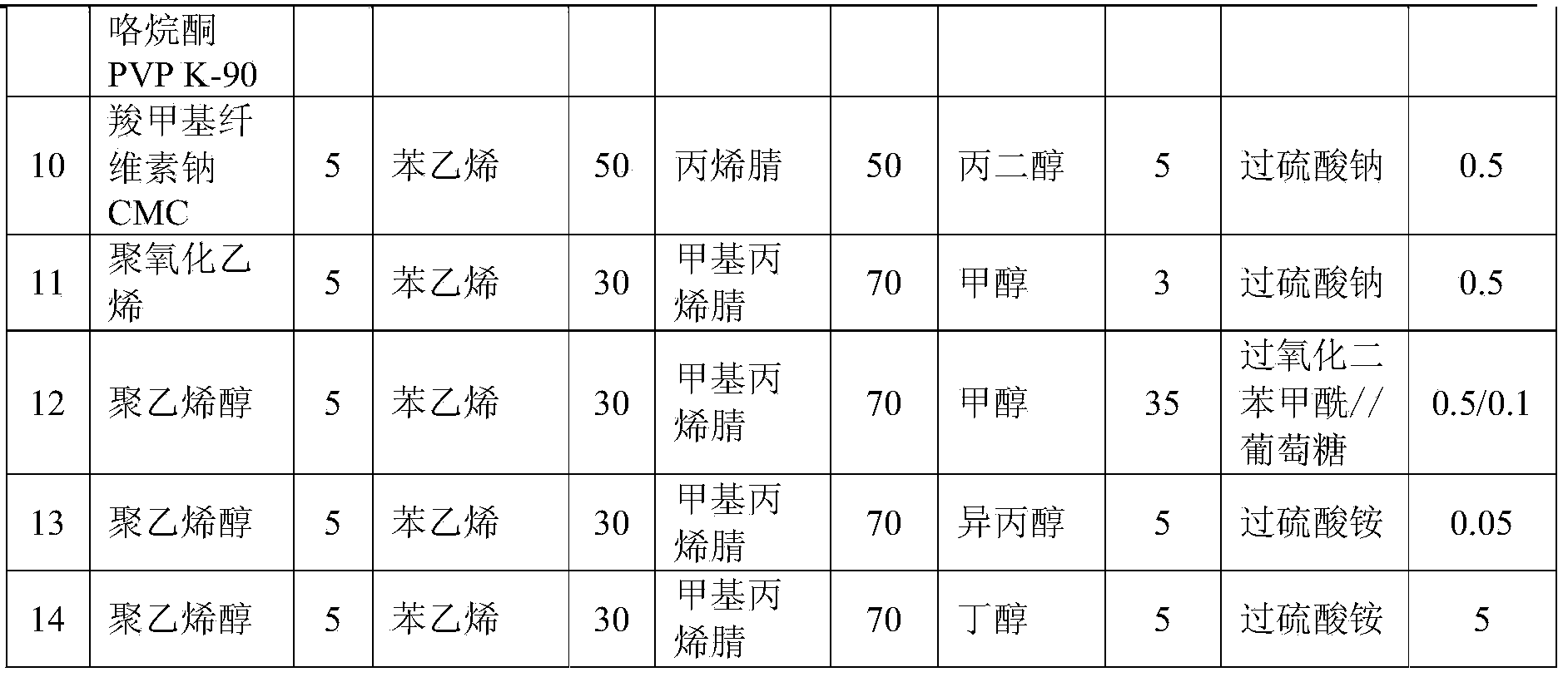

Examples

Embodiment 1

[0032] Dissolve 5 parts by weight of polyvinyl alcohol PVA205 (polymerization degree 500, alcoholysis degree 88.5 mol%, Japan Kuraray) in 120 parts by weight deionized water, and add 30 parts by weight of styrene and 70 parts by weight of acrylonitrile while stirring. Emulsify to obtain monomer emulsified dispersion.

[0033] Add 70 parts by weight of deionized water and 5 parts by weight of methanol to a glass reactor (Shanghai Heqi Glass Instrument Co., Ltd.) equipped with a reflux condenser, a separatory funnel, a thermometer, and a nitrogen pipe. Add 0.5 parts by weight of ammonium persulfate dissolved in 10 parts by weight of water as an initiator solution at ℃. After 2 minutes, use a plunger pump (Tokyo Rika VSP-1050) to add the monomer emulsion dispersion to the reactor. 4 The dripping was completed within hours, and the reaction was continued for 2 hours after the dripping was completed to obtain a polymer emulsion with a solid content of 33.8 wt% and a pH of 4.8. See th...

Embodiment 2

[0065] 20 parts by weight of polyvinylpyrrolidone PVP was dissolved in 120 parts by weight of deionized water, and 10 parts by weight of isoprene and 90 parts by weight of methacrylonitrile were added while stirring to emulsify to obtain a monomer emulsion dispersion.

[0066] Add 70 parts by weight of deionized water and 15 parts by weight of isopropanol to a high-pressure reactor equipped with a thermometer and a nitrogen pipe (Wuxi Mingyan Group Co., Ltd.). The temperature is raised to 80°C, and 1 part by weight is added at 80°C. An initiator solution prepared by dissolving sodium persulfate in 10 parts by weight of water. After 2 minutes, add the monomer emulsified dispersion liquid in the early stage to the reactor. After 8 hours of dripping, continue the reaction for 2 hours after the dripping to obtain the solid content. It is a 36.5wt% polymer emulsion with a pH of 4.5.

[0067] Carbon residue measurement: The obtained polymer emulsion was dried at 105°C for 24 hours, and t...

Embodiment 3

[0071] Dissolve 20 parts by weight of polyvinyl alcohol PVA205 (polymerization degree 500, alcoholysis degree 88.5 mol%, Japan Kuraray) in 120 parts by weight deionized water, and add 30 parts by weight of ethyl acrylate and 70 parts by weight of acrylonitrile while stirring Perform emulsification to obtain a monomer emulsified dispersion.

[0072] Add 70 parts by weight of deionized water and 45 parts by weight of butanol to a glass reactor equipped with reflux condenser, separatory funnel, thermometer and nitrogen gas pipe. The temperature is raised to 80°C, and 4.5 parts by weight of tert-butyl are added at 80°C. Initiator solution prepared by dissolving base hydrogen peroxide in 10 parts by weight of water, 1.0 part by weight of glucose as reducing agent, add the monomer emulsion dispersion in the reactor after 2 minutes, and finish dripping in 4 hours. The reaction was continued for 2 hours to obtain a polymer emulsion with a solid content of 33.8 wt% and a pH value of 1.3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com