Electrolyte and its preparation method and application

An electrolyte and electrolyte additive technology, applied in the field of lithium batteries, can solve the problems of battery gas production and cycle performance deterioration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

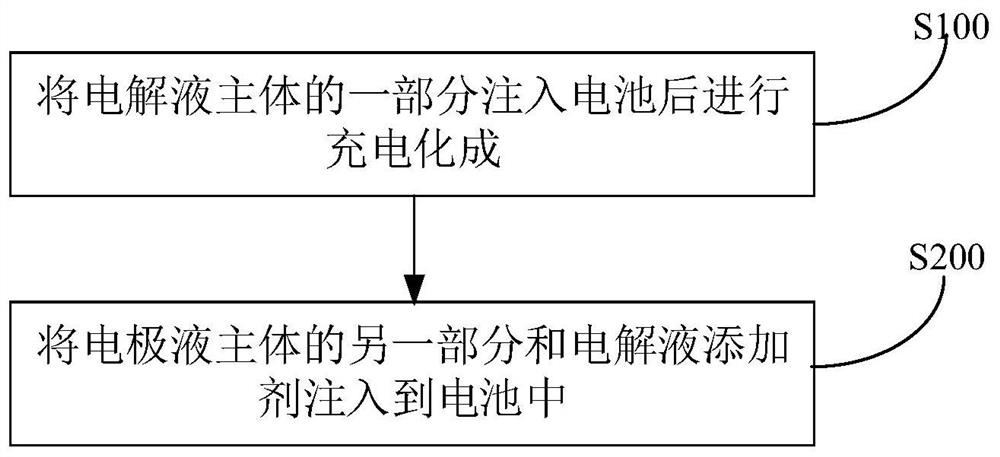

[0057] (1) Inject a part of the main electrolyte (1.0M LiPF6, EC / EMC / DMC=2 / 3 / 5) (accounting for 75% of the total battery weight) into the battery (the positive pole of the battery is NCM ternary (LiNi 0.8 co 0.1 mn 0.1 o 2 ) material, the negative electrode adopts pure graphite respectively) and charge and form at 0.05C to generate a solid electrolyte interface film on the negative electrode surface of the battery;

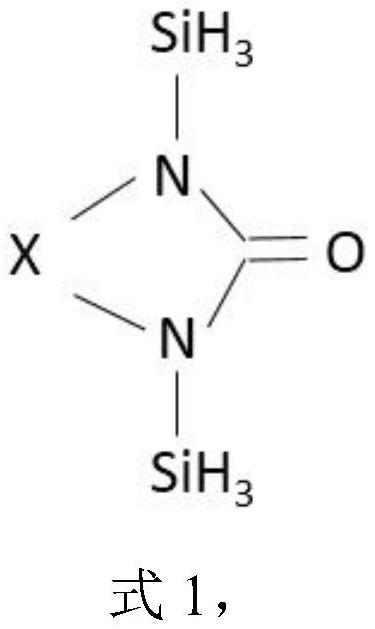

[0058] (2) Another part of the electrode solution body (1.0M LiPF6, EC / EMC / DMC=2 / 3 / 5) and the electrolyte additive (compound shown in formula 1, X is -CH 2 , the amount added is 0.5wt% of the weight of the electrolyte) into the battery.

Embodiment 2

[0060] (1) Inject a part of the electrolyte body (1.0M LiPF6, EC / EMC / DMC=2 / 3 / 5) (accounting for 80% of the total battery weight) into the battery (the positive pole of the battery is NCM ternary (LiNi 0.8 co 0.1 mn 0.1 o 2 ) material), the negative electrode adopts graphite doped with 10wt% Si) and charges and forms it at 0.15C to generate a solid electrolyte interface film on the surface of the negative electrode of the battery;

[0061] (2) Another part of the electrode solution body (1.0M LiPF6, EC / EMC / DMC=2 / 3 / 5) and the electrolyte additive (compound shown in formula 1, X is -C 2 h 4 , the amount added is 0.01wt% of the weight of the electrolyte) into the battery.

Embodiment 3

[0063] (1) Inject a part of the main electrolyte (1.0M LiPF6, EC / EMC / DMC=2 / 3 / 5) (accounting for 85% of the total battery weight) into the battery (the positive pole of the battery is NCM ternary (LiNi 8 co 1 mn 1 o 2 ) material, the negative electrode adopts Si material) and then charge and form at 0.25C to generate a solid electrolyte interface film on the surface of the negative electrode of the battery;

[0064] (2) Another part of the electrode solution body (1.0M LiPF6, EC / EMC / DMC=2 / 3 / 5) and the electrolyte additive (compound shown in formula 1, X is -C 3 h 6 , the amount added is 1wt% of the weight of the electrolyte) into the battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com