Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

156results about How to "Improve surface stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

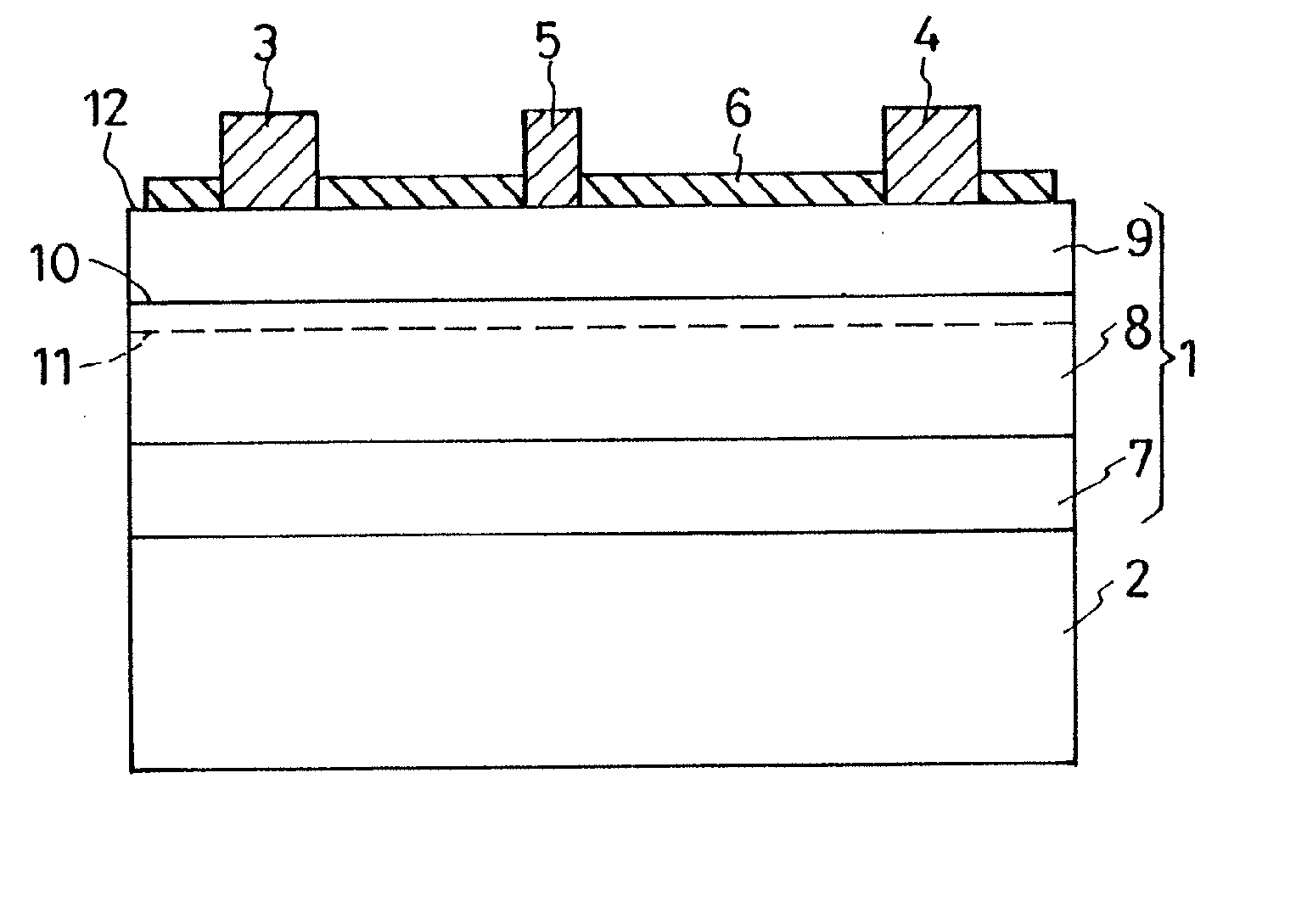

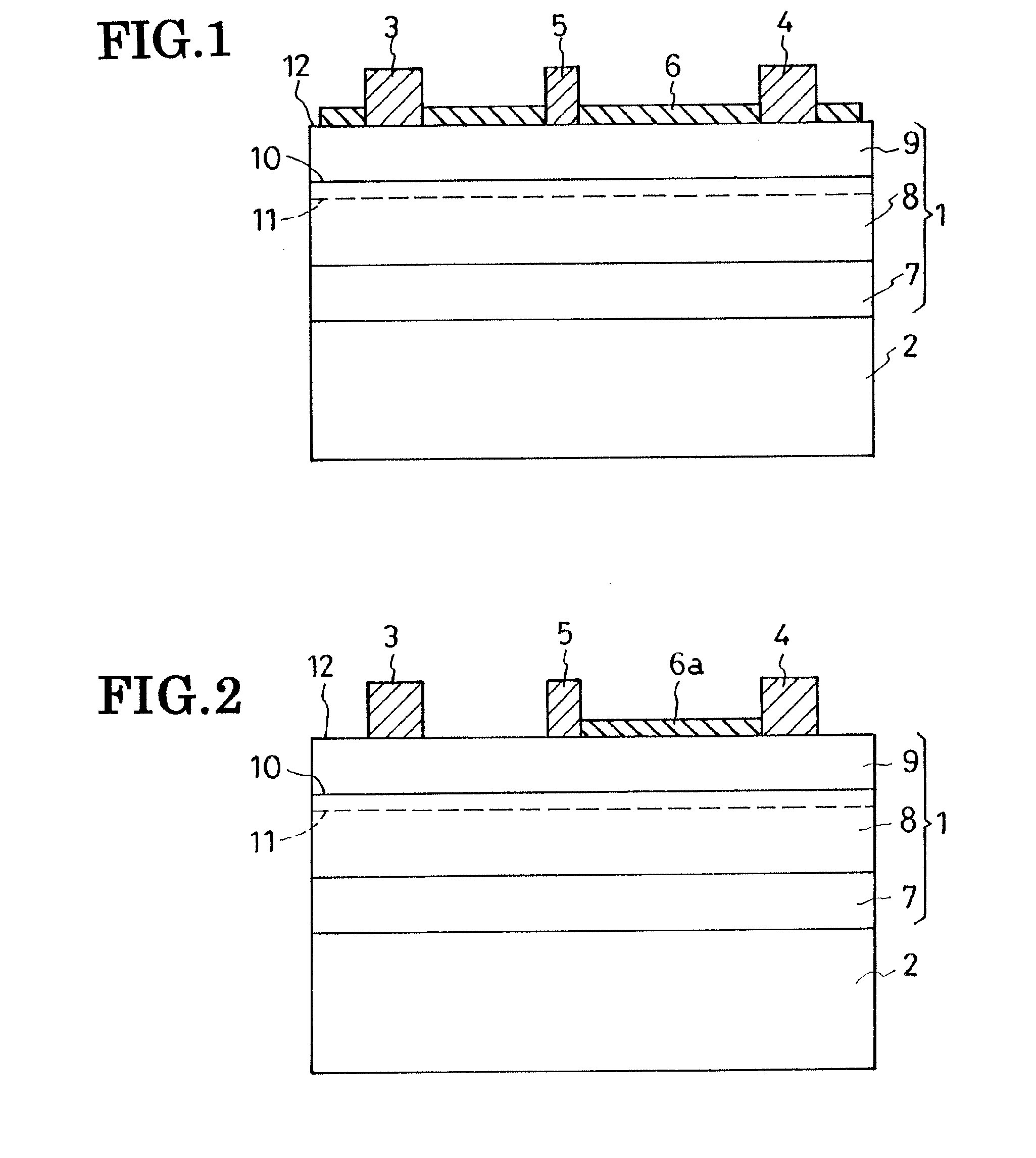

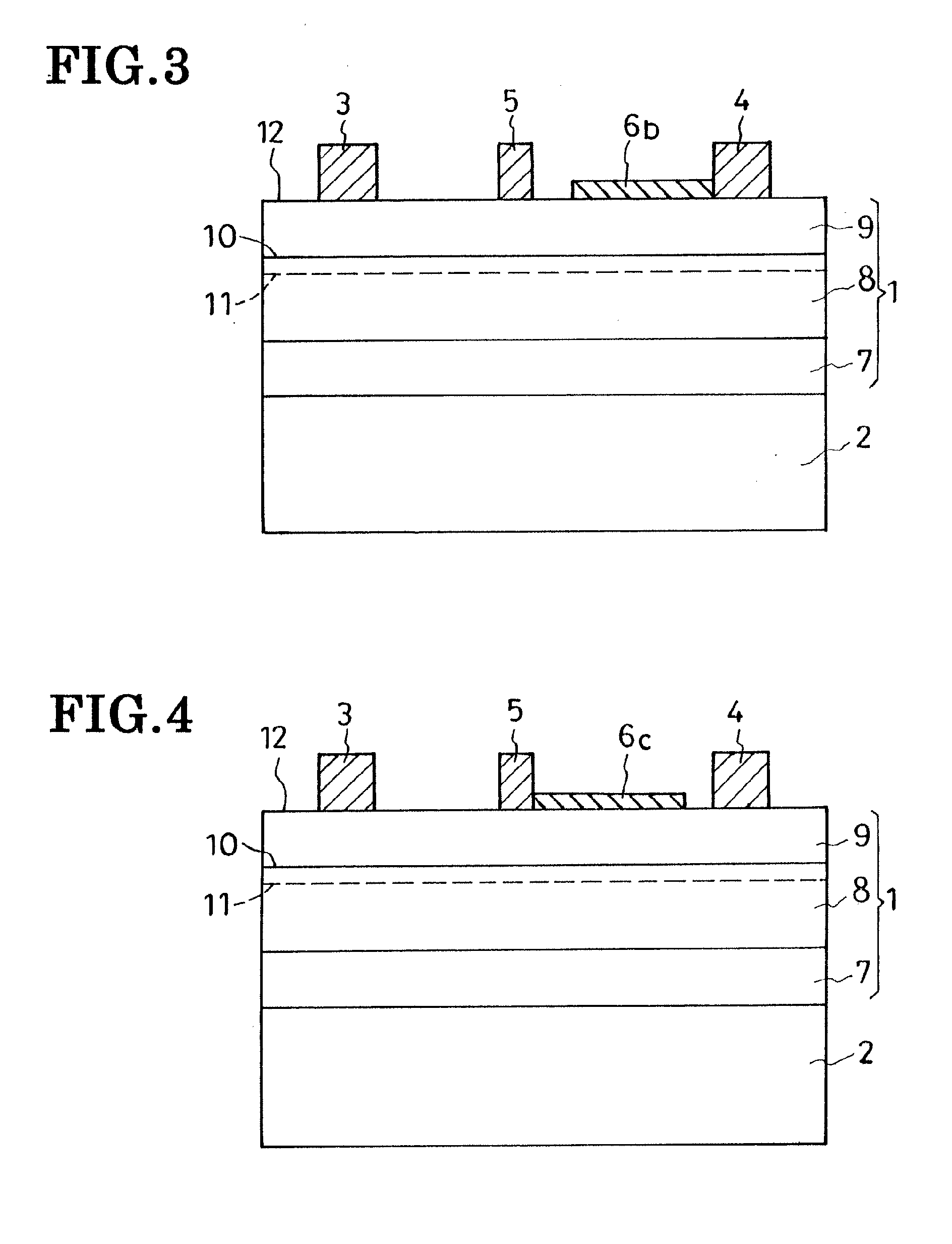

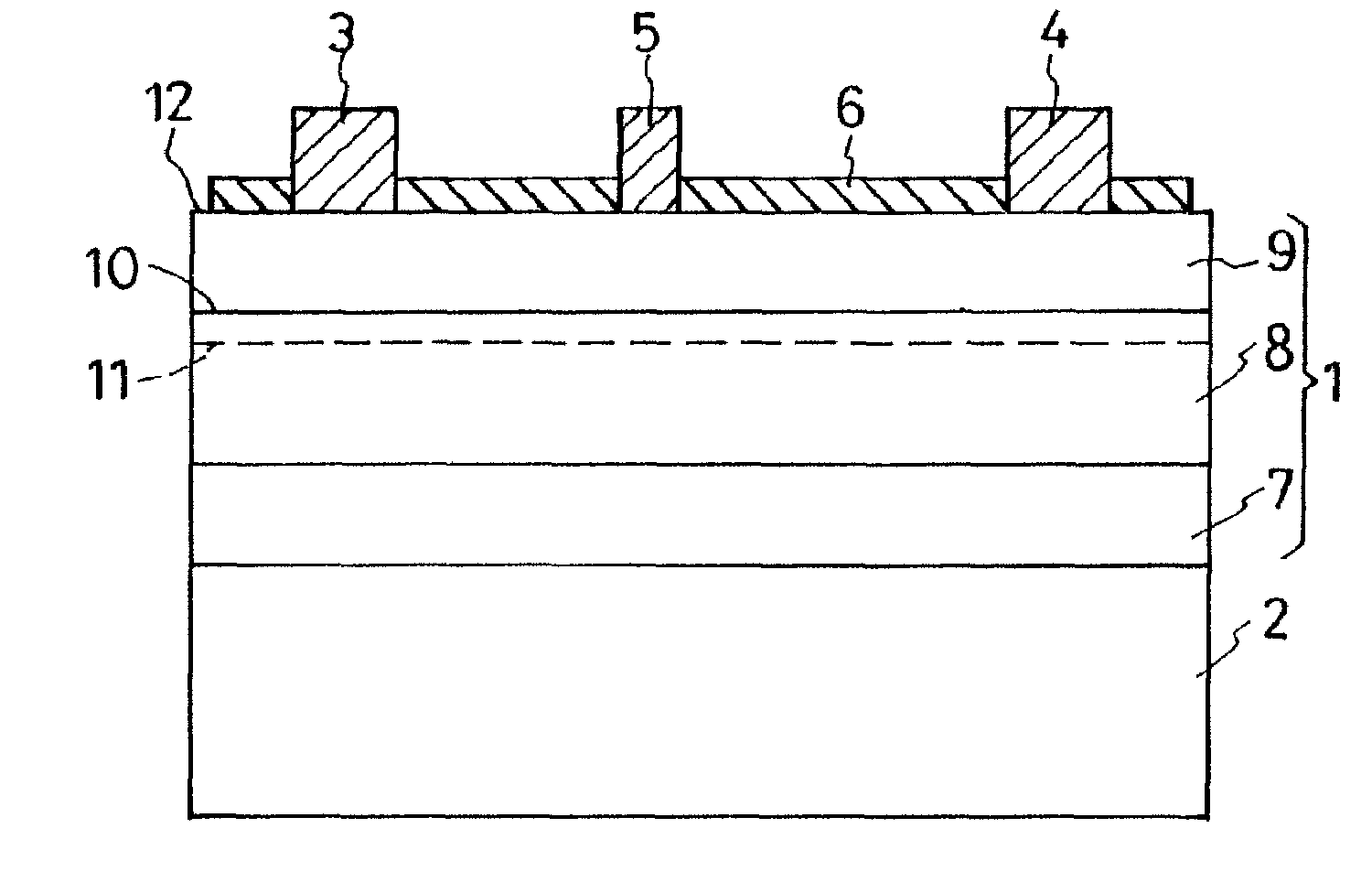

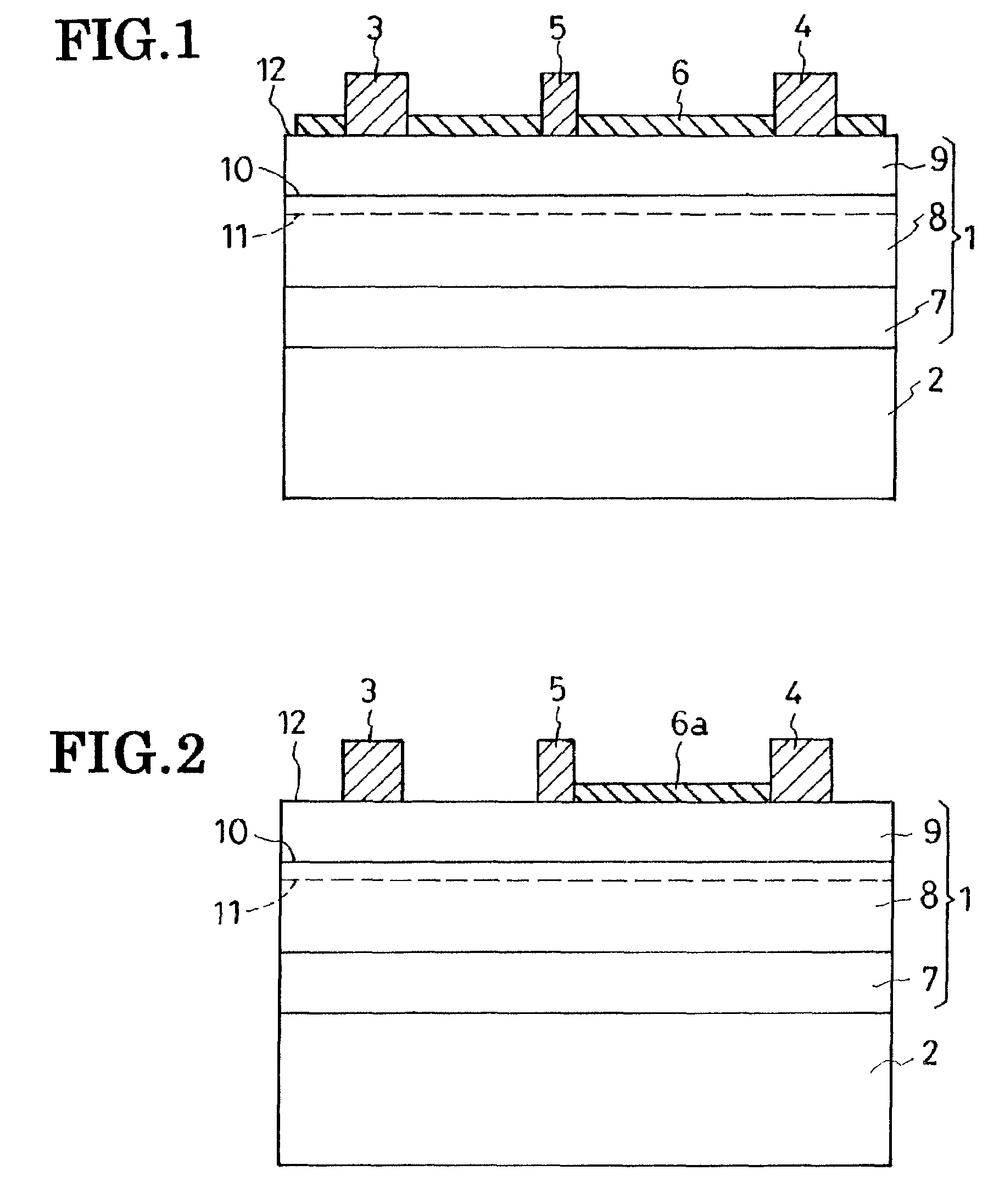

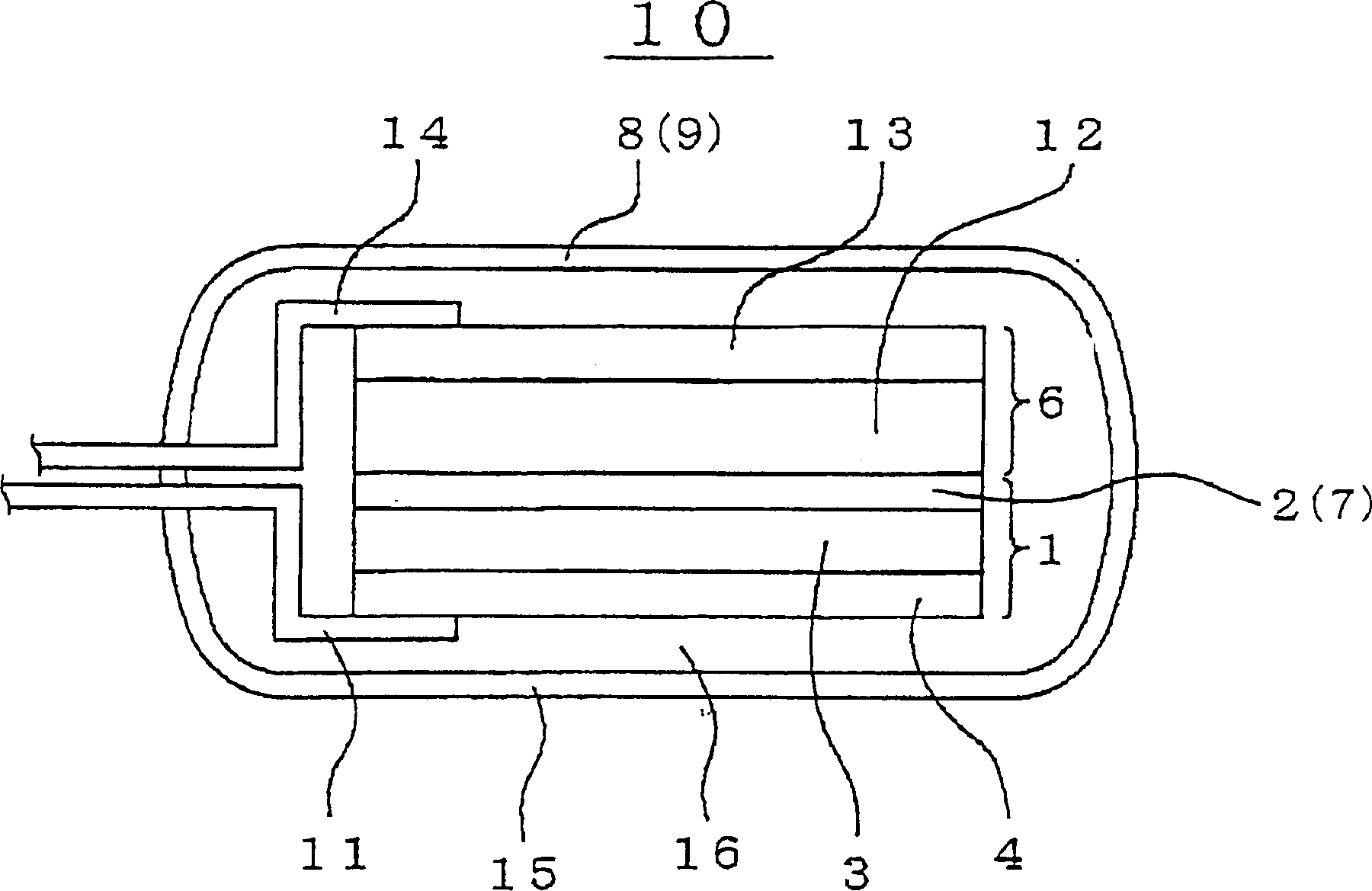

Surface-stabilized semiconductor device

InactiveUS20080121876A1Economical and reliableImprove pressure resistanceSemiconductor/solid-state device detailsSolid-state devicesHigh-electron-mobility transistorOrganic semiconductor

A high electron mobility transistor is disclosed which has a main semiconductor region formed on a silicon substrate. The main semiconductor region is a lamination of a buffer layer on the substrate, an electron transit layer on the buffer layer, and an electron supply layer on the electron transit layer. A source, drain, and gate overlie the electron supply layer. Also formed on the electron supply layer is a surface-stabilizing organic semiconductor overlay which is of p conductivity type in contrast to the n type of the electron supply layer.

Owner:SANKEN ELECTRIC CO LTD

Surface-stabilized semiconductor device

InactiveUS7714360B2Improve pressure resistanceLow mobilitySemiconductor/solid-state device detailsSolid-state devicesOrganic semiconductorSilicon

A high electron mobility transistor is disclosed which has a main semiconductor region formed on a silicon substrate. The main semiconductor region is a lamination of a buffer layer on the substrate, an electron transit layer on the buffer layer, and an electron supply layer on the electron transit layer. A source, drain, and gate overlie the electron supply layer. Also formed on the electron supply layer is a surface-stabilizing organic semiconductor overlay which is of p conductivity type in contrast to the n type of the electron supply layer.

Owner:SANKEN ELECTRIC CO LTD

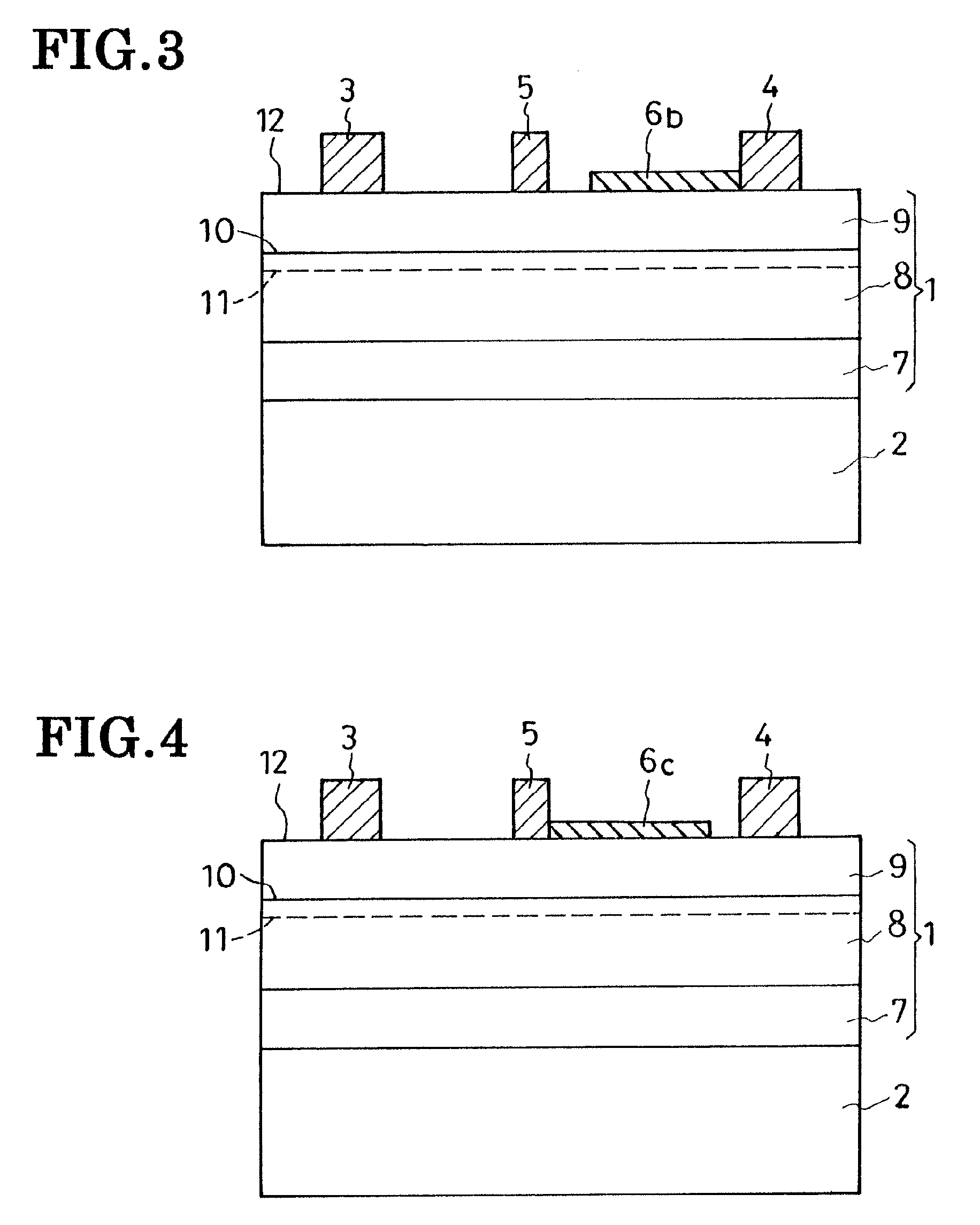

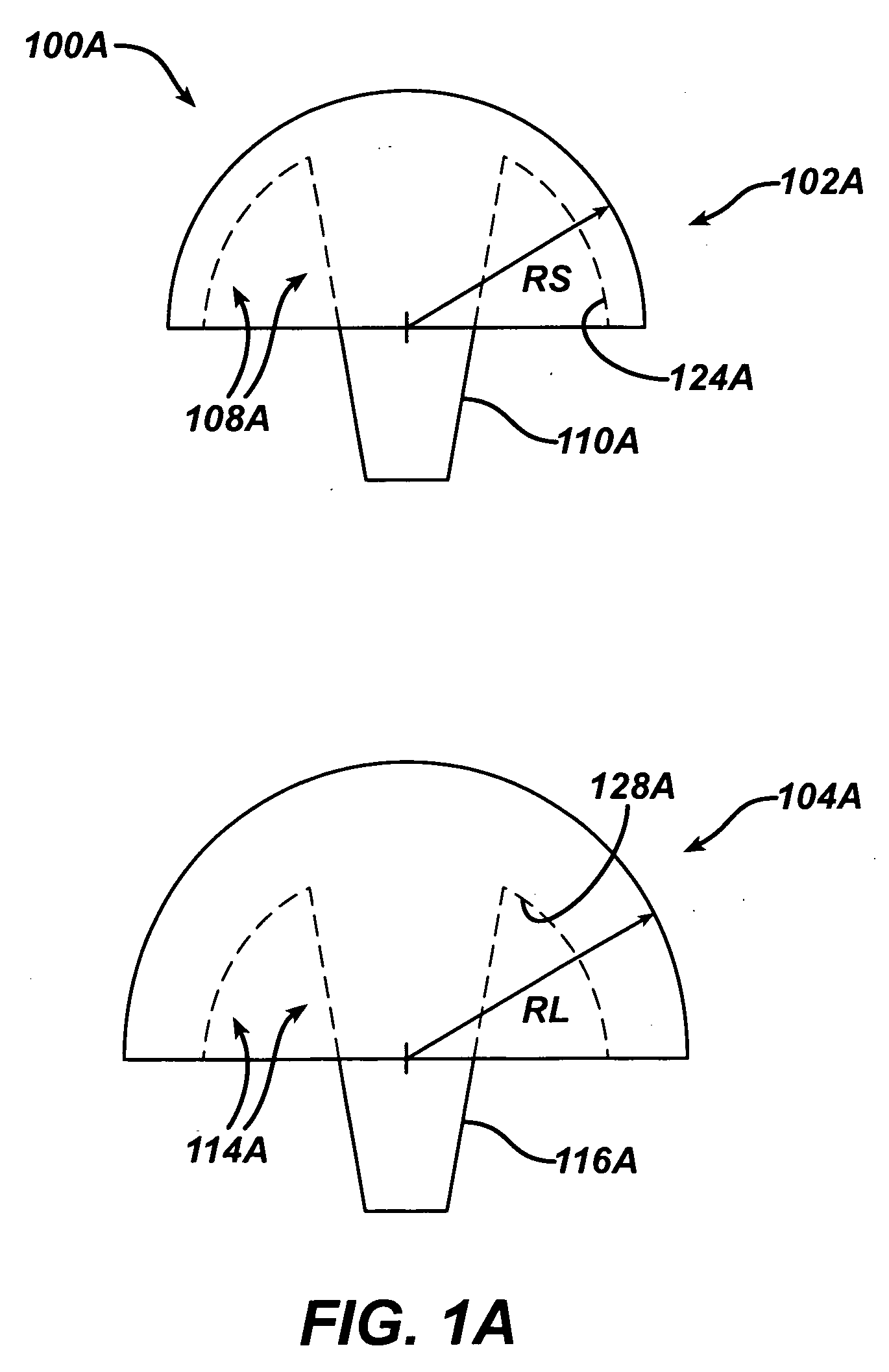

Punch, implant and associated method

InactiveUS20060149390A1Shorten the timeMeet cost performance requirementsBone implantDiagnosticsJoint arthroplastyMedicine

An instrument for preparing a cavity for a stem of a prosthetic implant for use in performing joint arthroplasty on a head of a long bone is provided. The instrument includes a body and a punch extending from the body. The punch includes a portion of the punch having a shape similar to the stem of the implant.

Owner:DEPUY PROD INC

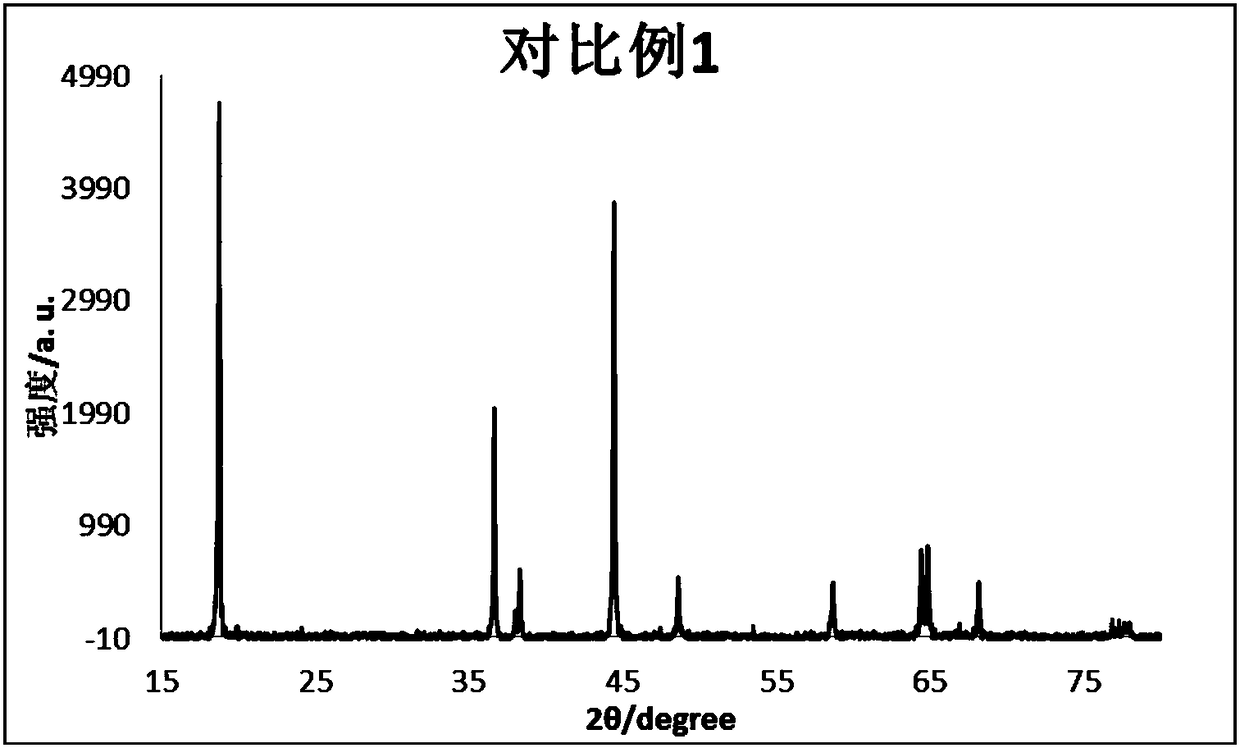

Modified high nickel ternary positive electrode material and its preparation method and lithium ion battery

InactiveCN108206277AImprove the first discharge capacityImprove the first Coulombic efficiencyCell electrodesSecondary cellsAluminium-ion batteryElectrical conductor

The invention discloses a modified high nickel ternary positive electrode material. The surface of a high nickel ternary positive electrode material is coated with a coating layer containing a fast ion conductor. The fast ion conductor has the chemical general formula of Li3x1La2 / 3-x1Ma1TiNz1O3, Li2+2x2Zn1-x2GeO4 or LiM'2(PO4)3, wherein M represents Ba<2+> and / or Sr<2+>, N represents Al<3+> and / orZr<4+>, x1 is greater than or equal to 0.04 and less than or equal to 0.167, a1 is greater than or equal to 0 and less than or equal to 1, z1 is greater than or equal to 0 and less than or equal to 1, x2 is greater than -0.3 and less than 0.8, and M' represents one or more of Zr, Ti, Ge and Hf. Compared with the existing positive electrode material, the modified high nickel ternary positive electrode material is provided with the coating layer containing the fast ion conductor and the coating layer can react with residual lithium on the surface of the material to reduce residual lithium on the surface of the material and inhibit side reactions of the residual lithium and the electrolyte so that material surface stability and cycle performances are improved. The modified high nickel ternary positive electrode material has good lithium ion deintercalation ability, improves the first discharge capacity of the material and first coulombic efficiency and has a good application prospect. The invention also discloses a preparation method of the modified high nickel ternary positive electrode material and a lithium ion battery.

Owner:CONTEMPORARY AMPEREX TECH CO

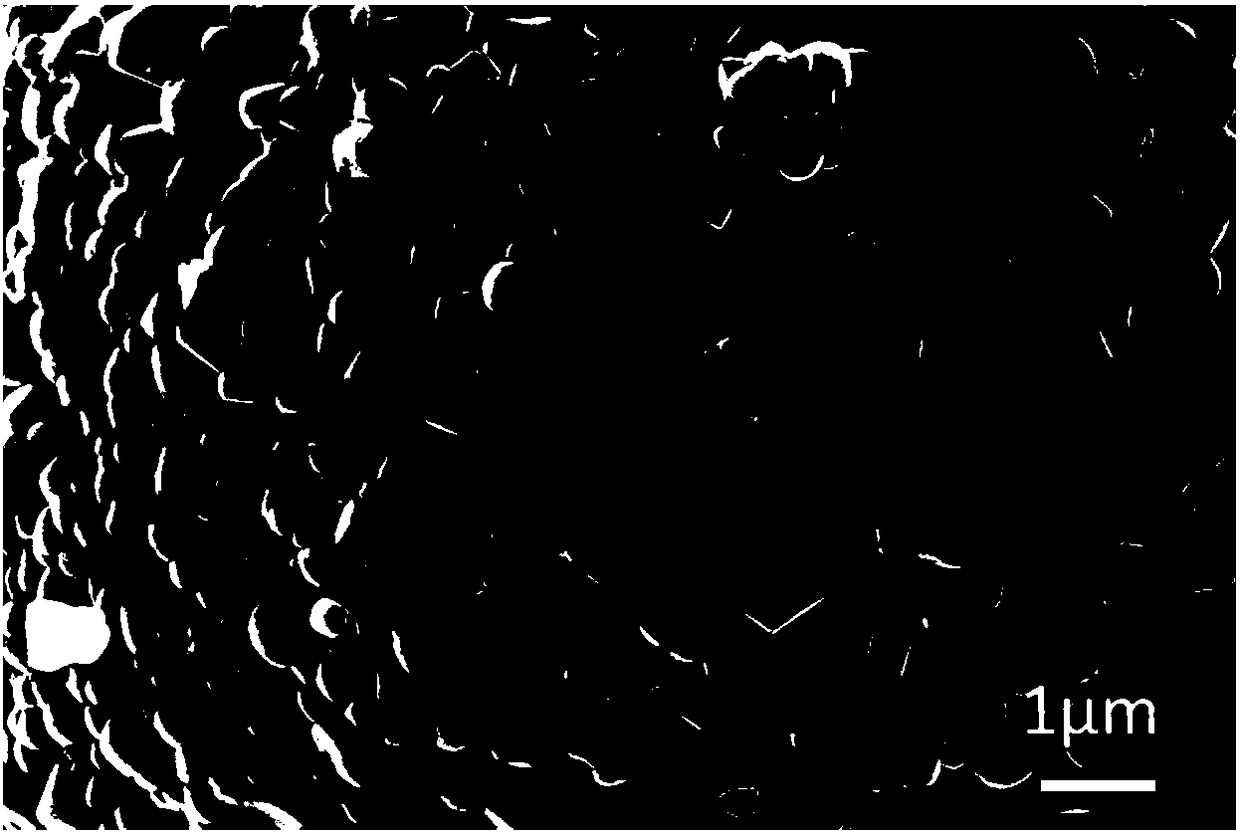

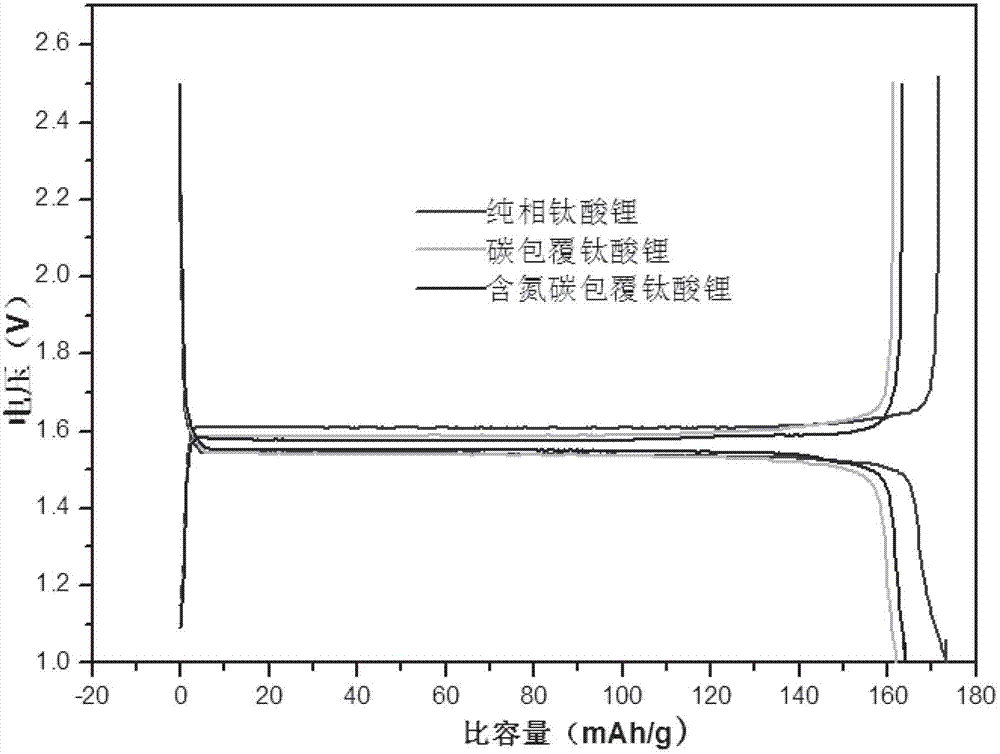

Synthetic method of nitrogen-enriched carbon coated lithium titanate composite material prepared by introduction of ionic liquid as carbon source

InactiveCN102820458AImprove electronic conductivityImprove surface stabilityCell electrodesSecondary cells servicing/maintenanceVacuum dryingCarbon coated

The invention discloses a synthetic method of a nitrogen-enriched carbon coated lithium titanate composite material prepared by the introduction of an ionic liquid as a carbon source. The synthetic method comprises the following steps of: 1) weighing lithium salt, titanium dioxide and the carbon source in proportion, adding alcohol, carrying out ball milling dispersion, and carrying out vacuum drying to prepare a precursor; 2) sintering the prepared precursor at the temperature of 750-950 DEG C under the protection of an inert atmosphere so as to preliminarily obtain lithium titanate with a carbon material coated on the surface; and 3) adding the ionic liquid and deionized water in proportion into the preliminarily obtained carbon-coated lithium titanate, carrying out ball milling, stirring and sintering. The lithium titanate composite material has a spherical morphology of nano-primary particle composed micrometer secondary particles, and the surface of the lithium titanate composite material is uniformly coated with a layer of nitrogen-enriched carbon material. Its electronic conductivity is not only effectively raised, but surface stability of the material is also enhanced. The obtained material has excellent rate capability and cycle performance. In addition, gas expansion problem of lithium titanate cells is effectively improved. The nitrogen-enriched carbon coated lithium titanate composite material has a wide application prospect in the field of lithium ion battery.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

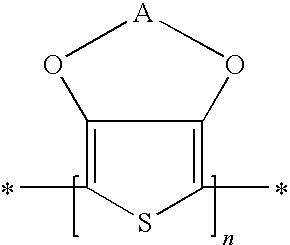

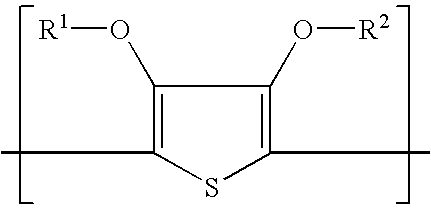

Layer configuration with improved stability to sunlight exposure

ActiveUS7820078B2Improve stabilityReduce surface resistanceHybrid capacitor electrodesConductive materialLight-emitting diodeHydrocarbons.aliphatic

Disclosed are a light-emitting diode, a photovoltaic device, a transistor, and an electroluminescent device, each comprising a layer disposed on a support, the layer comprising a [A] composition exclusive of hydroquinone comprising at least one polymer comprising (3,4-dialkoxythiophene) monomer units, a polyanion, at least one polyhydroxy group-containing aromatic compound exclusive of sulfo groups, at least one amino-compound or heterocyclic compound with at least one ring nitrogen atom, and at least one compound selected from the group consisting of polyhydroxy- and / or carboxy group or amide or lactam group containing aliphatic compounds and aprotic compounds with a dielectric constant ≧15.

Owner:AGFA GEVAERT AG

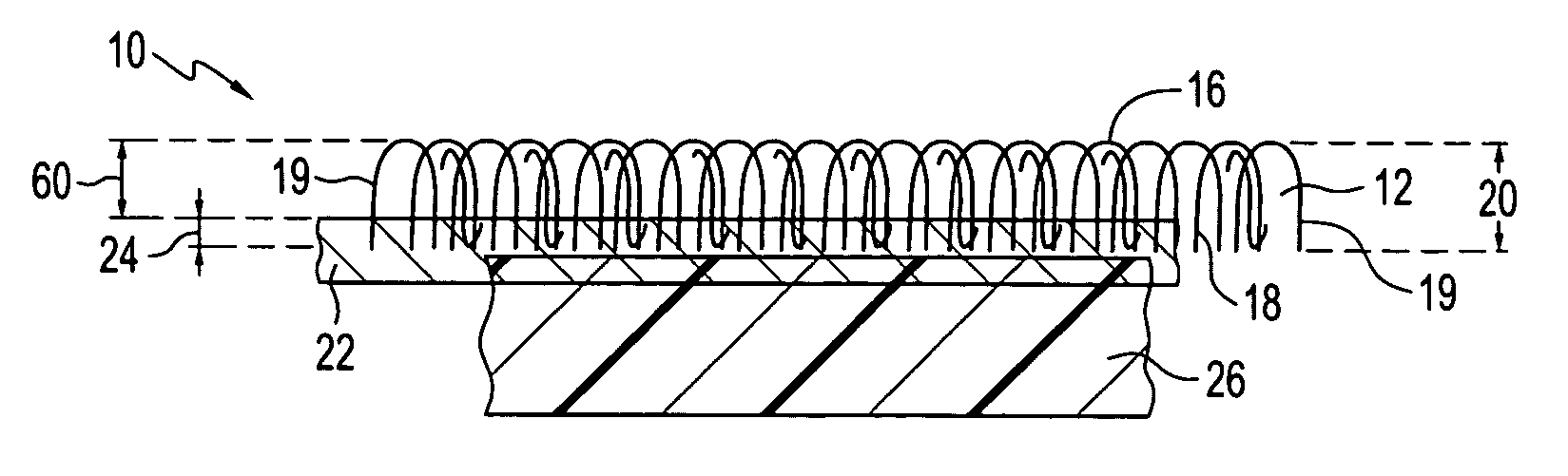

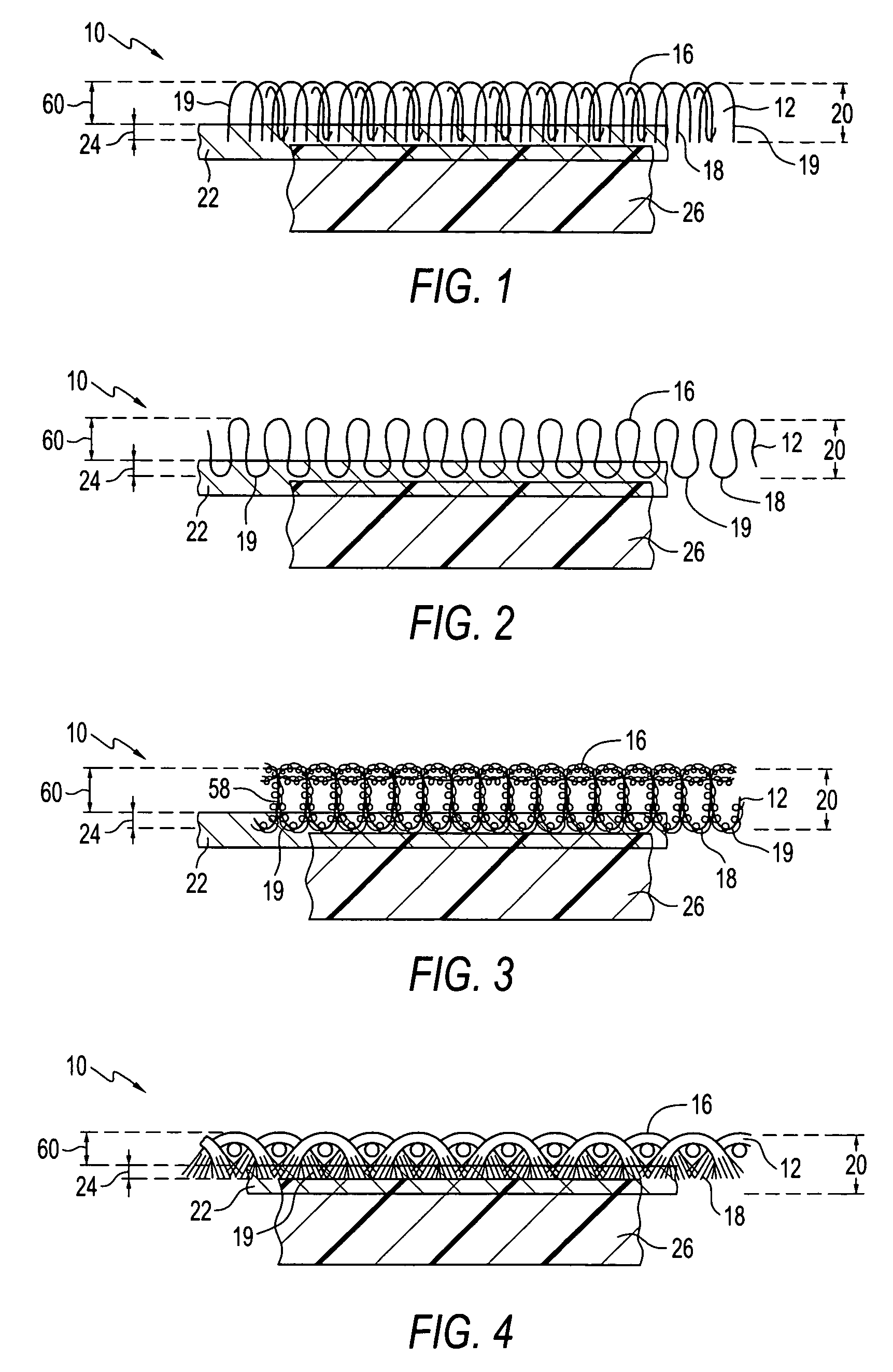

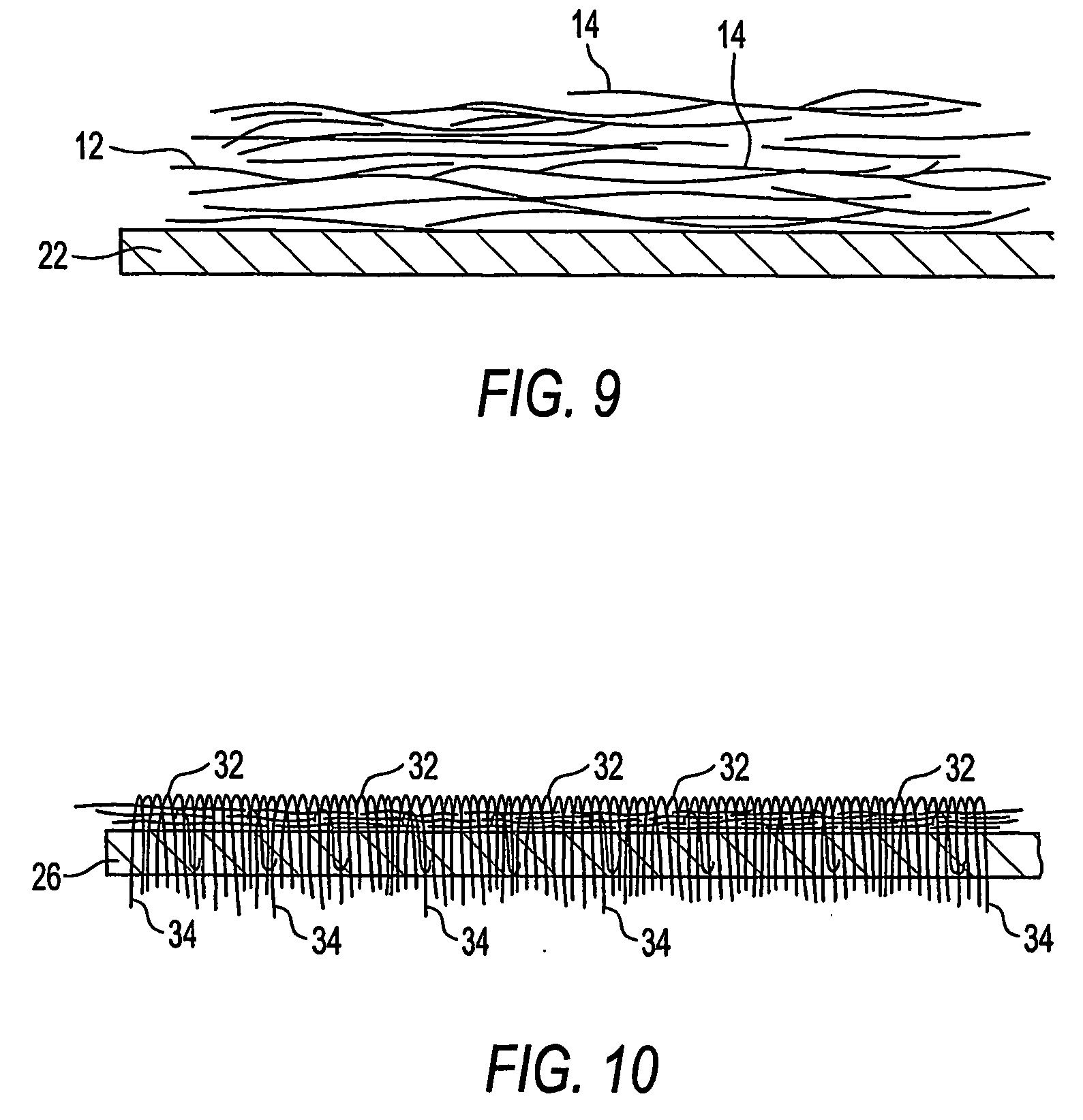

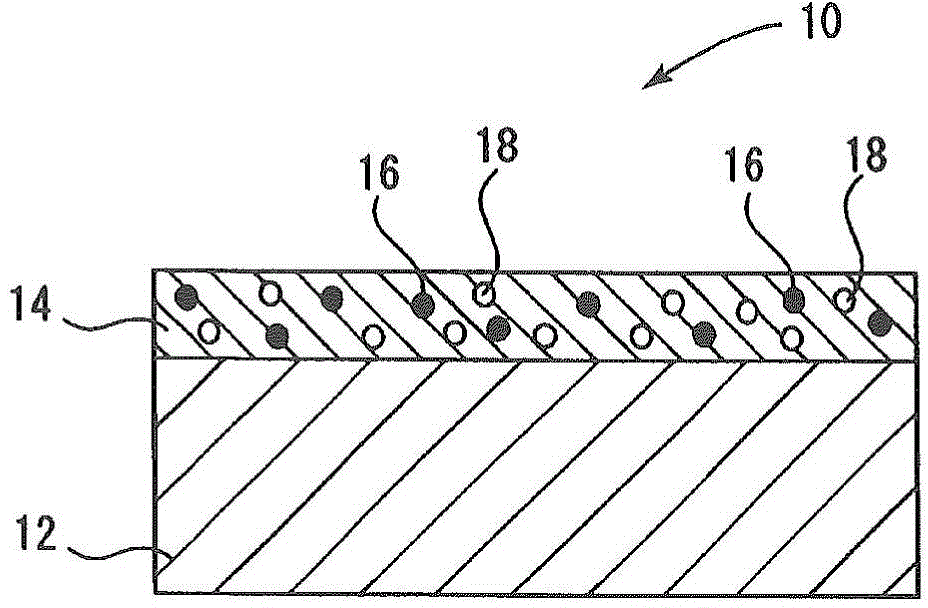

Fabric-faced composites and methods for making same

InactiveUS20050003141A1Desired level of surface stabilityImprove retentionLiquid surface applicatorsCovering/liningsEngineeringMechanical engineering

The present invention is directed to multiple layer composites suitable for use as wall and floor coverings, among other uses, that provide a strong durable structure and a soft textile or fabric face. The composite includes a face layer bonded to an adhesive layer such that the adhesive layer penetrates into the face layer. The face layer can have legs extending there from, and such legs are anchored by the adhesive layer to provide stronger attachment between the adhesive layer and the face layer. A backing layer may also be provided in contact with the adhesive layer such that the adhesive layer also embeds into the backing layer, and the legs extending from the face layer may penetrate into the backing layer.

Owner:J&J FLOORING GRP LLC

Simple and easy preparation method for super-hydrophobic fiber and textile and application thereof

InactiveCN102154834AExcellent superhydrophobic propertiesWide range of choicesFibre treatmentFiberRolling angle

The invention relates to a simple and easy preparation method for super-hydrophobic fiber and textile with high contact angle and low rolling angle and application thereof. Surface chemical modification is directly carried out on intrinsic coarse structures on the surface of the fiber and textile so as to prepare a fiber product with super-hydrophobic performance; the method comprises the following steps of: firstly, cleanly washing materials, then carrying out isocyanate modification on the material, and finally modifying low surface energy material. The raw material is cheap and is easily available; reaction conditions are relatively mild; the operation is simple; and the requirement on the device is low. The obtain product has good super-hydrophobic performance; the contact angle of 10microliter of water is 156 degrees; and the product has wide application in fields of self-cleaning fibers and textiles.

Owner:HUNAN UNIV

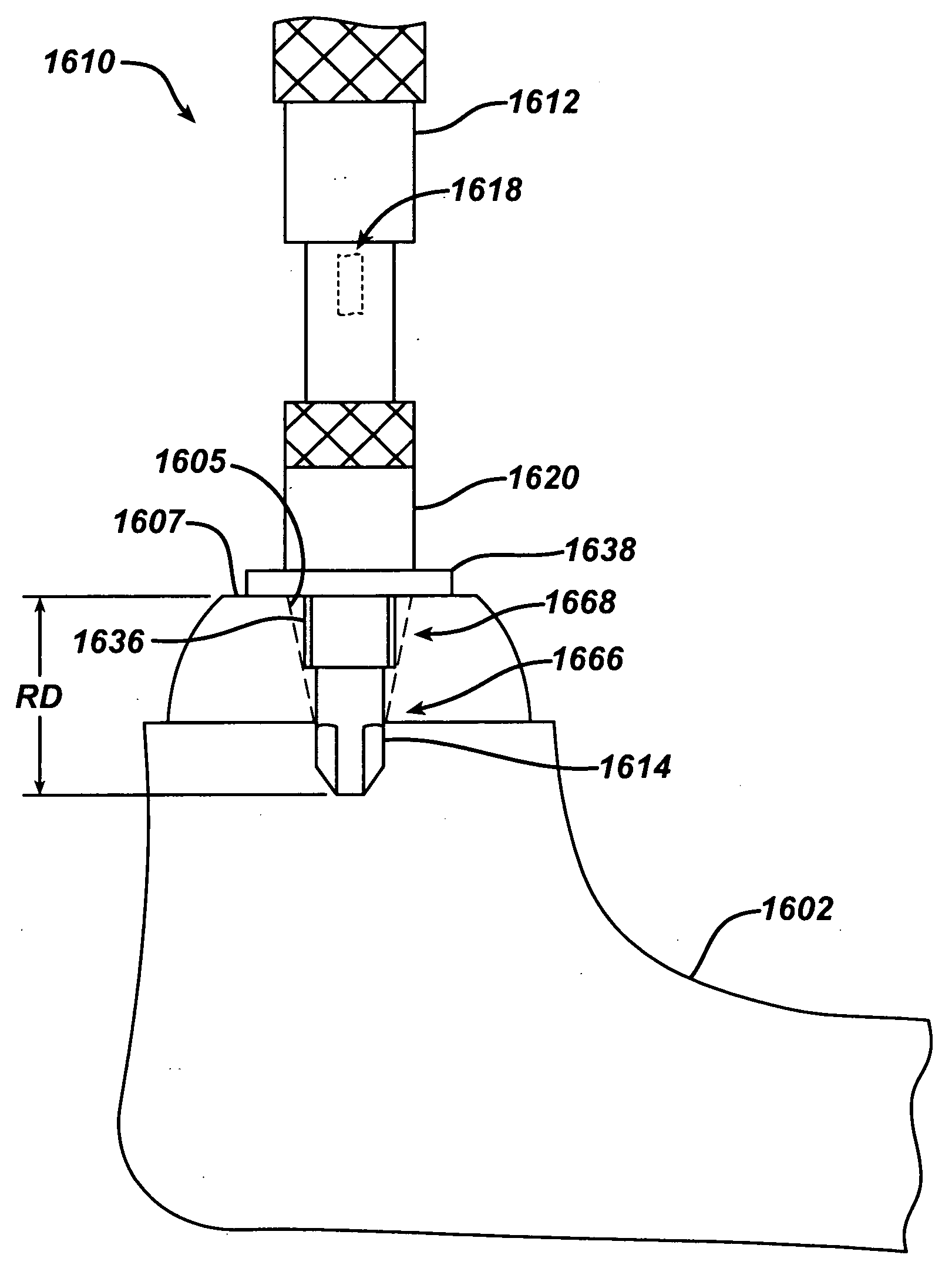

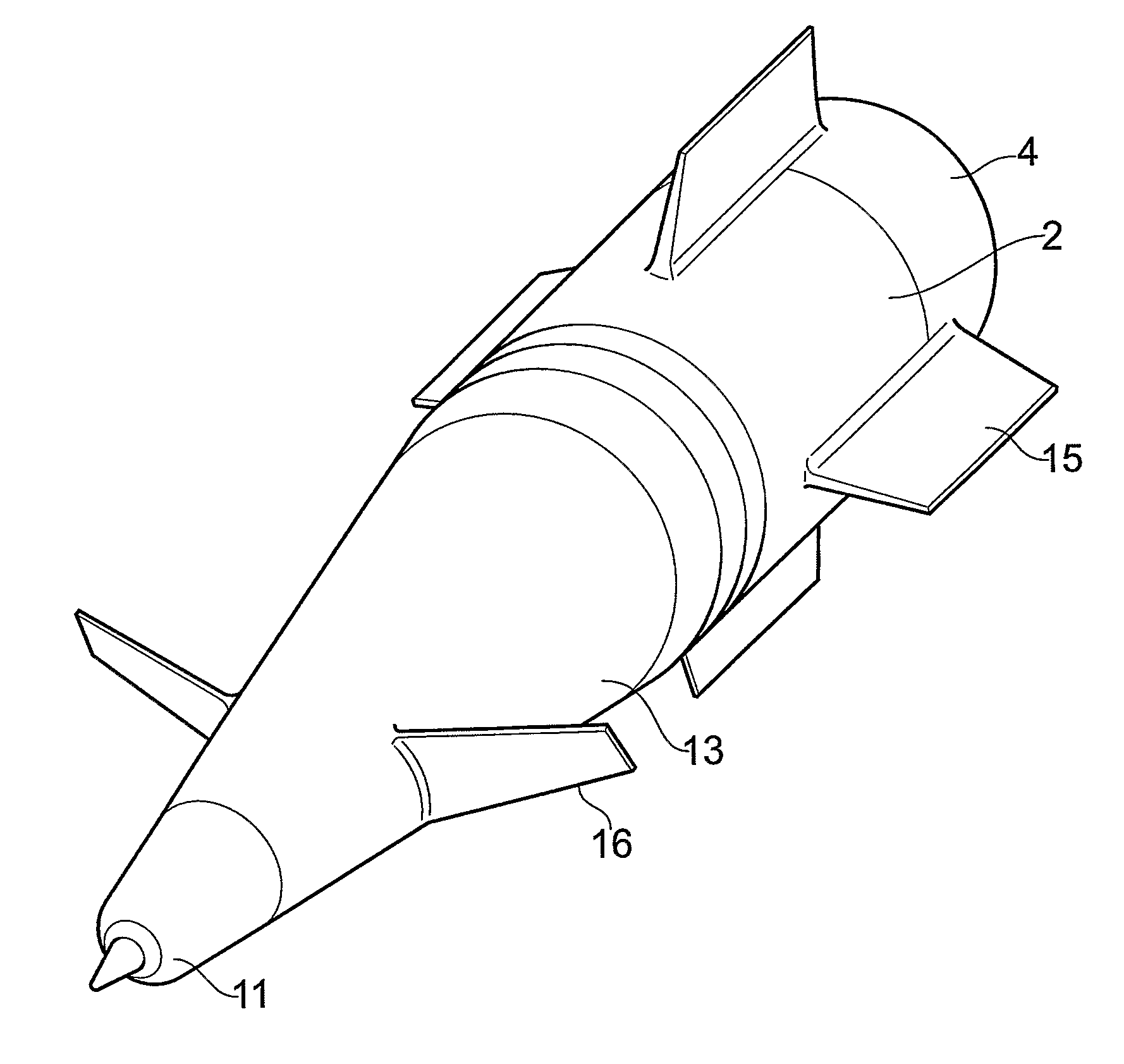

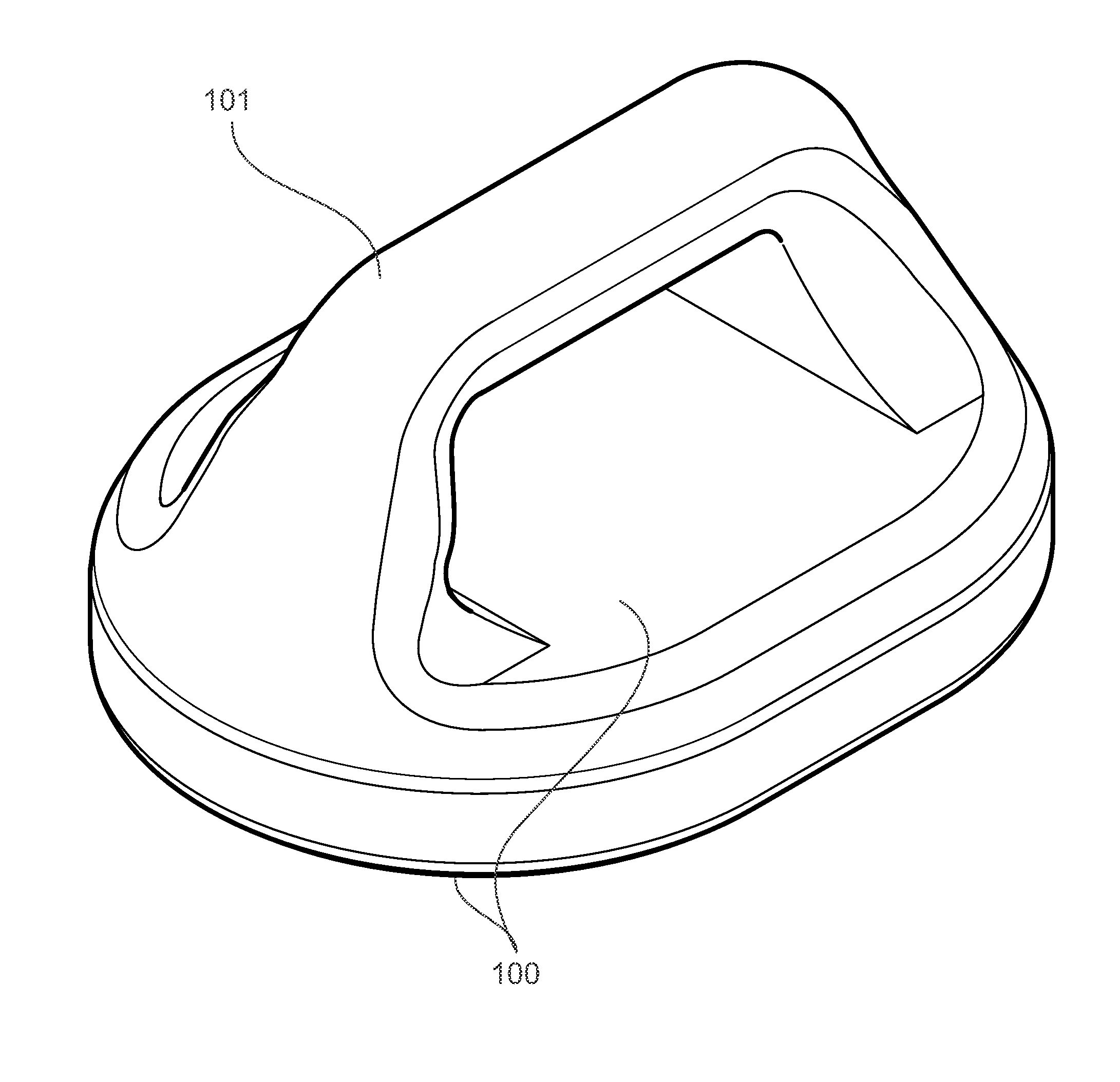

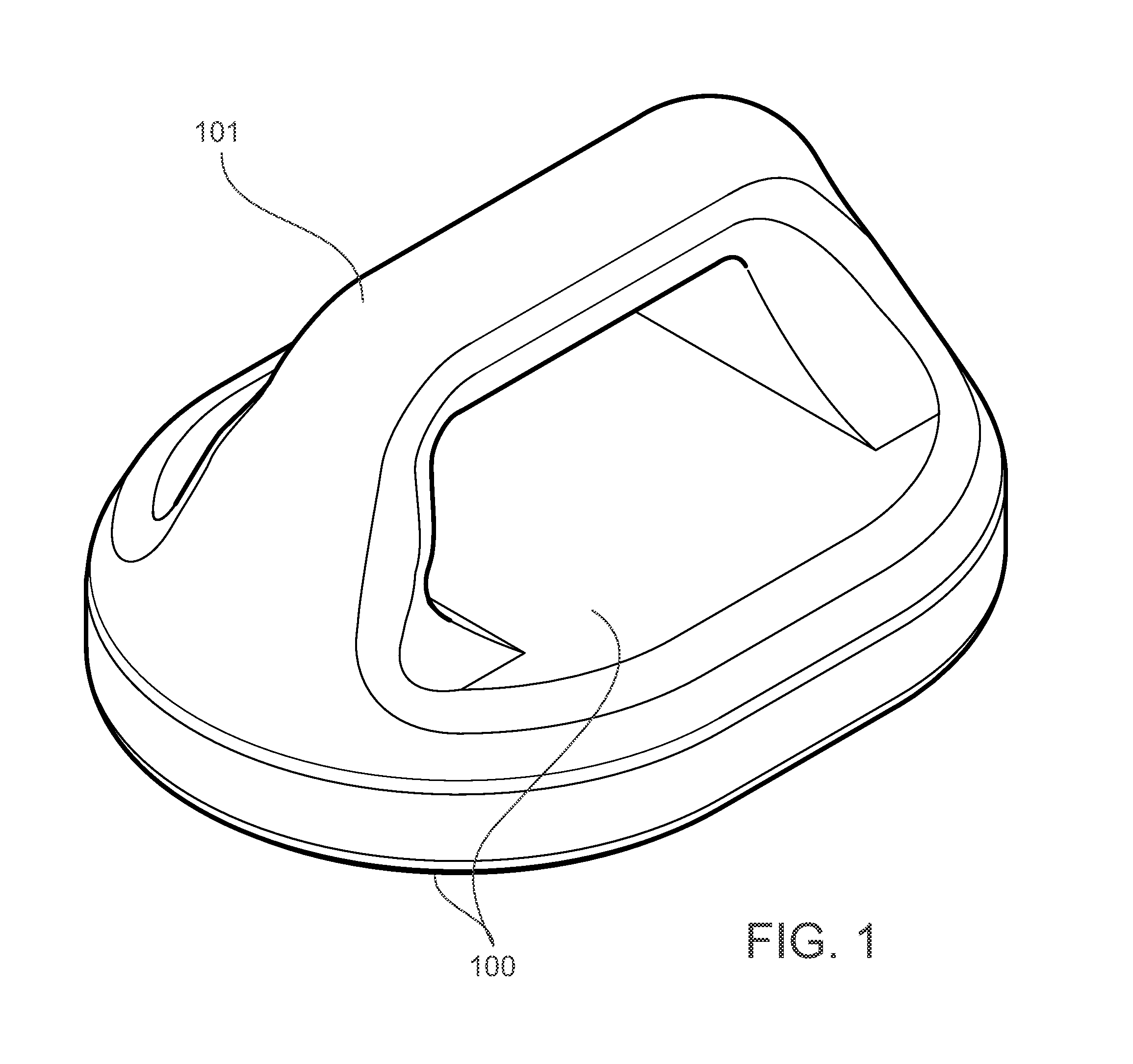

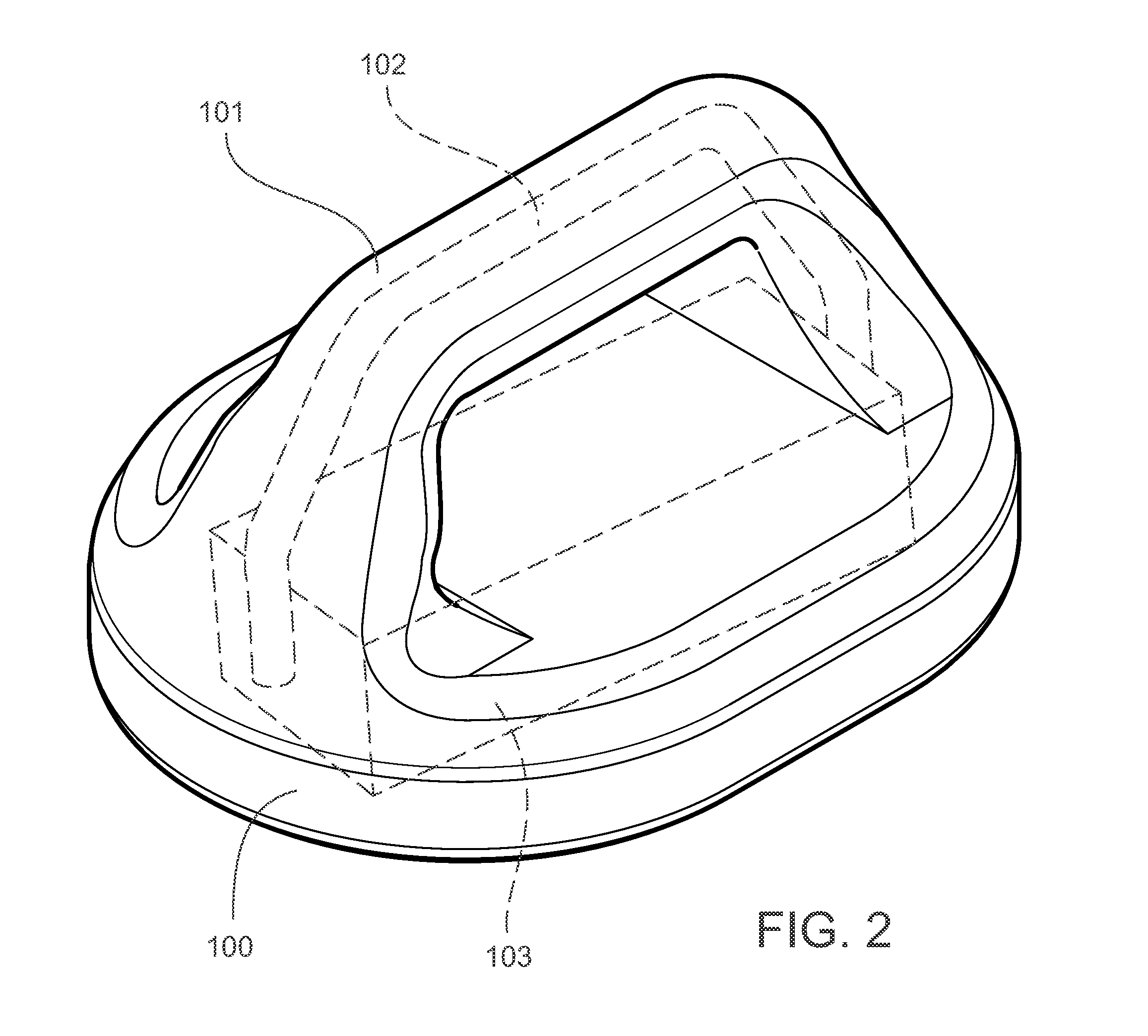

Buoy

InactiveUS7900571B2Increase downward forceDecrease the inclinationTowing/pushing equipmentBuoysAngle of incidenceBuoy

Owner:ULTRA ELECTRONICS LTD

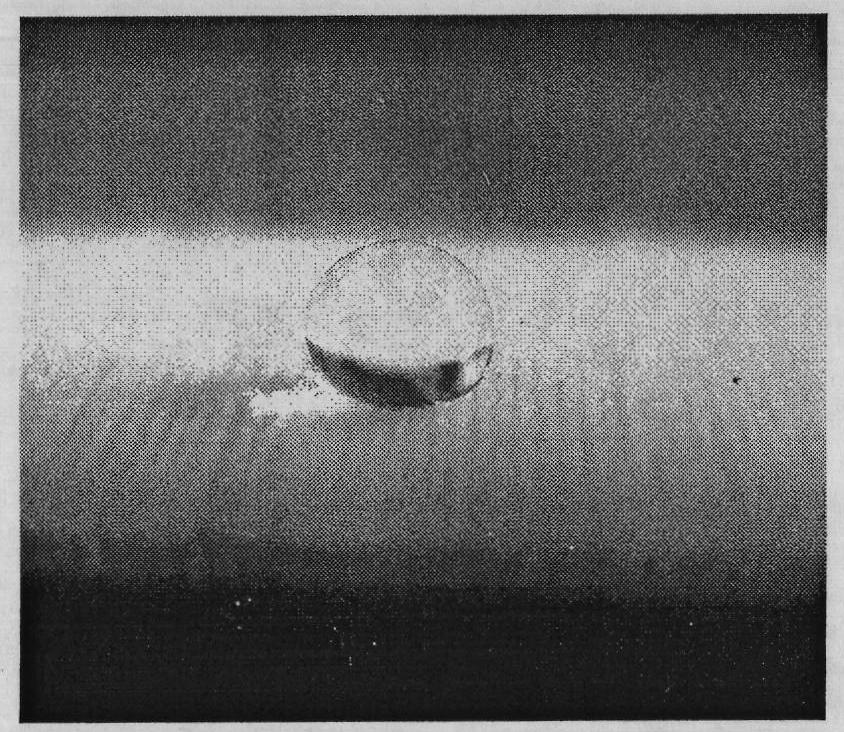

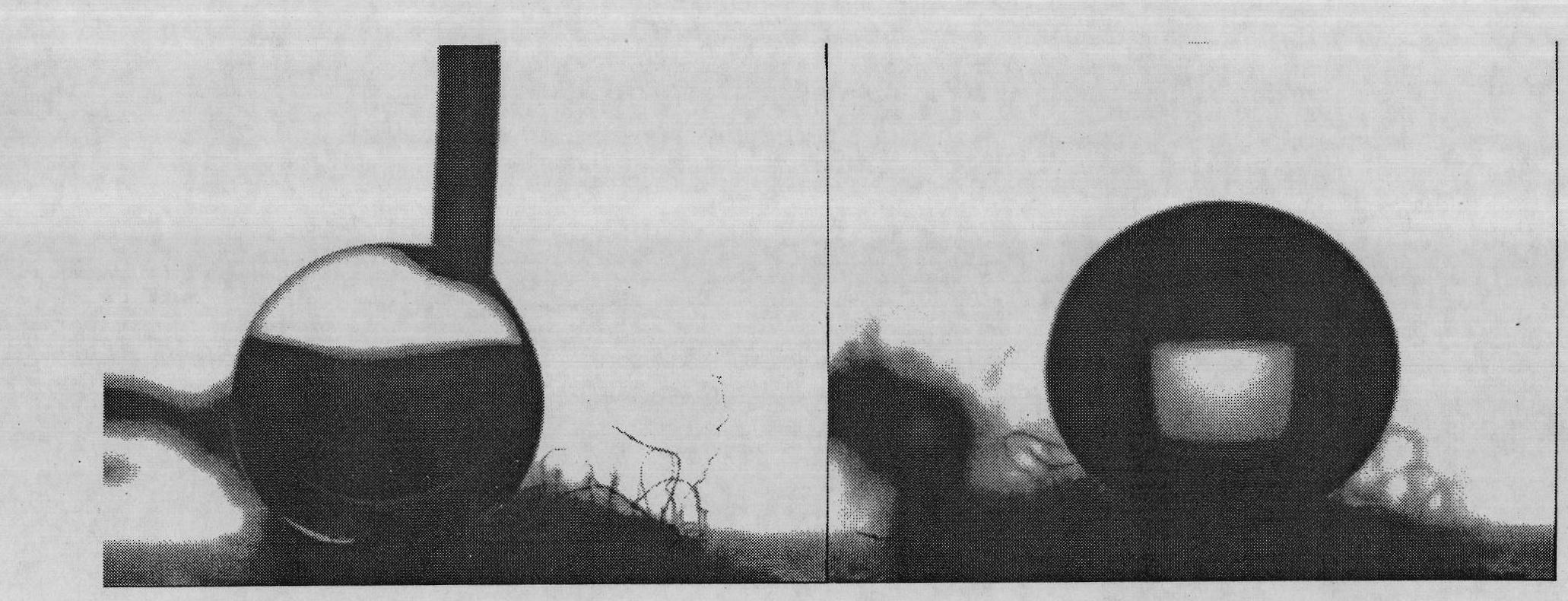

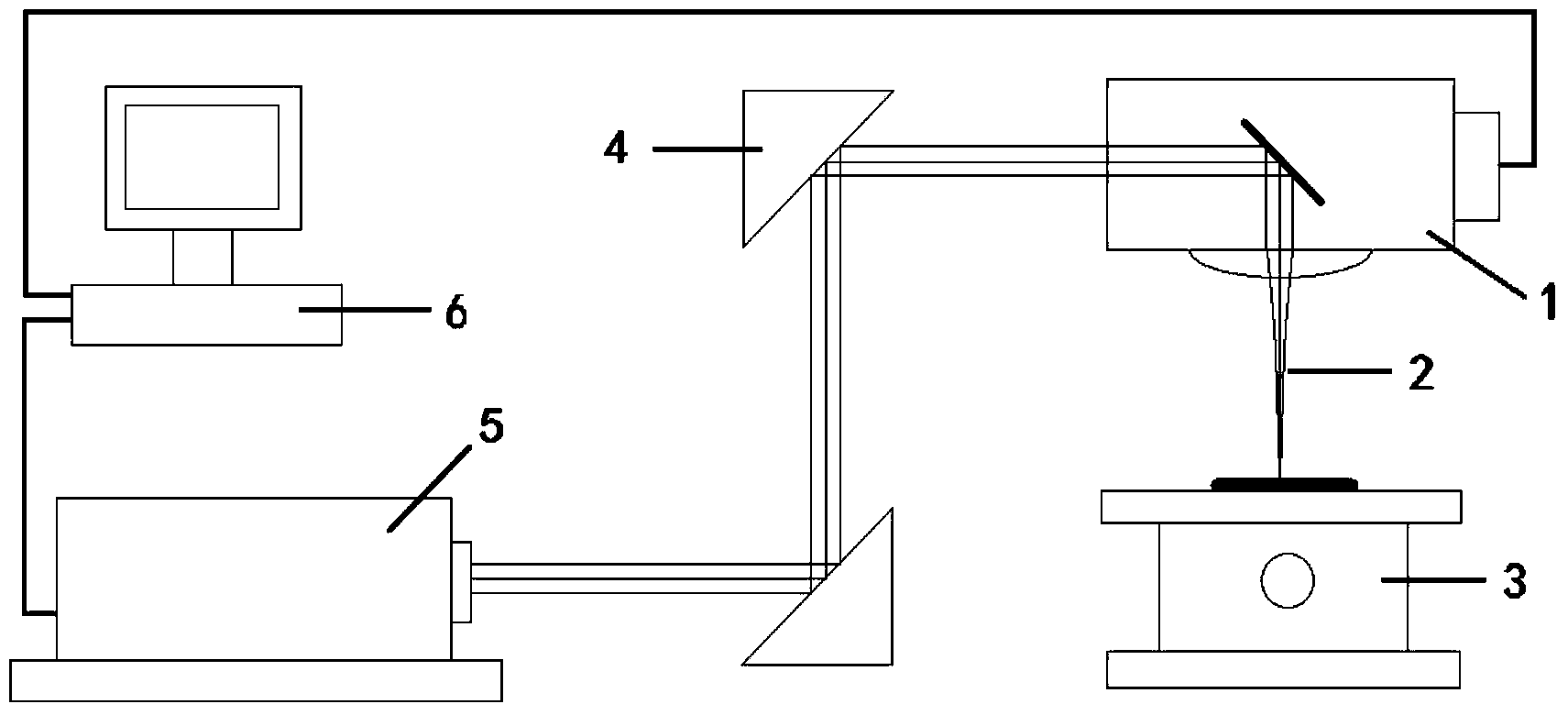

Method for enabling PTFE (Polytetrafluoroethylene) or FEP (Fluorinated Ethylene Propylene) surface to have super-hydrophobic and underwater high reflective properties simultaneously

ActiveCN103551734AGood surface stabilityInternal nature influenceWelding/soldering/cutting articlesLaser beam welding apparatusOptical pathFluorinated ethylene propylene

A method for enabling a PTFE (Polytetrafluoroethylene) or FEP (Fluorinated Ethylene Propylene) surface to have super-hydrophobic and underwater high reflective properties simultaneously belongs to the laser machining field. According to the method, a 1064 nm picosecond laser micro-machining system is utilized to machine a one-dimensional or a dimensional trench array with a 25 mum seam width in PTFE and FEP surfaces so as to enable the surfaces to have super-hydrophobicity; if a prepared super-hydrophobic sample is completely immersed in water, a super-hydrophobic surface may take on a metallic luster high reflective surface. The method comprises the operating steps of: adjusting a picosecond laser light path, drawing a machining path by utilizing professional software, adjusting a picosecond laser output power based on a machining requirement, outputting picosecond pulse laser for machining when the laser power meets the requirement, achieving a super-hydrophobic requirement without subsequent cleaning after the machining is finished, and immersing the finished product in water to make a metal-like high reflective surface appear directly.

Owner:BEIJING UNIV OF TECH

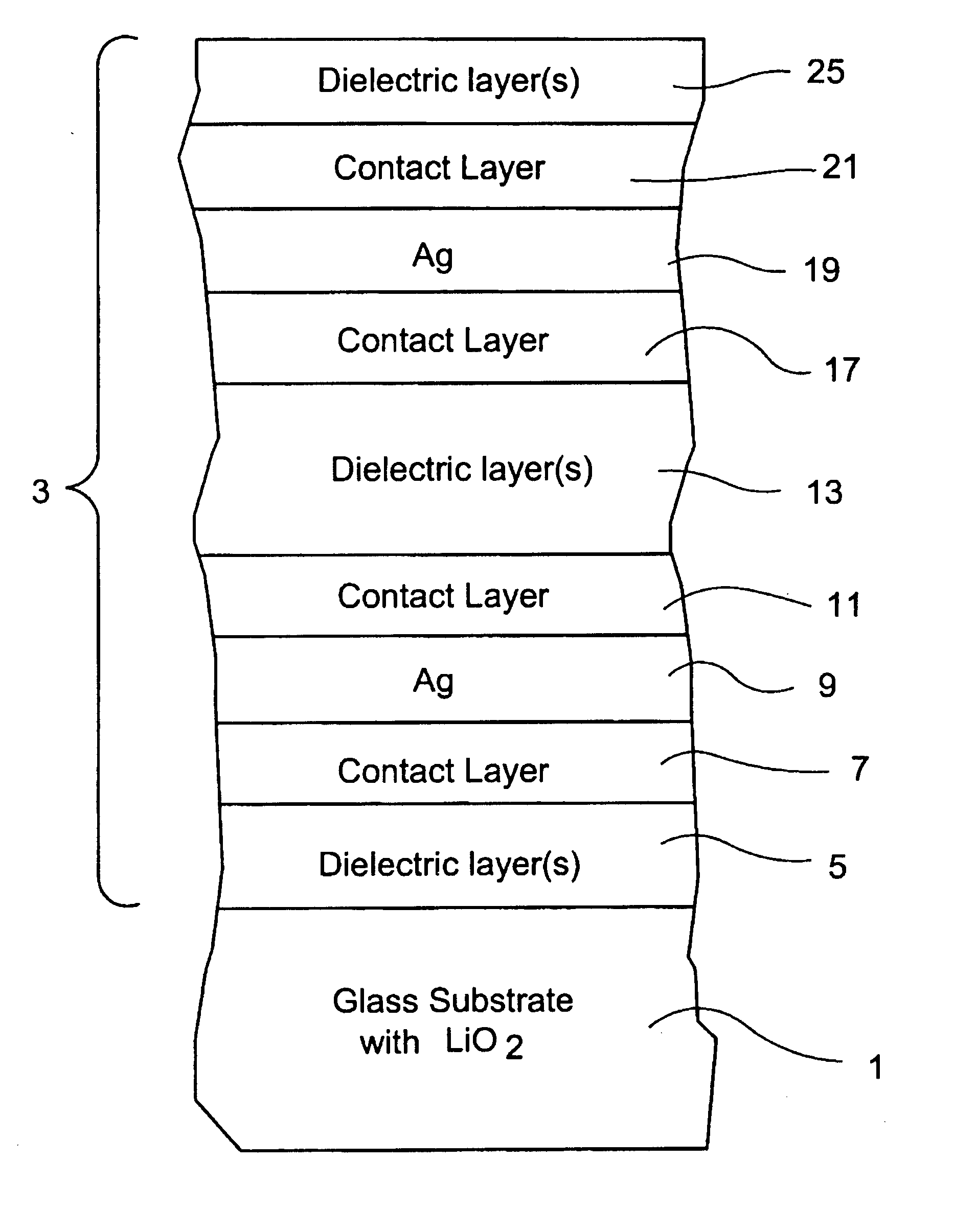

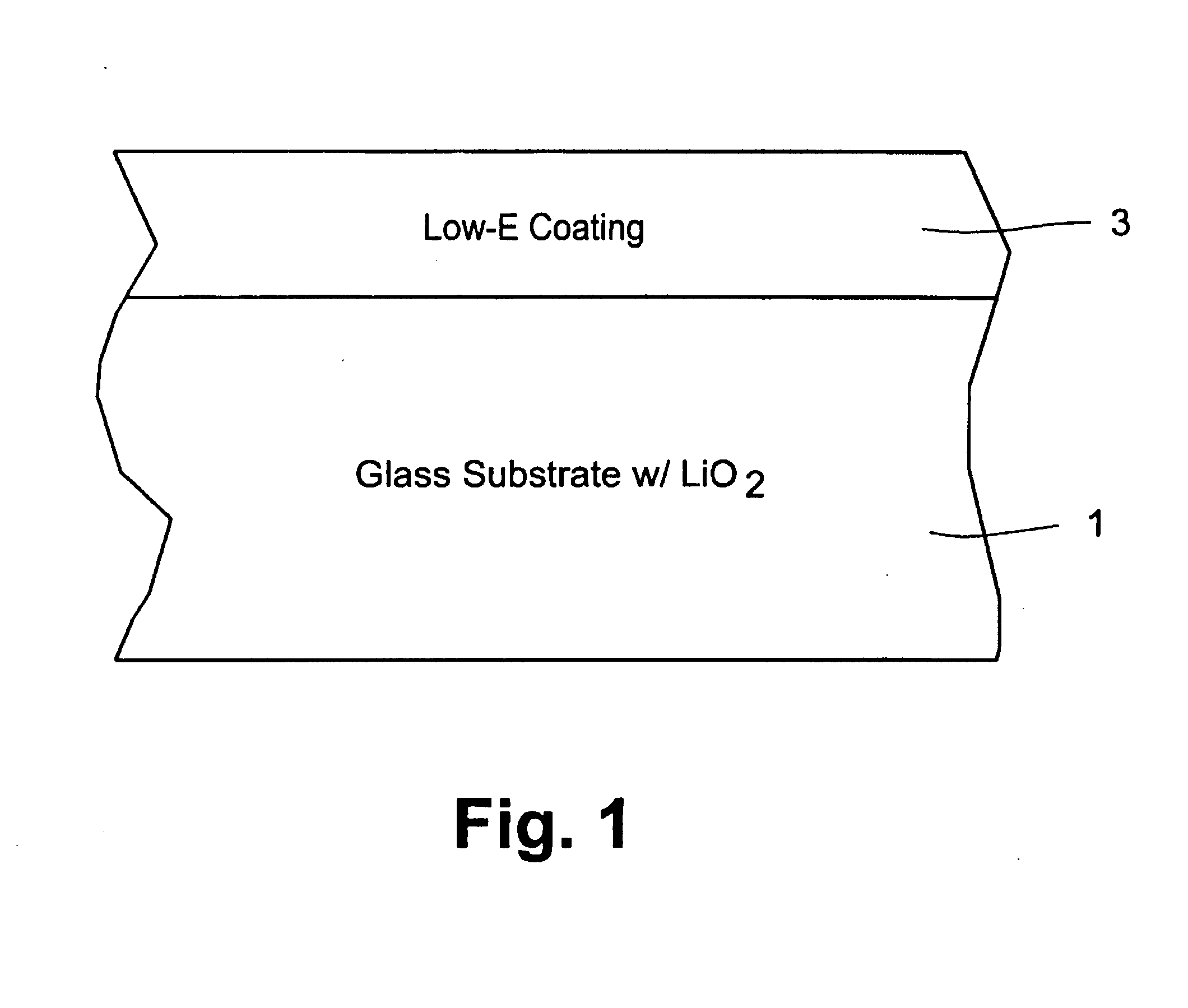

Coated article including soda-lime-silica glass substrate with lithium and/or potassium to reduce sodium migration and/or improve surface stability and method of making same

InactiveUS20070036987A1Reduce sodium migrationImprove surface stabilityGlass/slag layered productsCoatingsLithium oxideLow emissivity

A coated article includes a glass substrate that supports a coating such as a low-E (low emissivity) coating. In certain example embodiments, the glass substrate is formed of a soda-lime-silica based glass composition manufactured using a float process. In certain example embodiments, lithium oxide (e.g., LiO2) and / or potassium oxide (K2O) is used in the soda-lime-silica based glass substrate in order to reduce sodium migration and / or improve surface stability. Such coated articles are useful, for example and without limitation, in architectural, vehicular and / or residential glass window applications.

Owner:GUARDIAN GLASS LLC

Thermosetting phosphate casting binder as well as preparation method and application method thereof

The invention provides a thermosetting phosphate casting binder. The thermosetting phosphate casting binder is prepared from the following raw materials in percentage by weight: 50 percent to 57 percent of industrial phosphoric acid, 9 percent to 12 percent of aluminum hydroxide, 0.75 percent to 2.18 percent of boric acid, 0.66 percent to 2.48 percent of citric acid, 0.075 percent to 0.57 percentof silicic acid, 0.075 percent to 0.47 percent of a water-soluble high molecular material, 0.75 percent to 3.53 percent of magnesium carbonate, 3.5 percent to 6.5 percent of magnesium chloride, 0.035percent to 0.19 percent of a silane coupling agent and the balance of pure water. According to the thermosetting phosphate casting binder provided by the invention, organic acid, inorganic acid and the water-soluble high molecular material are used for modifying a phosphoric acid binder, so that the aim of remarkably improving the performance of heat-curing sand by the phosphoric acid binder is realized; the thermosetting phosphate casting binder provided by the invention has the advantages of high binding strength, rapid curing speed and good moisture resistance and has a wide application prospect in a casting industry.

Owner:HUBEI UNIV OF TECH

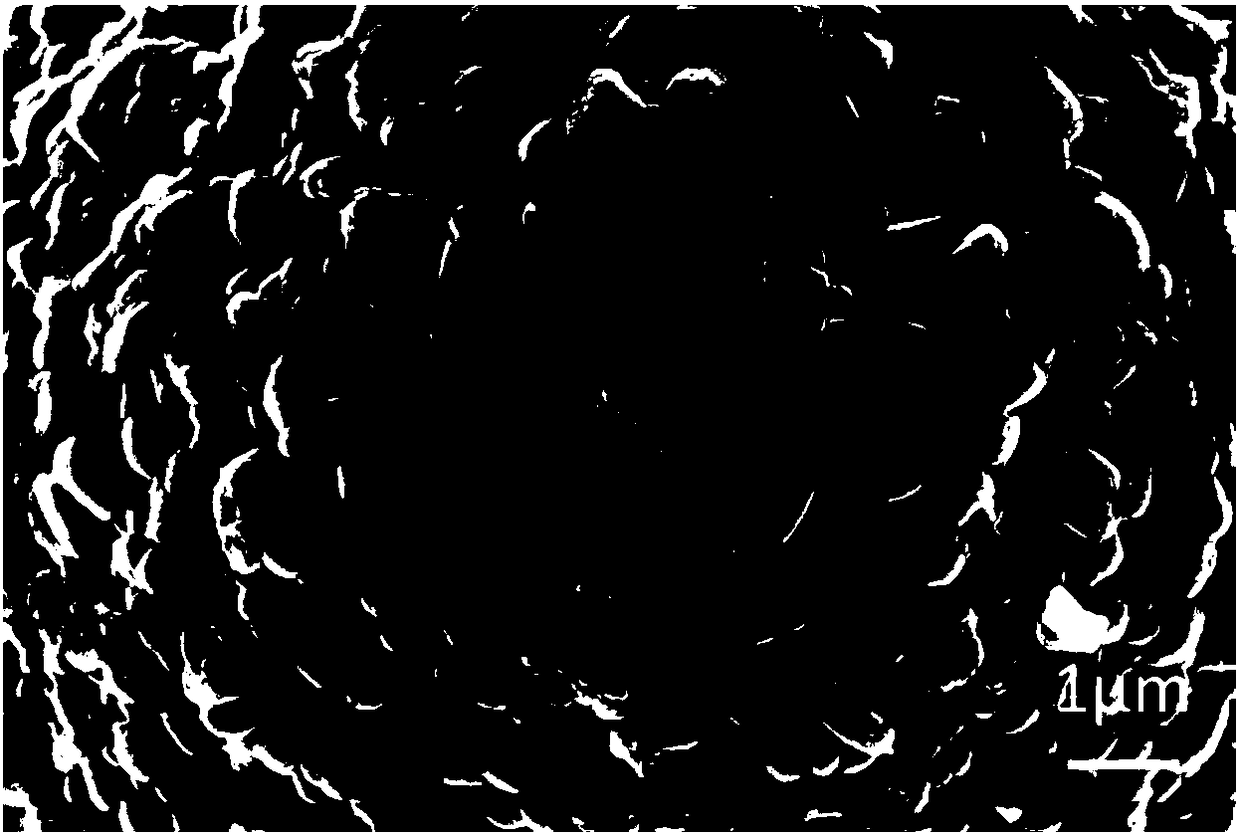

Lithium ion battery cathode material with variable slope concentration gradient doping structure and preparation thereof

InactiveCN108649205AThe rate of change of concentration increasesGood element doping distributionElectrode thermal treatmentSecondary cellsSurface layerSynthesis methods

The invention discloses a lithium ion battery cathode material with a variable slope concentration gradient doping structure and a synthesis method thereof. For solving the problems of capacity fadingand rate performance degradation which are brought by the conventional doping method, an element with a variable slope concentration gradient structure is doped, thereby obtaining the lithium ion battery cathode material with the concentration of a doping element continuously changed from the center of a material particle to the surface of the material particle; and change rate is gradually increased from inside to outside, so that the concentration of the doped element inside the material is slowly changed, the concentration of the doped element on the surface of the material is rapidly changed, and change of the concentration of the doped element is mainly concentrated on a surface layer. The method improves stability of the internal structure and the surface of the material while sideeffect is not introduced, the problems such as phase change of the material, volume change and dissolution of transition metal elements in a charge-discharge cycle process are reduced, cycle life of the material is greatly prolonged, and safety performance of the material is greatly improved.

Owner:HARBIN INST OF TECH

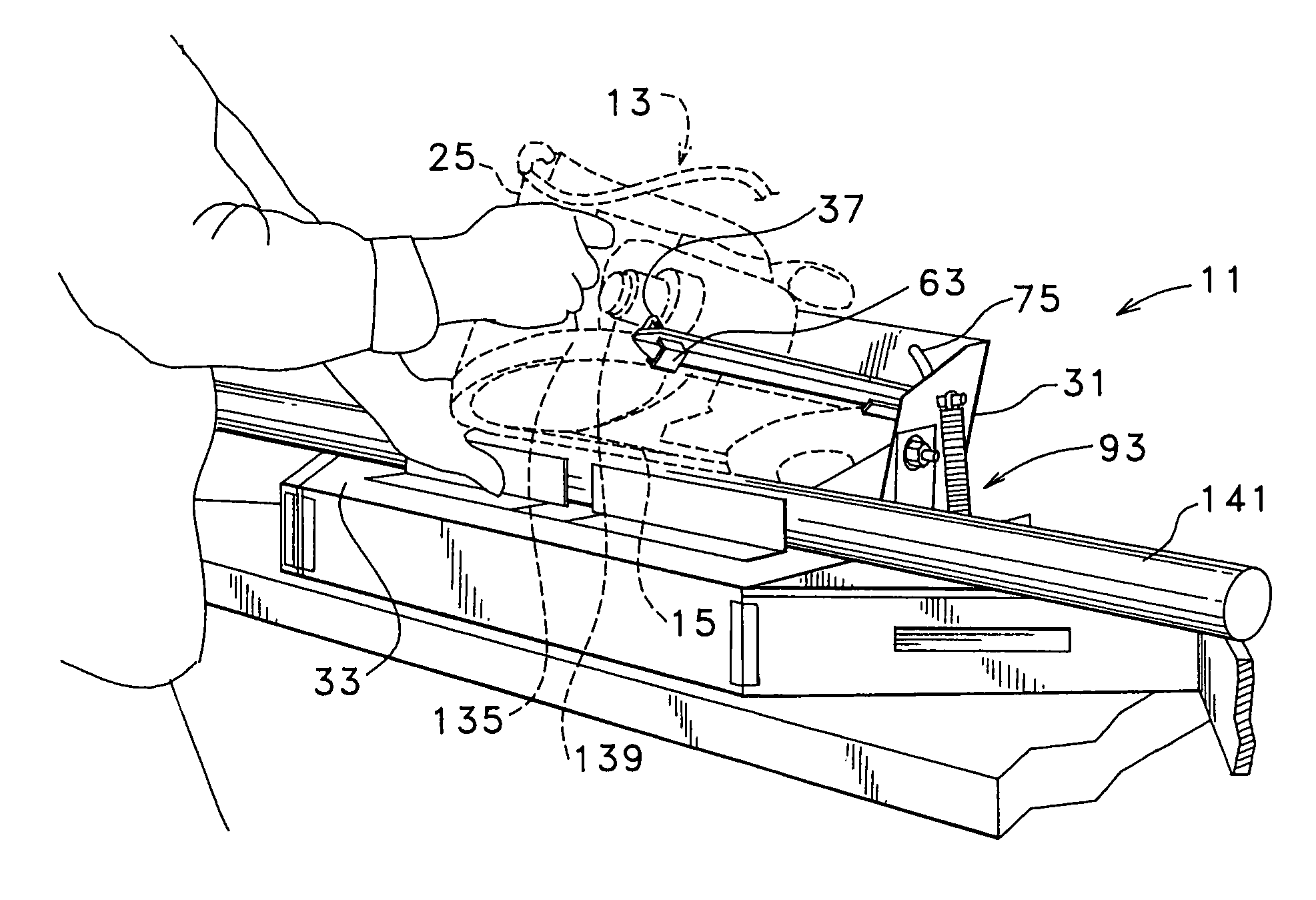

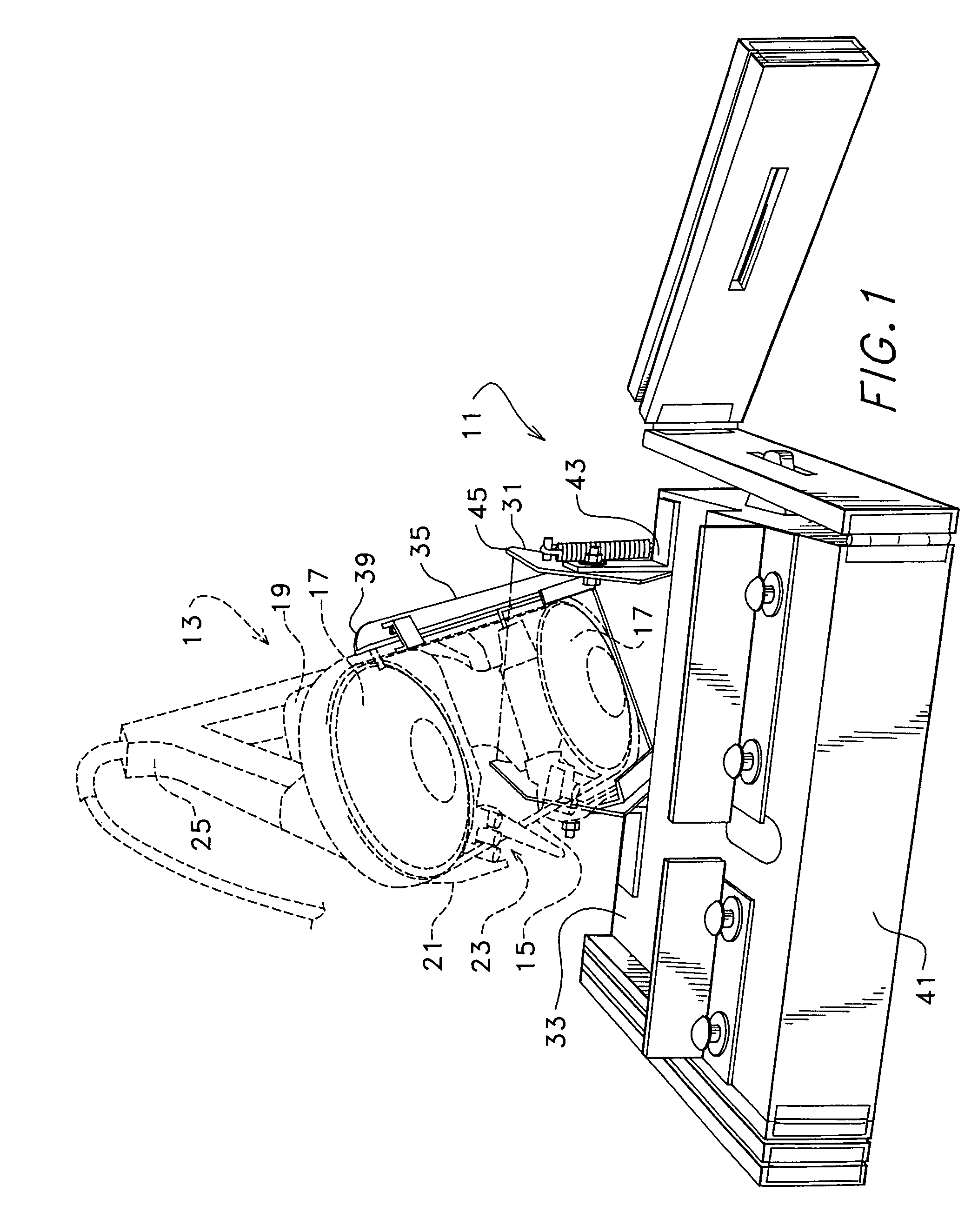

Operational support for portable band saw

InactiveUS7159499B1Improve surface stabilityMetal sawing devicesGang saw millsEngineeringMechanical engineering

Apparatus and methods for operational support and guidance of pivoting movement of portable band saws are disclosed. The apparatus includes a pivoting mount maintained at a work surface. A support is connected with the mount and includes a forward bracket adjacent to the mount for receiving a front portion of a blade housing structure of the portable band saw. An extension bar of the support supports a rear portion of the blade housing structure, a securing latch at the extension provided to releasably maintain the rear portion of the blade housing structure supported thereat.

Owner:LANSER JERRY L

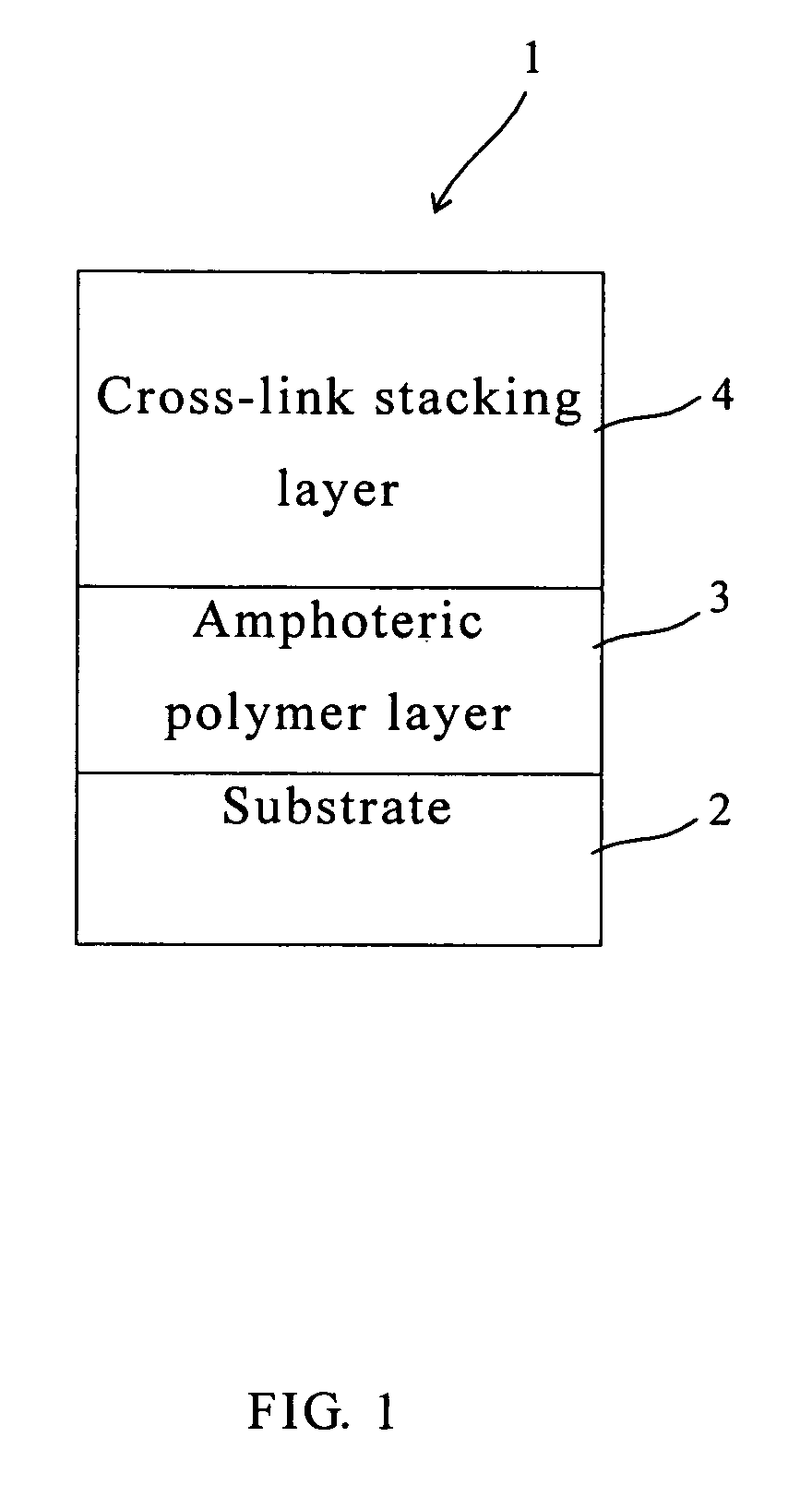

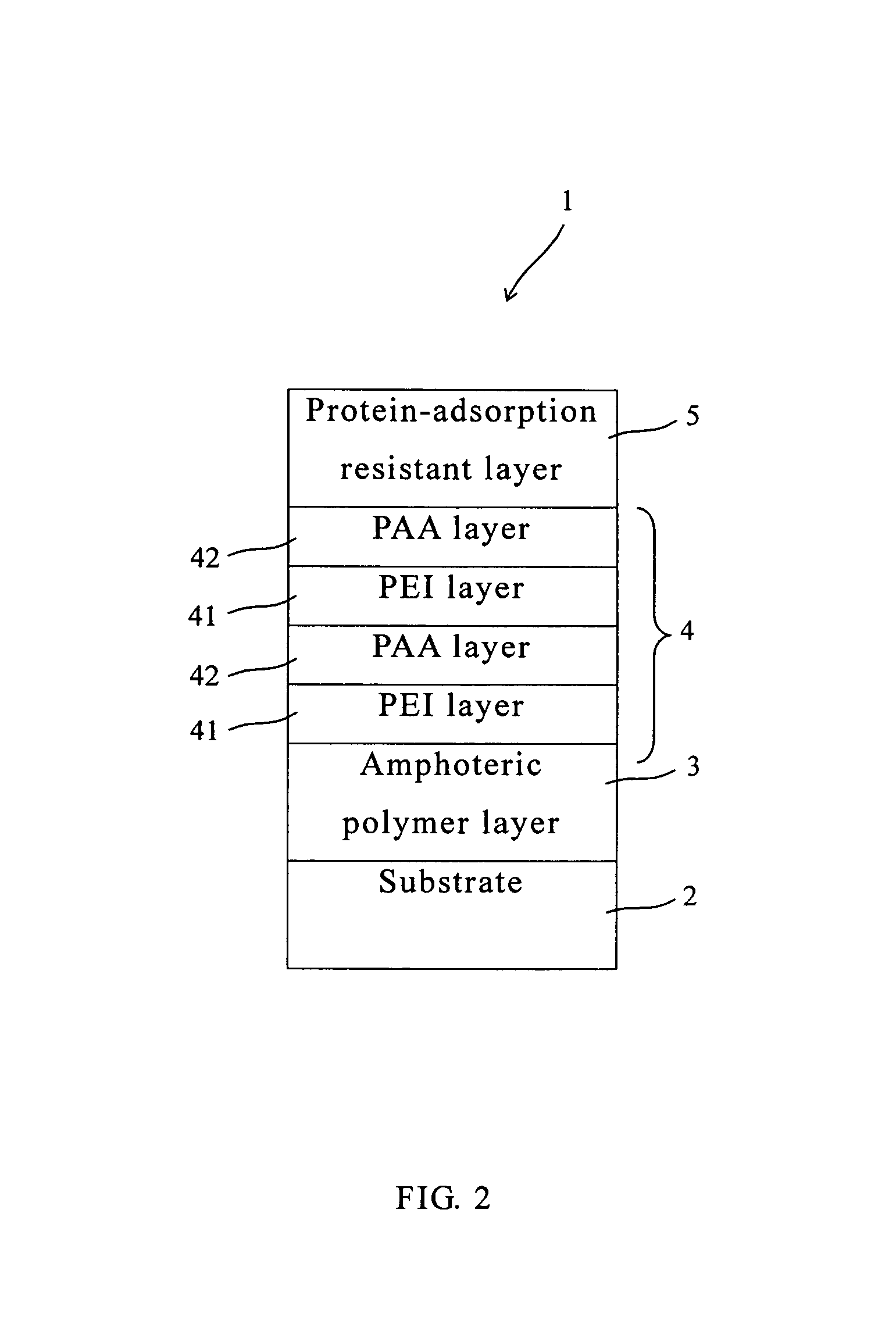

Long-term hydrophilic modification of PDMS substrate and method for manufacturing the same

InactiveUS20060263612A1Effective resistanceImprove surface stabilitySynthetic resin layered productsCellulosic plastic layered productsCross-linkInstability

The present invention relates to a hydrophilic surface structure of the non-hydrophilic substrate and the manufacturing method for using the same. The hydrophilic substrate surface structure is fabricated by forming an amphiphilic polymer layer, a cross-linked stacking layer, and a hydrophilic layer in sequence on the surface of a non-hydrophilic substrate. For example, the hydrophobic surface of poly(dimethylsiloxane) (PDMS) can be made from hydrophobic to hydrophilic and the hydrophilicity can be retained for a long period of time and resist protein adsorption. The hydrophilic thin films give long term stability to the PDMS surface by resisting hydrophobicity recovery, which is the major problem with PDMS. The disclosed method can further be used in the immobilization of protein and other molecules. This method can also be used for modifying other substrates which suffer problems of surface instability.

Owner:NAT CHENG KUNG UNIV

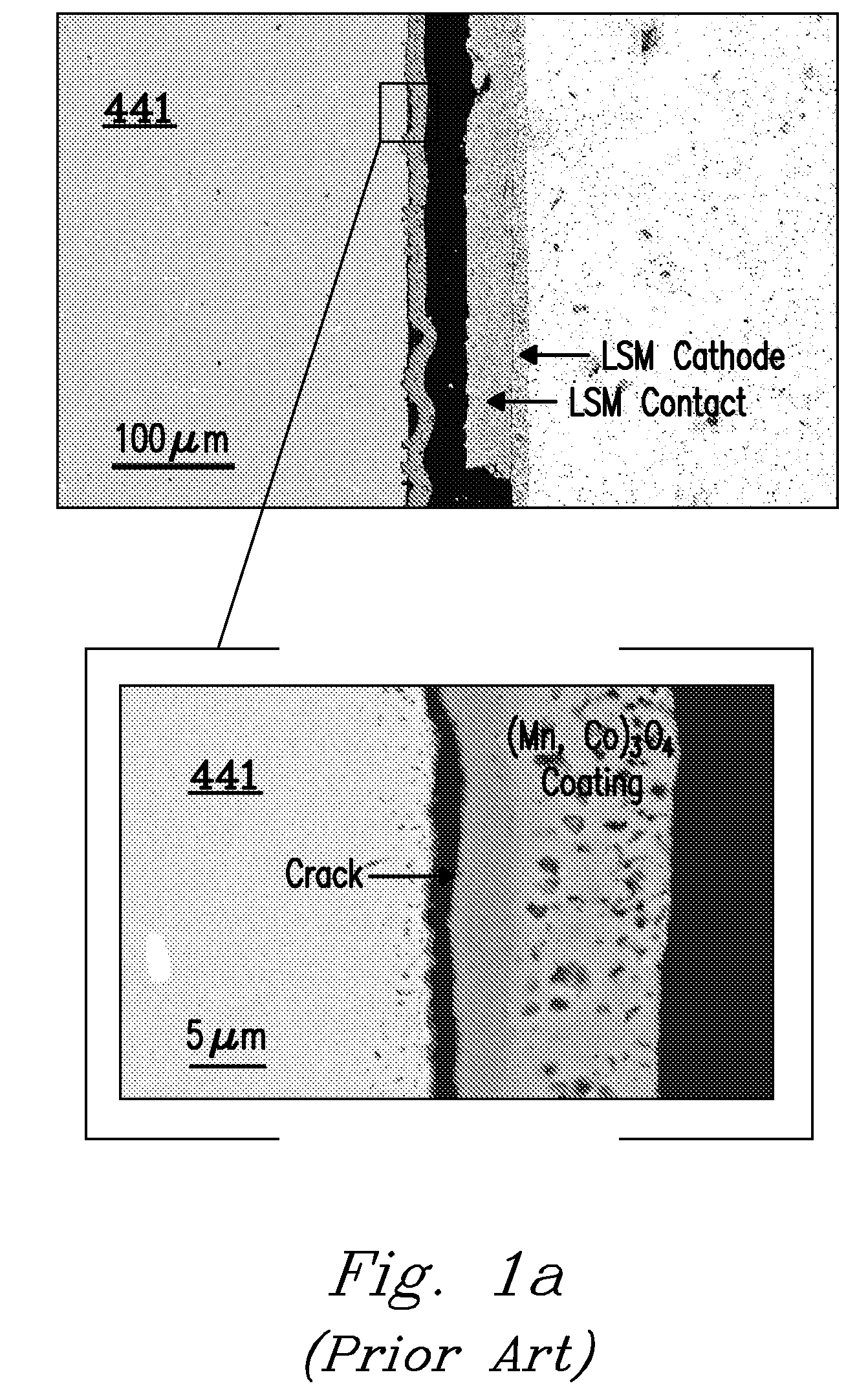

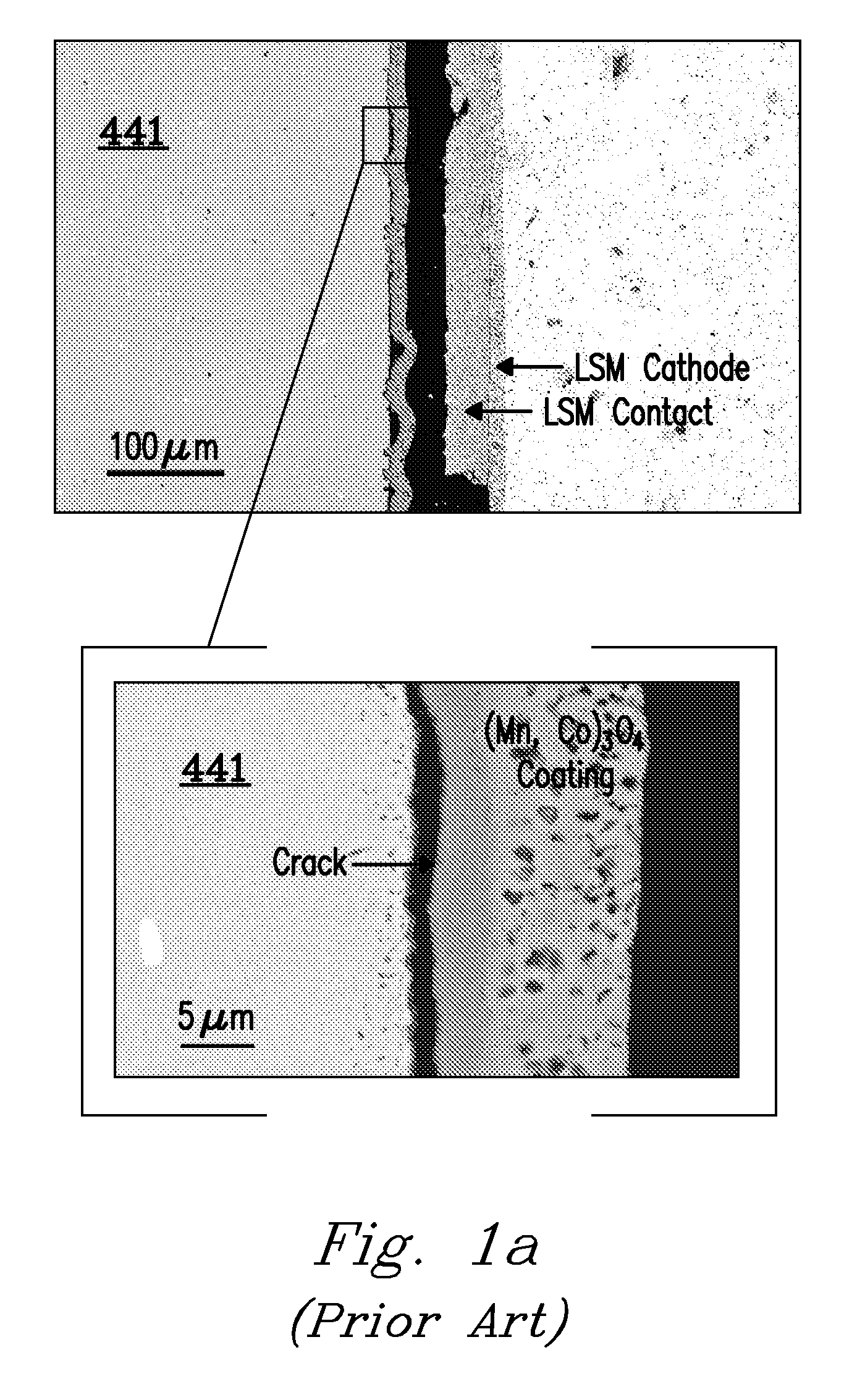

Approach for improved stability and performance of SOFC metallic interconnects

ActiveUS8241817B2Improve adhesionImprove performanceElectrode carriers/collectorsSolid electrolyte fuel cellsRare-earth elementOxide coating

Owner:BATTELLE MEMORIAL INST

Surface Stabilized Safety Enhanced Free-Weights

Surface stabilized safety enhanced free-weights and exercise methods that offer the benefits of free-weight resistance training, bodyweight exercises, and body positioning exercises with increased effectiveness, versatility, and safety.

Owner:WHITE DEREK

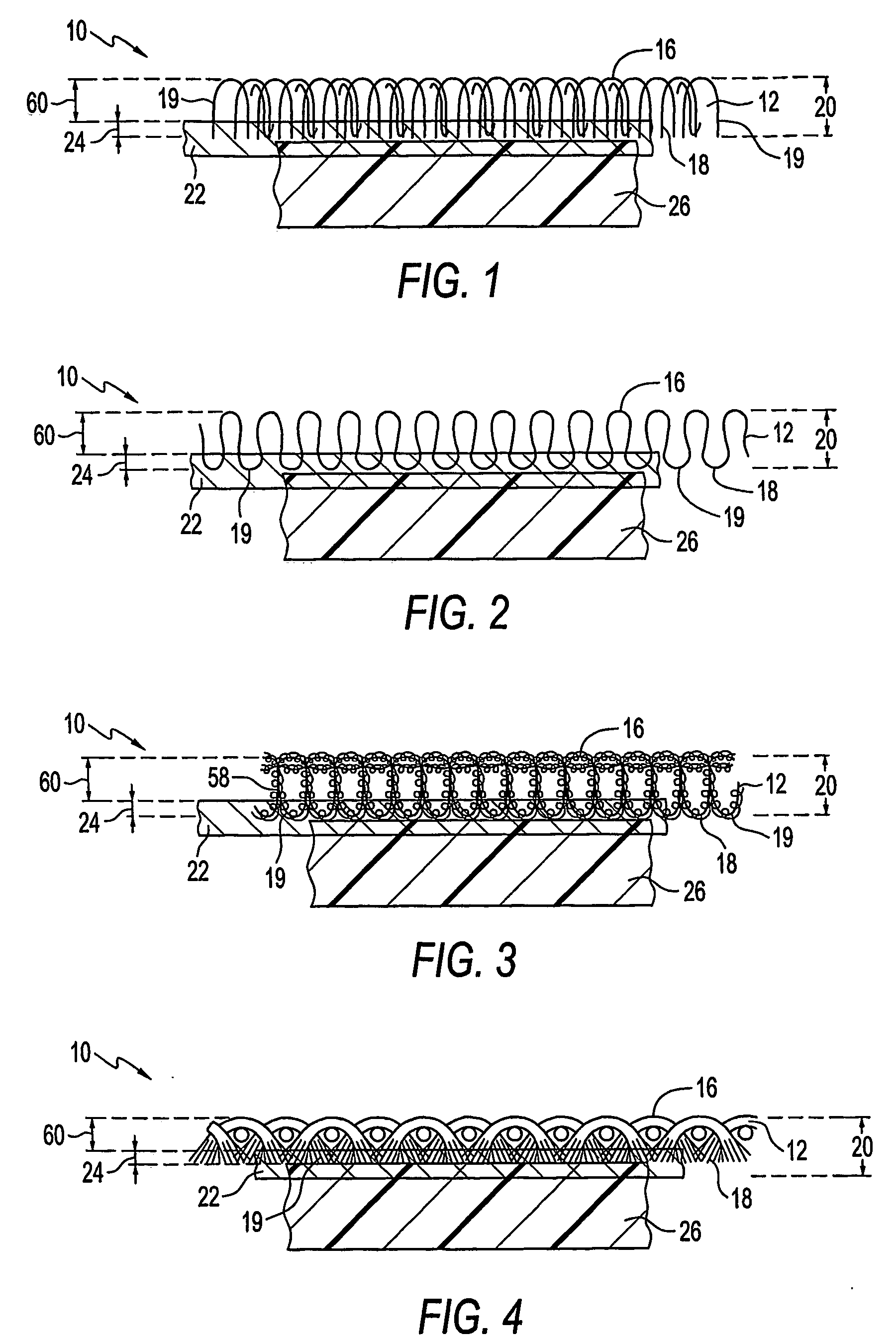

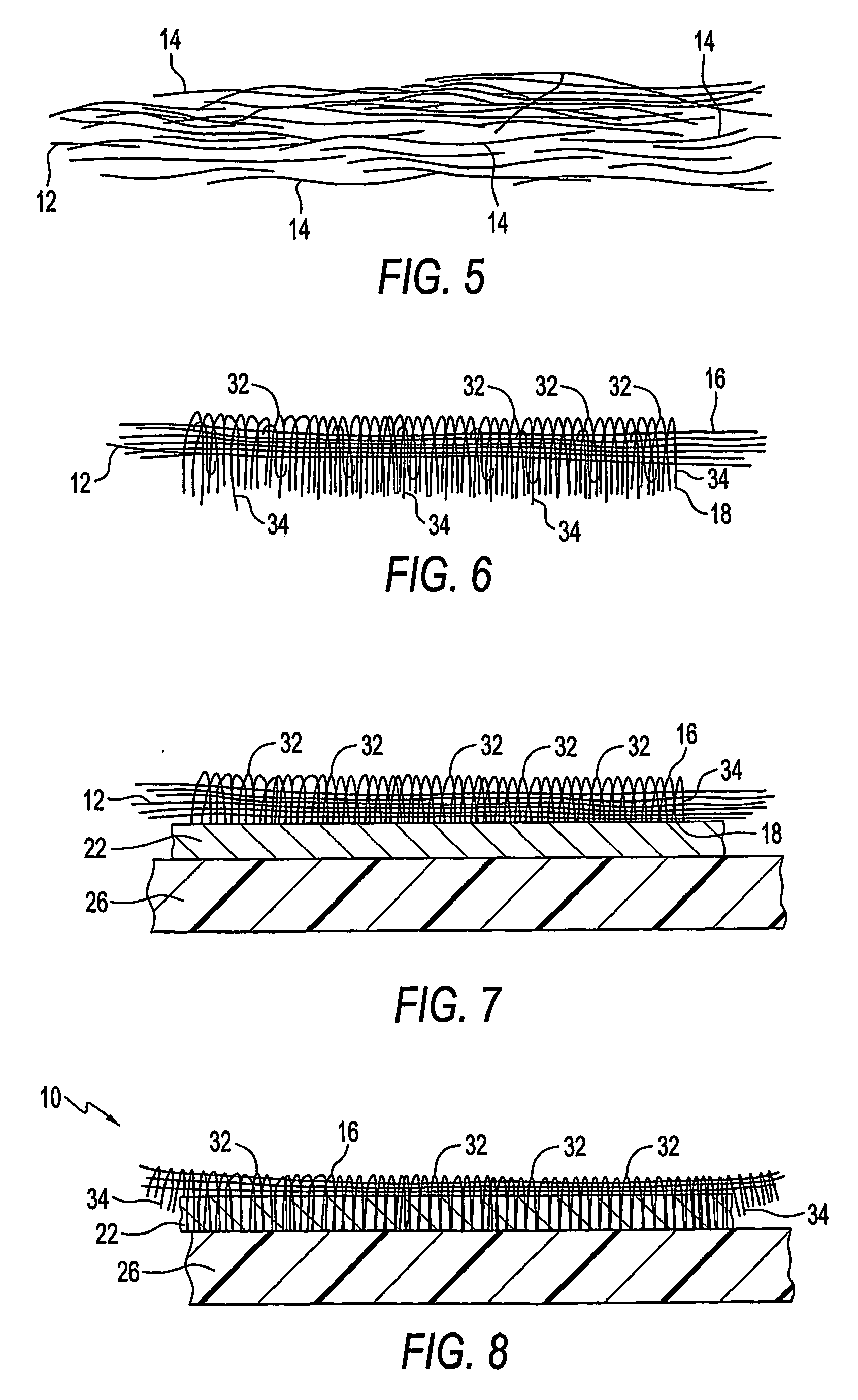

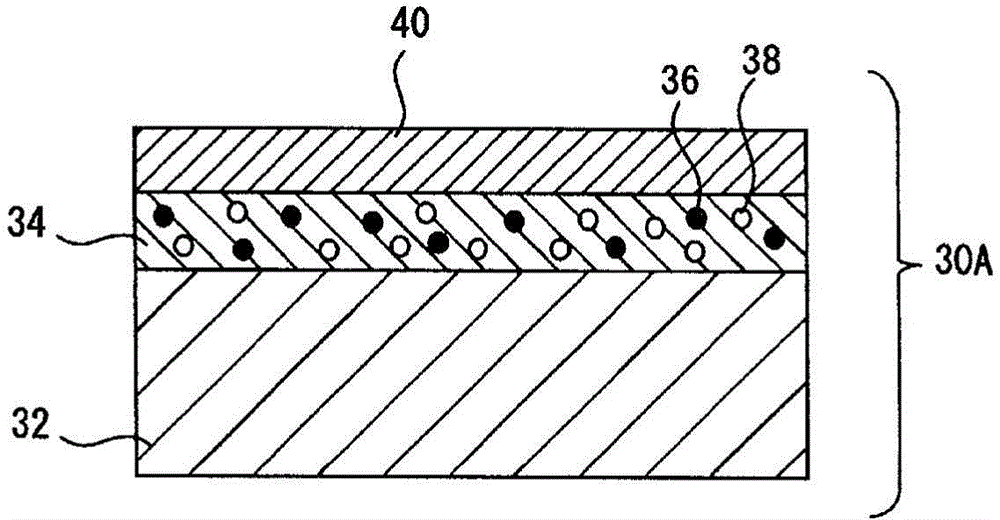

Fabric-faced composites and methods for making same

InactiveUS20060183389A1Stable levelImprove surface stabilityCovering/liningsLamination ancillary operationsEngineeringFloor covering

The present invention is directed to multiple layer composites (10) suitable for use as wall and floor coverings, among other uses, that provide a strong durable structure and a soft textile or fabric face. The composite includes a face layer (12) bonded to an adhesive layer (22) such that the adhesive layer (22) penetrates into the face layer (12). The face layer (12) can have legs (19, 34) extending there from, and such legs (19, 34) are anchored by the adhesive layer to provide stronger attachment between the adhesive layer and the face layer. A backing layer (26) may also be provided in contact with the adhesive layer (22) such that the adhesive layer also embeds into the backing layer (26), and the legs (19, 34) extending from the face layer may penetrate into the backing layer.

Owner:DZS LLC

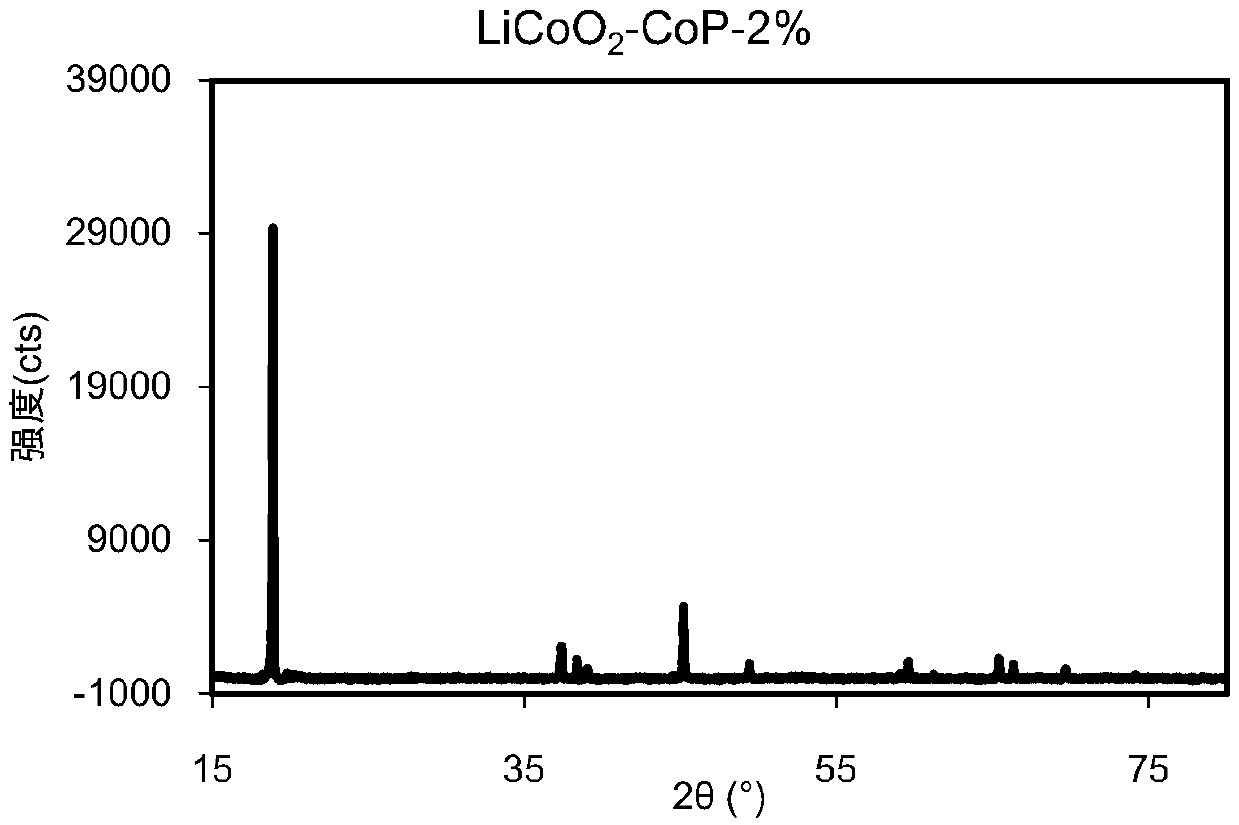

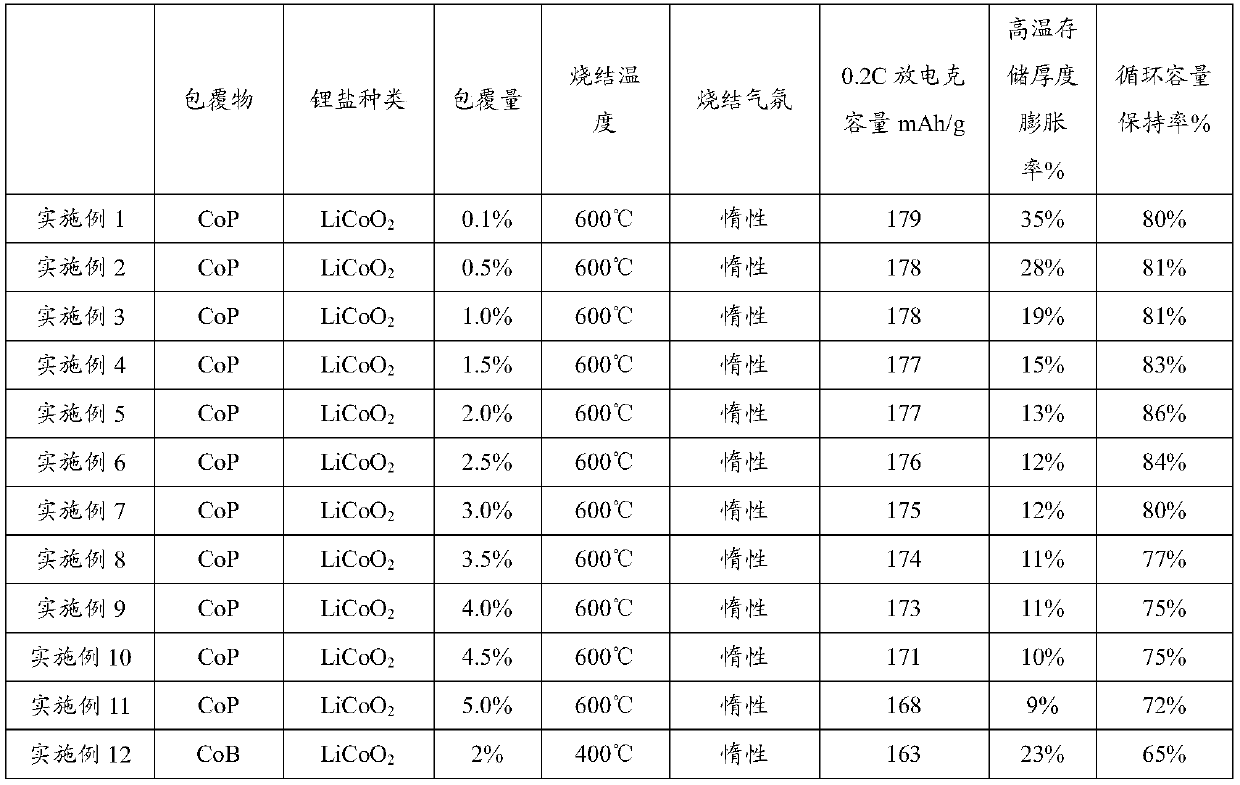

Positive electrode material, positive electrode sheet containing same and lithium ion battery

ActiveCN110459736AImprove surface stabilityImprove securityCell electrodesSecondary cellsElectrical batterySodium-ion battery

The invention relates to a positive electrode material, a positive electrode sheet containing the positive electrode material, and a lithium ion battery. The positive electrode material comprises an active material and a coating layer coating the surface of the active material. The coating layer comprises a compound containing cobalt. A heterostructure material layer exists between the coating layer and the active material layer. The heterostructure material contains one or more elements of Li, Co, O, or M, wherein M includes at least one of N, P, S, or B. The invention further provides the lithium ion battery. According to the positive electrode material of the battery, a certain amount of cobalt-containing compound with embeddable lithium ions coats the surface of the particles of the active material to form a coating material with a stable surface structure; the surface stability of the particles of the active material can be effectively improved; and the safety performance of the battery is improved.

Owner:NINGDE AMPEREX TECH

Novel Approach for Improved Stability and Performance of SOFC Metallic Interconnects

ActiveUS20100178586A1Improves scale adherenceLow costElectrode carriers/collectorsSolid electrolyte fuel cellsRare-earth elementOxide coating

The present invention provides a material and a method for its creation and use wherein a reactive element, preferably a rare earth element, is included in an oxide coating material. The inclusion of this material modifies the growth and structure of the scale beneath the coating on metal substrate and improves the scale adherence to the metal substrate.

Owner:BATTELLE MEMORIAL INST

Preparation method of modified monocrystalline ternary cathode material for lithium ion batteries

InactiveCN109841822AImprove surface stabilityImprove surface activityCell electrodesSecondary cellsOrganic solventSingle crystal

A preparation method of a modified monocrystalline ternary cathode material for lithium ion batteries comprises the following steps: ball-milling and mixing a monocrystalline ternary cathode materialprecursor and a lithium source, sintering the mixture, crushing the mixture by air flow and sifting the mixture; dispersing the soluble salt of a surface coating material in anhydrous organic solvent,and obtaining homogenized solution after ultrasonic treatment; adding the crushed and sifted monocrystalline ternary cathode material to the solution and carrying out stirring to make the soluble salt adsorbed uniformly onto the surface of the monocrystalline ternary cathode material; removing the liquid and drying the material to obtain a monocrystalline ternary cathode material solid adsorbed with the soluble salt on the surface; and roasting the solid to form a monocrystalline ternary cathode material with an oxygen coating layer on the surface. A battery prepared by using the modified monocrystalline ternary cathode material has better capacity performance and rate performance, and the preparation method of the invention is simple in operation and suitable for industrial production.

Owner:CENT SOUTH UNIV

Lithium accumulator with improved negative pole structure and its preparing method

InactiveCN1392624AImprove stabilityInhibition of basic growthElectrode rolling/calenderingLi-accumulatorsLithiumElectrode

A lithium secondary battery includes: a positive electrode; and a negative electrode, which further includes a lamination structure comprising: a lithium ion supporting layer capable of supporting lithium ions; and an amorphous-state lithium-based layer in contact directly with the lithium ion supporting layer.

Owner:NEC CORP

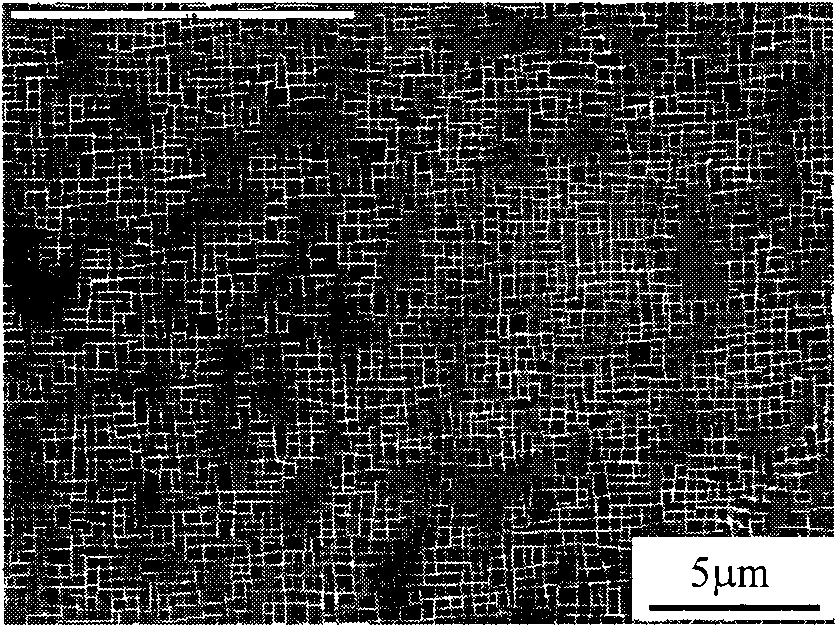

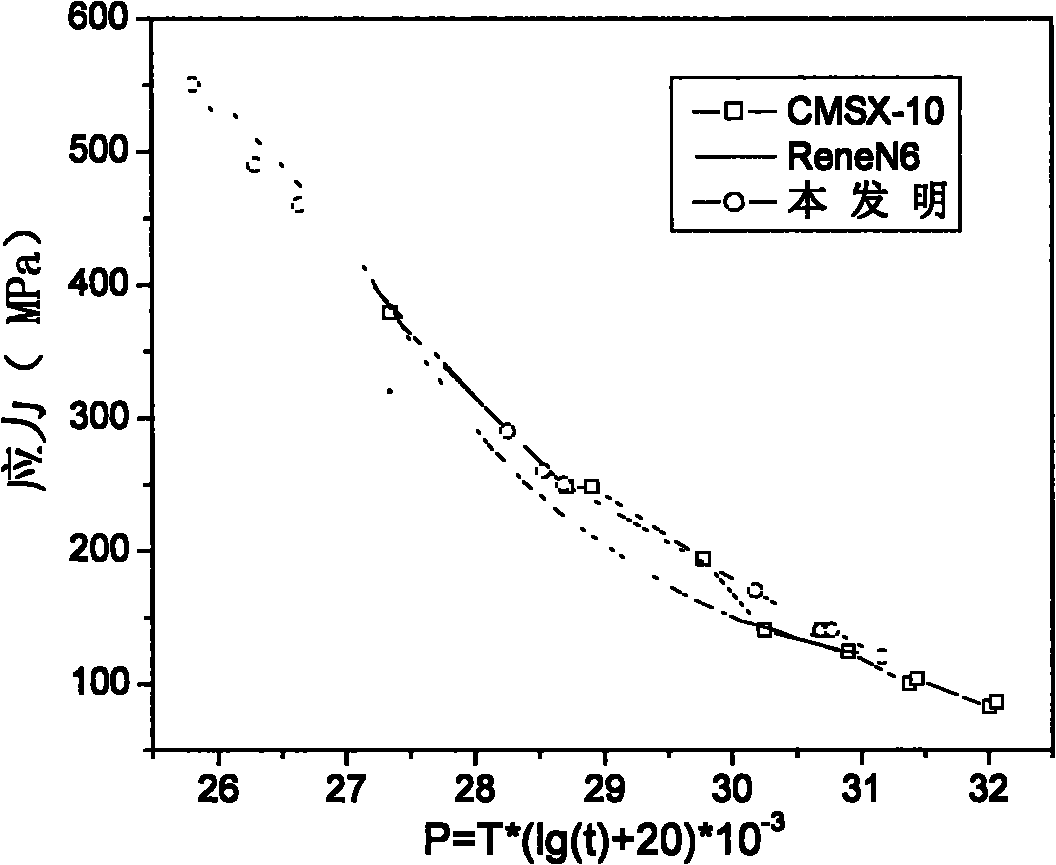

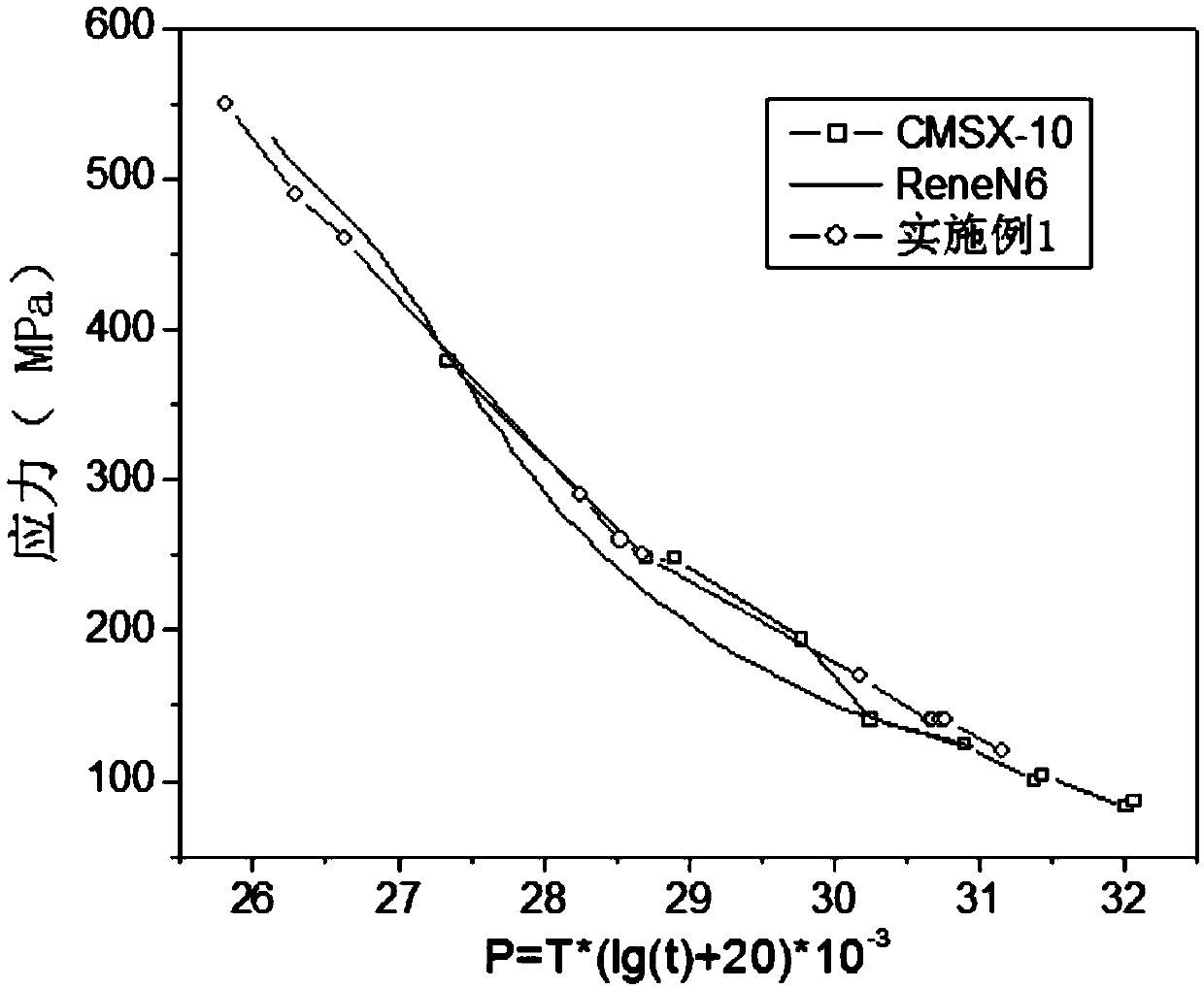

High strength and completely antioxidative third generation monocrystalline high temperature alloy and preparation method thereof

InactiveCN102418147AHigh strengthHigh creep limitPolycrystalline material growthAfter-treatment detailsFurnace temperatureSolution treatment

The invention relates to the field of high strength monocrystalline high temperature alloy and especially provides a high strength and completely antioxidative third generation monocrystalline high temperature alloy with low cost, and is mainly suitable for blade material of an aircraft engine used at a temperature higher than 1100 DEG C. The alloy comprises chemical components (wt%) of 3-5% of Cr, 5-12% of Co, 6-8% of W, 0.1-2% of Mo, 4.5-5.5% of Re, 5.5-7% of Al, 6-10% of Ta and the balance of Ni. The preparation method is as below: a monocrystalline blade or a testing rod is prepared at a monocrystalline growth furnace temperature gradient of 40K / cm-80K / cm, a cast temperature of 1480-1550 DEG C, with a shuttering temperature and a cast temperature kept at the same and a growth rate of 4-8mm / min; then, the alloy is treated with solid solution homogenizing treatment, high temperature aging treatment and low temperature aging treatment to gain high lasting intensity and creep limit. The alloy has a life no less than 200 h under a lasting condition of 1100 DEG C / 140 MPa and a lasting intensity similar to CMSX-10 and good high temperature antioxidative property, which is good surface stability Besides, a heat treatment window is wide, and the solid solution treatment is easy to control.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

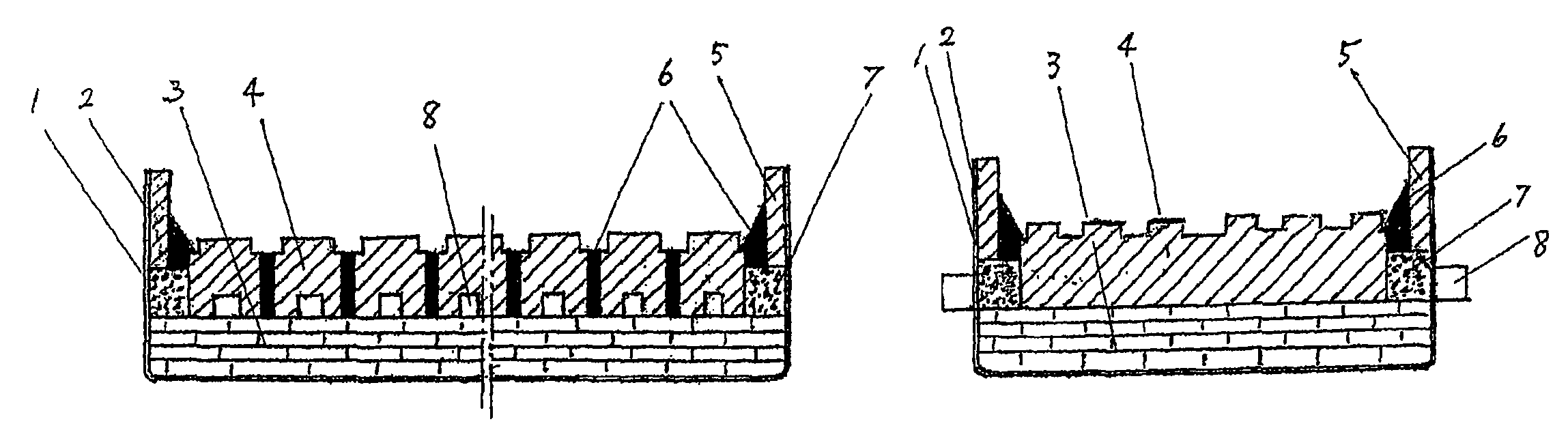

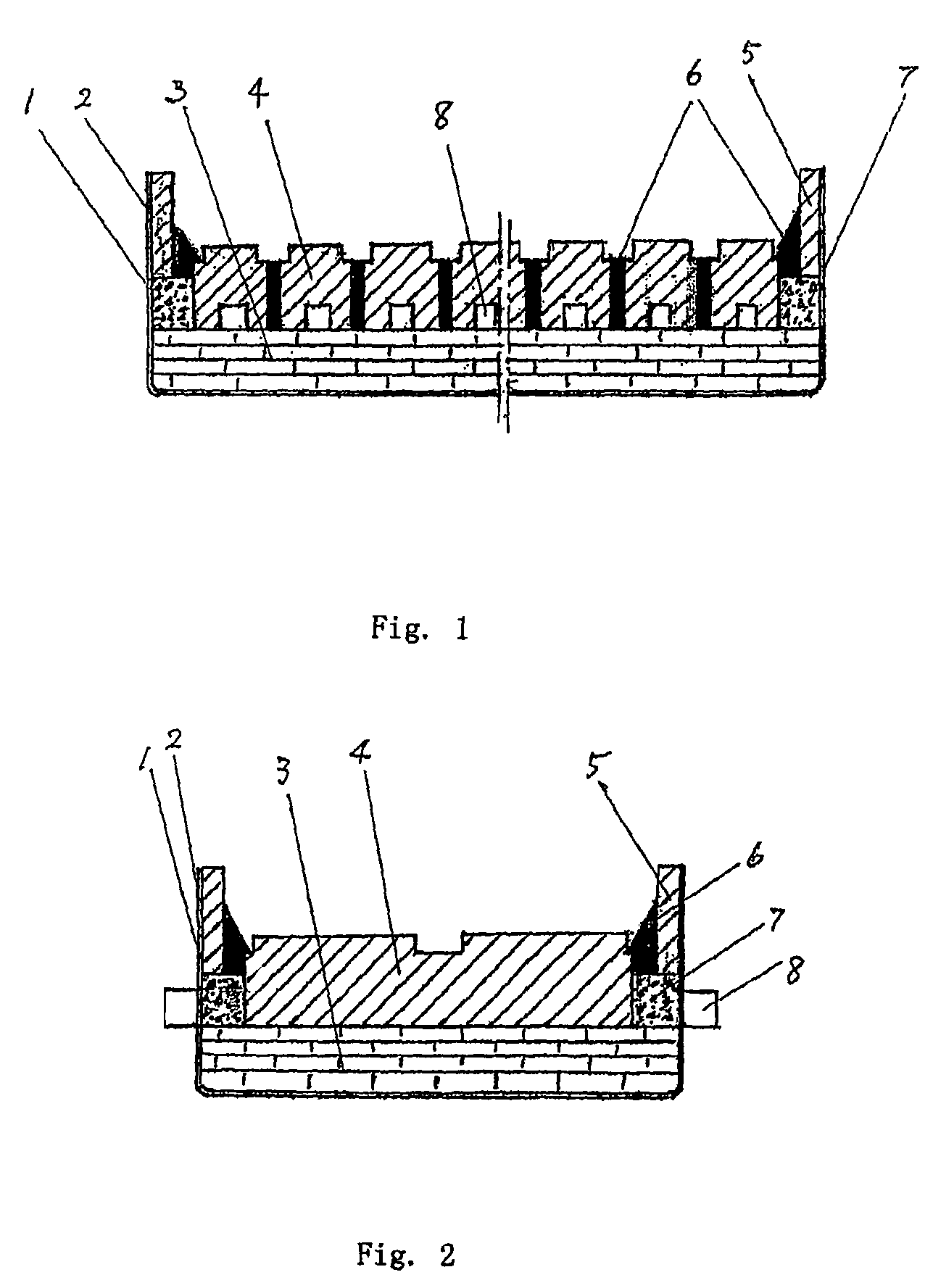

Aluminum electrolytic cells having heterotypic structured cathode carbon blocks

Owner:NORTHEASTERN UNIV ENG & RES INST +2

Long-term hydrophilic modification of PDMS substrate and method for manufacturing the same

InactiveUS7670686B2Improve surface stabilityEffective resistanceSynthetic resin layered productsMedical devicesCross-linkInstability

Owner:NAT CHENG KUNG UNIV

Production method for thin-film crystal wafer, semiconductor device using it and production method therefor

InactiveUS20060060132A1Suppress formationGood chemical stabilityPolycrystalline material growthSemiconductor/solid-state device manufacturingWork functionSingle crystal

The n+-GaAs layer 8 of the GaAs single crystal 10 is formed by epitaxial growth, followed by epitaxially growing the Si-layer 11 in the same epitaxial growth furnace, and then the aluminum electrode 12 is formed on the Si-layer 11 as an ohmic electrode. The Si-layer 11 can suppress the formation of a surface defect level on the surface of the n+-GaAs layer 8 and can effectively prevent the formation of an unnecessary potential barrier. Since the Si-layer 11 has a smooth surface and is excellent in chemical stability, a good ohmic electrode can be obtained by forming the electrode 12 using aluminum or the like has a suitable work function to the Si-layer 11.

Owner:SUMITOMO CHEM CO LTD

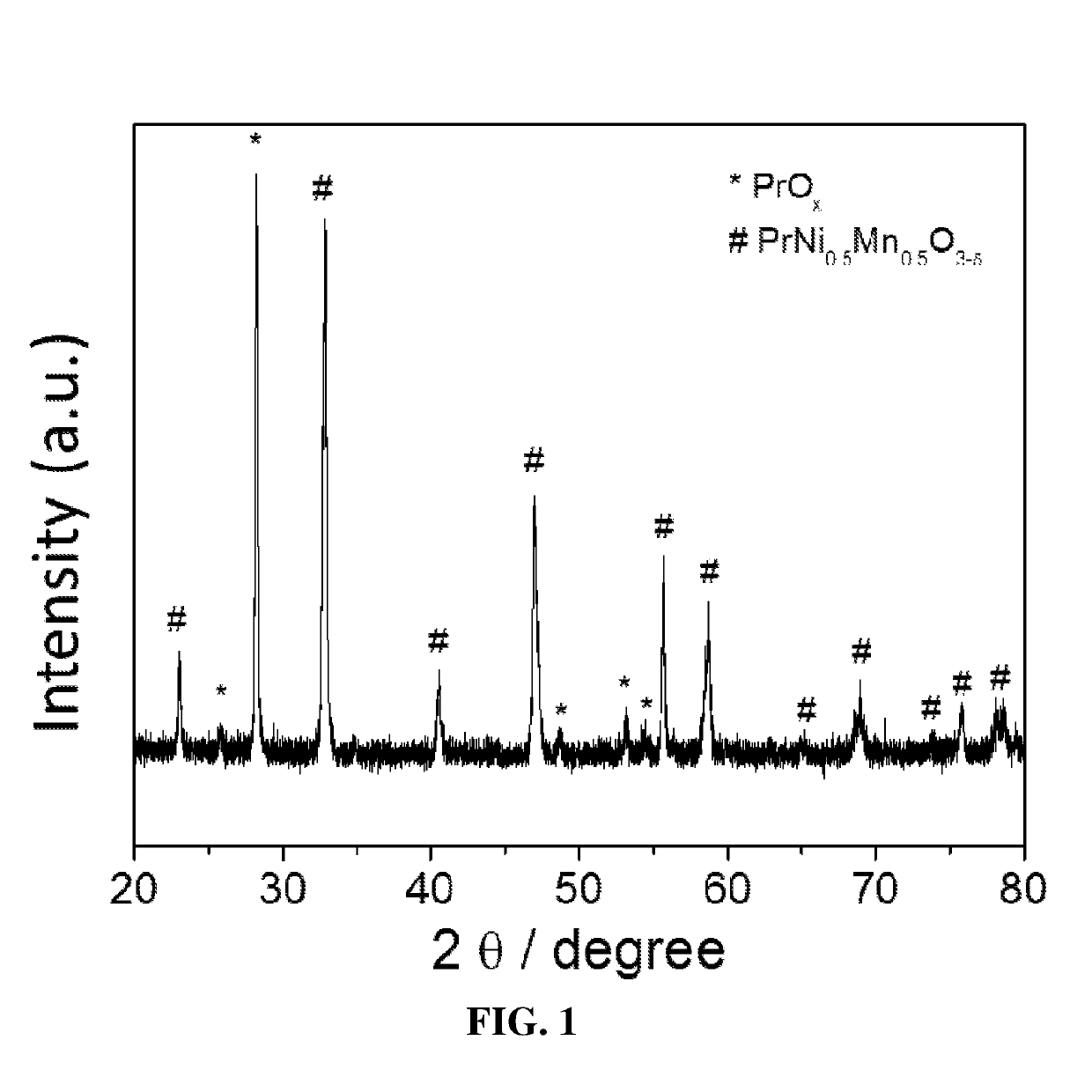

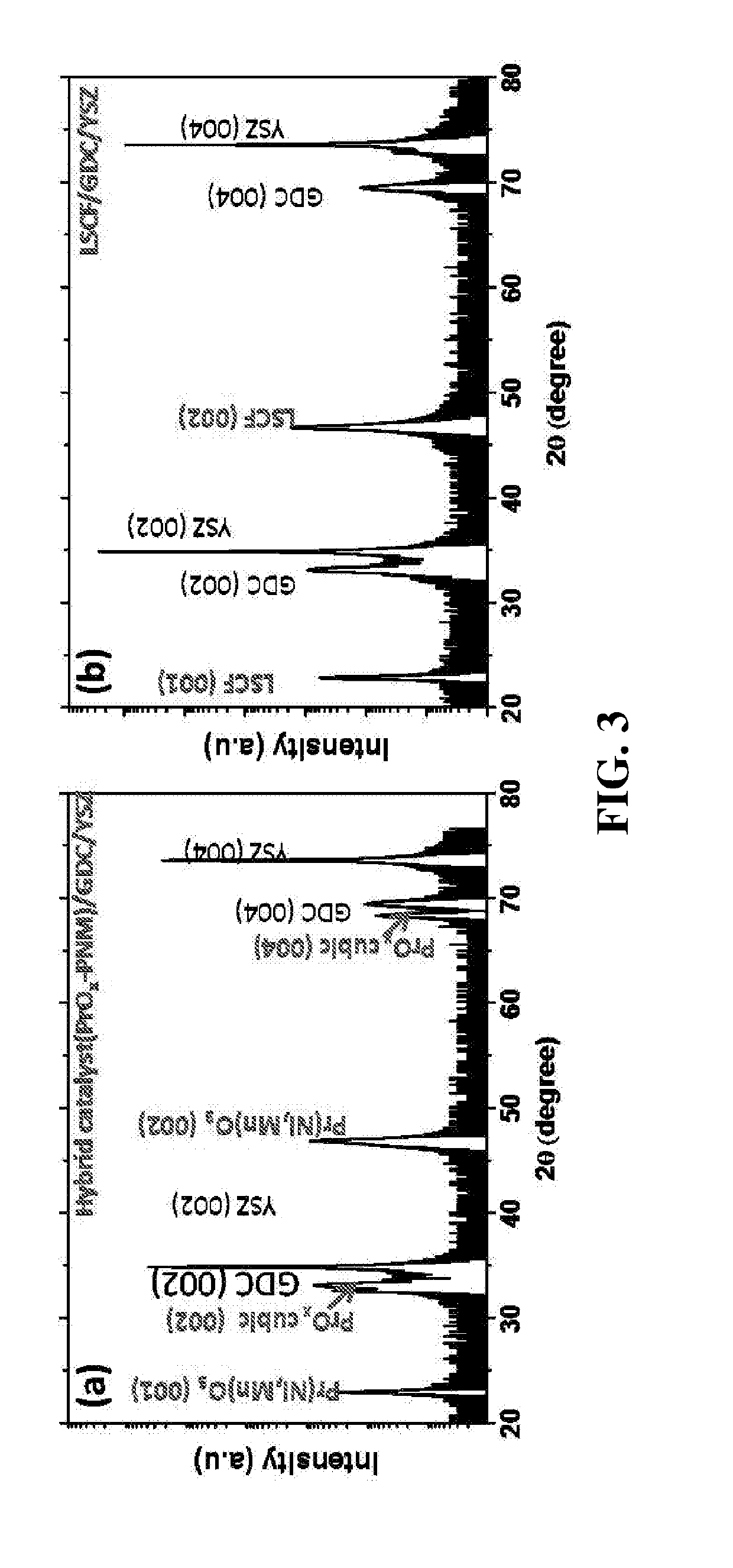

Catalyst coating of a perovskite film and particles exsoluted from the perovskite film

ActiveUS20190140287A1Increase orr rateCost reductionCell electrodesFuel cellsOxygen vacancyChemistry

A hybrid catalyst coating composed of a conformal thin film with exsoluted PrOx nano-particles. The conformal PNM thin film can be a perovskite composition of PrNi0.5Mn0.5O3 (PNM). The PrOx nano-particles dramatically enhance the oxygen reduction reaction kinetics via a high concentration of oxygen vacancies while the thin PNM film effectively suppresses strontium segregation from the cathode of an intermediate-temperature solid oxide fuel cell.

Owner:GEORGIA TECH RES CORP

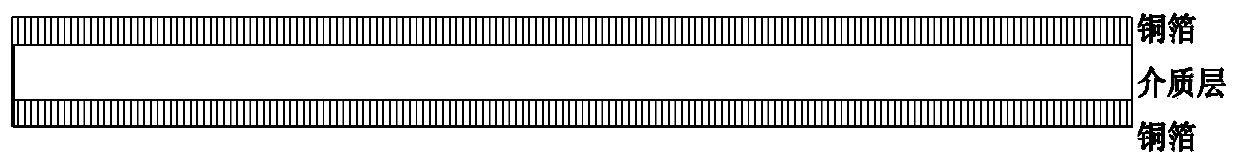

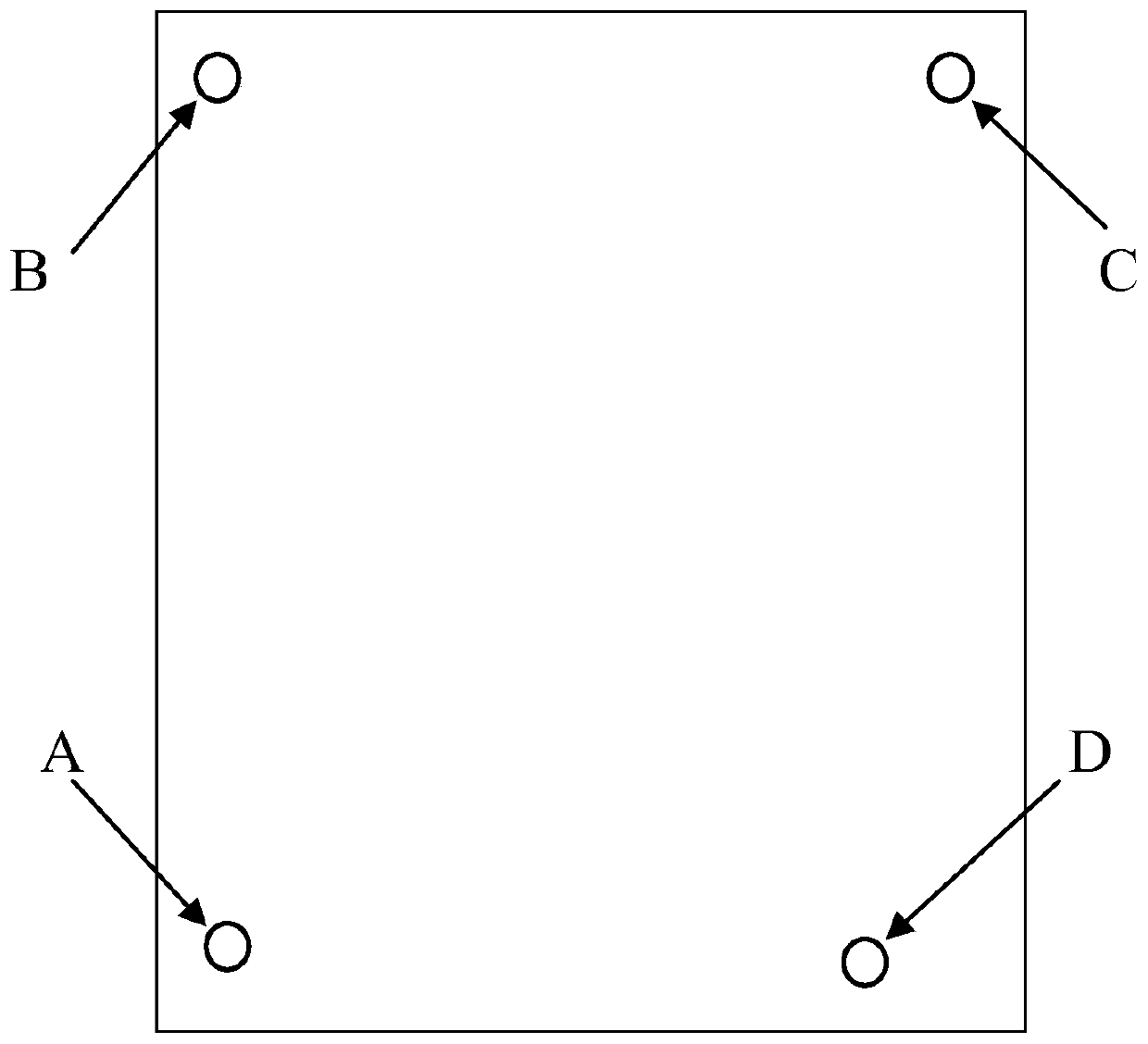

HDI board fabrication method and HDI board

InactiveCN109922612AHigh hole filling efficiencyImprove production efficiencyElectrical connection printed elementsMultilayer circuit manufactureElectrical and Electronics engineeringInterconnection

The invention discloses an HDI board fabrication method and an HDI board. The HDI board fabrication method comprises the steps of processing a core board by a core board processing step, performing browning, prepreg pasting and protection film on the processed core board, drilling a position corresponding to a micropore of the core board, filling the hole with conductive paste to obtain an interconnection unit, and finally, laminating a plurality of interconnection units in one time to achieve interconnection of an arbitrary layer so as to obtain the HDI board. Through hole filling by the conductive paste, the hole filling efficiency is high; moreover, the core board coated with the conductive paste and a prepreg is used as the interconnection unit, the plurality of interconnection units are laminated in one time to fabricate the HDI board, the board is not needed to fabricated by lamination layer by layer, the fabrication efficiency of the HDI board is effectively improved, and the technical problem that the a conventional lamination method for fabricating HDI board in the prior art is extremely long in process flow to cause extremely low fabrication efficiency of the HDI board issolved.

Owner:深圳明阳电路科技股份有限公司

High endurance strength and excellent oxidation resistance third generation single crystal high-temperature alloy and preparation thereof

InactiveCN109576532AHigh strengthHigh creep limitPolycrystalline material growthFrom frozen solutionsChemical compositionSingle crystal superalloy

The invention provides a low cost, high strength and fully oxidation resistance third generation single crystal high-temperature alloy. The high-temperature alloy is mainly suitable for aircraft engine blade materials used at the temperature of 1100 DEG C or above. The alloy is prepared from the chemical components in percentage by weight: 3-5% of Cr, 5-12% of Co, 6-8% of W, 0.1-2% of Mo, 4.5-5.5%of Re, 5.5-6.5% of Al, 6-10% of Ta, 0-0.6% of Nb, 0-0.2% of Hf, 0-0.05% of Y, 0-0.04% of C, and the balance of Ni. A preparation method comprises the steps that single crystal blades or test rods areprepared within a temperature gradient range of a single crystal growth furnace being 40 K / cm-80 K / cm, at a casting temperature of 1500-1550 DEG C, under the condition that a mould shell temperatureis consistent with the casting temperature, and within the growth rate range of 4-8 mm / min. Then after solid solution homogenization treatment, high temperature aging treatment, and low temperature aging treatment, the alloy has high endurance strength and creep limit. The service life is greater than or equal to 200 h at the endurance condition of 1100 DEG C / 140 MPa, and the endurance strength ofthe alloy is comparable to that of CMSX-10; and the performance of high temperature oxidation resistance is good, specifically, surface stability is good. A heat treatment window is wide, and solid solution treatment is easy to control.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

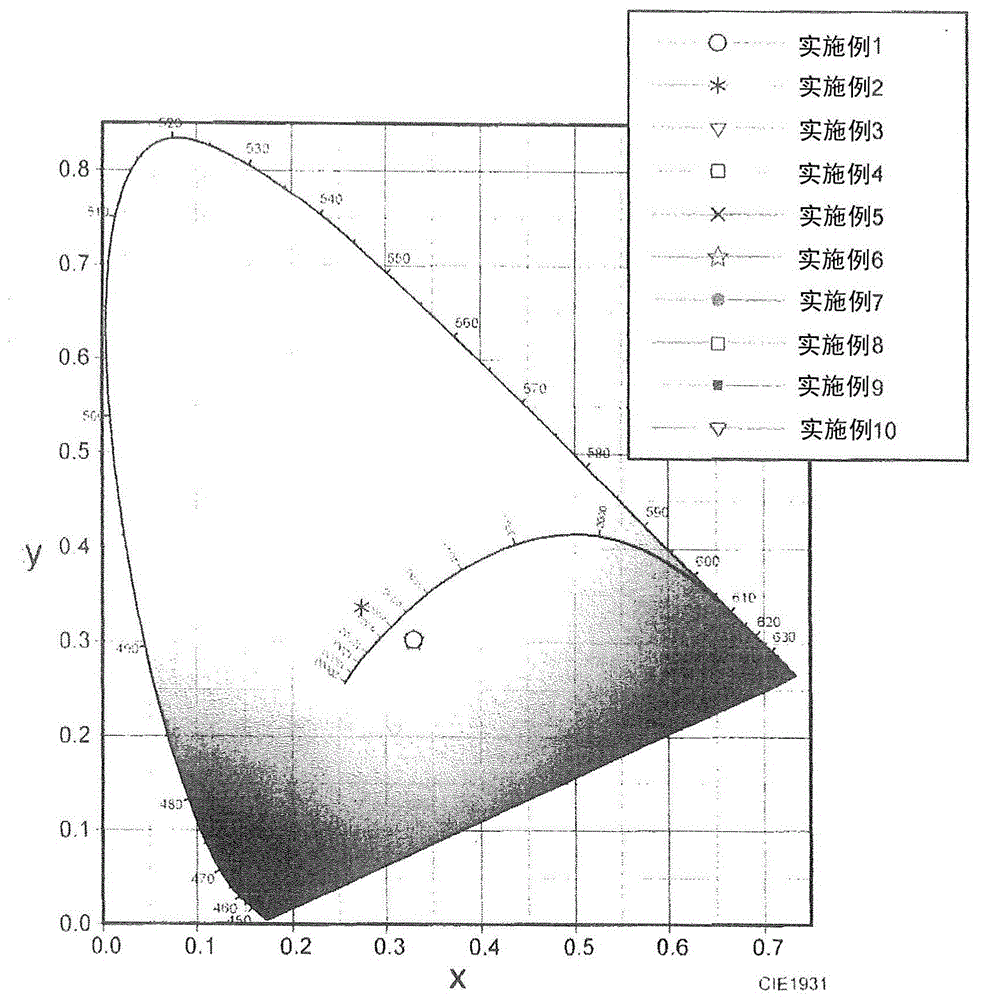

Silica glass member for wavelength conversion, and production method therefor

InactiveCN104903266AHigh environmental toleranceImprove heat resistanceCoatingsThin material handlingSurface layerWater vapor

The invention provides a silica glass member for wavelength conversion for which environmental tolerance, heat resistance, durability and color rendering properties are high, which can be produced using a low-heat process, and which can efficiently convert wavelengths; and a production method therefor. The silica glass member for wavelength conversion is formed by a silica glass substrate and a silica glass surface layer film formed on the surface of the substrate. The silica glass surface layer film is obtained by coating the surface of the silica glass substrate with a polysilazane-containing solution which contains phosphor particles the average particle diameter of which is 0.1 mu m-20 mu m and spherical silica fine particles which are hydrophobic and have an average particle size of 1nm-100nm, drying the coated substrate in the air, and carrying out heating of the same in a water-vapor atmosphere. In the polysilazane-containing solution, the ratio of phosphor particles to the total amount of the polysilazane and phosphor particles is 10:3-7 parts by mass, and the NH group concentration of the silica glass surface layer film is no more than 1000ppm.

Owner:SHIN ETABU QUARTZ PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com