Simple and easy preparation method for super-hydrophobic fiber and textile and application thereof

A super-hydrophobic and fiber-based technology, which is applied in fiber processing, textiles and papermaking, etc., can solve the problems of high cost, harsh experimental conditions, and difficulty in large-scale production, and achieves low application difficulty, improved surface stability, and good super-hydrophobic performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

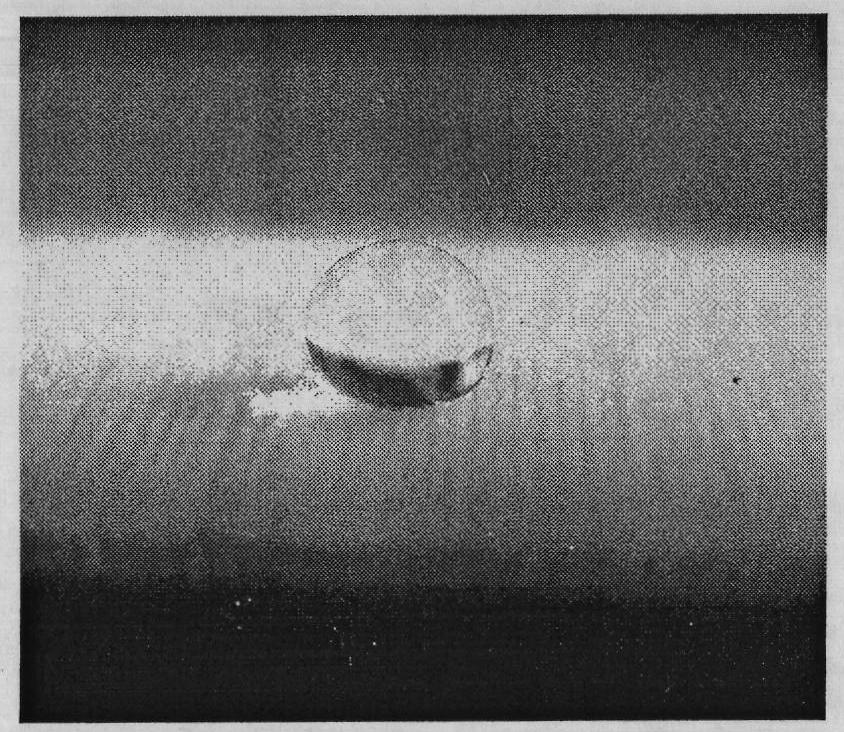

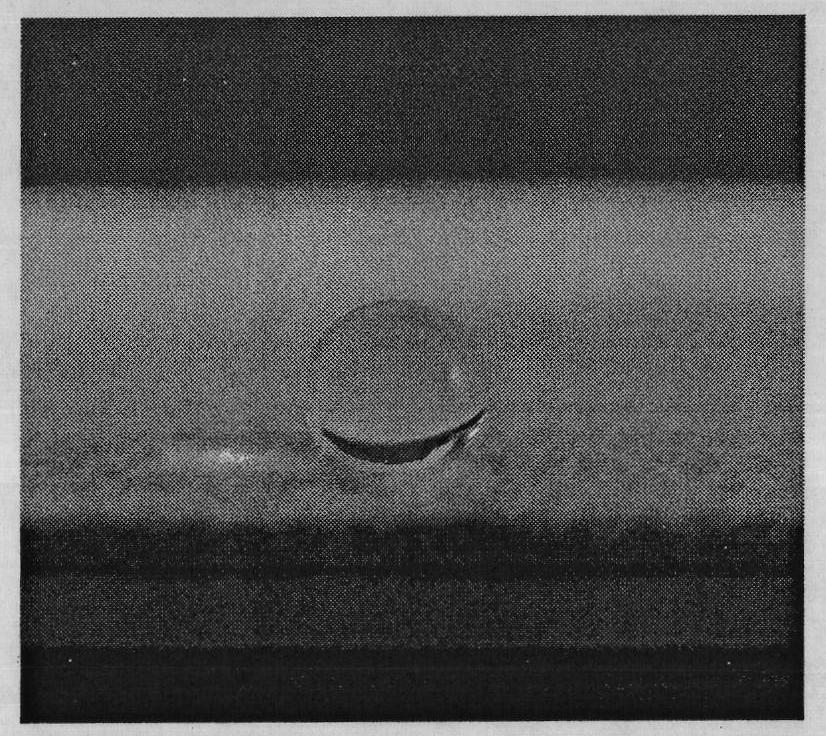

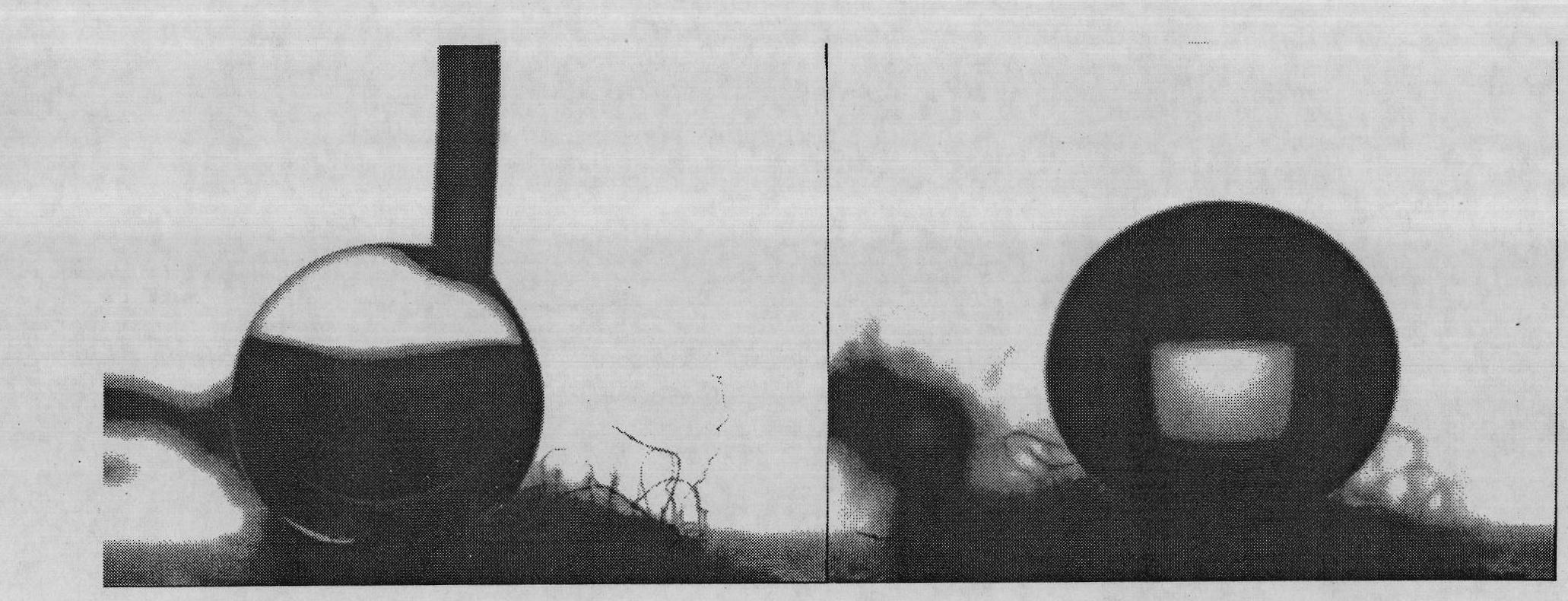

Image

Examples

Embodiment 1

[0027] Material pretreatment: After cleaning the fibers and fabrics with water or ethanol or acetone, dry them for use;

[0028] Isocyanate modification: place clean and dry fibers and fabrics in 1 wt% isocyanate solution (such as ethyl acetate solution of toluene-2,4-diisocyanate), N 2 Under protection, react in a water bath or an oil bath at 60-80°C for 1 hour, take it out, and wash with a solvent (such as ethyl acetate);

[0029] Low surface energy modification: place the fiber and fabric modified by isocyanate in 1wt% low surface energy substance solution (such as the ethyl acetate solution of hydroxy silicone oil), in N 2 Under protection, react in a water bath or an oil bath at 60-80°C for 1 hour, take it out, wash it with a solvent (such as ethyl acetate, ethanol), and dry it in vacuum at 50°C for 2 hours.

Embodiment 2

[0031] Material pretreatment: After cleaning the fibers and fabrics with water or ethanol or acetone, dry them for use;

[0032] Preparation of isocyanate-terminated low surface energy substances: such as the preparation of isocyanate-terminated silicone oil, adding hydroxyl silicone oil and toluene-2,4-diisocyanate to ethyl acetate solution, controlling the molar ratio of isocyanate to hydroxyl to 2: 1, N 2 Under protection, react in a water bath or an oil bath at 60-80°C for 1 hour, and set aside;

[0033] Surface treatment of materials: put fibers and fabrics in ethyl acetate solution of isocyanate-terminated silicone oil, N 2 Under protection, react in a water bath or an oil bath at 60-80°C for 1 hour, take it out, wash it with a solvent (such as ethyl acetate, ethanol), and dry it in vacuum at 50°C for 2 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com