Super-hydrophobic composite coating and preparation method thereof

A composite coating, super-hydrophobic technology, applied in coatings, epoxy coatings, devices for coating liquids on the surface, etc., can solve the problems of long cycle, difficult to expand application, complex operation, etc. Wide application range and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A preparation method of super-hydrophobic composite coating includes the following steps:

[0032] Step (1), at room temperature, ultrasonically disperse a certain amount of epoxy resin and its curing agent in an organic solvent to form a uniform solution, and then spray it on the surface of the substrate and dry for a period of time;

[0033] Step (2), at room temperature, ultrasonically disperse a certain amount of epoxy resin and its curing agent in an organic solvent to form a uniform solution, and then add a certain amount of inorganic nano fillers to it and magnetically stir for a certain period of time to make it uniformly dispersed. Then spray it on the surface of the substrate prepared in step (1);

[0034] Step (3), at room temperature, ultrasonically disperse a certain amount of polydimethylsiloxane (PDMS) and its curing agent in an organic solvent to form a uniform solution, and then spray it on the substrate prepared in step (2) The surface is dried for a period ...

Embodiment 1

[0039] Step (1): At room temperature, 0.07g of epoxy resin E51 and 0.0175g of curing agent methyltetrahydrophthalic anhydride were ultrasonically dispersed in 0.5g of ethyl acetate to form a uniform solution, and then sprayed on a 25mm×80mm aluminum alloy sheet And dry treatment at 130℃ for 2.5h;

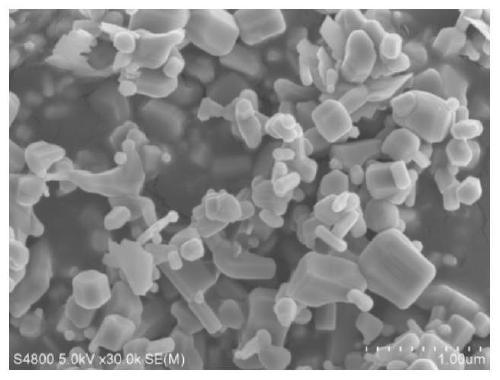

[0040] Step (2): At room temperature, 0.06g of epoxy resin E51 and 0.015g of curing agent methyltetrahydrophthalic anhydride were ultrasonically dispersed in 1g of ethyl acetate to form a uniform solution, and then 0.18g of ZnO was added to it and stirred 2h to make it evenly dispersed, and then spray it on the surface of the aluminum alloy sheet prepared in step (1);

[0041] Step (3): At room temperature, 0.01g PDMS Sylgard-184A and 0.001g curing agent Sylgard-184B were ultrasonically dispersed in 1g n-hexane to form a uniform solution, and then sprayed on the aluminum prepared in step (2) The surface of the alloy sheet is dried at 140°C for 2 hours, and the super-hydrophobic coating ...

Embodiment 2

[0044] Step (1): At room temperature, 0.05g epoxy resin E51 and its curing agent methyltetrahydrophthalic anhydride 0.0125g are ultrasonically dispersed in 0.3g ethyl acetate to form a uniform solution, and then sprayed on 45×45mm leather and combined Dry treatment at 150℃ for 1.5h;

[0045] Step (2): At room temperature, 0.08g of epoxy resin E51 and 0.02g of curing agent methyltetrahydrophthalic anhydride were ultrasonically dispersed in 1.2g of ethyl acetate to form a uniform solution, and then 0.2g of TiO was added to it 2 And stir for 2 hours, and then spray it on the leather surface prepared in step (1);

[0046] Step (3): At room temperature, 0.015g PDMS Sylgard-184A and its 0.0015g curing agent Sylgard-184B are ultrasonically dispersed in 0.8g n-hexane to form a uniform solution, and then sprayed on the prepared in step (2) The surface of the leather is dried at 130°C for 5 hours, and the super-hydrophobic coating can be obtained after fully curing.

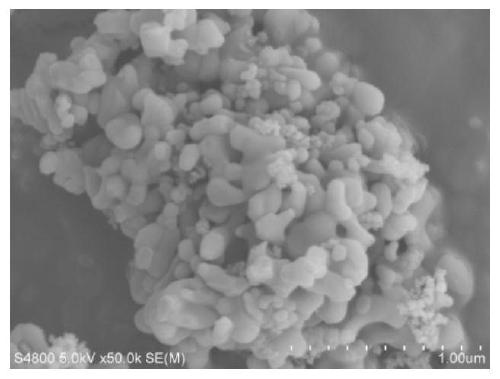

[0047] figure 2 TiO use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com