Synthetic method of nitrogen-enriched carbon coated lithium titanate composite material prepared by introduction of ionic liquid as carbon source

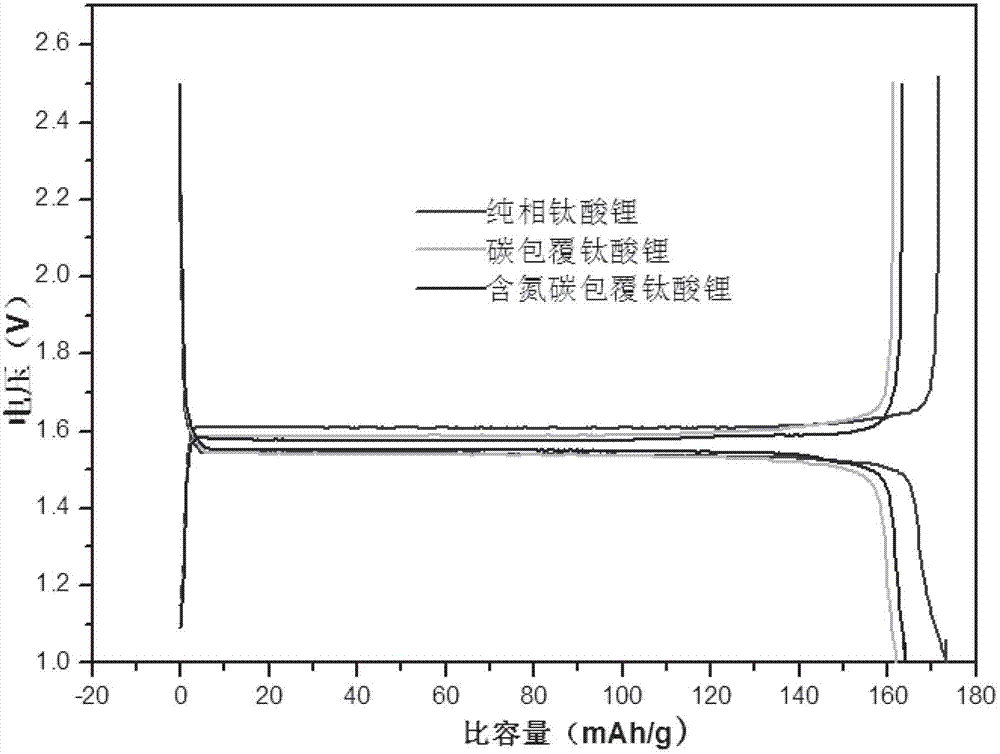

An ionic liquid and lithium titanate-coated technology, which is applied in electrical components, battery electrodes, circuits, etc., can solve the problems of electrolyte loss, low electronic conductivity of pure-phase lithium titanate, and electrolyte reaction, so as to improve flatulence problem, the effect of excellent rate performance and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] a) Weigh lithium carbonate, titanium dioxide and polyvinyl alcohol according to the molar ratio of lithium, titanium and carbon as 4.2:5:0.2, add a certain amount of alcohol and place them in a ball mill for stirring and ball milling. The ball milling time is 5 hours. The finished slurry is placed in a vacuum drying oven for drying treatment at a temperature of 80 degrees and a drying time of 8 hours.

[0028] b) The dried precursor was placed in an atmosphere protection furnace for sintering, and the temperature was raised to 800 °C at a heating rate of 2 °C / min, kept for 12 hours, and naturally cooled to room temperature to obtain a primary carbon-coated lithium titanate material.

[0029] c) Weigh a certain amount of primary carbon-coated lithium titanate material, and weigh 1-ethyl-3-methylimidazolium dicyandiamide salt (EMIM -DCA), add an appropriate amount of deionized water for another ball milling dispersion treatment, add an appropriate amount of deionized wate...

Embodiment 2

[0032] a) Weigh lithium carbonate, titanium dioxide and polyvinyl alcohol according to the molar ratio of lithium, titanium and carbon elements of 4.2:5:0.5, add a certain amount of alcohol and place them in a ball mill for stirring and ball milling. The ball milling time is 8 hours. The finished slurry is placed in a vacuum drying oven for drying treatment at a temperature of 90 degrees and a drying time of 10 hours.

[0033] b) The dried precursor was placed in an atmosphere protection furnace for sintering, and the temperature was raised to 850 °C at a heating rate of 5 °C / min, kept for 12 hours, and naturally cooled to room temperature to obtain a primary carbon-coated lithium titanate material.

[0034] c) Weigh a certain amount of primary carbon-coated lithium titanate material, and weigh 1-ethyl-3-methylimidazolium dicyandiamide salt (EMIM -DCA), adding an appropriate amount of deionized water for another ball milling dispersion treatment, adding an appropriate amount o...

Embodiment 3

[0037] a) Weigh lithium carbonate, titanium dioxide and polyvinyl alcohol according to the molar ratio of lithium, titanium and carbon elements of 4.2:5:0.8, add a certain amount of alcohol and place them in a ball mill for stirring and ball milling. The ball milling time is 10 hours. The finished slurry is placed in a vacuum drying oven for drying treatment at a temperature of 100 degrees and a drying time of 12 hours.

[0038] b) The dried precursor was placed in an atmosphere protection furnace for sintering, and the temperature was raised to 880 °C at a heating rate of 8 °C / min, kept for 12 hours, and naturally cooled to room temperature to obtain a primary carbon-coated lithium titanate material.

[0039] c) Weigh a certain amount of primary carbon-coated lithium titanate material, and weigh 1-ethyl-3-methylimidazolium dicyandiamide salt (EMIM -DCA), adding an appropriate amount of deionized water for another ball milling dispersion treatment, adding an appropriate amount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com