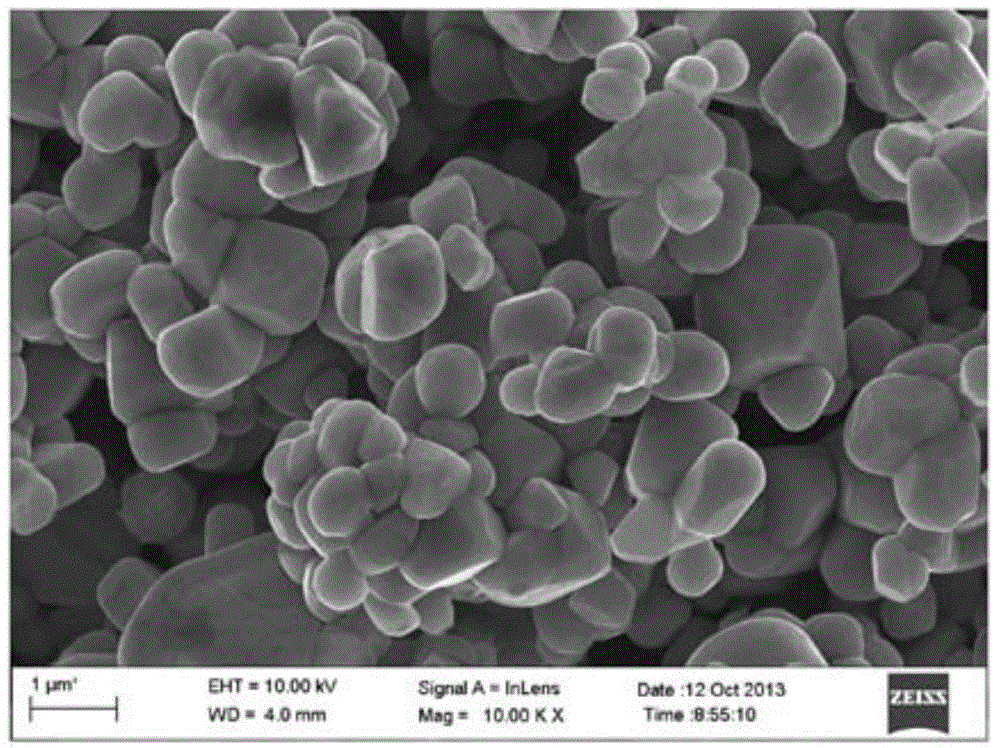

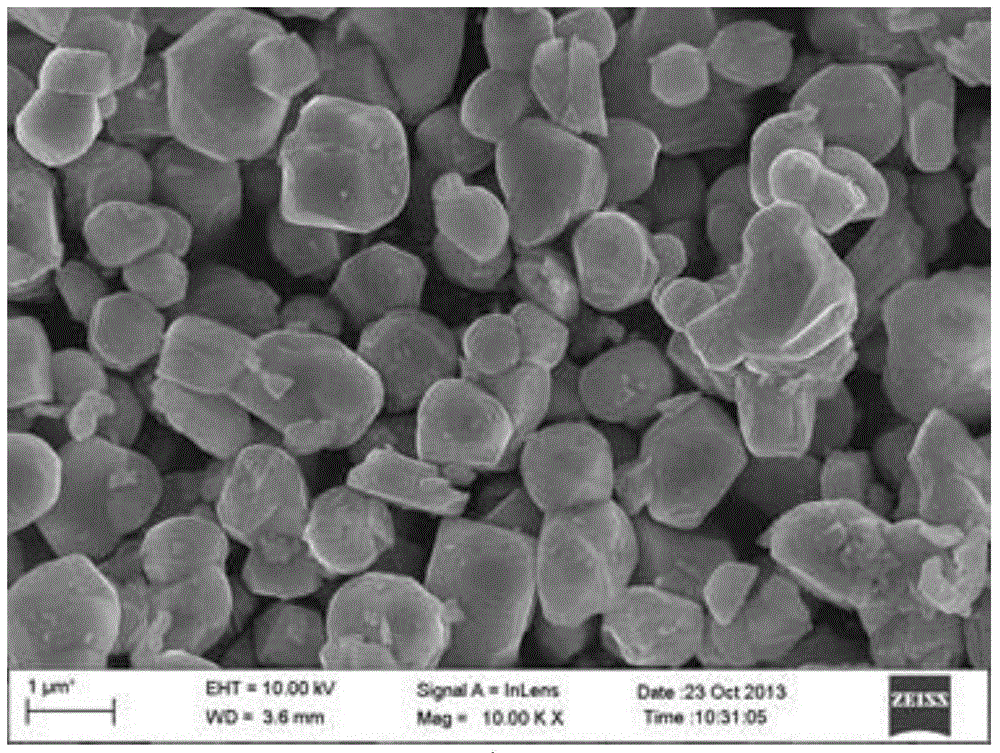

Preparation method of single-crystal-morphology lithium ion battery ternary positive material

A lithium-ion battery, cathode material technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of reduced capacity retention, inability to obtain carbon coating, and particularly obvious impact on battery cycle performance, to overcome the problem of easy agglomeration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041]Preparation of cathode material:

[0042] 1) This step is exactly the same as step 1) of Comparative Example 1;

[0043] 2) Weigh 100g of the precursor obtained from step 1) and put it into a crucible, then add 0.5g of lithium fluoride (auxiliary agent), grind and mix evenly, put them together in a high-temperature muffle furnace at 900°C in an air atmosphere Sintering, the holding time is 6 hours, to obtain spherical oxide powder;

[0044] 3) Mix the product obtained in the above steps with 50.8g of lithium carbonate, grind it for 4 hours to make it evenly mixed; carry out sintering at 970°C in a muffle furnace under an air atmosphere, and the holding time is 12 hours;

[0045] 4) Ball mill and disperse the powder prepared in step 3) for 4 hours, pass through a 200-mesh sieve, put the sample in a crucible, put it into a high-temperature muffle furnace for sintering at 1000°C, and keep it for 10 hours to obtain a single crystal The morphology of the positive electrode ...

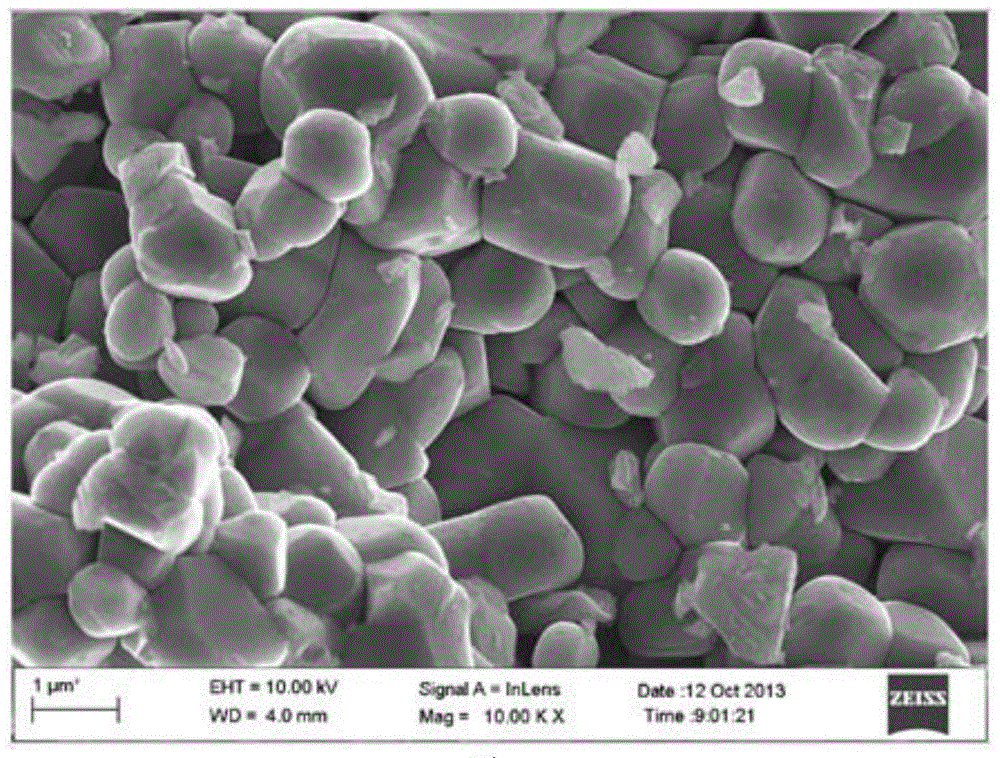

Embodiment 2

[0048] Preparation of cathode material:

[0049] 1) The cathode material precursor was synthesized by co-precipitation method, and 2 mol / L metal salt (both nitrate) mixed solution, 2 mol / L NaOH solution, and 3 mol / L ammonia solution were added dropwise into the reaction vessel. The molar ratio of nickel element, cobalt element and manganese element contained in the solution is 5:2:3 and the valence of the elements is +2. The pH value of the control system is 10.0, and the water bath is heated to 50°C; after 12 hours of reaction, filter, After washing and vacuum drying at 120 °C for 8 h, the flower cluster precursor (Ni 1 / 2 co 1 / 5 mn 3 / 10 )(OH) 2 , its D50 is about 4μm, and its BET is about 130m 2 / g;

[0050] 2) Weigh 100g of the precursor obtained from step 1) into the crucible, then add 0.5g of boron oxide (auxiliary), grind and mix evenly, put them together in a high-temperature muffle furnace and sinter at 600°C in an air atmosphere , the holding time is 10 hours, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| D50 | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com