Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

126results about How to "Improve the first discharge capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hard carbon negative electrode material of lithium ion battery, preparation method and application of hard carbon negative electrode material

InactiveCN102820455AIncrease capacityImprove the first Coulombic efficiencyCell electrodesDischarge efficiencyPhysical chemistry

The invention relates to a hard carbon negative electrode material of a lithium ion battery, and a preparation method and application of the hard carbon negative electrode material. The hard carbon negative electrode material is doped with silicon and phosphorus, wherein the mass ratio of silicon precursor, phosphorus precursor and hard carbon precursor is 1:(0.1 to 5):(5 to 30). Due to the addition of silicon / phosphorus, the hard carbon negative electrode material provided by the invention is remarkably improved in the first discharge capacity (up to 550.8mAh / g), the first charge / discharge efficiency (up to 80.9%) and the first coulombic efficiency by doping, is remarkably reduced in the irreversible capacity, and has the advantages of excellent cycle performance and rate capability, good PC (poly carbonate) consistency and high PC resistance, wherein the capacity retention ratio is above 95% after discharge cycle for 100 weeks at a high discharge rate of 10C.

Owner:天津市贝特瑞新能源科技有限公司

Modified high nickel ternary positive electrode material and its preparation method and lithium ion battery

InactiveCN108206277AImprove the first discharge capacityImprove the first Coulombic efficiencyCell electrodesSecondary cellsAluminium-ion batteryElectrical conductor

The invention discloses a modified high nickel ternary positive electrode material. The surface of a high nickel ternary positive electrode material is coated with a coating layer containing a fast ion conductor. The fast ion conductor has the chemical general formula of Li3x1La2 / 3-x1Ma1TiNz1O3, Li2+2x2Zn1-x2GeO4 or LiM'2(PO4)3, wherein M represents Ba<2+> and / or Sr<2+>, N represents Al<3+> and / orZr<4+>, x1 is greater than or equal to 0.04 and less than or equal to 0.167, a1 is greater than or equal to 0 and less than or equal to 1, z1 is greater than or equal to 0 and less than or equal to 1, x2 is greater than -0.3 and less than 0.8, and M' represents one or more of Zr, Ti, Ge and Hf. Compared with the existing positive electrode material, the modified high nickel ternary positive electrode material is provided with the coating layer containing the fast ion conductor and the coating layer can react with residual lithium on the surface of the material to reduce residual lithium on the surface of the material and inhibit side reactions of the residual lithium and the electrolyte so that material surface stability and cycle performances are improved. The modified high nickel ternary positive electrode material has good lithium ion deintercalation ability, improves the first discharge capacity of the material and first coulombic efficiency and has a good application prospect. The invention also discloses a preparation method of the modified high nickel ternary positive electrode material and a lithium ion battery.

Owner:CONTEMPORARY AMPEREX TECH CO

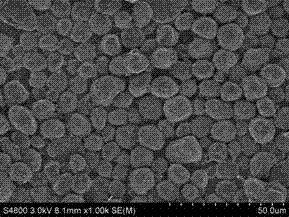

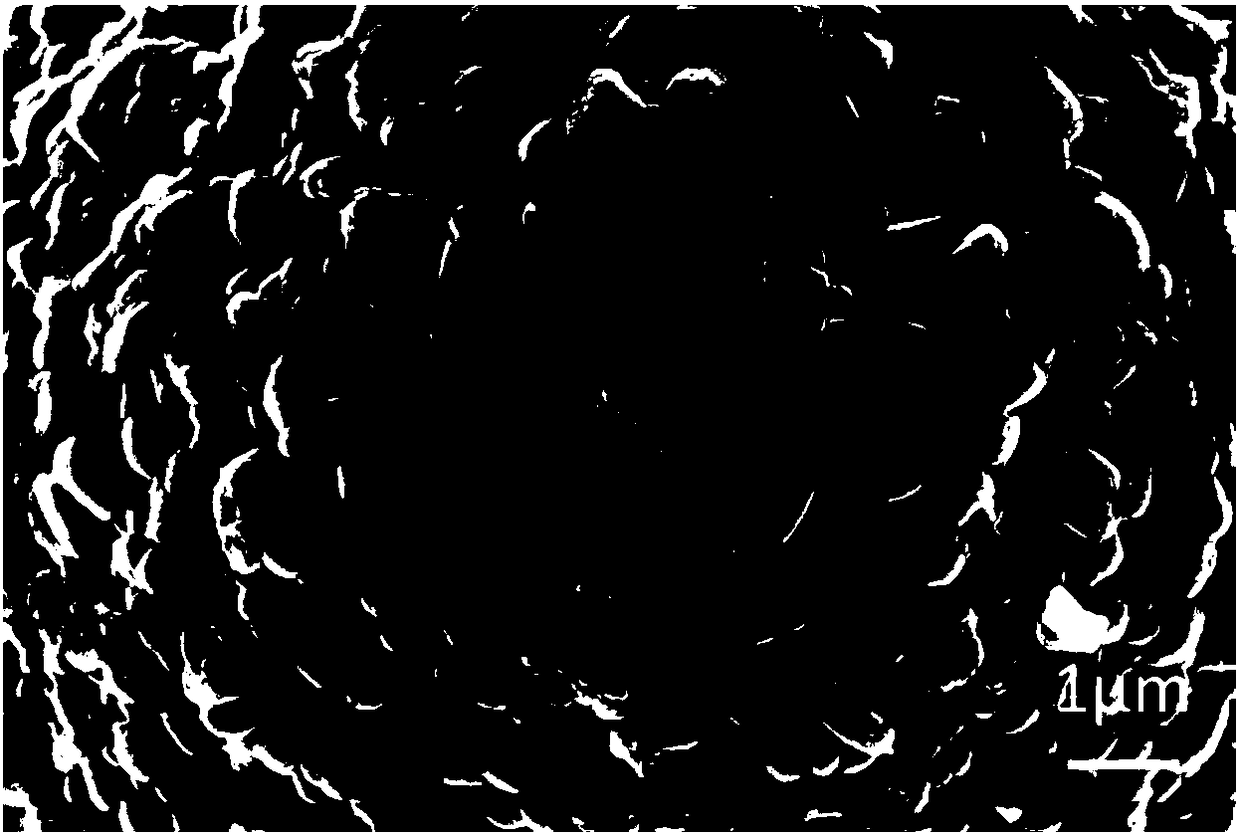

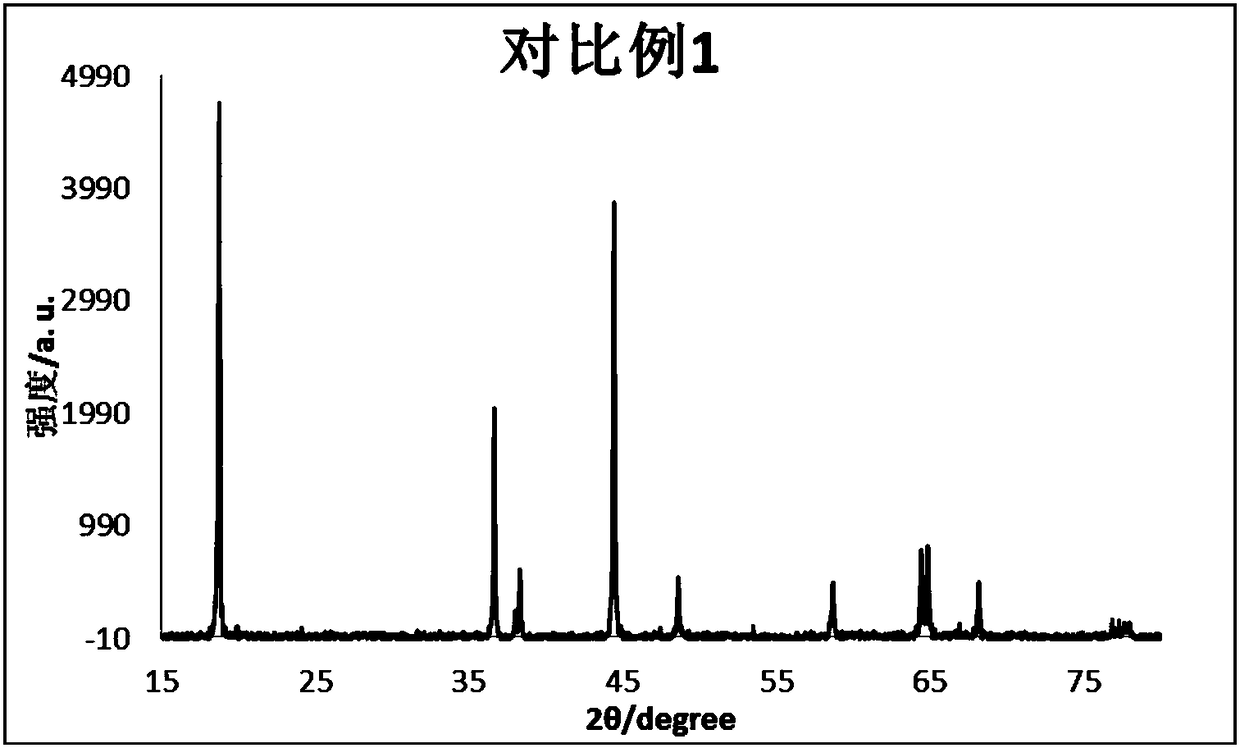

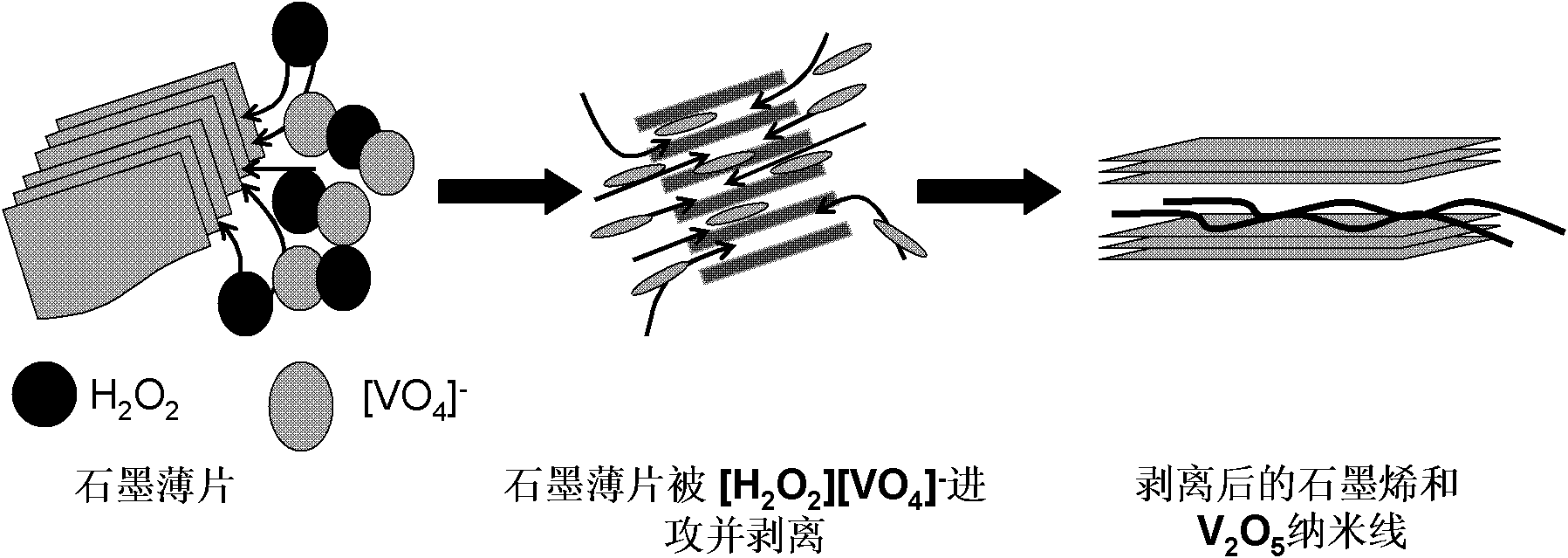

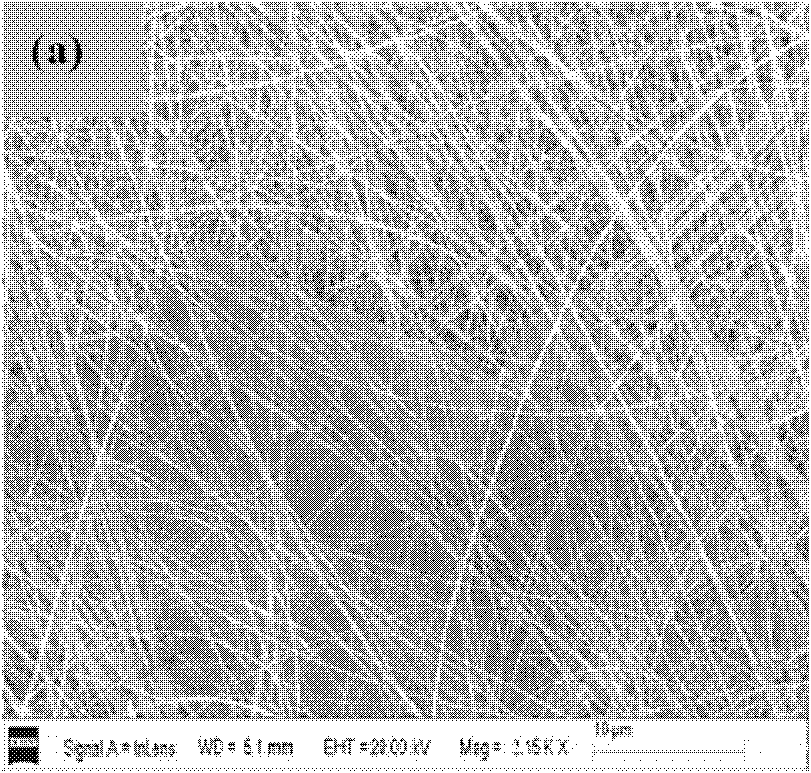

Ultra-long single crystal V2O5 nano wire/graphene anode material and preparation method

InactiveCN102208631AImprove the first discharge capacityImproved dynamicsCell electrodesIonCvd graphene

The invention discloses an ultra-long single crystal V2O5 nano wire / graphene anode material and a preparation method, and belongs to the field of lithium ion battery electrode materials and preparation thereof. The V2O5 nano wire / graphene anode material consists of a two-dimensional graphene nano sheet and one-dimensional V2O5 nano wires, wherein the ultra-long single crystal V2O5 nano wires are regularly distributed on the surface and the interlayer of the transparent graphene nano sheet to form a sandwich structure. The preparation method comprises the following steps of: dispersing vanadium oxide powder and merchant graphite into deionized water, adding an oxidant, fully stirring mixture uniformly, performing ultrasonic treatment, putting the mixture into an autoclave, keeping the mixture for certain time at a certain temperature, and performing vacuum drying to obtain the ultra-long single crystal V2O5 nano wire / graphene composite anode material. The invention has the advantages that: the first discharge capacity, the magnification performance and the electrochemical cyclical stability of the composite anode material are remarkably improved. The method is simple, environment-friendly, convenient for operation and easy to realize large-scale production.

Owner:BEIJING UNIV OF CHEM TECH

Artificial graphite lithium ion battery anode material and preparation method thereof

ActiveCN103887502AMaterial rigidity weakenedReduce rigidityCell electrodesSecondary cellsGraphiteSilicon dioxide

The invention discloses an artificial graphite lithium ion battery anode material and a preparation method thereof. The preparation method comprises the following steps: (1) mixing coal tar maltha with an additive according to a weight ratio of 5:1-50:1, well mixing, performing thermopolymerization reaction; (2) performing reduced pressure treatment of the reaction product; (3) performing carbonizing treatment, crushing, and grading treatment; (4) performing graphitization treatment. The additive is one or more of silicon, silica and silicon carbide. The artificial graphite lithium ion battery anode material has a high compaction density and first discharge capacity, and cells prepared by using the material as a lithium ion battery anode material have excellent comprehensive properties, stable structure, and good safety performance. The preparation method is simple and practical in process, wide in raw material source, and low in cost.

Owner:SHANGHAI SHANSHAN TECH CO LTD

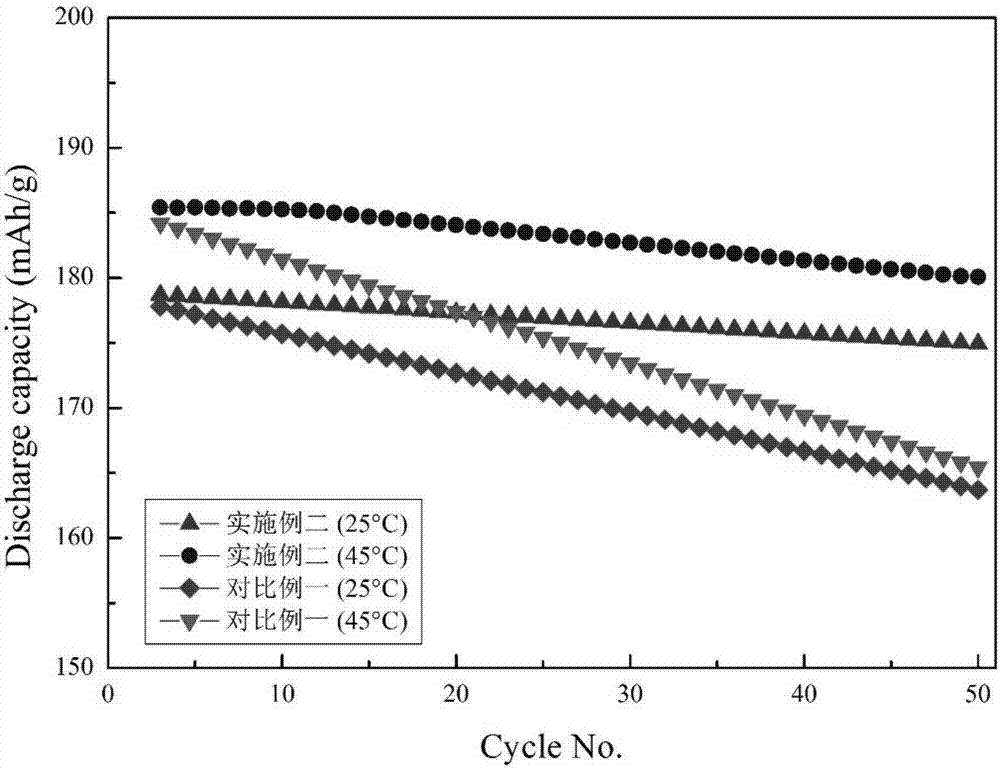

Method for preparing ternary anode material of long-service-life and high-capacity lithium ion battery

ActiveCN103682316AIncrease capacityImprove cycle performanceCell electrodesCapacity lossMaterial synthesis

A method for preparing a ternary anode material of a long-service-life and high-capacity lithium ion battery and belongs to the technical field of material synthesis. The method comprises the following steps: weighing a lithium source and NixCoyMnz(OH)2, uniformly mixing, pre-burning at a temperature of 400-600 DEG C for 2-6 h, and forging at a temperature of 700-1000 DEG C for 6-16 h; uniformly mixing the ternary anode material, the lithium source and nanometer TiO2; forging at a temperature of 700-950 DEG C for 3-8 h to obtain the ternary anode material which is prepared by twice lithium adding and twice forging. The ternary anode material is prepared through twice lithium adding and twice forging, and the extra lithium source which is introduced through twice lithium adding and twice forging is electrochemically pre-embedded in an anode. Meanwhile, the Li+ diffusion rate can be effectively increased through the doping of Ti4+, and the irreversible capacity loss is reduced. In an interval of 2.3-4.6 V, a discharging platform is prolonged, and the first discharging capacity, the cyclic performance and the rate performance of the material are obviously improved. The method is simple, effective, economical and practical and has a remarkable industrial application effect.

Owner:HARBIN INST OF TECH

Sodium doped lithium-rich manganese based cathode material for lithium ion battery and preparation method thereof

ActiveCN104201337AImprove discharge specific capacityImprove cycle stabilityCell electrodesSecondary cellsManganeseSodium-ion battery

The invention relates to a sodium doped lithium-rich manganese based cathode material for a lithium ion battery. The material is a sodium salt doped lithium-rich manganese based solid solution cathode material of which the general formula is xLi[Li1 / 3Mn2 / 3]O2.(1-x)LiNi0.2Co0.2Mn0.6O2, wherein x is equal to or greater than 0.4 and is equal to or less than 0.7, the doped quantity of sodium elements is 1-10% of the mol content of lithium elements, and the sodium salt is one selected from Na2CO3, Na2C2O4 and NaNO3. The mol content of ternary phase manganese of the sodium doped lithium-rich manganese based cathode material for the lithium ion battery is greater than 50%, and the manganese with high reserves and low price is used for replacing cobalt and nickel, so that the application cost can be reduced. Compared with the prior art, the sodium doping provided by the invention can improve the discharging specific capacity and the circulating stability of the rich lithium manganese based cathode material.

Owner:HEBEI UNIV OF TECH

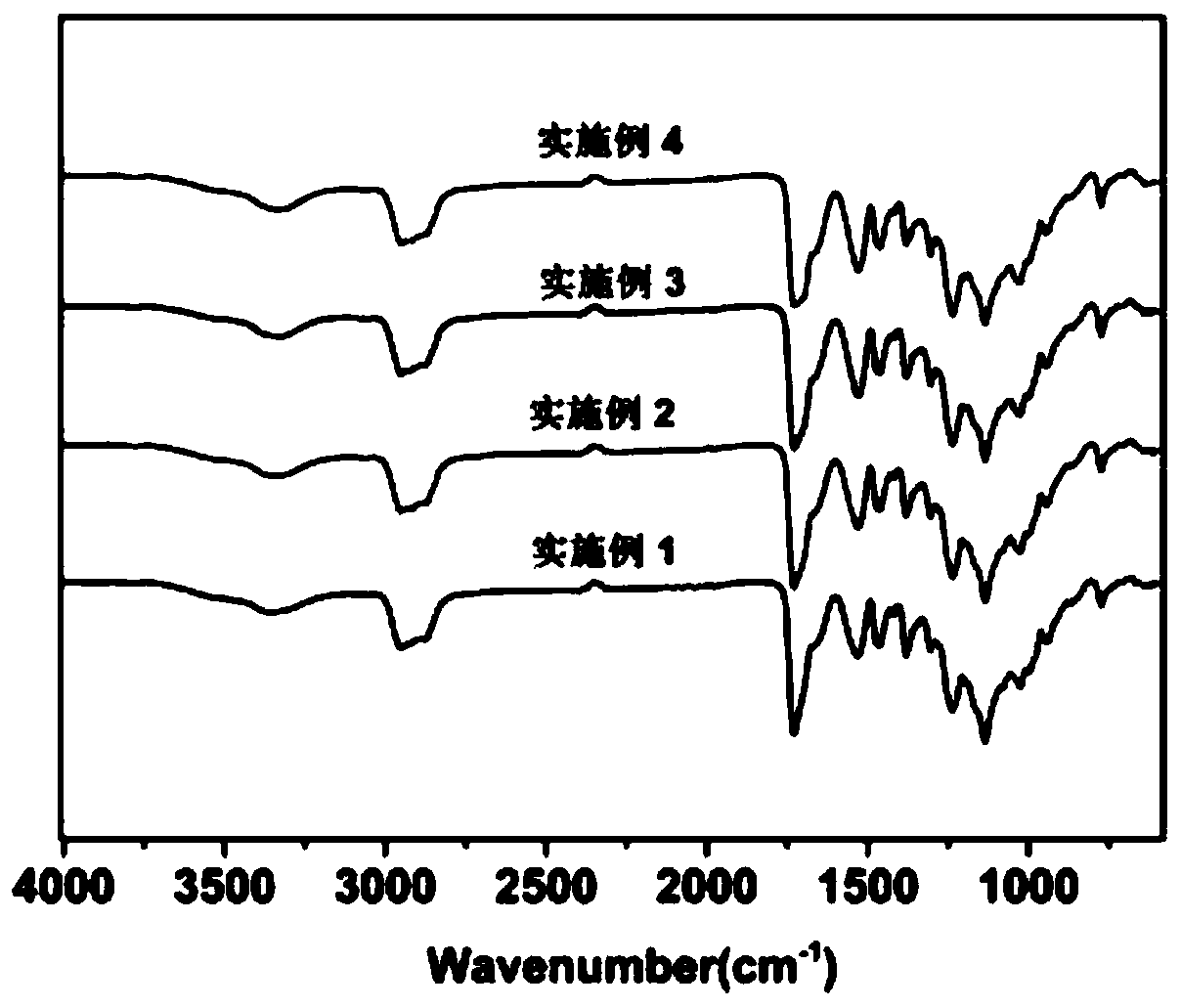

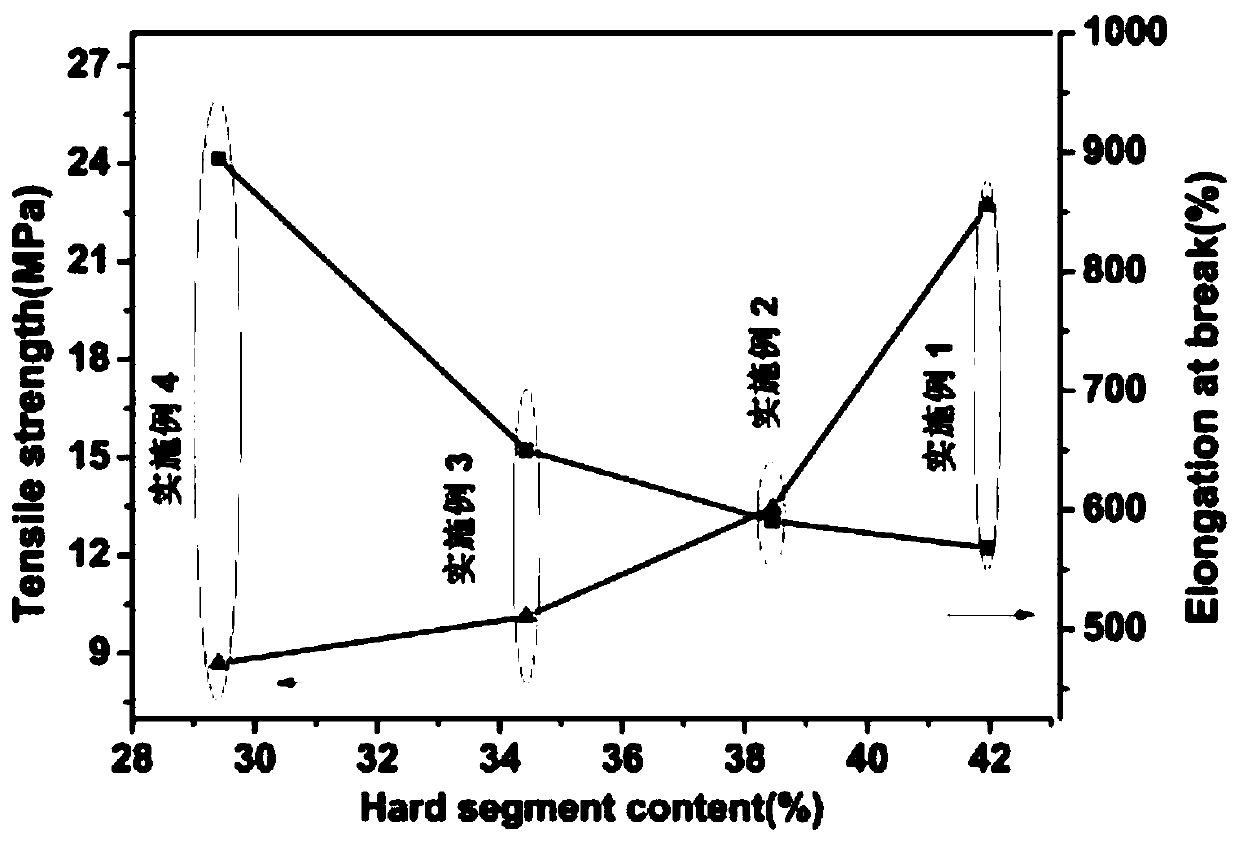

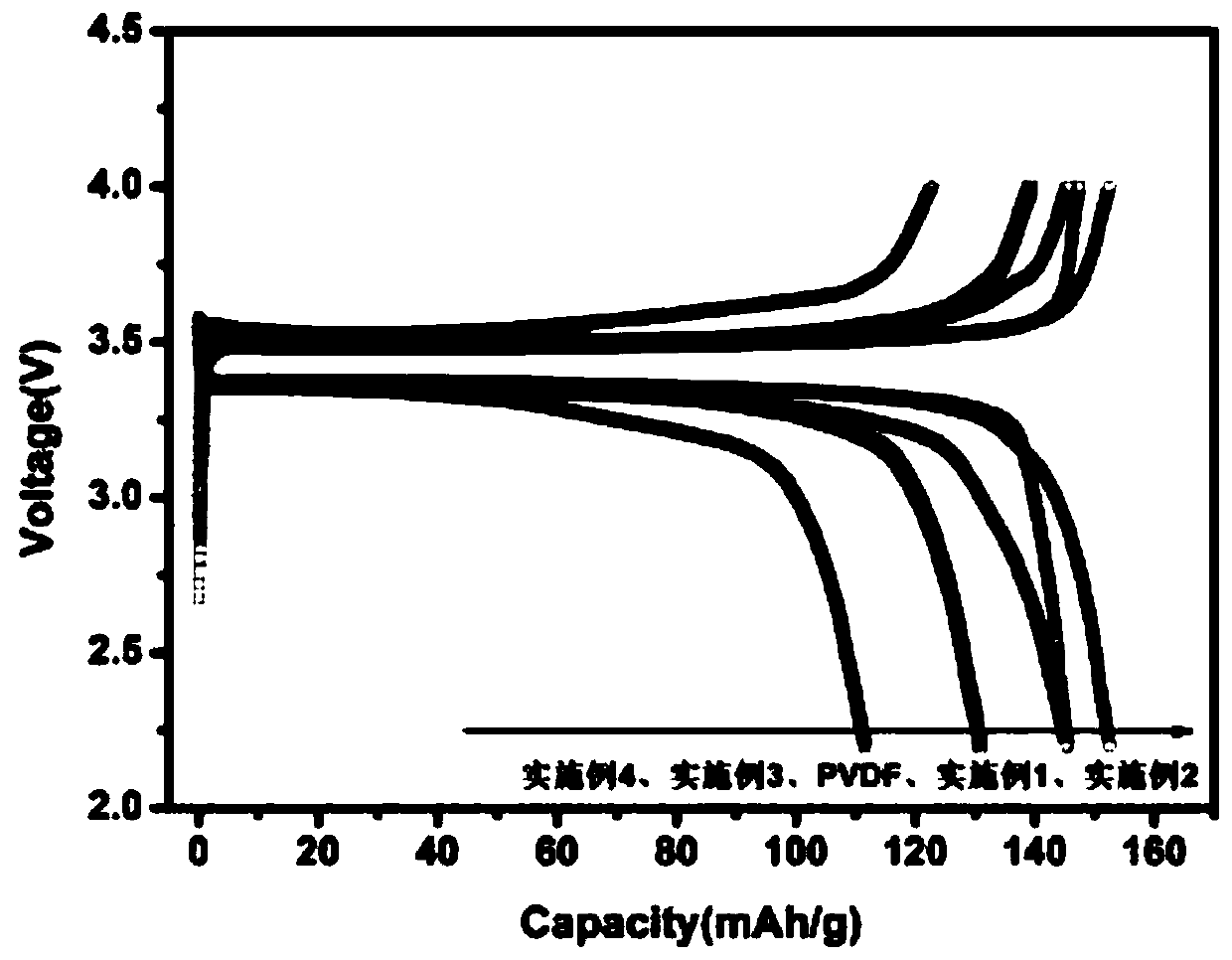

Preparation method for waterborne polyurethane binder and lithium-ion battery anode slurry containing waterborne polyurethane binder

InactiveCN110144033AImprove flexibilityNo demulsificationCell electrodesSecondary cellsHydrophilic monomerDistillation

The invention discloses a preparation method for a waterborne polyurethane binder and a lithium-ion battery anode slurry containing the waterborne polyurethane binder, and relates to the technical field of lithium ions. The preparation method for the waterborne polyurethane binder comprises the following steps: subjecting macromolecular dihydric alcohol to dehydration treatment, mixing dehydratedmacromolecular dihydric alcohol with diisocyanate, carrying out a reaction under heating, then carrying out cooling, adding a side-chain type nonionic hydrophilic monomer, carrying out a reaction under heating, then carrying out cooling, adding a micromolecular chain extender, a catalyst and a solvent, carrying out a reaction under heating, and carrying out cooling and discharging so as to obtaina prepolymer emulsion; and adding water into the prepolymer emulsion, carrying out emulsification under high-speed dispersion, then adding a diamine chain extender, and carrying out pressure-reduced distillation to remove the solvent so as to obtain a waterborne polyurethane emulsion with a side-chain structure. The polyurethane binder prepared by using the preparation method provided by the invention has good flexibility and excellent bonding performance, and is used in an anode slurry; and a button type lithium-ion battery assembled by using the anode slurry has large first discharge capacity and good cycle performance.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Microwave synthesis method for multi-element lithium manganate-doped positive electrode material of lithium ion battery

InactiveCN101800309AImprove the first discharge capacityGood charge and discharge cycle performanceCell electrodesElectrolysisSynthesis methods

The invention relates to a microwave synthesis method for a multi-element lithium manganate-doped positive electrode material of a lithium ion battery. The method comprises the following steps: adding deionized water into raw materials comprising lithium carbonate micropowder, industrial pure electrolytic manganese dioxide micropowder, analytical pure magnesium oxide micropowder, nickelic trioxide micropowder and chromic oxide micropowder to perform wet combination; mixing the raw materials with a ball mill; drying; mixing and sieving the dried products to serve as crude materials; shaping the crude materials into green bodies, and putting the green bodies into a microwave oven for sintering; and after the sintering is finished, taking the materials out, crushing and sieving the materials to obtain the lithium manganate-doped positive electrode material of the lithium ion battery. The material serving as a positive electrode active material can be used for preparing a positive plate of the lithium ion battery. The method has the characteristics of simpleness, energy saving and consumption reduction, low cost and contribution to industrial production; and the assembled lithium ion battery has the advantages of high initial discharge capacity and high charge and discharge cycling performance. The lithium manganate-doped positive electrode material of the lithium ion battery obtained by the method can be applied to electric automobiles, mobile phones, laptops and other equipment.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

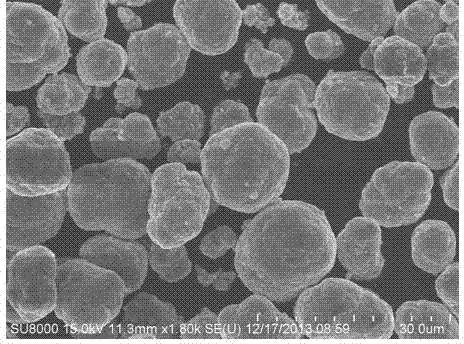

Surface modified graphitized interphase carbon micro-powder and preparation method thereof

ActiveCN102195036AIncrease compaction densityIncrease gram capacityCell electrodesSecondary cellsCapacitancePre treatment

The invention provides surface modified graphitized interphase carbon micro-powder and a preparation method thereof. The method comprises the following steps of: (1) performing pretreatment to crush the raw material of the interphase carbon micro-powder; (2) adding an additive and fully mixing; (3) performing graphitization treatment; and (4) performing ball-grinding and shaping treatment. As an anode material of a lithium battery, the obtained surface modified graphitized interphase carbon micro-powder has the advantages of the conventional interphase carbon canoed materials, improves the compacted density and the first discharge capacitance, reduces the specific area, produces cells with high comprehensive performance and therefore is a new replacement product of the interphase anode material.

Owner:福建杉杉科技有限公司

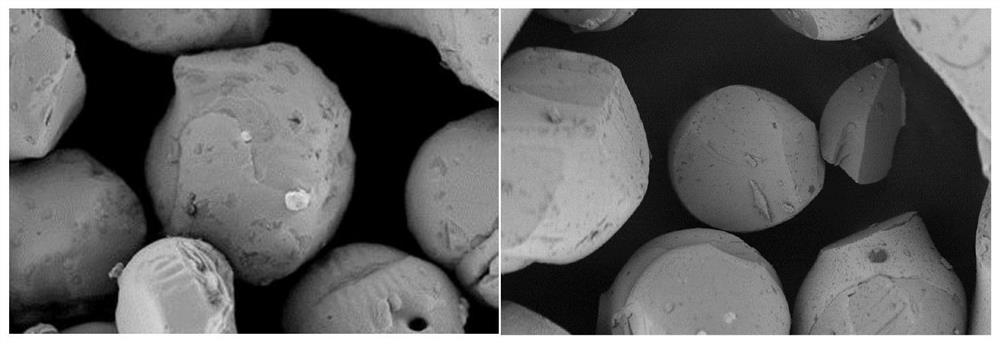

Prussian blue positive pole material and preparation method thereof, and electrochemical energy storage device

ActiveCN109698345AImprove the first discharge capacityReduce spreadCell electrodesSecondary cellsPhysical chemistryPrussian blue

The invention provides a prussian blue positive pole material and a preparation method thereof, and an electrochemical energy storage device. The molecular formula of the positive pole material is AxMc[M'(CN)6]y, wherein the A is one or more of H<+>, Li<+>, Na<+>, K<+> and NH4<+>, the M is transition metal, and M' is also the transition metal, 0 < x <= 2, 0 < y < 1, and 0 < c <= 1. The positive pole material has a porous structure and a high specific surface area, so that the diffusion and transmission path of ions and electrons can be obviously shortened, both the ion and electron conductiveproperties of the electrochemical energy storage device can be enhanced, and therefore, the cycle performance and rate performance of the electrochemical energy storage device can be improved; and thecontact with a conductive agent can be also increased, the electron conductive properties of the electrochemical energy storage device can be further enhanced, and the cycle performance and rate performance can be further improved as well.

Owner:CONTEMPORARY AMPEREX TECH CO

Lithium battery nickel-cobalt lithium manganate ternary anode material and preparation method thereof

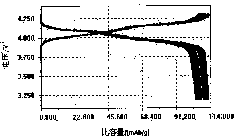

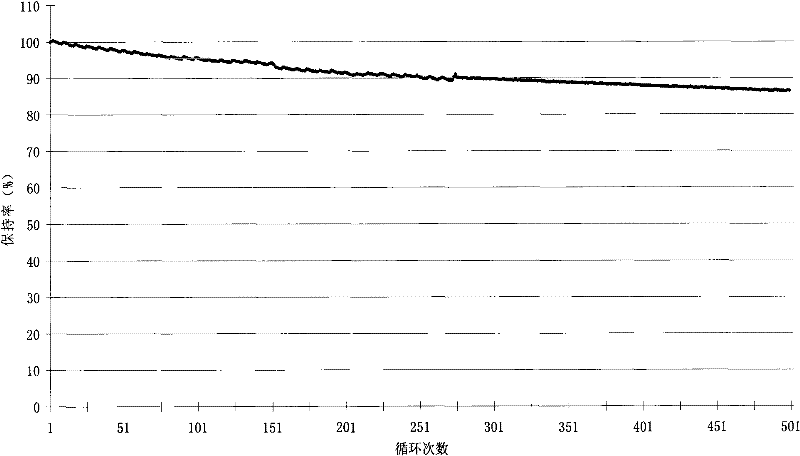

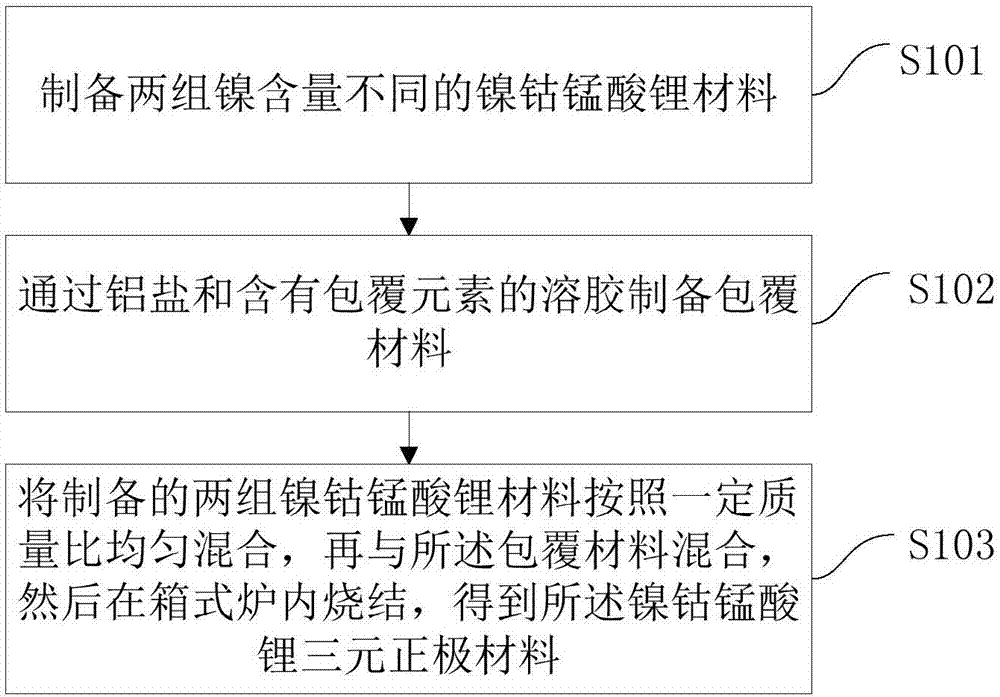

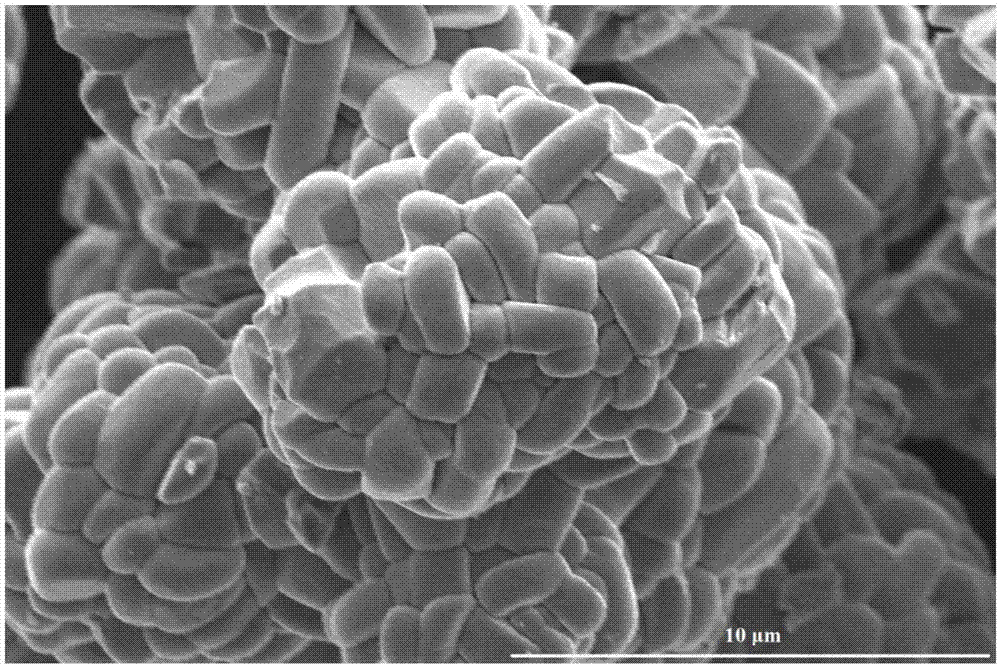

ActiveCN107302087AIncrease capacityCompact structureSecondary cellsPositive electrodesCobaltLithium battery

The invention is applicable to the field of lithium battery anode materials and provides a lithium battery nickel-cobalt lithium manganate ternary anode material and a preparation method thereof. The preparation method comprises the following steps: preparing two groups of nickel-cobalt lithium manganate materials of different nickel contents; preparing a coating material from an aluminum salt and sol with a coating element; uniformly mixing the two groups of the prepared nickel-cobalt lithium manganate materials according to a certain mass ratio, further mixing with the coating material, and sintering in a tank type furnace, thereby obtaining the nickel-cobalt lithium manganate ternary anode material. As the nickel-cobalt lithium manganate materials of different nickel contents are mixed, the specific capacity of the material is increased; and as the surface of the material is coated by the coating material with at least one element of Zr, Mg, Ti, Ce, La, Nb, Ba, V, Ni, Co, Mn and Al, the circulation property of the material can be improved. The material is simple in preparation process and is capable of ensuring excellent and stable product properties.

Owner:GEM (HUBEI) NEW ENERGY MATERIALS CO LTD

Carbon-coated high-capacity lithium-rich manganese ternary cathode material with MOF as carbon source and preparation method thereof

ActiveCN109742349AIncrease capacityImprove the first discharge capacityCell electrodesSecondary cellsNickel saltFiltration

The invention discloses a carbon-coated high-capacity lithium-rich manganese ternary cathode material with an MOF as a carbon source and a preparation method thereof. The preparation method comprisesthe following specific steps that (1) a solution containing lithium is added to a mixture solution containing manganese salts, nickel salts, cobalt salts, and ammonium persulfate, after stirring and mixing, hydrothermal reaction is conducted in a hydrothermal kettle, and after the hydrothermal reaction, a ternary lithium-rich manganese material is obtained by suction filtration, washing and drying; and (2) the ternary lithium-rich manganese material and the carbon source with a metal organic framework compound (MOF) as the main component are mixed and ball-milled through ball milling, after the ball milling, drying is conducted, obtained samples are heat-treated, and the carbon-coated high-capacity lithium-rich manganese ternary cathode material with the MOF as the carbon source is obtained. According to the carbon-coated high-capacity lithium-rich manganese ternary cathode material with the MOF as the carbon source, first discharge capacity is high, and cycle performance is good.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

Lithium-rich cathode material doped with lithium manganate at Mn site, and preparation method of lithium-rich cathode material

InactiveCN107994226AImprove thermal stabilityReduce churnCell electrodesCyclic processOxygen vacancy

The invention provides a lithium-rich cathode material doped with lithium manganate at a Mn site, and a preparation method of the lithium-rich cathode material. The preparation method of the lithium-rich cathode material doped with the lithium manganate at the Mn site comprises the following steps: evenly mixing a lithium source, a manganese source, doped metal salt and a metal complexing agent, carrying out ultrasonic gas atomization on the obtained mixture, and calcining to obtain spherical lithium manganate powder; mixing the obtained spherical lithium manganate powder with a spherical cathode material, coating and calcining. The lithium-rich cathode material provided by the invention is prepared by doping the lithium manganate at the Mn site, thus effectively inhibiting oxygen evolution and solving the problem of voltage drop in a circulating process; the tap density of powder can be improved by mixing, so that the energy density of the material is further improved; due to the stepof coating, the loss of oxygen vacancies and the migration of transition metal ions are reduced; after the lithium-rich cathode material is adopted, the first time efficiency is increased, the safetyperformance of batteries is improved, and the energy density of the material is improved.

Owner:桑顿新能源科技(长沙)有限公司

Lithium ion batteries cathode material and preparation method thereof

InactiveCN104752685AAchieve reversible exchangeAvoid decompositionCell electrodesChemical compositionPhysical chemistry

The invention discloses a lithium ion batteries cathode material and a preparation method thereof, and more specifically relates to the lithium ion batteries cathode material coated by orthosilicate and the preparation method thereof. A coating layer comprises the chemical composition of Li1+aMnbMcSiO4(M=Co, Ni, Fe, Mg, Al, Ti, Zr, and a is greater than or equal to -0.1 and less than or equal to 0.1, b is greater than 0 and less than or equal to 1.0, c is greater than or equal to 0 and less than or equal to 1.0). The cathode material has good overcharge resistance performance and thermostability. The preparation method is characterized in that orthosilicate and a salting liquid containing Mn(and M) are mixed to form sol, then a cathode material core is added, an orthosilicate coating layer containing Mn(and M) is formed on at least part of the surface of the cathode material core, and the lithium ion batteries cathode material can be obtained after heat treatment.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

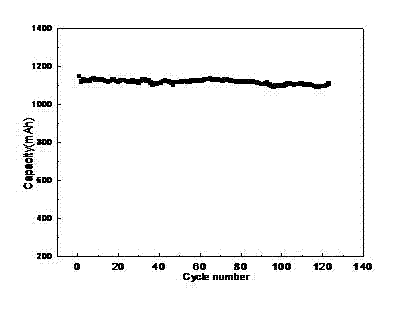

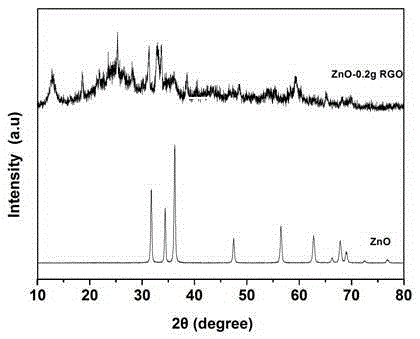

Preparing method and application of ZnO-Graphene lithium ion battery cathode material

InactiveCN105336935AImprove the first discharge capacityImprove cycle stabilityCell electrodesSecondary cellsButton batteryGraphite

The invention discloses a preparing method and application of a ZnO-Graphene lithium ion battery cathode material. According to the preparing method, ZnO is embedded into Graphene through a hydrothermal synthesis method, and a ZnO-Graphene compound is obtained. The ZnO-Graphene compound serves as the lithium ion battery cathode material to be assembled into a button cell, and charging and discharging tests are carried out at the electric current density of 40 mA / g. It is shown through results that the initial discharging capacity of ZnO is 1,222.1 mAh / g and is slightly different from the initial discharging capacity (1,299.5 mAh / g) of ZnO-Graphene, the circulation stability of ZnO is very poor, and the discharging capacity is reduced to 109.1 mAh / g at the fifth week. However, the discharging capacity of ZnO-RGO still is stilled maintained at 307.3 mAh / g at the fortieth week and is far higher than that of uncompounded ZnO, and the circulation stability of the ZnO-Graphene electrode material is far higher than that of uncompounded ZnO. The added graphene slows down the capacity fading and the volume effect of the electrode material, and thus the electric conductivity and circulation capacity of the material are improved.

Owner:TIANJIN NORMAL UNIVERSITY

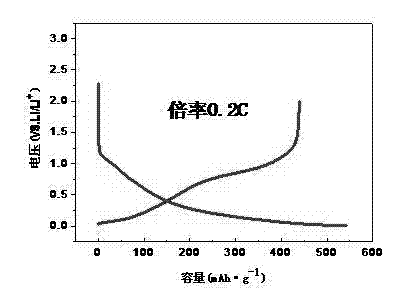

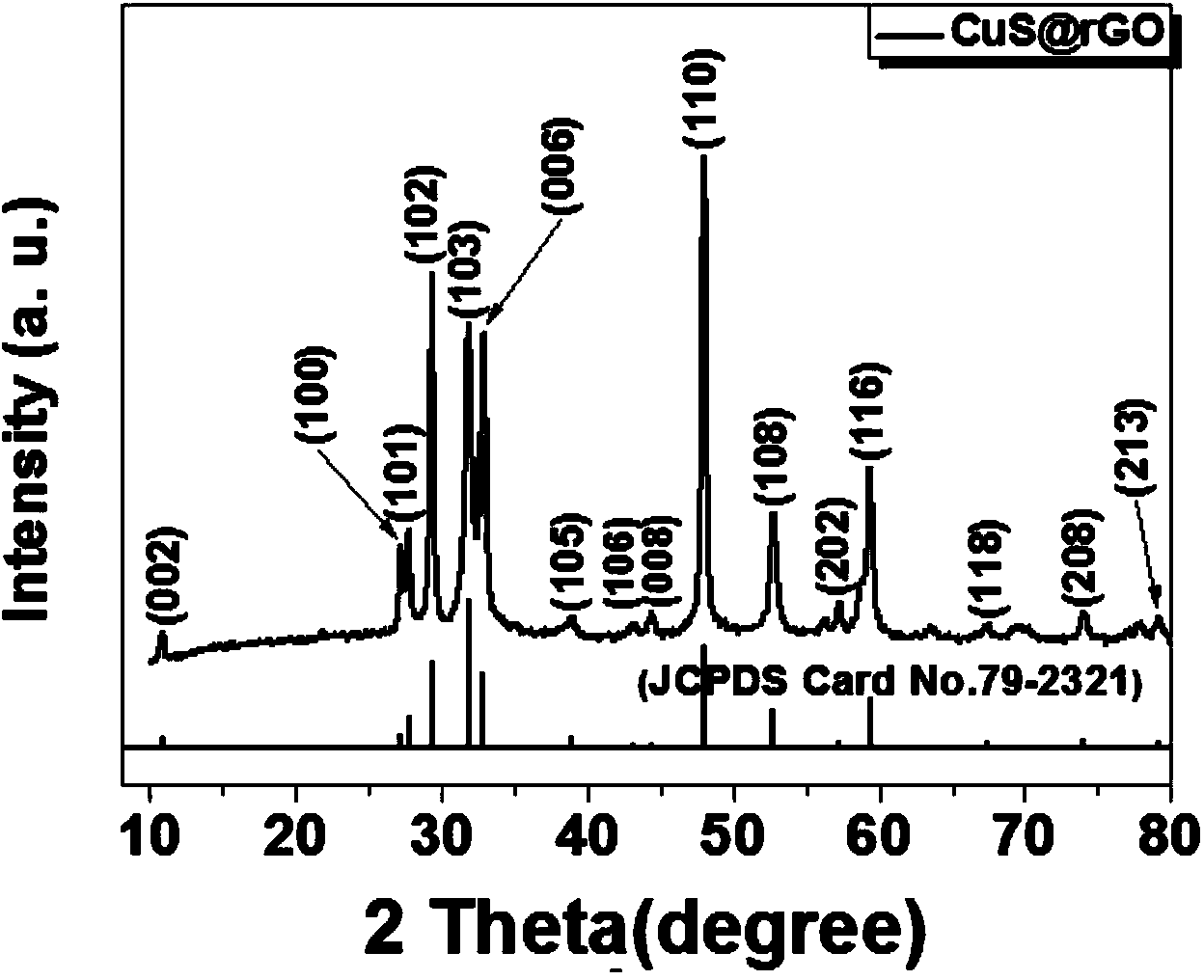

Anode material CuS@rGO of lithium ion battery and preparation method of anode material CuS@rGO

ActiveCN103730661AReduce volume expansion and shrinkageImprove cycle stabilityCell electrodesSecondary cellsSulfurSolvent

The invention belongs to the field of manufacture of optoelectronic devices and in particular relates to an anode material with good cycle performance of a lithium ion battery and a preparation method of the anode material. The preparation method comprises the following steps: with glutathione as a sulfur source, adhering Cu<2+> to the surface of GO in a waterborne solvent, and then carrying out reaction on the Cu<2+> and -SH in the glutathione by virtue of a hydrothermal method to form CuS nano-particles which are distributed in the GO; and then carrying out reduction on the GO to form rGO by virtue of a second hydrothermal method, thus forming the nano CuS / reducing grapheme composite, CuS@rGO. The CuS@rGO is used as the anode material of the lithium ion battery and is very high in the first discharge capacity, the reversible capacity and the coulomb efficiency.

Owner:CHANGZHOU UNIV

Li-O site lithium manganate doped lithium-enriched positive electrode material and preparation method thereof

ActiveCN108091858AIncrease energy densityImprove securityMaterial nanotechnologyCell electrodesLithiumOxygen vacancy

The invention provides a Li-O site lithium manganate doped lithium-enriched positive electrode material and a preparation method thereof. The Li-O site lithium manganate doped lithium-enriched positive electrode material is prepared through mixing a manganese source, a lithium source and an element lithium doped compound and then carrying out a process including solid-phase sintering, wet-processcladding, material mixing and calcination. The prepared positive electrode material realizes doping on a Li site and an O site of lithium manganate and the aims of effectively inhibiting oxygen evolution, improving the rate performance, keeping an oxygen vacancy in a charging process, improving the initial efficiency, improving the safety performance of a battery and improving the energy density of the material are realized.

Owner:余姚市海泰贸易有限公司

Lithium ion battery negative electrode active material, lithium ion battery negative electrode, lithium ion battery, battery pack and battery power vehicle

ActiveCN109553085AImprove the first discharge capacityImprove discharge rateMaterial nanotechnologyFinal product manufactureAluminium-ion batteryDesorption

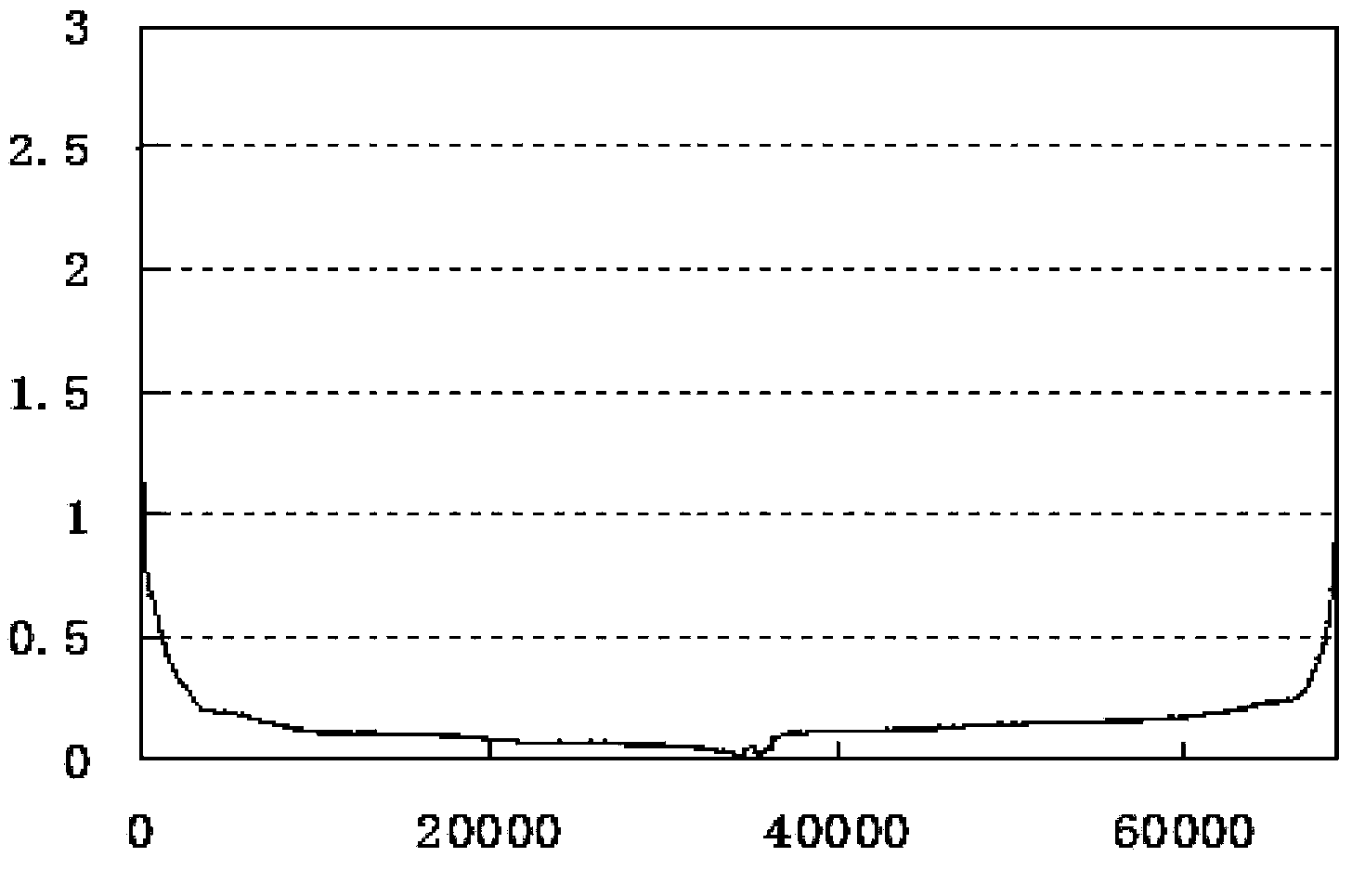

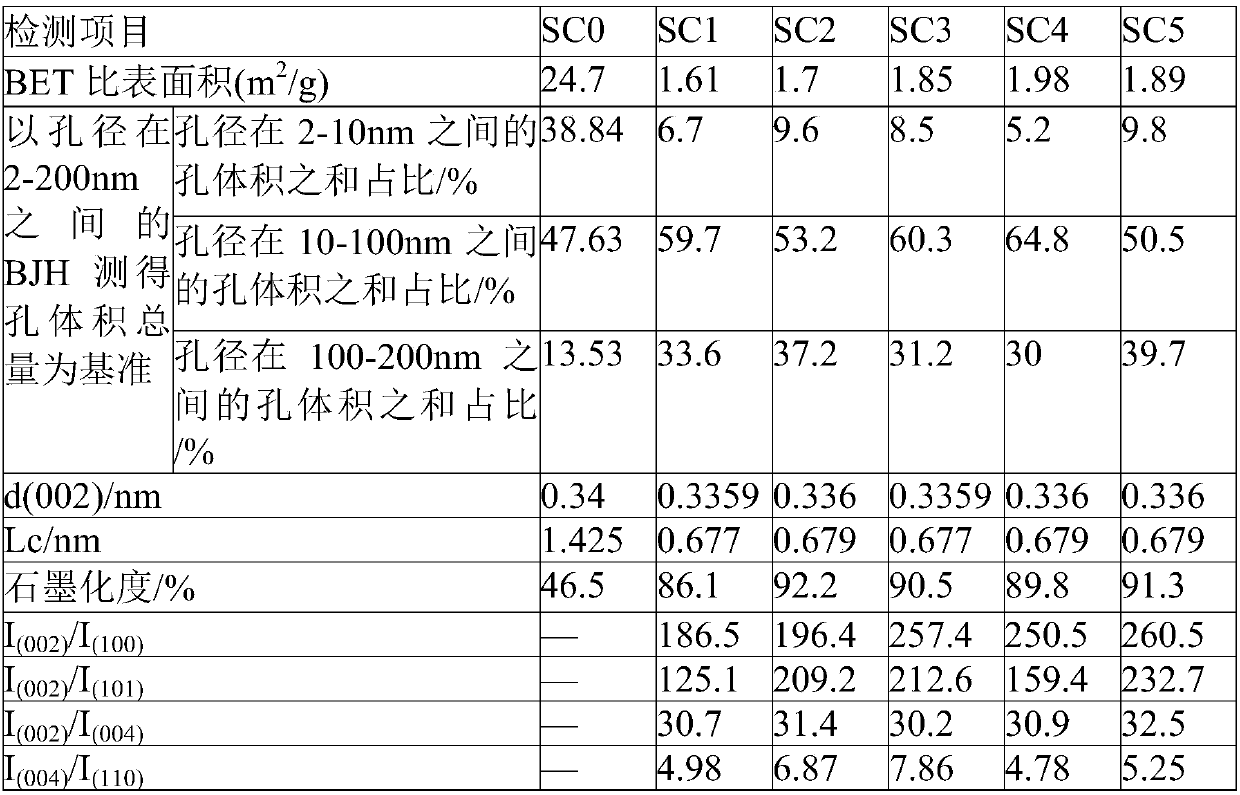

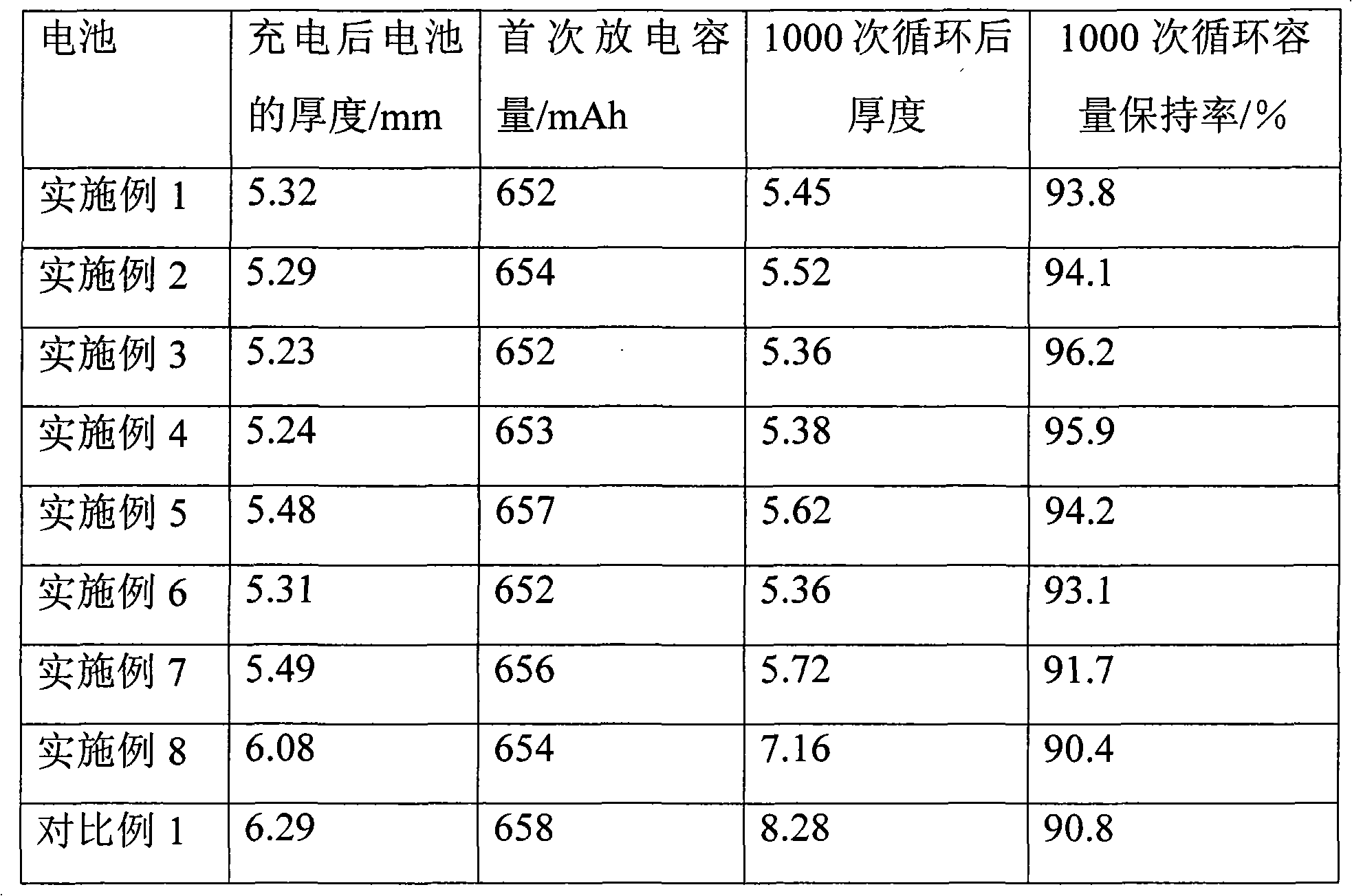

The invention relates to the field of lithium ion battery negative electrode carbon materials, particularly to a lithium ion battery negative electrode active material, a lithium ion battery negativeelectrode, a lithium ion battery, a battery pack and a battery power vehicle. According to the present invention, in the pore structure, measured through N2 adsorption and desorption, of the lithium ion battery negative electrode carbon particles, by using the total pore volume measured by BJH having a pore size of 2-200 nm as the reference, the sum of the volumes of pores with a pore size of 2-10nm is 5-10%, the volumes of pores with a pore size of 10-100 nm account for 50-65%, the volumes of pores with a pore size of 100-200 nm account for 30-40%, and the carbon particles have a BET specific surface area of 1-4 m<2> / g, preferably 1.4-1.9 m<2> / g. According to the present invention, the button cell made of the carbon particles has a charging capacity of 392-403.65 mAh / g and a discharge capacity of 360-373 mAh / g, and the discharge capacity at 5C rate is maintained at 1985.7-2029.8 mAh after the button cell is assembled into the columnar battery.

Owner:HUNAN JINYE HIGH TECH CO LTD

Electrode material and lithium ion battery with same

InactiveCN101901891ASolve flatulenceImprove securityFinal product manufactureActive material electrodesMaterials scienceLithium electrode

The invention provides an electrode material, which comprises an electrode active material, binder and metal hydride, can well solve the swollen problem of the lithium ion battery, in particular the swollen problem of the lithium ion battery containing lithium titanate, hard carbon, soft carbon and other easy-absorbent anode active materials, can well control the quality of the battery in a use process, and improve the quality and safe performance of the lithium ion battery. The invention also provides the lithium ion battery containing the electrode material, and has excellent circulating performance and higher first discharge capacity.

Owner:BYD CO LTD

A lithium supplemental additive and its preparation method are provide

ActiveCN109004195AAvoid safety hazardsThe preparation method is simple and reliableFinal product manufactureCell electrodesCharge dischargeLithium-ion battery

The invention discloses a lithium supplement additive and a preparation method thereof, and a lithium ion battery containing the lithium supplement additive. A lithium supplemental additive is a powerparticle, that median particle size D50 is greater than or equal to 0.1 mu m and less than or equal to 20 mu m, and the chemical formula is xLi 2O. YM. ZNaOb, wherein, y) 0, z) 0, 2x-Y-Z*a)0.1, b)0;M is one or more of Co, Mn and N is one or more of Co, Mn, Al and Ti. The lithium supplement additive is combined with metal lithium, Compared with organic lithium, organic lithium is more stable andsafer. When added in lithium ion battery, organic lithium can provide lithium source during the first charge, which can compensate the lithium consumption when the positive electrode and negative electrode form SEI film, improve the first discharge capacity, cycle performance and energy density, and is especially suitable for the negative electrode system with low first charge-discharge efficiency.

Owner:安普瑞斯(无锡)有限公司

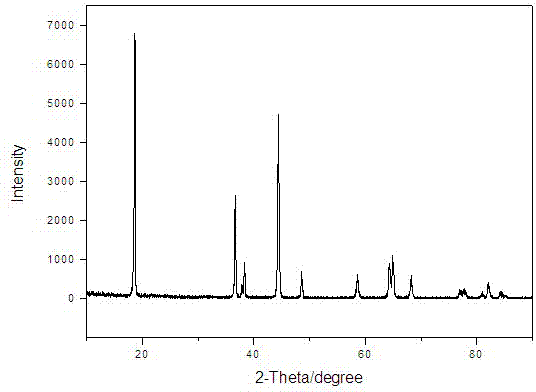

Preparation method for rare-earth-doped high-compaction ternary material

ActiveCN103840133AImprove the first discharge capacityHigh yieldCell electrodesSecondary cellsLithium carbonateChemistry

The invention discloses a preparation method for a rare-earth-doped high-compaction ternary positive material. The preparation method comprises the following steps: adding lithium carbonate powder into a star-shaped ball mill; adding an amides reagent solution of a rare earth oxide (R2O3) into the lithium carbonate powder; then adding a ternary precursor; selecting absolute ethyl alcohol as a liquid medium and carrying out ball milling for 90+ / -30 minutes, wherein the mol ratio of Li / M(Ni+Co+Mn) is 1.05+ / -0.02 and the mol ratio of R / M(Ni+Co+Mn) is 0.010+ / -0.005; drying the materials which are subjected to the ball milling in vacuum; sintering for the first time; dispersing and grading the sintered materials and washing by de-ionized water; sintering for the second time and dispersing to obtain liquid-phase doped rare earth-ternary material powder; putting the powder into a permeation furnace; and expanding and permeating in N2 of 500-650 DEG C for 3-6 hours to obtain target grains. The prepared doped ternary material is compacted and the primary discharging capacity is obviously improved.

Owner:四川兴能新材料有限公司

Preparation method of manganese containing nickel cobalt lithium oxide

InactiveCN1753213AImprove the first discharge capacityReduce production processAlkaline accumulator electrodesLithium oxideLithium hydroxide

The invention relates to a method for preparing Mn-containing NiCoLi oxide in the technical field of Li-ion battery anode material, mainly mixing lithium hydroxide or lithium carbonate with bivalent Ni source, bivalent Mn source, bivalent Co source and compound of doping element, then adding in solvent for ball-milling, drying and screening, and finally sintering in the air to make it. The method reduces producing procedures and production cost; by doping and special processing modes, improves circulating stability and raises primary discharging content, thus playing the role in promoting the development of Li-ion batteries.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

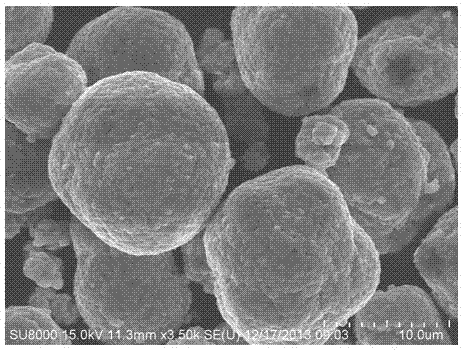

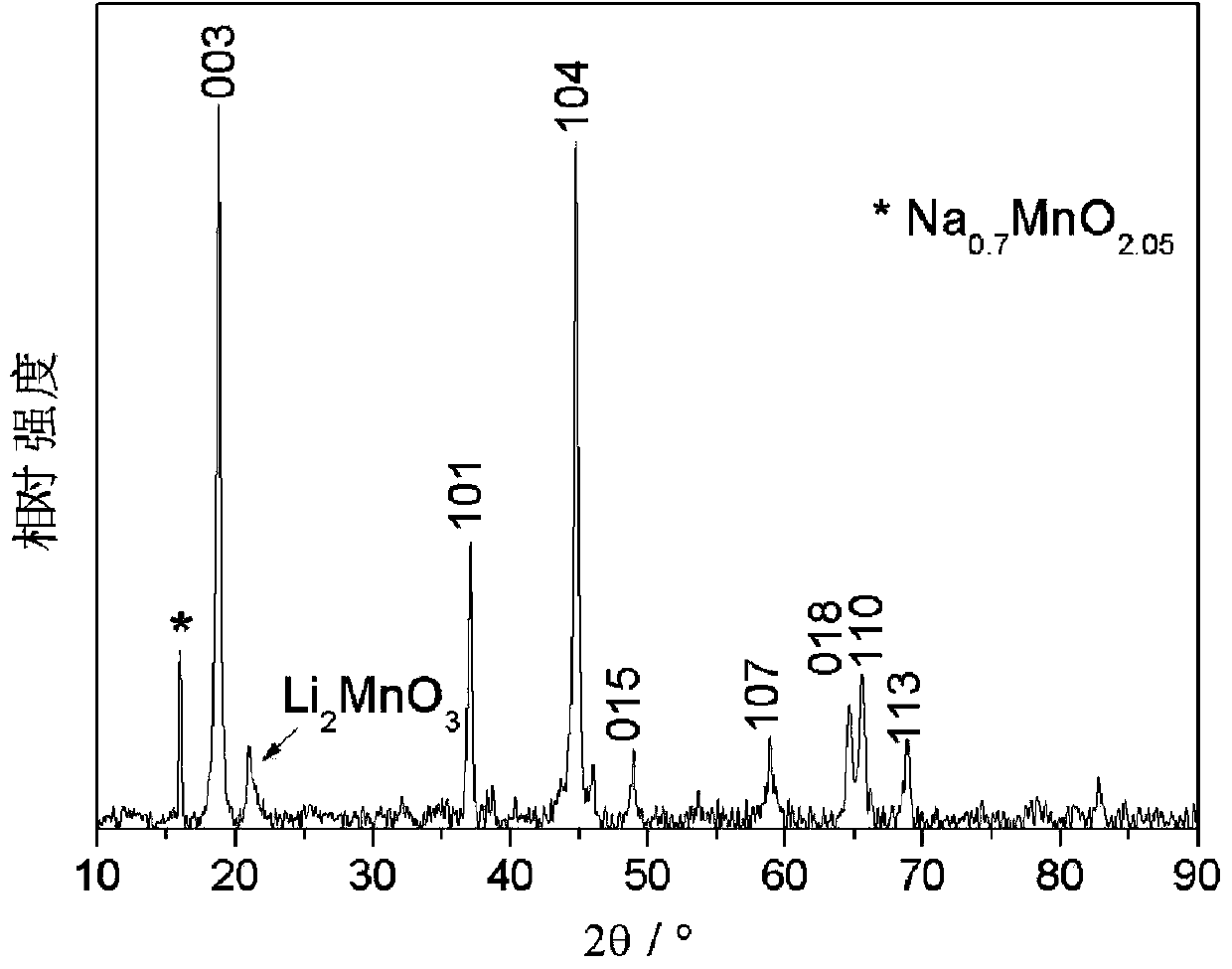

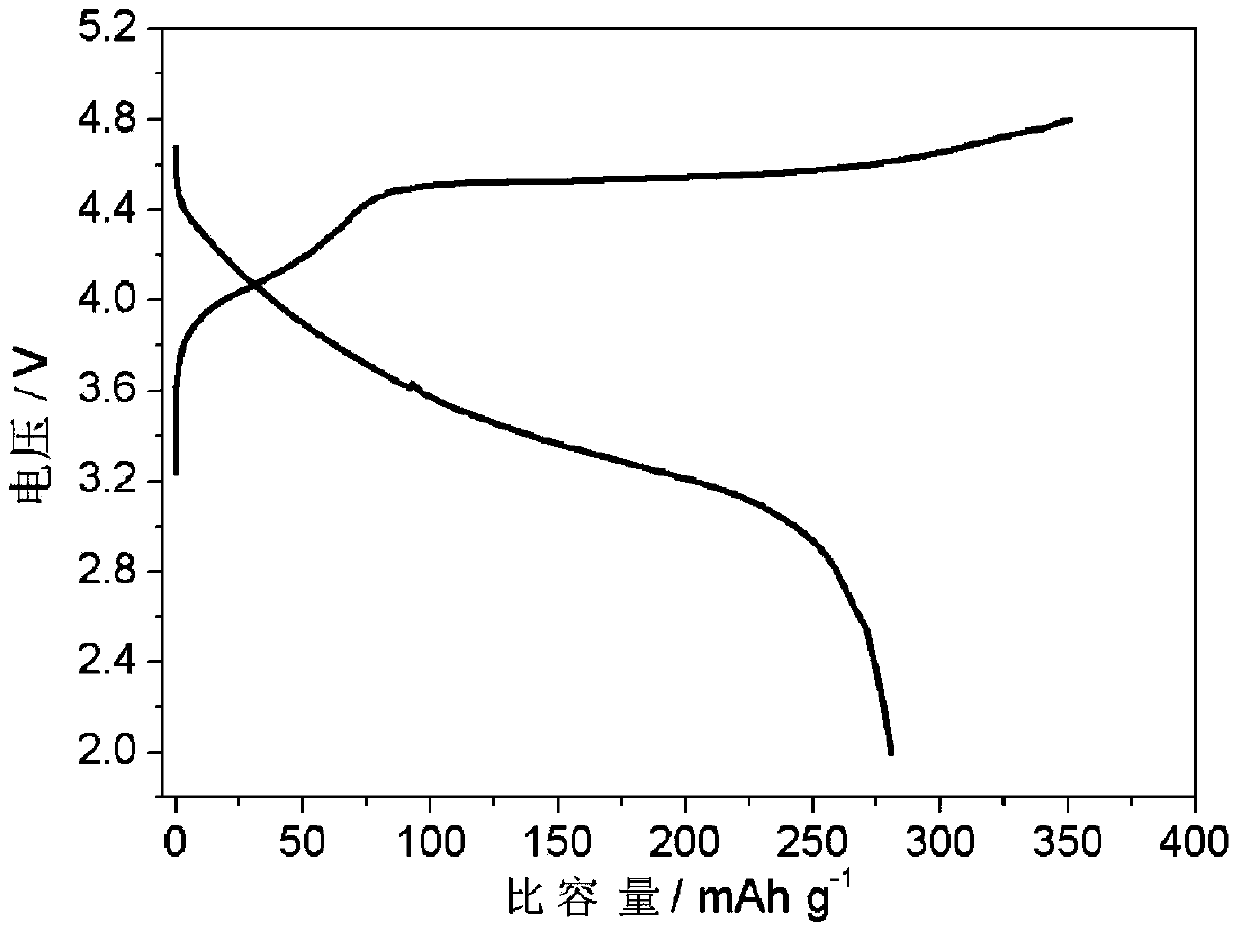

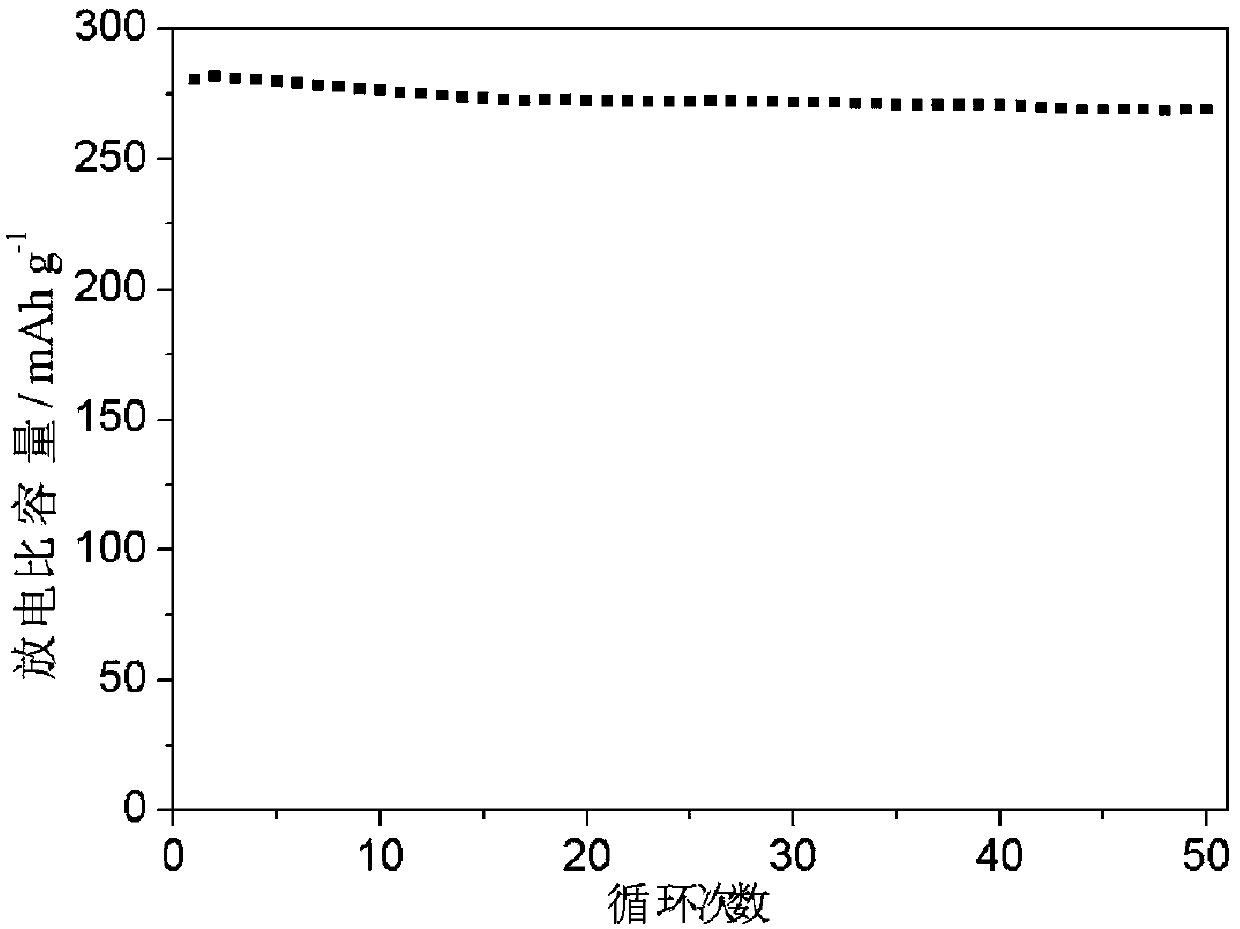

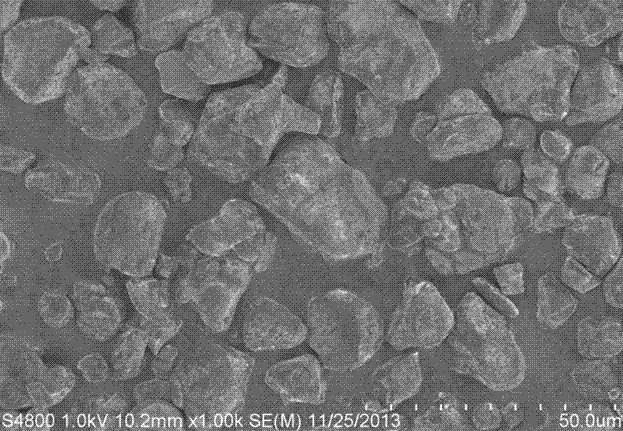

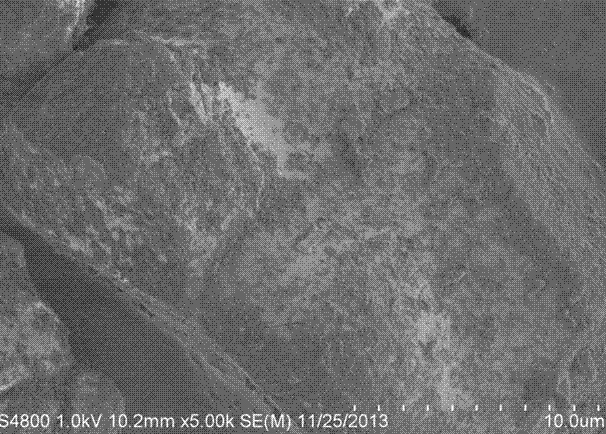

Manufacturing method for layered lithium manganate cathode material for lithium ion battery

InactiveCN102249341AImprove the first discharge capacityImprove cycle performanceManganates/permanganatesElectrolysisSesquioxide

The invention relates to a manufacturing method for a layered lithium manganate cathode material for a lithium ion battery, which adopts electrolytic manganese dioxide as a raw material, and comprises the following steps: performing high-temperature calcination to obtain manganese sesquioxide; mixing the manganese sesquioxide and anhydrous sodium carbonate according to a molar ratio of 1:1, performing sintering to obtain NaMnO2; weighing a lithium source and NaMnO2 according to a molar ratio of 6-10:1, filtering the mixed solution, washing the precipitates, drying to obtain the layered lithium manganate. The layered lithium manganate of a lithium ion battery cathode manufactured by the invention has a charge capacity of above 200 mAh / g, and a discharge capacity of above 180 mAh / g, and has a high first discharge capacity, and good cycle performance.

Owner:耿世达

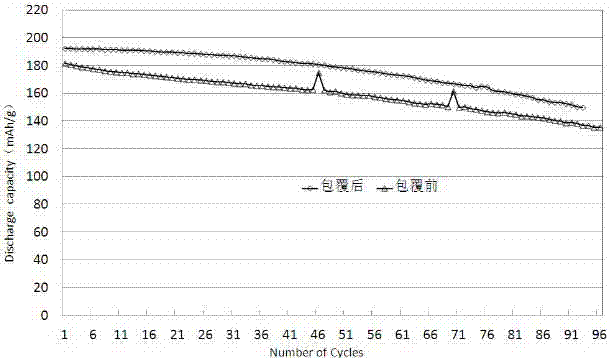

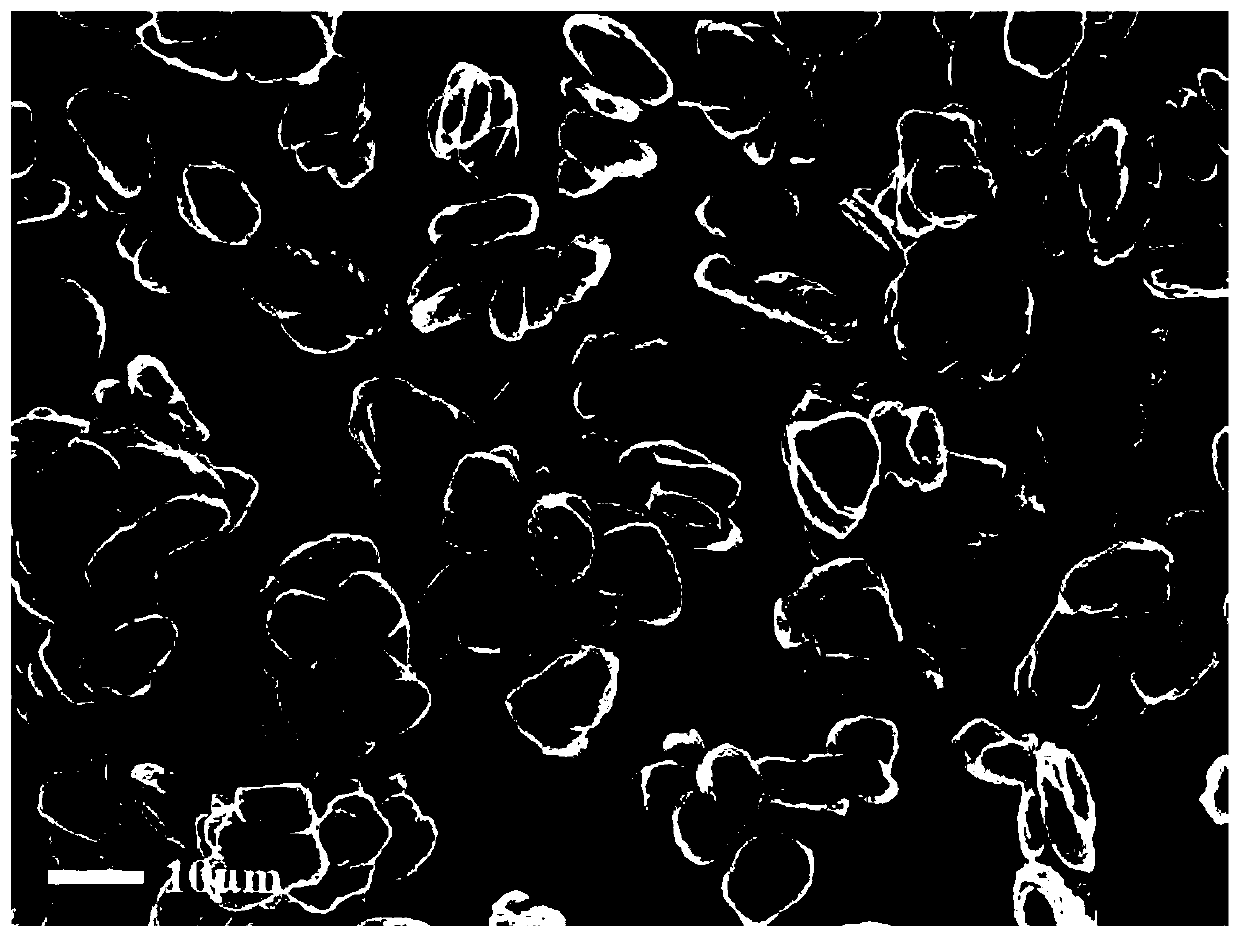

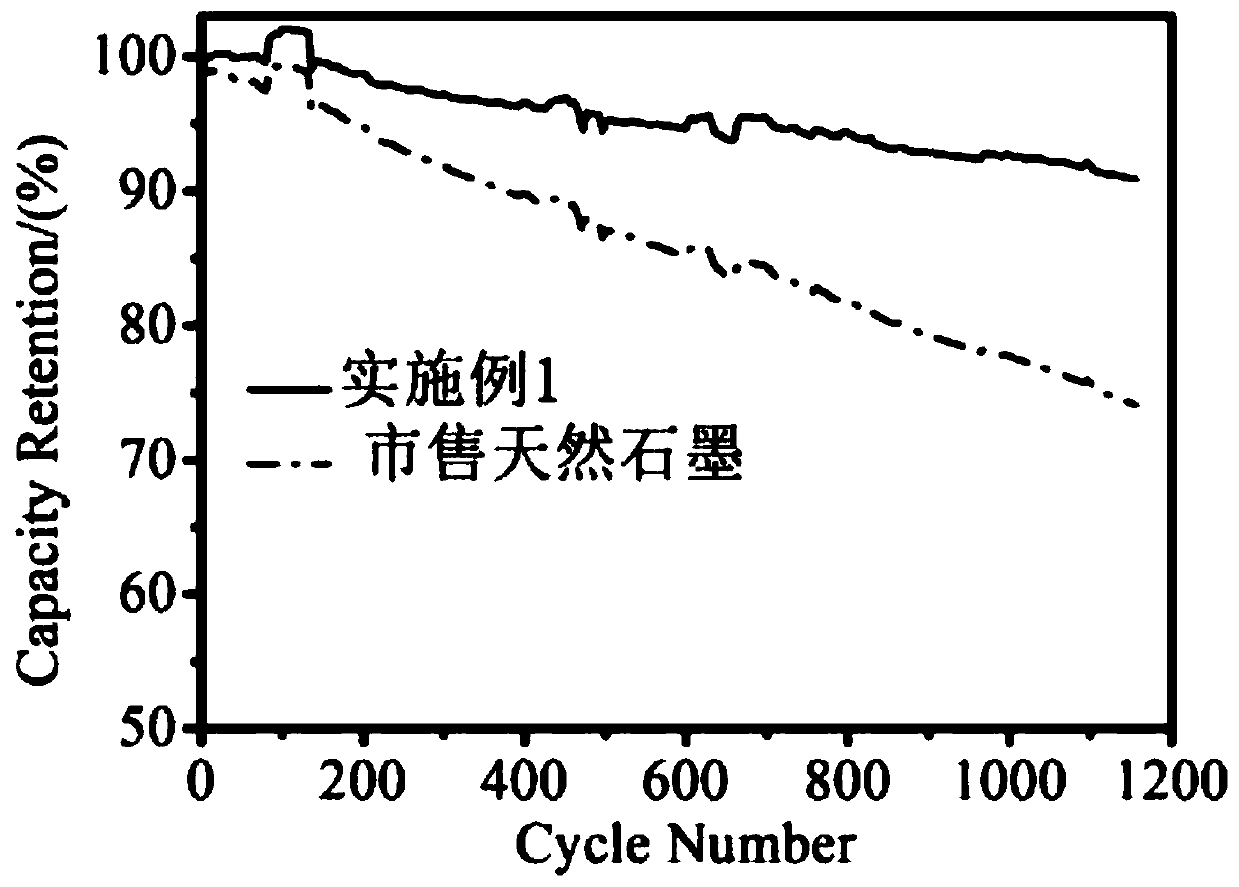

Modification method for natural graphite, modified natural graphite and application of modified natural graphite

PendingCN110775971AReduce surface defectsImprove isotropyGraphiteNegative electrodesPhysical chemistryBattery cell

The invention discloses a modification method for natural graphite, modified natural graphite and an application of the modified natural graphite. The modification method for the natural graphite includes the following steps: S1, performing high-temperature treatment on the natural graphite in an air atmosphere to partially oxidize the natural graphite to obtain partially oxidized natural graphite; and S2, mixing the partially oxidized natural graphite and a liquid-phase coating agent, performing high-temperature carbonization treatment in an inert atmosphere, and performing graphitizing to obtain the modified natural graphite. The modified natural graphite prepared by the method has a simple production process, and a lithium ion battery anode material prepared from the modified natural graphite has the advantages of stable performance, low costs, and excellent cycle performance.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

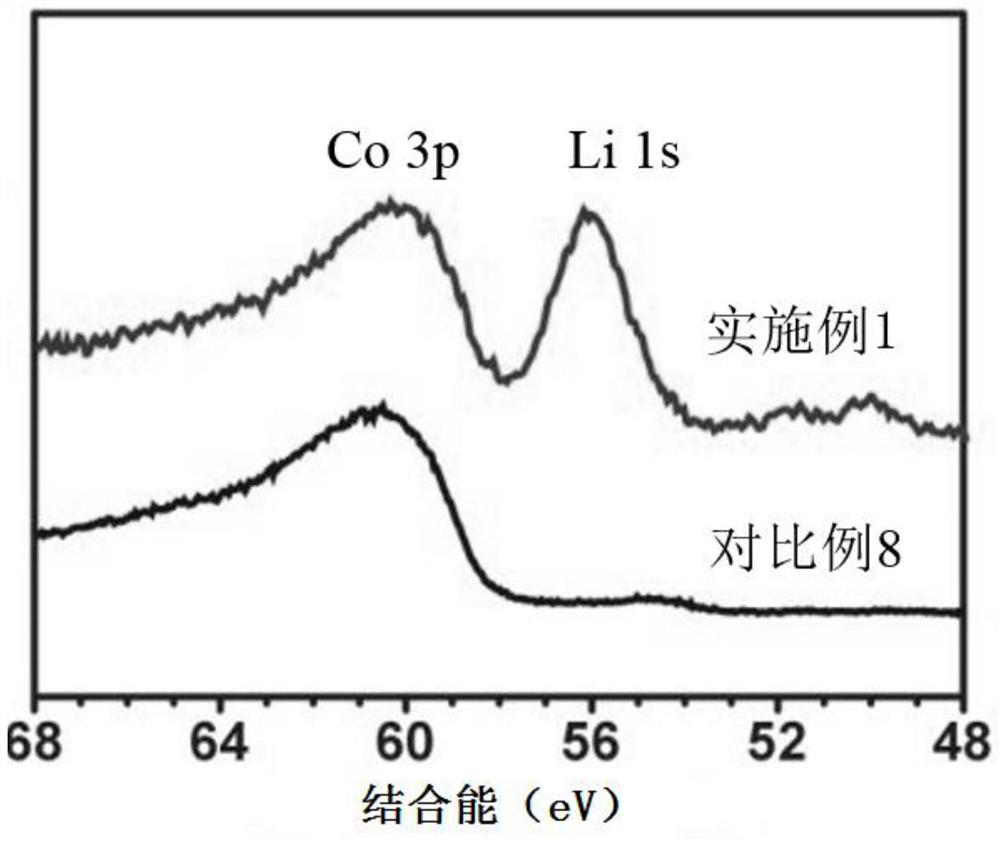

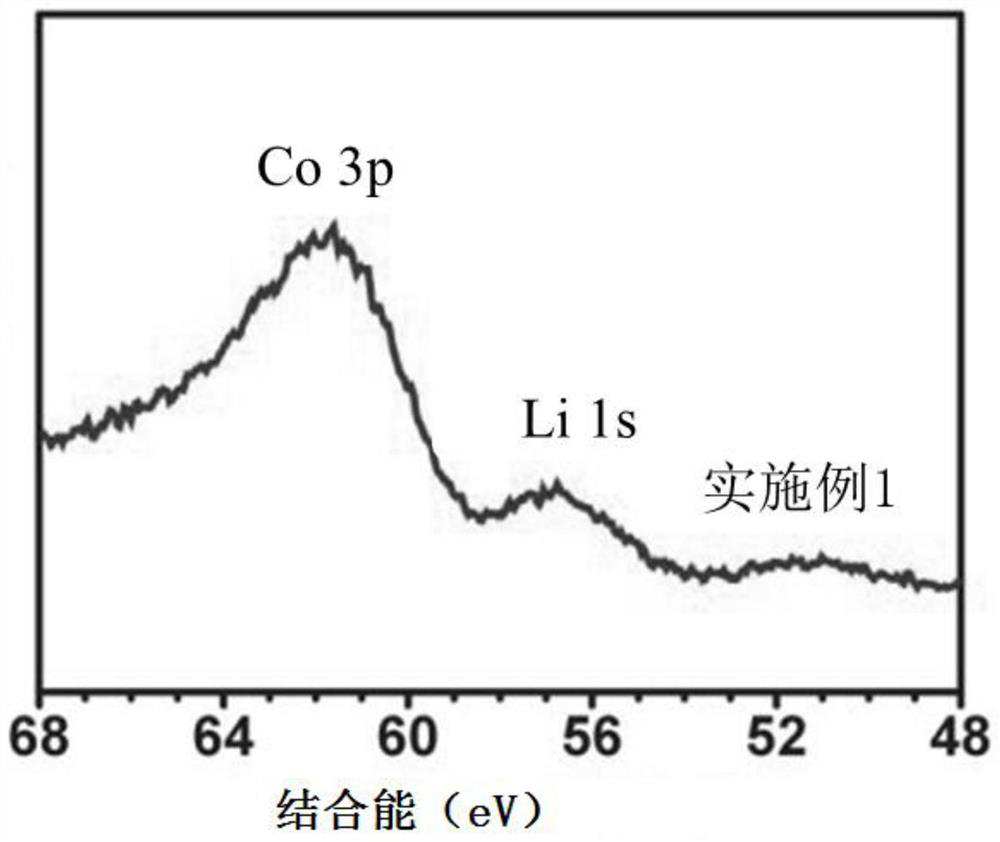

Pre-lithiated lithium ion positive electrode material and preparation method and application thereof

ActiveCN111799457AImprove structural stabilityHigh interface activityPositive electrodesCobalt compoundsLithiumPhysical chemistry

The invention discloses a pre-lithiated lithium ion positive electrode material and a preparation method and application thereof. The chemical formula of the lithium ion positive electrode material isLi2O / [A(3-x)Mex]1 / 3-LiAO2, A comprises M, and M is at least one of Ni, Co and Mn; Me is at least one of Ni, Mn, Al, Mg, Ti, Zr, Y, Mo, W, Na, Ce, Cr, Zn or Fe; and 0 < x < 0.1. Multiple elements areco-doped and have a synergistic effect, so that irreversible phase change under high voltage is inhibited, and the structural stability of the base material is improved; the spinel phase A(3-x)MexO4 structure contains doping elements, the interfacial activity of the material is improved through combined action, and more electrochemical active sites are introduced.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

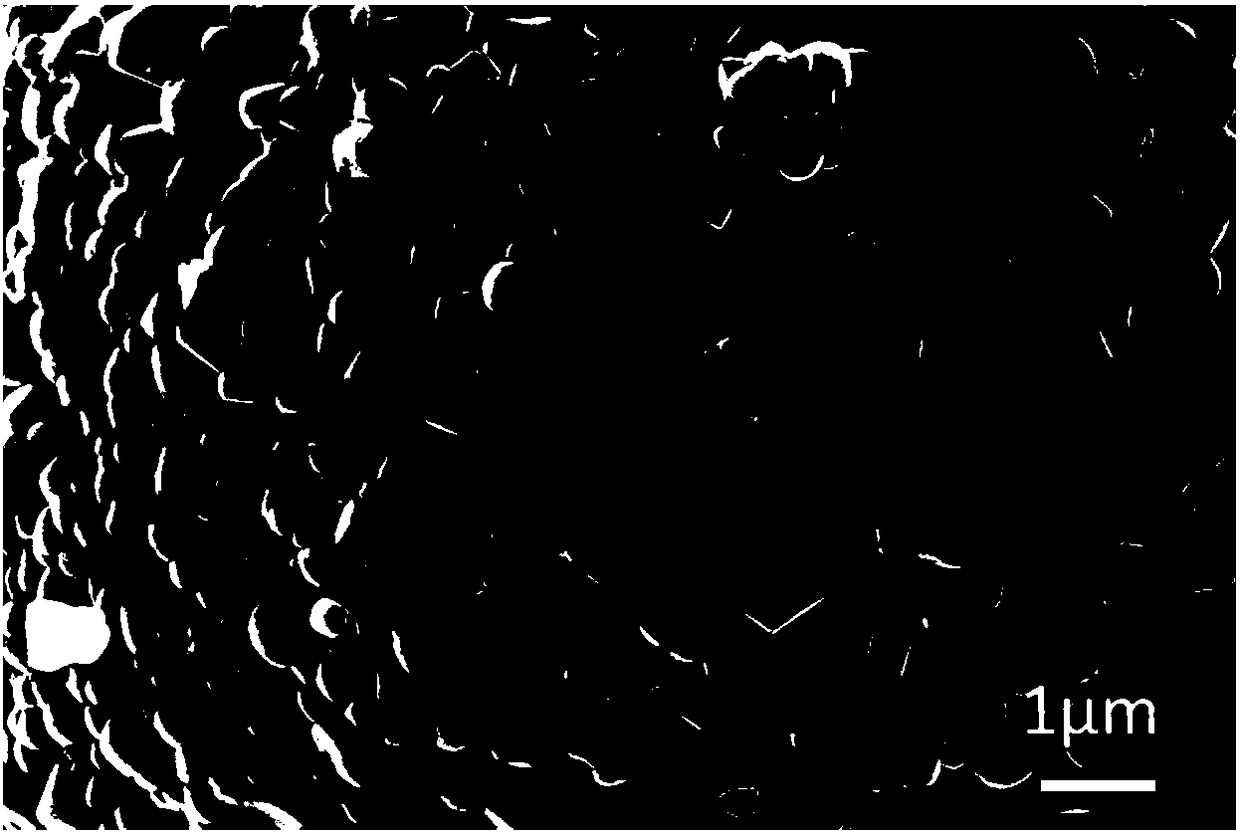

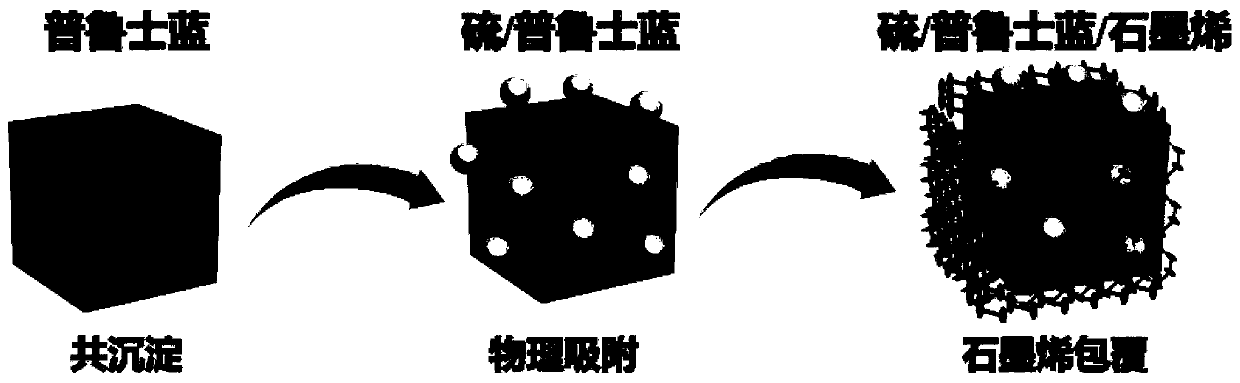

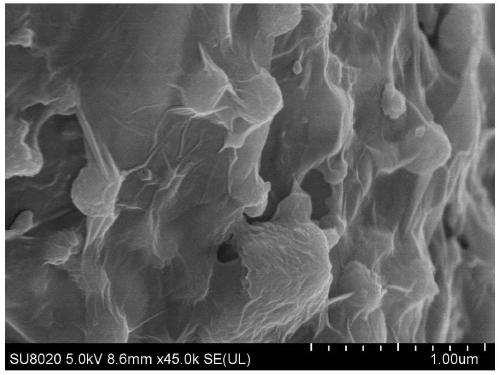

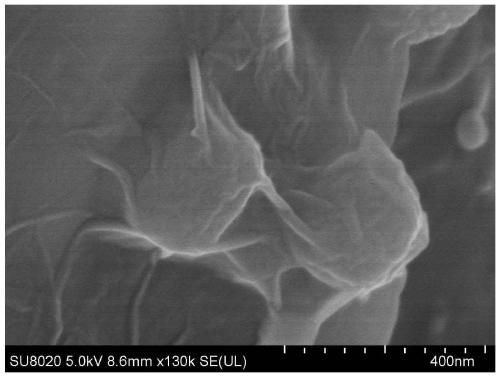

Preparation method and application of graphene/sulfur/prussian blue analogue composite material

ActiveCN111048762AInhibition of the shuttle effectSpecial layered structurePositive electrodesLi-accumulatorsFreeze-dryingLithium sulfur

The invention discloses a preparation method and application of a graphene / sulfur / prussian blue analogue composite material, and belongs to the field of preparation methods of lithium-sulfur battery materials. The preparation method comprises the steps: adding prussian blue analogue and sulfur powder into a certain volume of carbon disulfide solution, uniform stirring, evaporating the carbon disulfide solution to dryness at a certain temperature, centrifugally washing the obtained product with distilled water, and drying to obtain the sulfur / prussian blue analogue composite material; and diluting a graphene aqueous suspension with a certain concentration, ultrasonically dispersing for a certain time, adding a certain mass of sulfur / prussian blue analogue composite material, adding a certain volume of hydrazine hydrate, stirring for a certain time, washing the obtained product with distilled water, and carrying out vacuum freeze drying to obtain the graphene / sulfur / prussian blue analogue composite material. The first discharge capacity is as high as 850mAh / g; and the capacity can be kept at 900mAh / g under the multiplying power of 0.5 C, and the excellent multiplying power performance is realized.

Owner:HARBIN UNIV OF SCI & TECH

Lithium-intercalated metal oxide and preparation method and application thereof

ActiveCN111977706AImprove the first discharge capacityHigh capacity retentionSecondary cellsPositive electrodesLithium metalPhysical chemistry

The invention belongs to the field of lithium ion batteries, and relates to a lithium-intercalated metal oxide and a preparation method and application thereof. The preparation method of the lithium-intercalated metal oxide comprises the following steps: sequentially carrying out chemical corrosion crystallization reaction, magnetic separation, solid-liquid separation and washing on nickel-containing metal and / or nickel-containing metal oxide, an oxidant I, water and a complexing agent, pre-sintering the obtained nickel-containing metal hydroxide in an oxidizing atmosphere at the temperature of 180-350 DEG C for 2-10 hours, and sequentially carrying out lithium intercalation reaction, solid-liquid separation and calcination on the obtained nickel-containing precursor, an alkali metal compound, an oxidant II, water and an optional additive. The lithium-intercalated metal oxide prepared by the method provided by the invention is used as a lithium ion battery cathode material, so that thefirst discharge capacity and capacity retention rate of the lithium ion battery can be effectively improved. In addition, no wastewater is generated in the chemical corrosion crystallization reactionprocess, and water is continuously consumed, so that the purpose of environmental friendliness can be achieved.

Owner:XTC NEW ENERGY MATERIALS(XIAMEN) LTD

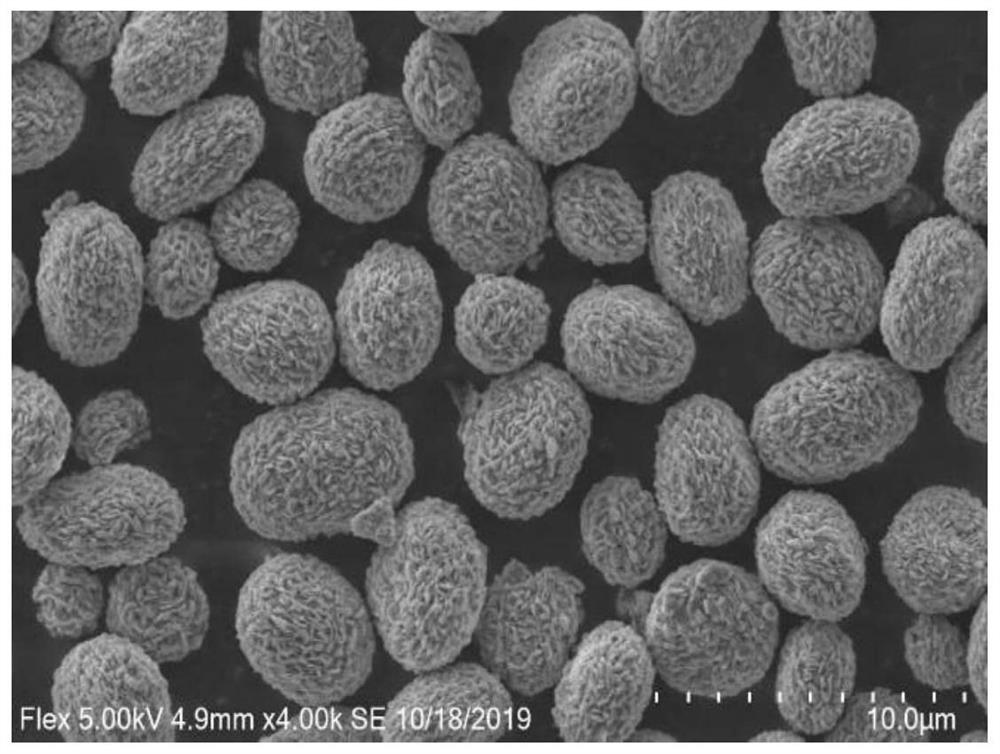

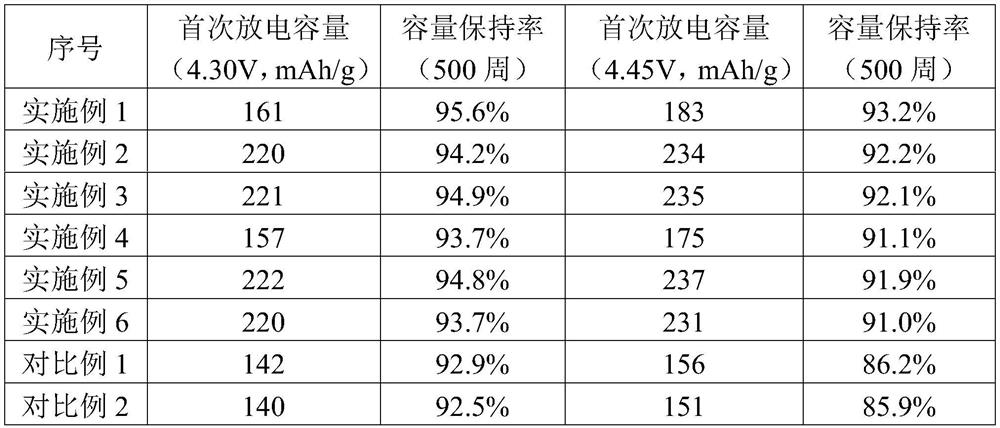

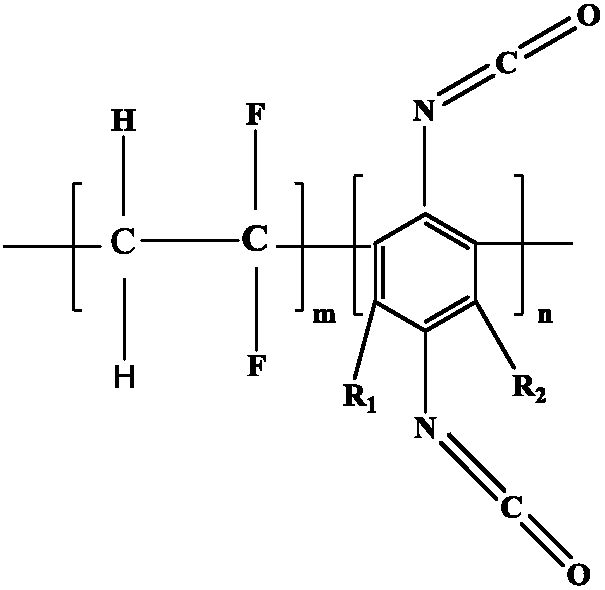

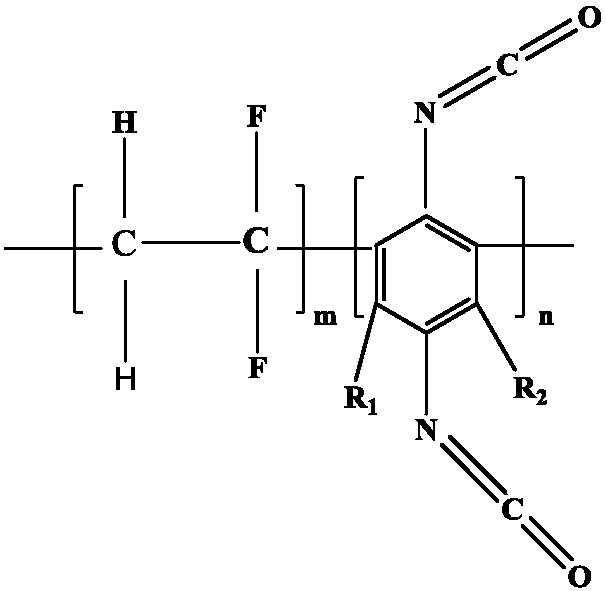

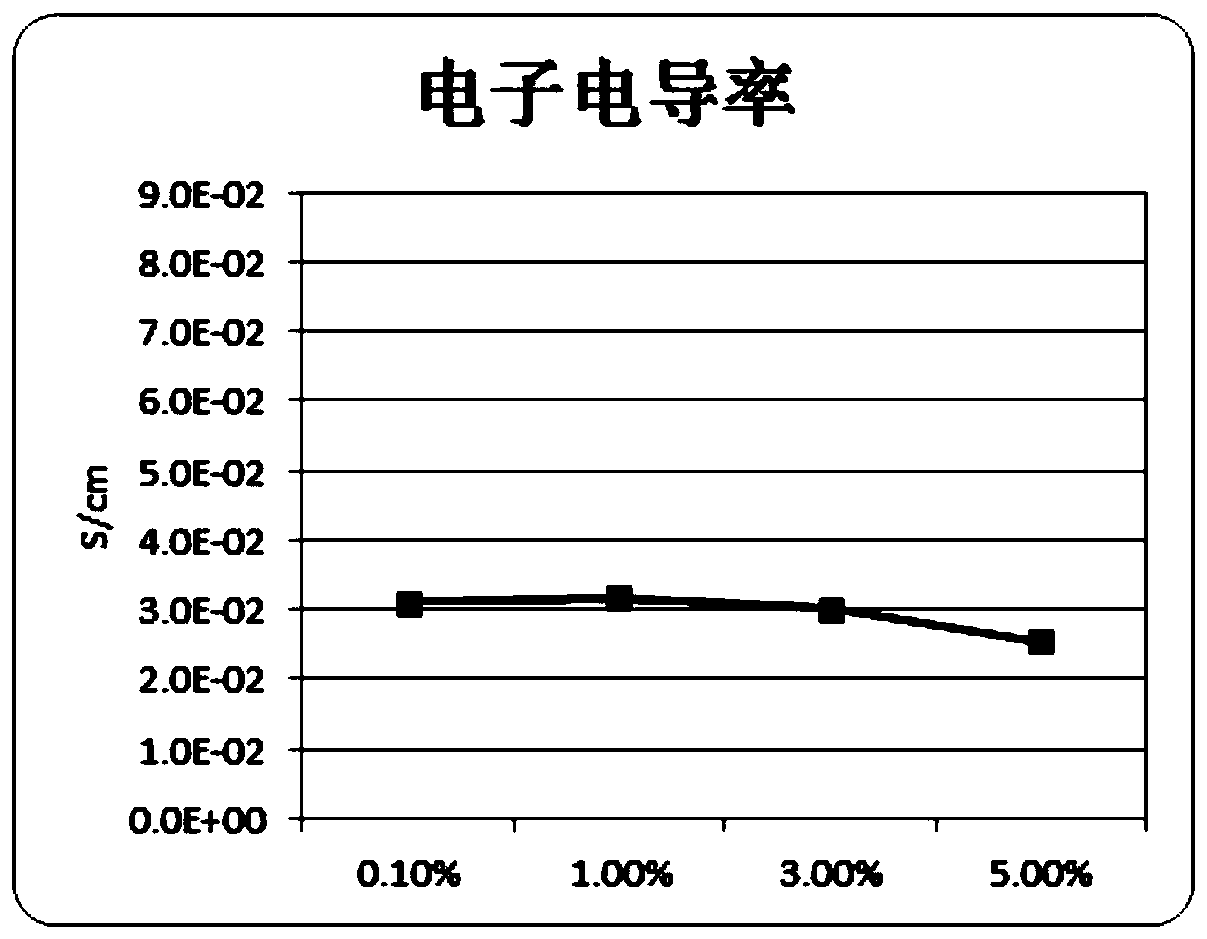

Cyanate ester modified PVDF binder, positive pole piece applying same and lithium-sulfur battery

InactiveCN108565465AImprove conductivityImprove the first discharge capacityCell electrodesLi-accumulatorsCyclic processPole piece

The invention discloses a cyanate ester modified PVDF binder, a positive pole piece applying the same and a lithium-sulfur battery. The cyanate ester modified PVDF binder is formed by polymerizing a monomer vinylidene fluoride and an isocyanate monomer. A cyanate ester modified PVDF binder molecular chain contains cyan functional groups, the electrical conductivity of the positive pole piece can be improved, and polysulfide in the battery cyclic process can be effectively adsorbed, so that the initial discharge capacity and cyclic stability of the lithium-sulfur battery are improved, and the shuttle effect of the lithium-sulfur battery is relieved; in addition, the cyan functional groups contained in the binder can form hydrogen-bond interaction with oxidizing functional groups on the surface of aluminum foil, the bonding power of the positive pole piece is improved, the phenomenon that active substances fall off in repeated charge-discharge cycles is avoided, the multiplying power property of the battery charge-discharge cycles is improved, and the recycling service life is prolonged.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

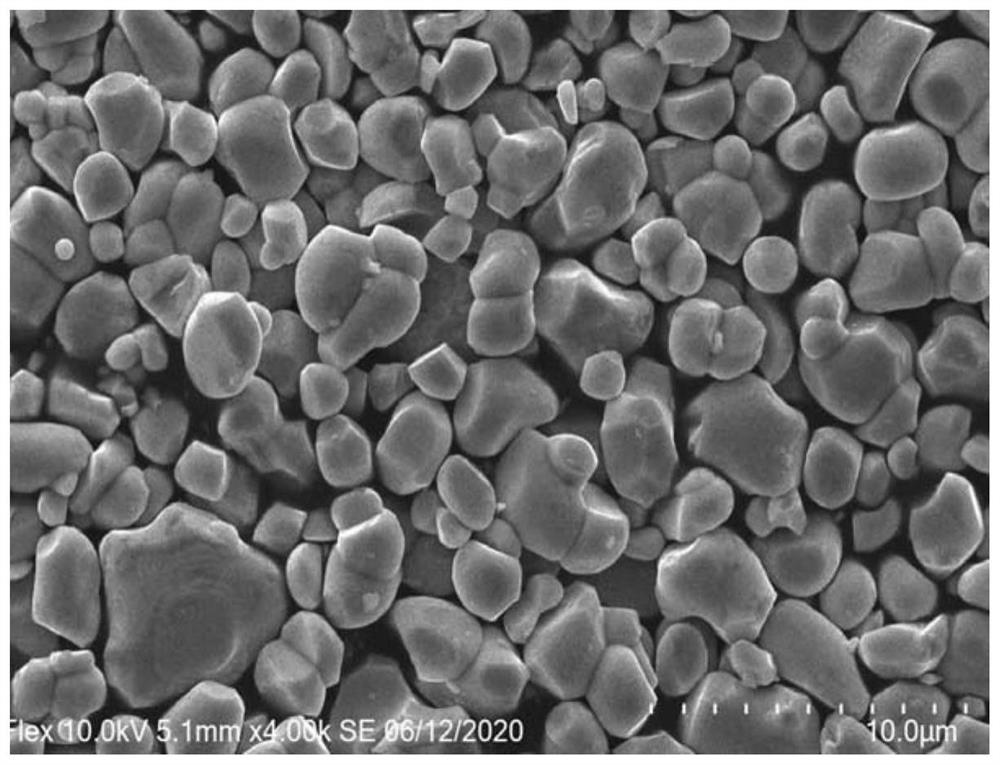

Ternary anode material, preparation method thereof and lithium-ion battery containing material

InactiveCN109920991AImprove electronic conductivity declineImprove lamellar structure instabilityCell electrodesSecondary cellsSolventNickel

The invention relates to the field of lithium-ion batteries and discloses a ternary anode material, a preparation method thereof and a lithium-ion battery containing the material. The process comprises the steps that a ternary anode material and conductive inorganic salt are mixed uniformly and dissolved in a solvent to obtain a first mixed solution, and the solvent in the first mixed solution isdried by distillation to obtain mixed powder; the mixed powder is calcined to obtain a calcination product containing ternary anode material particles coated with an inorganic lithium salt compound; an oxidant, conductive polymer monomers and the calcination product are dissolved in a solvent to obtain a second mixed solution, the conductive polymer monomers are subject to oxidative polymerizationto generate a conductive polymer, and the outer layer of the inorganic lithium salt compound of all the ternary anode material particles is coated with the conductive polymer; and the mixed solutionis filtered, washed and dried, and then the ternary anode material of the lithium-ion battery is obtained. The technical scheme is beneficial for suppressing side effects of an electrolytic solution on the surface of the high-nickel ternary anode material; the first discharge capacity of the lithium-ion battery is improved; and rate discharge and circulation properties of the high-nickel ternary anode material are enhanced.

Owner:江西星盈科技有限公司

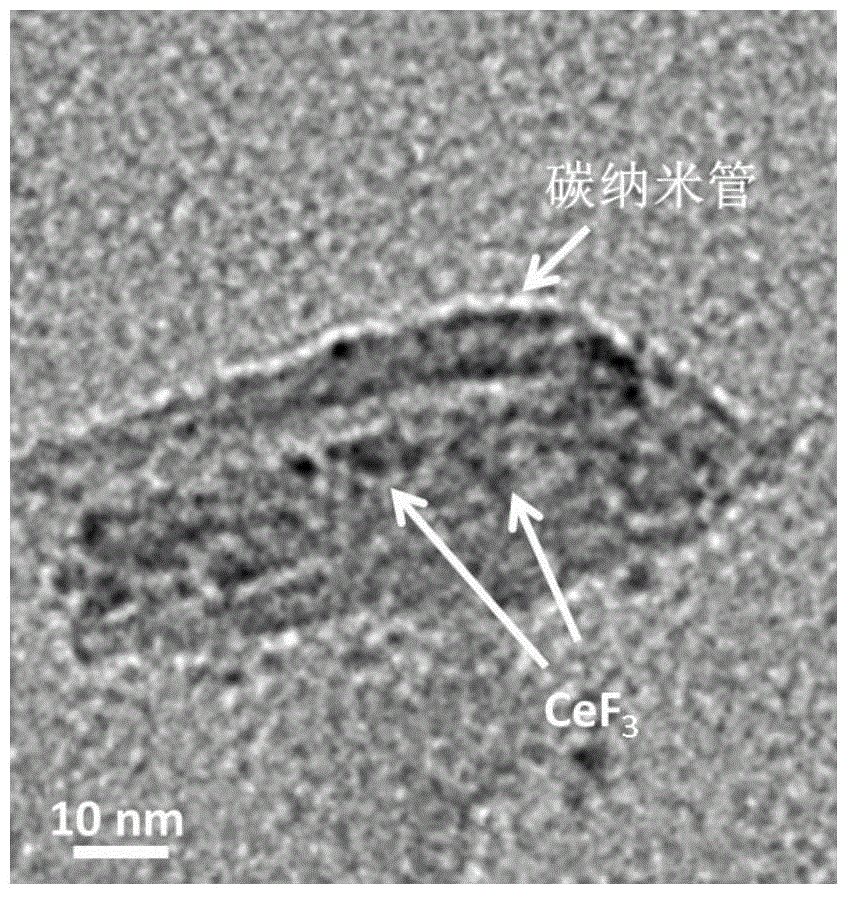

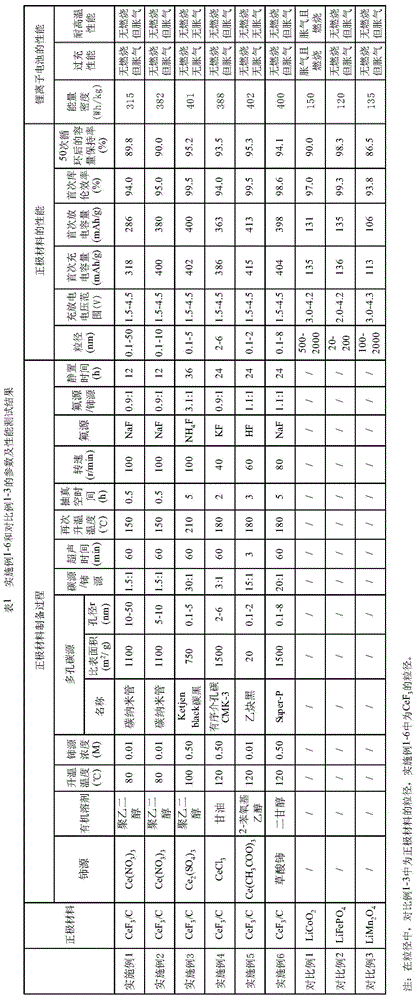

Lithium ion battery, and anode material and preparation method thereof

ActiveCN105098137AThe preparation method is simple and feasibleEasy to operateCell electrodesHigh energyPorous carbon

The invention provides a lithium ion battery, and an anode material and a preparation method thereof. The anode material of the lithium ion battery is compounded by CeF3 and carbon and has a chemical formula of CeF3 / C, the carbon is porous carbon, and the CeF3 is positioned in the pores of the porous carbon. The lithium ion battery comprises an anode plate, a cathode plate, an isolating membrane and electrolyte, wherein the anode plate comprises anode materials, the isolating membrane is positioned between the anode plate and the cathode plate, and the anode material is the anode material of the lithium ion battery. The anode material of the lithium ion battery has the advantages of high initial charge capacity, high initial discharge capacity, high initial coulombic efficiency and good cycle performance. The lithium ion battery has the advantages of high energy density, good safety performance and low cost.

Owner:CONTEMPORARY AMPEREX TECH CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com