Pre-lithiated lithium ion positive electrode material and preparation method and application thereof

A cathode material and lithium ion technology, applied in the field of pre-lithiation-treated lithium ion cathode material and its preparation, can solve the problems of reducing battery compatibility and failing to improve safety performance and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

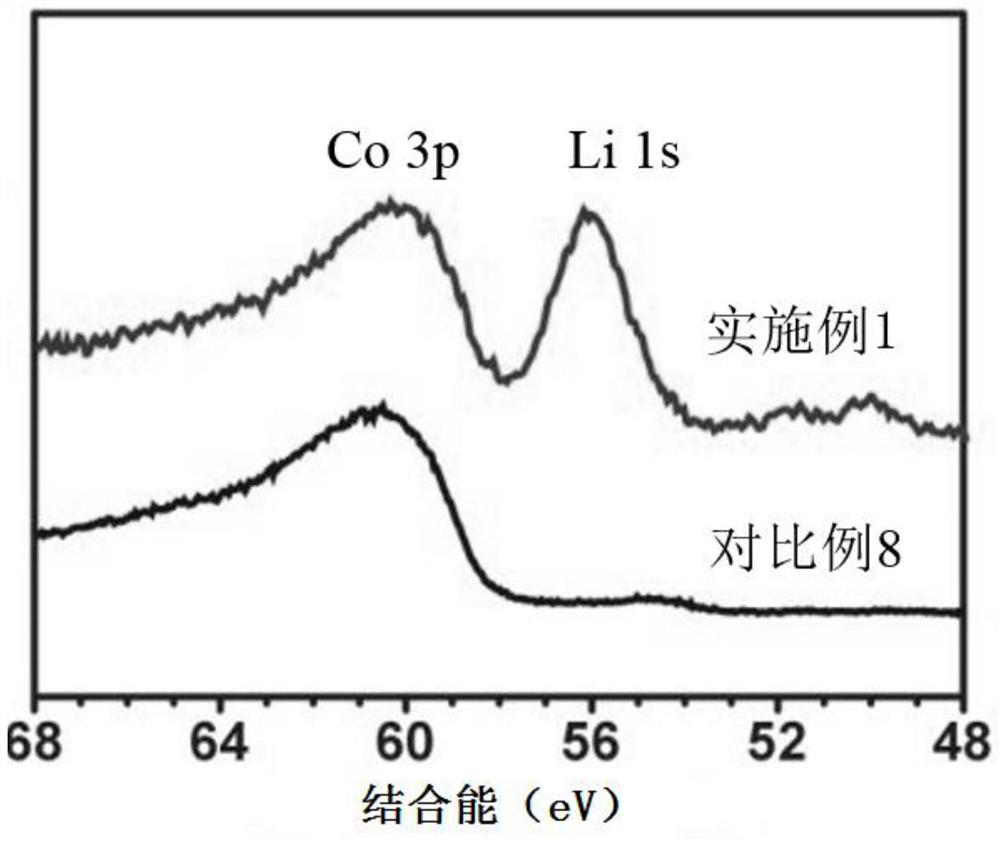

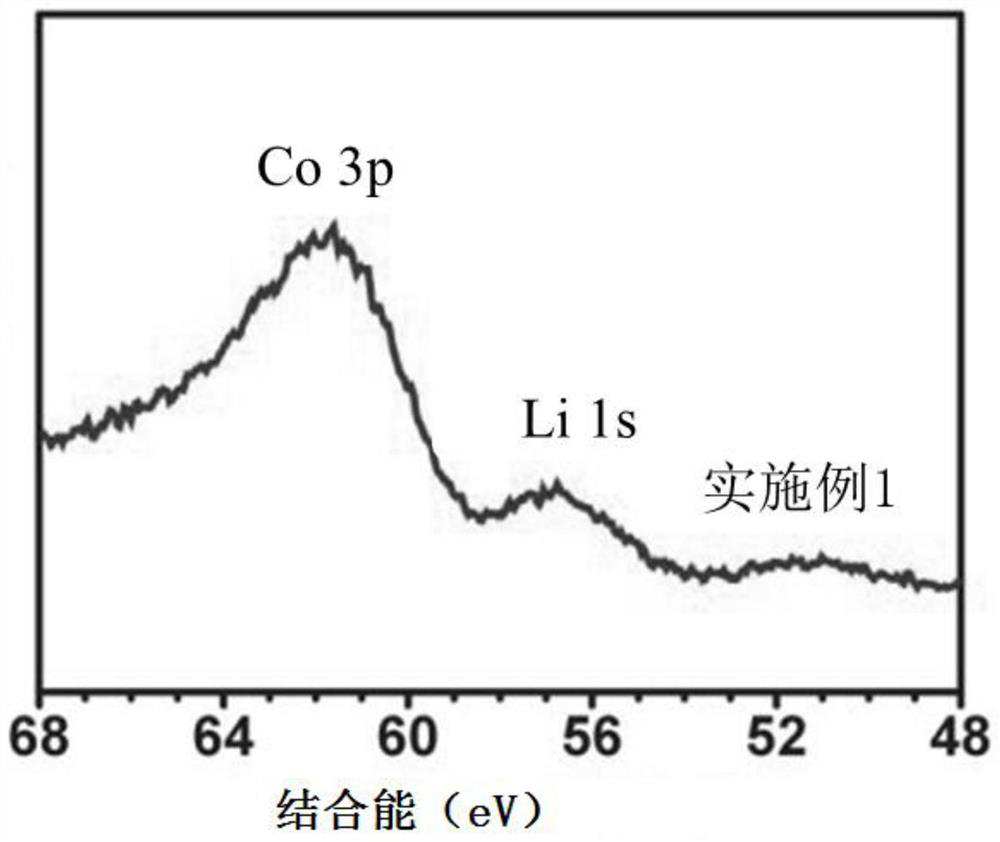

Embodiment 1

[0054] The lithium ion cathode material of the pre-lithiation treatment of the present embodiment, its chemical formula is (Li 2 O / [Co 2.95 (TiAl) 0.05 ] 1 / 3 ) 0.01 ·(Li 1.01 co 0.96 Mg 0.008 Al 0.024 Zr 0.008 o 2 ) 0.99 .

[0055] A kind of pre-lithiation solution, is mixed by naphthalene, lithium carbonate and Al, Ti, then adds in the sulfuric acid solution and stirs, obtains the pre-lithiation solution (containing naphthalene-lithium-Me solution); Wherein naphthalene and lithium carbonate are molar ratio Mix for 2:1.

[0056] A kind of preparation method of the lithium ion cathode material of pre-lithiation treatment, comprises the following steps:

[0057] (1) 200L of cobalt sulfate solution with a configuration concentration of 0.4mol / L, 6.25L of magnesium sulfate solution with a configuration concentration of 0.1mol / L, 9.0L of aluminum sulfate with a configuration concentration of 0.2mol / L, and sulfuric acid with a configuration concentration of 0.1mol 6.25 ...

Embodiment 2

[0062] The lithium ion cathode material of the pre-lithiation treatment of the present embodiment, its chemical formula is (Li 2 O / [Co 2.94 (TiAl) 0.06 ] 1 / 3 ) 0.02 ·(Li 1.01 co 0.96 Mg 0.008 Al 0.024 Y 0.008 o 2 ) 0.98 .

[0063] The preparation method is roughly the same as in Example 1. The main difference is that in Example 2, the precursor doping elements are magnesium, aluminum, and yttrium. The tempering temperature is 450 ° C. After the pre-lithiation treatment, the pre-treatment layer N2 , the total mass of the N2 pretreatment layer accounts for 2.0% of the total mass of the material.

Embodiment 3

[0065] The lithium ion cathode material of the pre-lithiation treatment of the present embodiment, its chemical formula is (Li 2 O / [Co 2.92 (TiAl) 0.08 ] 1 / 3 ) 0.015 ·(Li 1.01 co 0.96 Mg 0.008 Al 0.02 Y 0.008 Ti 0.004 o 2 ) 0.985 .

[0066] The preparation method is roughly the same as in Example 1. The main difference is that in Example 3, the precursor doping elements are four elements: magnesium, aluminum, yttrium, and titanium, and the tempering time is 1h. After the pre-lithiation treatment, the pre-treatment layer N3, the total mass of the N3 pretreatment layer accounts for 1.5% of the total mass of the material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com