Lithium manganese oxide material and preparation method thereof

A lithium manganate and coating technology, which is applied in the field of high crystallinity lithium manganate material and its preparation, can solve the problems that the coating elements cannot form a concentration gradient, the coating is unevenly dispersed, and the coating effect cannot be achieved. , to achieve the effects of improving high temperature and normal temperature cycle performance and high temperature storage performance, excellent high temperature storage performance, good room temperature and high temperature cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

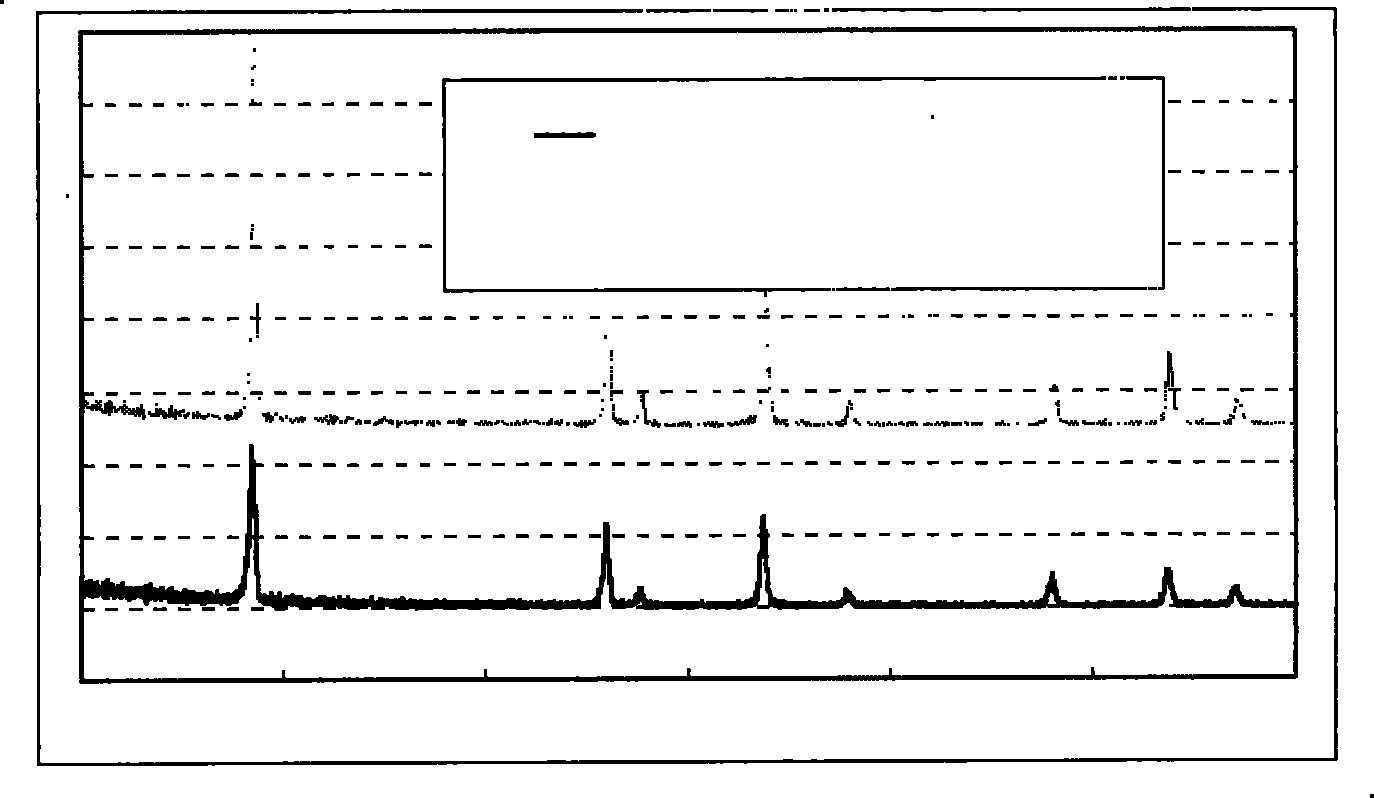

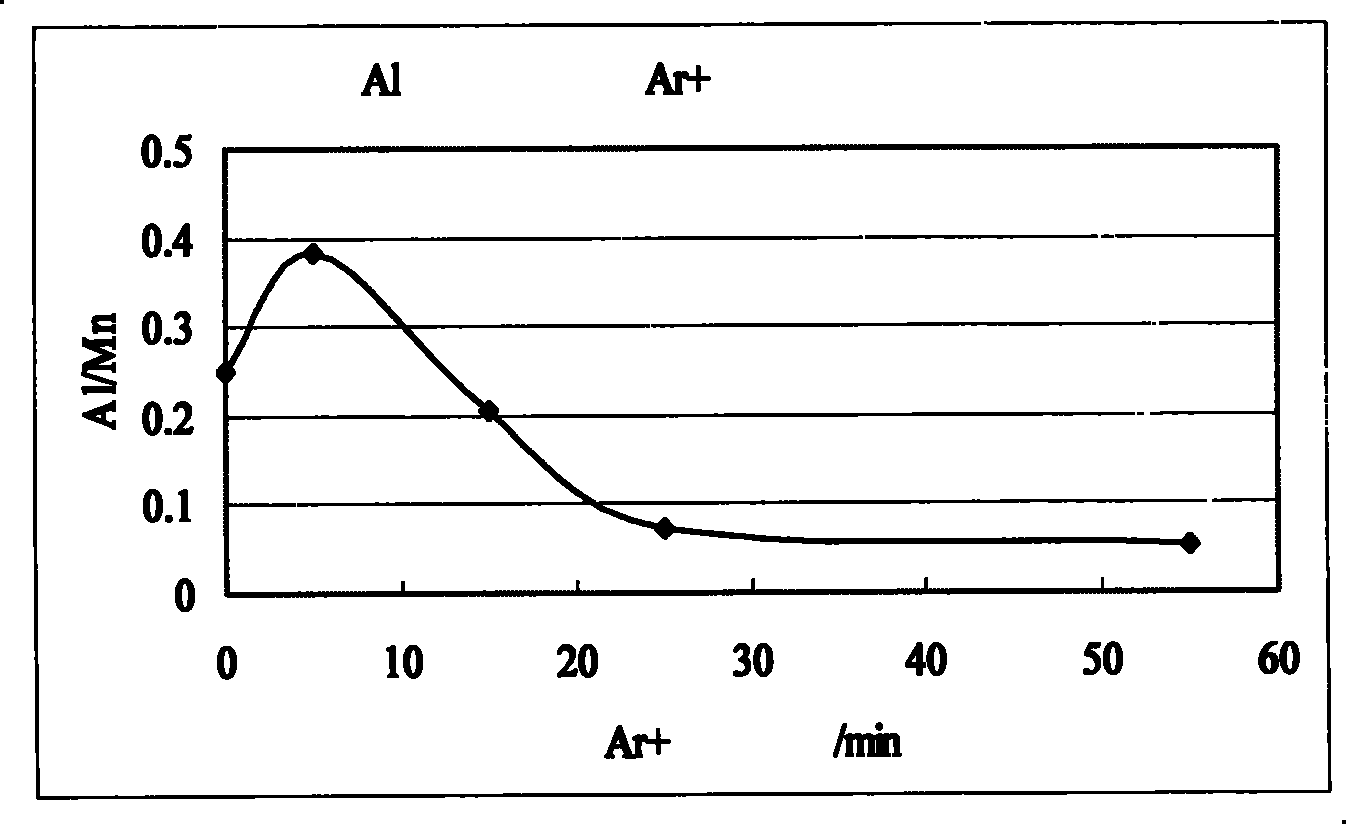

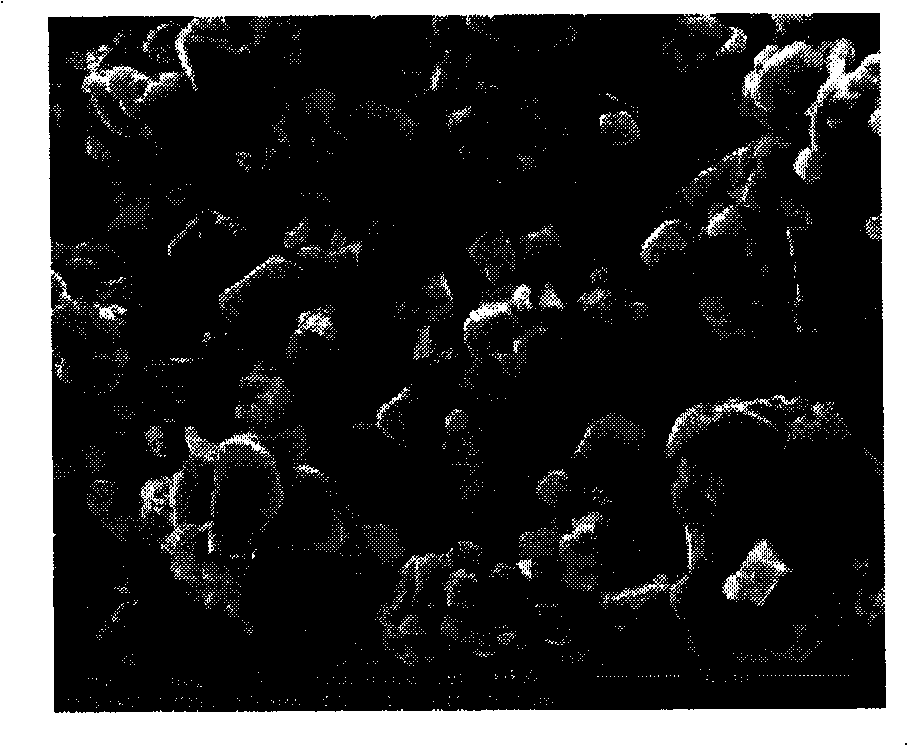

Image

Examples

Embodiment 1

[0046] A lithium manganate material is a lithium manganate modified material coated on a lithium manganate precursor with a primary crystal particle size of 0.5 μm to 20 μm. The lithium manganate material is Li 1.20 mn 1.90 Mg 0.025 B 0.025 Al 0.05 o 3.95 f 0.05 , the doping element is Mg, B, F, and the coating element is Al.

[0047] A preparation method of lithium manganate material, comprising the steps of:

[0048] (1) Weigh a certain amount of lithium carbonate, electrolytic manganese dioxide, magnesium oxide, boric acid and lithium fluoride according to the molar ratio of Li:Mn:Mg:B:F: 1.20:1.90:0.025:0.025:0.05 Mix in a material tank, sinter the uniformly mixed material at 850°C, cool naturally to room temperature, crush, and sieve to obtain a high-crystallinity lithium manganate precursor with a primary crystal particle size of 0.5-20 μm;

[0049] (2) Combine the precursor in step (1) with Al 2 o 3 Mixed in the mixing tank, where, Al 2 o 3 The molar ratio w...

Embodiment 2

[0054] A lithium manganate material, including a precursor and a coating, the precursor is a doped lithium manganate with a primary crystal particle size of 0.5 μm to 20 μm. The lithium manganate material is Li 0.95 mn 1.80 Mg 0.05 B 0.05 Al 0.025 Li 0.05 Mg 0.025 o 3.90 S 0.05 f 0.05 , the doping elements are Mg, B, S, and the coating elements are Al, Li, Mg, and F.

[0055] A preparation method of lithium manganate material, comprising the steps of:

[0056] (1) Weigh a certain amount of lithium hydroxide, manganese carbonate, magnesium oxide, boric acid, and ammonium sulfide according to the molar ratio of Li:Mn:Mg:B:S: 0.95:1.80:0.05:0.05:0.05, and place them in the mixing tank Mix in medium, sinter the uniformly mixed material at 750°C, cool naturally to room temperature, crush, and sieve to obtain a high-crystallinity lithium manganate precursor with a crystal particle size of 0.5-20 μm or more;

[0057] (2) Make the precursor in step (1) into a suspension, ad...

Embodiment 3

[0061] A lithium manganate material, including a precursor and a coating, the precursor is a doped lithium manganate with a primary crystal particle size of 0.5-20 μm. The lithium manganate material is Li 0.90 mn 1.80 co 0.02 Cr 0.02 B 0.02 V 0.02 Zn 0.02 Cr 0.025 co 0.025 Ni 0.025 Mg 0.025 o 3.80 f 0.05 Cl 0.05 Br 0.05 I 0.05 , the doping elements are Co, Cr, B, V, Zn, F, Cl, and the coating elements are Cr, Co, Ni, Mg, Br, and I.

[0062] A preparation method of lithium manganate material, comprising the steps of:

[0063] (1) Weigh a certain amount of lithium source, oxide Manganese, cobalt oxide, chromium oxide, boric acid, vanadium pentoxide, zinc oxide, lithium fluoride, zinc chloride, wherein the lithium source is a mixture of lithium bicarbonate, lithium oxide, lithium nitrate and lithium sulfate, placed in the mixing Mix in a tank, sinter the uniformly mixed material at 950°C, cool naturally to room temperature, crush, and sieve to obtain a high-cryst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com