Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

95 results about "Lithium bicarbonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium carbonate is a chemical compound that is often used in the creation of different types of products, including some bakeware. This compound has also proven helpful with some mental illnesses, such as bipolar disorder. In recent years, topical ointments containing this compound have been developed to treat various types of skin irritations.

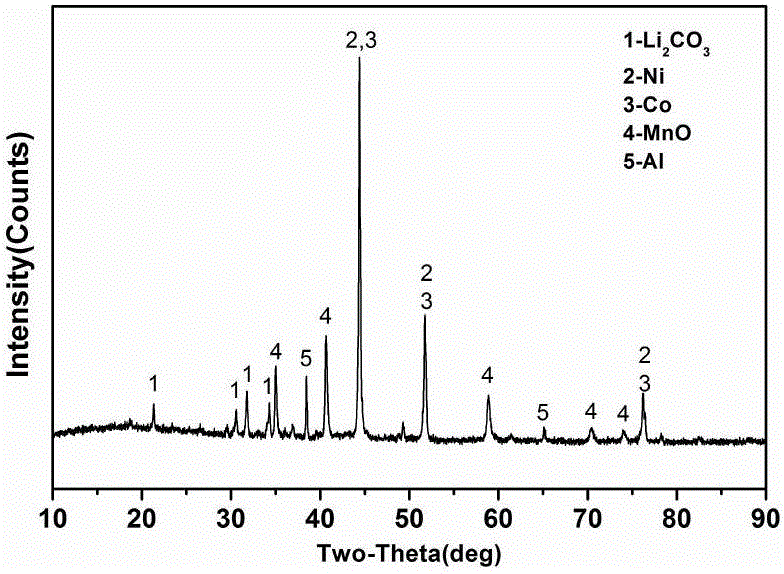

Method for comprehensively recovering valuable metals from waste lithium-ion battery material

ActiveCN106129511AEfficient recyclingHigh recovery rateWaste accumulators reclaimingProcess efficiency improvementManganeseAmmonia

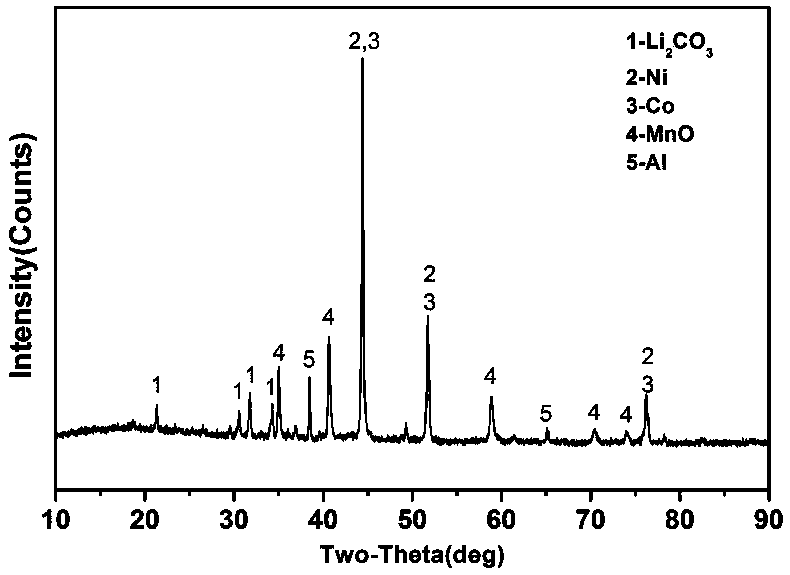

The invention discloses a method for comprehensively recovering valuable metals from a waste lithium-ion battery material. The method is characterized by comprising the steps of mixing a waste lithium-ion battery positive electrode material with a reducing agent, or mixing simply crushed whole battery with a carbon reducing agent; carrying out reducing roasting treatment at the temperature of 500-750 DEG C; firstly carbonizing and leaching a roasted product through CO2 to obtain a lithium bicarbonate water solution for preparing an Li2CO3 product; and leaching valuable elements of cobalt, nickel, manganese and the like from liquid leached residues through oxidation acid leaching or oxidation ammonia leaching, carrying out extracting and purifying and then preparing the corresponding compound product. The method is simple in technology and short in flow; the reagent cost is low; and valuable metal elements of lithium, the cobalt, the nickel, the manganese and the like in the waste lithium-ion battery material can be efficiently recovered.

Owner:GUANGDONG GUANGHUA SCI TECH

Method for extracting ultrahigh-purity lithium carbonate from salt lake brine with high magnesium-lithium ratio

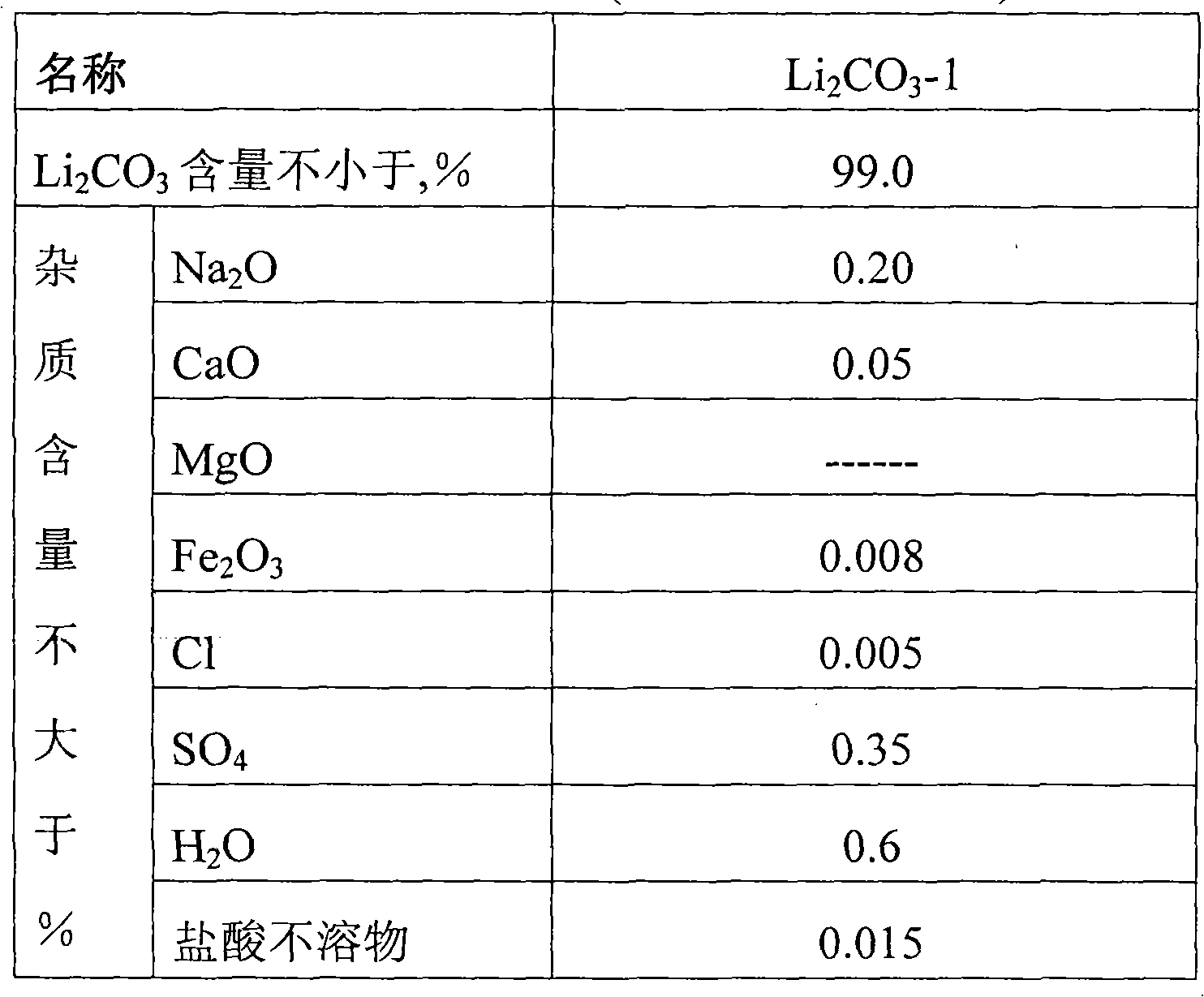

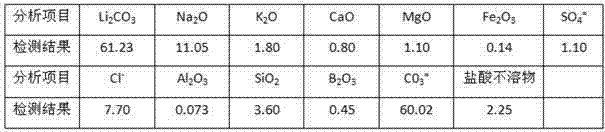

The invention discloses a method for extracting ultrahigh-purity lithium carbonate from chloride brine with a high magnesium-lithium ratio. The method comprises the following steps of: preparing a lithium chloride concentrated solution by an adsorption, desorption and evaporation concentration process; purifying, and precipitating lithium carbonate by using ammonium bicarbonate pulp; and converting into a lithium bicarbonate solution, filtering, and decarburizing. By improving steps and parameters of the conventional process, the purity of a product is more than 99.99 weight percent and the total amount of major impurities is not more than 0.002 weight percent without the introduction of additional high-cost purification steps such as ion exchange resin / membranes; and additional sodium ions are not introduced in the production process, byproducts at all stages can be recycled, and only an extremely small amount of waste solution is generated.

Owner:JIANGSU HAILONG LITHIUM IND TECH

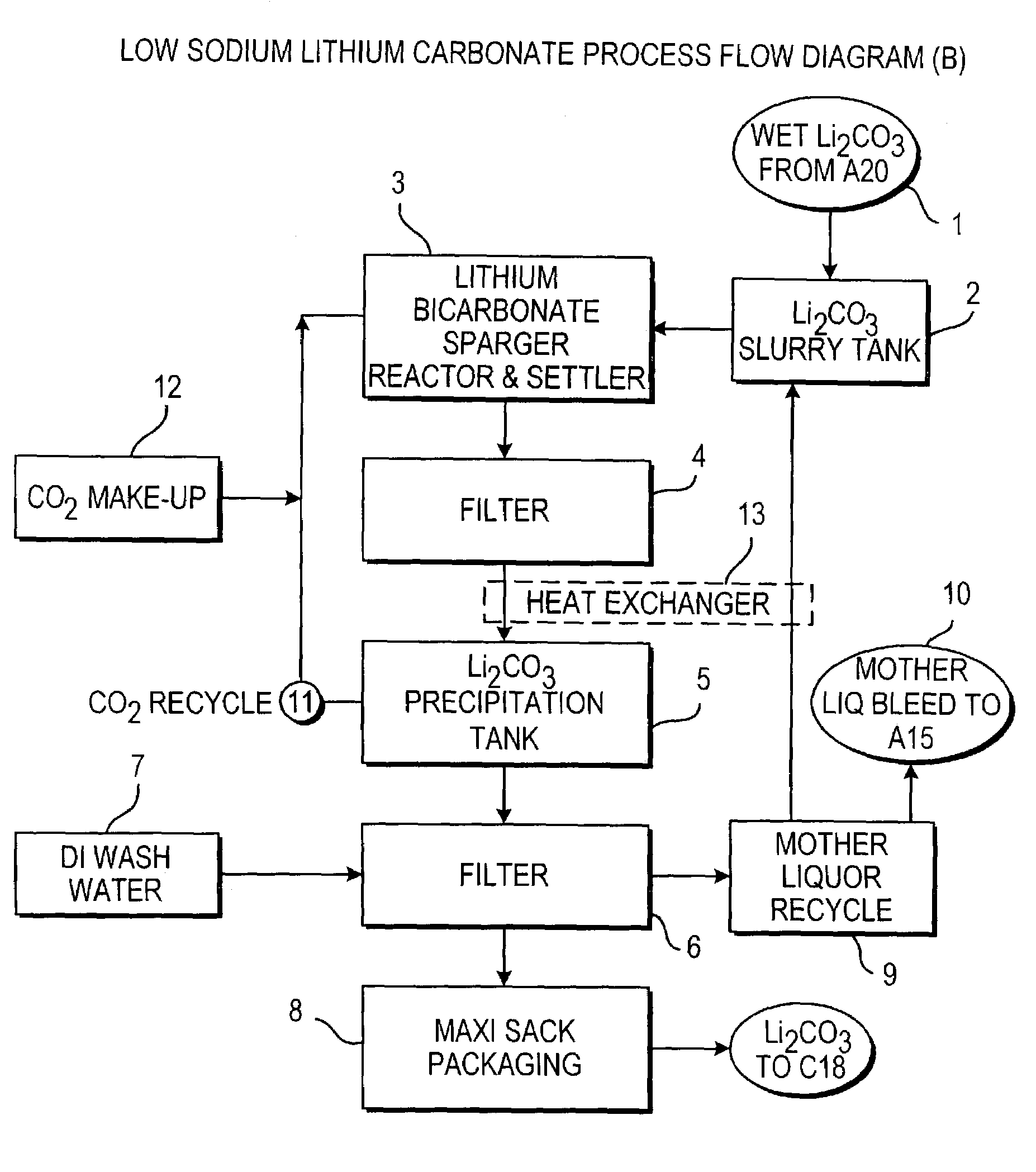

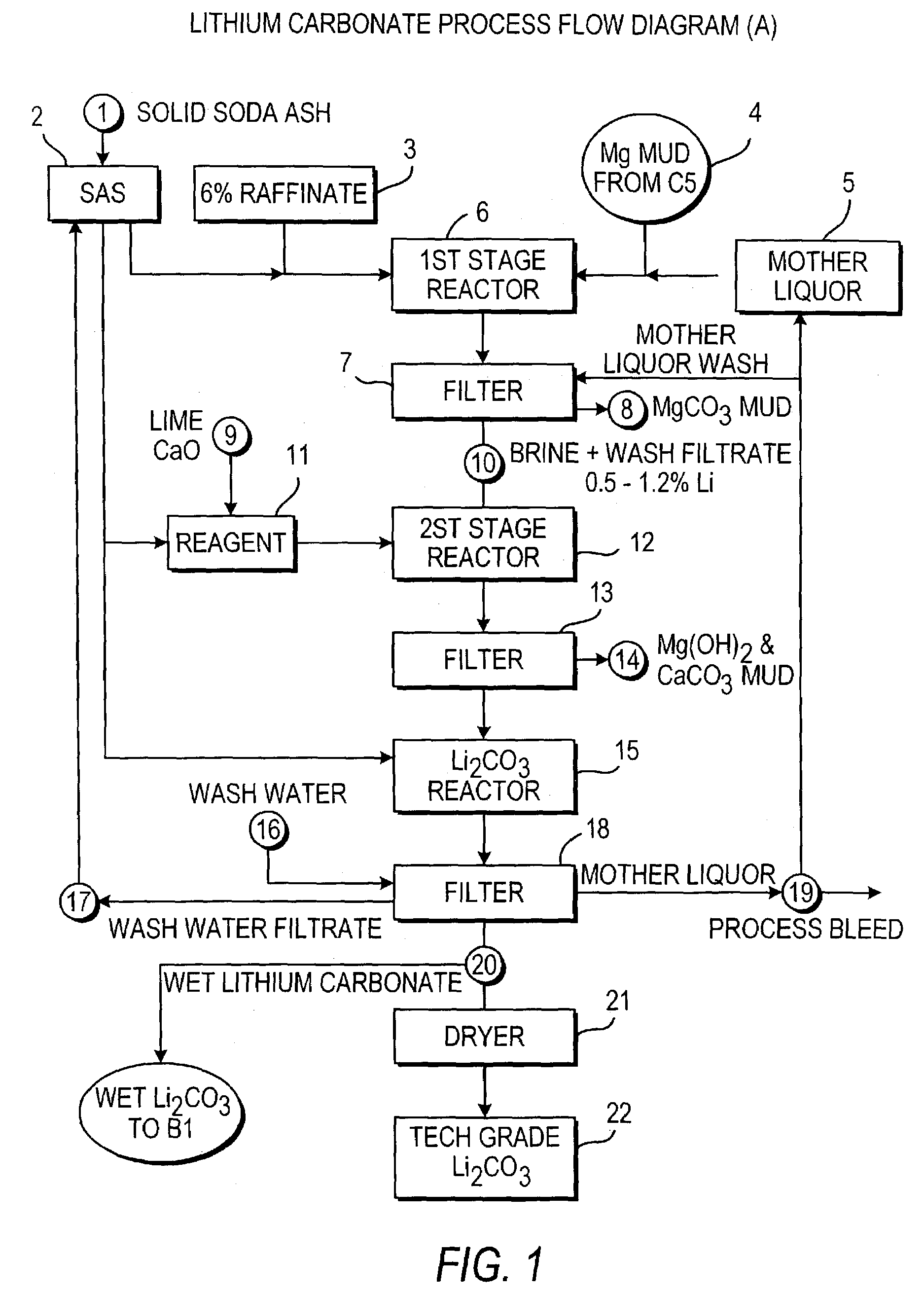

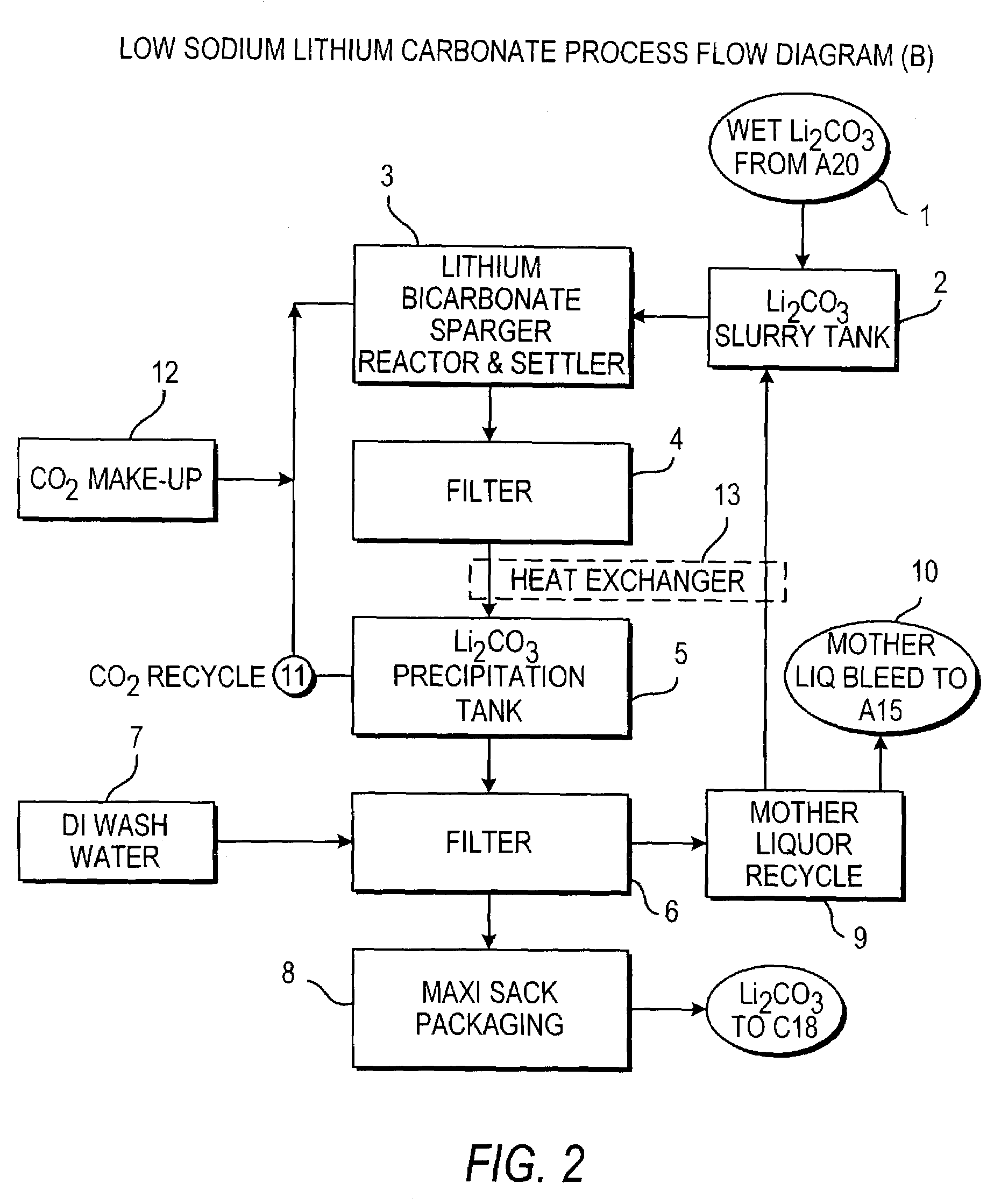

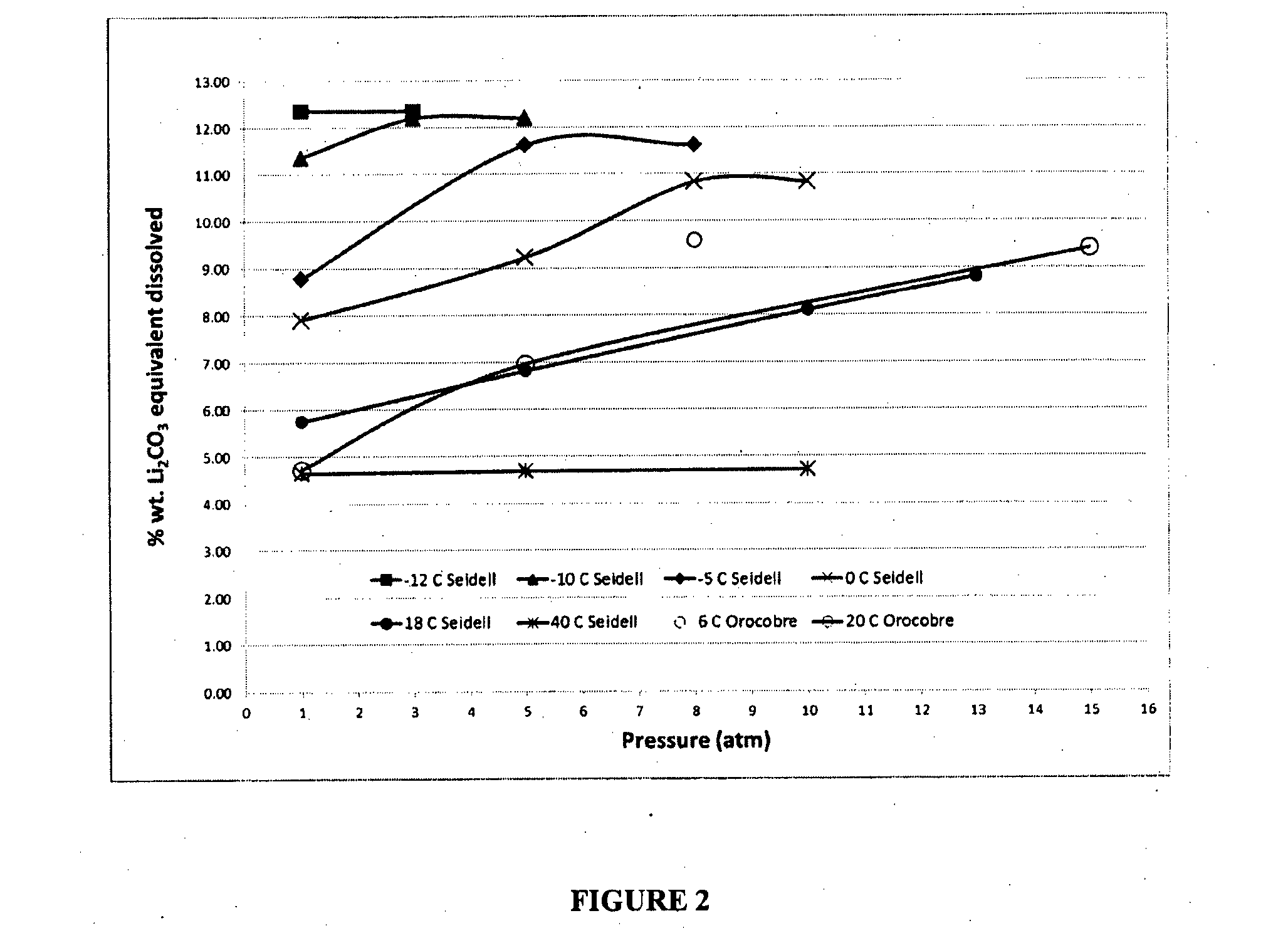

Production of lithium compounds directly from lithium containing brines

InactiveUS7157065B2Reduce in quantityPromote absorptionCalcium/strontium/barium carbonatesChemical/physical/physico-chemical processesSlurryLithium compound

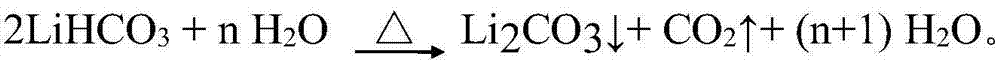

A continuous process for directly preparing high purity lithium carbonate from lithium containing brines by preparing a brine containing about 6.0 wt % lithium and further containing other ions naturally occurring in brines; adding mother liquor containing carbonate to precipitate magnesium; adding a solution of CaO and sodium carbonate to remove calcium and any residual magnesium; precipitating lithium carbonate from the purified brine by adding soda ash solution; filtering to obtain solid lithium carbonate; preparing an aqueous slurry of the lithium carbonate and introducing carbon dioxide gas at a temperature from at least minus 10 to +40° C.; passing the lithium bicarbonate solution through a filter to clarify the solution; introducing said filtered lithium bicarbonate solution into a reactor and adjusting the temperature of the solution to from 60–100° C. to precipitate ultra-pure lithium carbonate.

Owner:ROCKWOOD LITHIUM INC

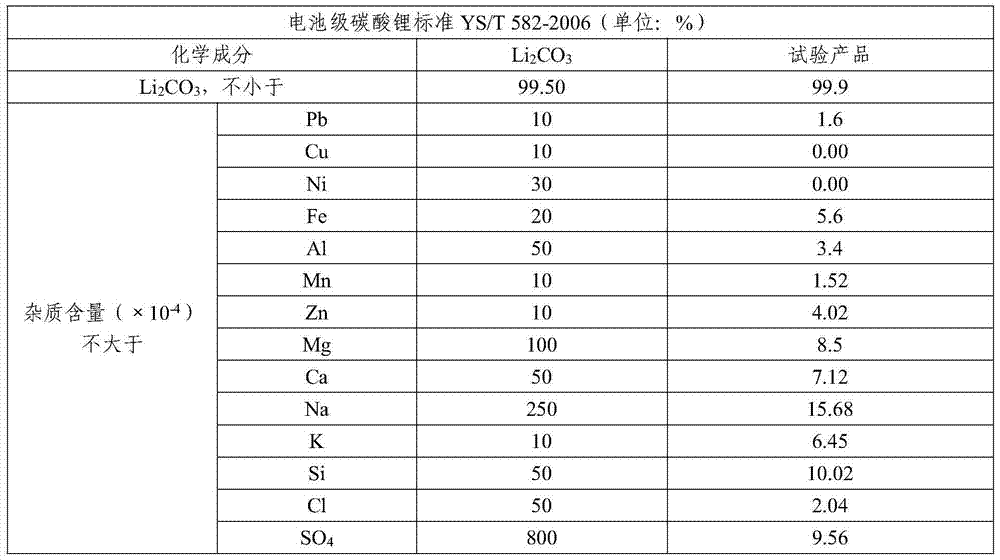

Method for preparing battery-grade lithium carbonate or high-purity lithium carbonate from industrial-grade lithium carbonate

InactiveCN103539169AHigh purityControl impurity contentLithium carbonates/bicarbonatesIon exchangeCarbonization

The invention discloses a method for preparing battery-grade lithium carbonate or high-purity lithium carbonate from industrial-grade lithium carbonate. The method comprises the following steps of: (1) carbonization: mixing the industrial-grade lithium carbonate with secondary distilled water to obtain slurry and then introducing carbon dioxide gas so that lithium carbonate solid is dissolved into a lithium bicarbonate solution; (2) ion exchange: removing main impurities such as calcium and magnesium out of the solution by using resin through carrying out ion exchange once or twice; and (3) pyrolysis: heating the solution subjected to ion exchange adsorption once for a certain time under the boiling condition, filtering, washing and drying to obtain the battery-grade lithium carbonate; and heating the solution subjected to ion exchange adsorption twice or more times for pyrolysis, filtering, washing and drying to obtain the high-purity lithium carbonate. The method provided by the invention is capable of effectively controlling the content of impurities, is short in process flow, low in energy consumption and friendly to environment, and also has high practical value.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

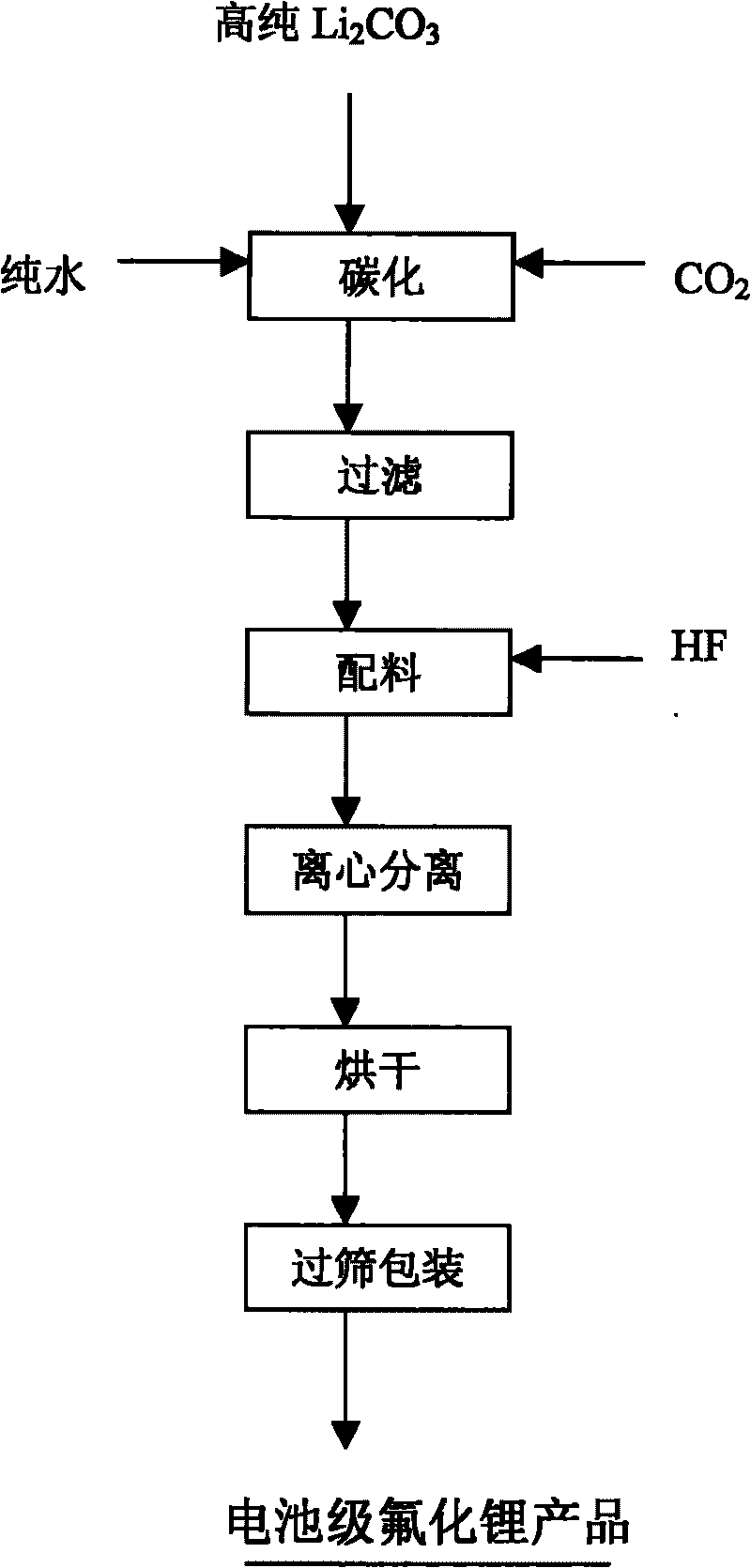

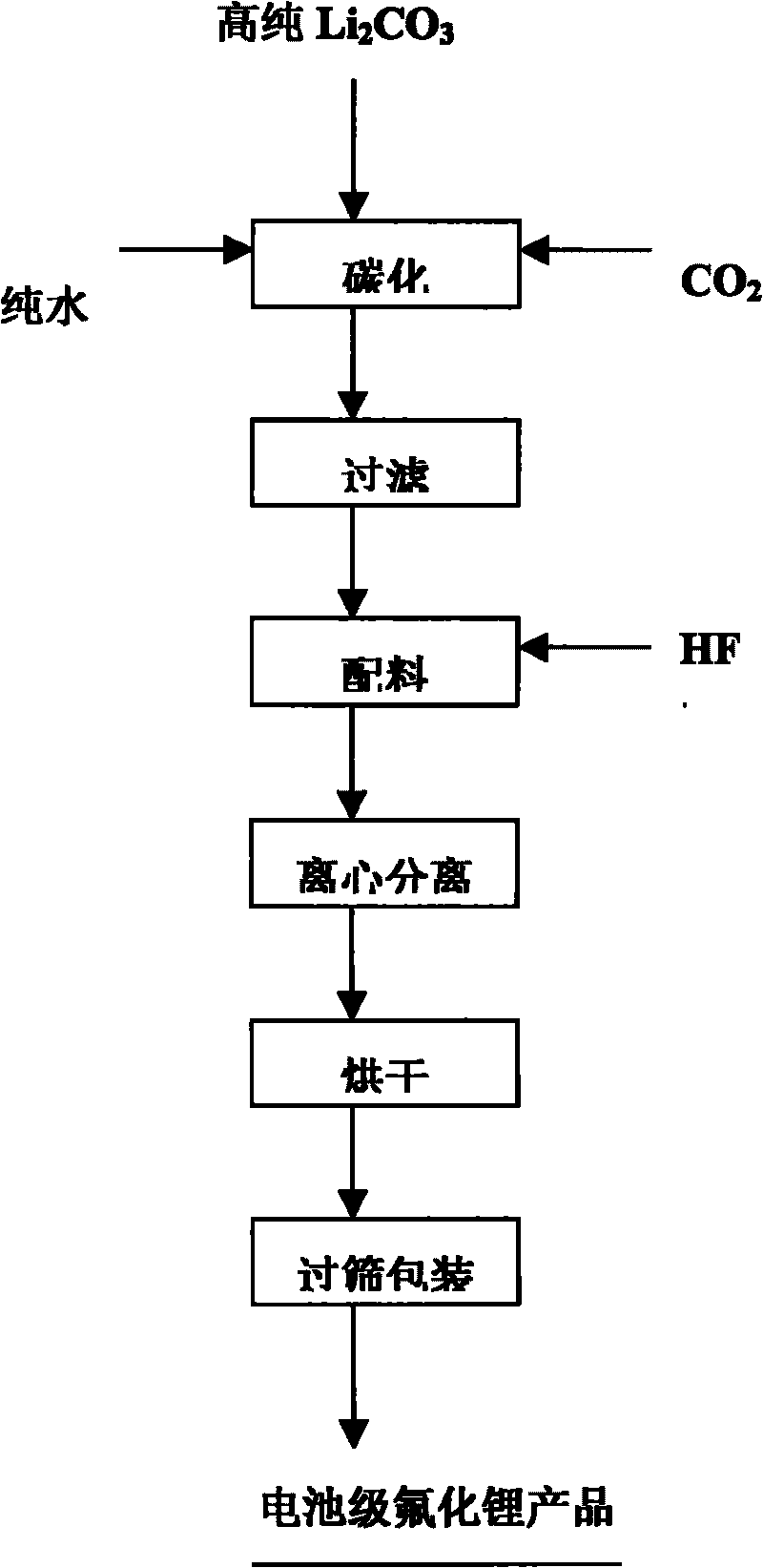

Preparation method of lithium fluoride

InactiveCN102030344AHigh yieldYield over 97%, high purityLithium halidesHydrofluoric acidLithium hydroxide

The invention provides a preparation method of lithium fluoride, which comprises the following steps: (1) introducing carbon dioxide into water, then adding the raw material lithium carbonate to obtain a lithium bicarbonate solution, then adding a precipitant, introducing carbon dioxide until the pH of the solution is 8-9, filtering, and collecting the lithium bicarbonate solution; and (2) adding hydrofluoric acid to the filtrate obtained in the step (1), carrying out fluoridation, then adding a lithium hydroxide solution, regulating the pH of the system to be 7-7.5, then filtering, collecting the filter cake, and drying to obtain the product lithium fluoride. In the invention, the industrial grade lithium carbonate is used, the total yield of the technical process achieves more than 97%, the purity is as high as 99.9% or above, and the impurity content in the product is as low as 80PPm or below.

Owner:SHANGHAI CHINA LITHIUM INDAL

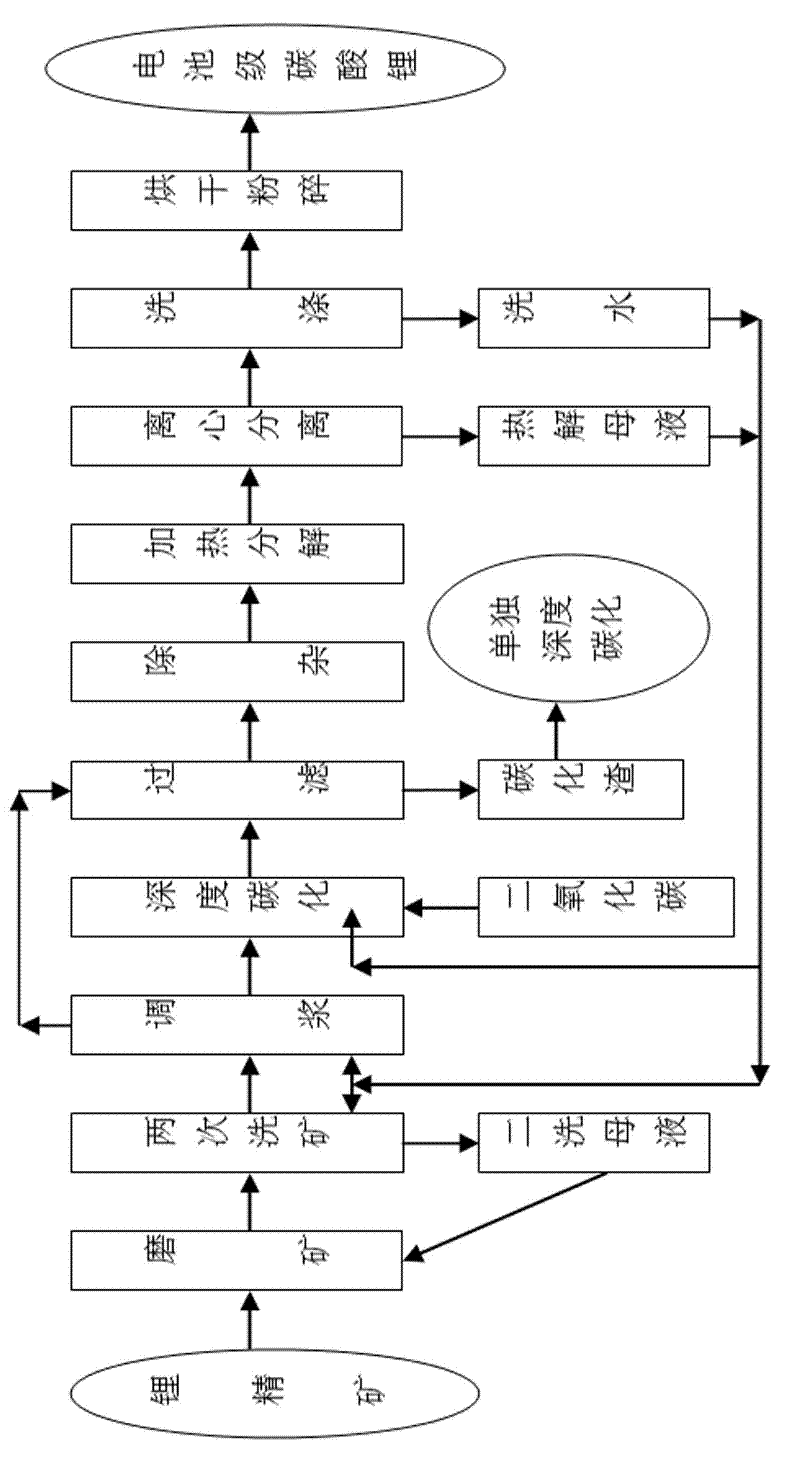

Process for producing battery-grade lithium carbonate through processing carbonate type lithium concentrate by deep carbonation method

The invention belongs to the technical field of lithium battery materials, and in particular relates to a process for producing battery-grade lithium carbonate through processing carbonate type lithium concentrate by a deep carbonation method. The process comprises grinding, twice ore washing, size mixing, deep carbonation, filtration, calcium removal, pyrolysis, centrifugal separation, washing, drying and smashing as well as carbonized slag recycling. The process principle is as follows: reacting lithium carbonate in the concentrate with carbon dioxide under the conditions of a certain carbon dioxide pressure, reaction temperature and final pH value so as to generate water-soluble lithium dicarbonate; after impurity removal and filtration, removing a part of indissolvable impurities, and dissolving the other part of soluble impurities into a solution; and heating the solution through utilizing the characteristic that lithium dicarbonate is not stable so that lithium dicarbonate is decomposed to generate a lithium carbonate precipitate, separating the lithium carbonate precipitate from the soluble impurities through separation and washing, so as to obtain a lithium carbonate product with required purity. The process is applied to industrial volume production; and the purity of obtained battery-grade lithium carbonate reaches 99.50-99.70%. The process disclosed by the invention is environmentally-friendly, low in energy consumption, low in cost and high in product quality.

Owner:BAIYIN ZABUYE LITHIUM IND

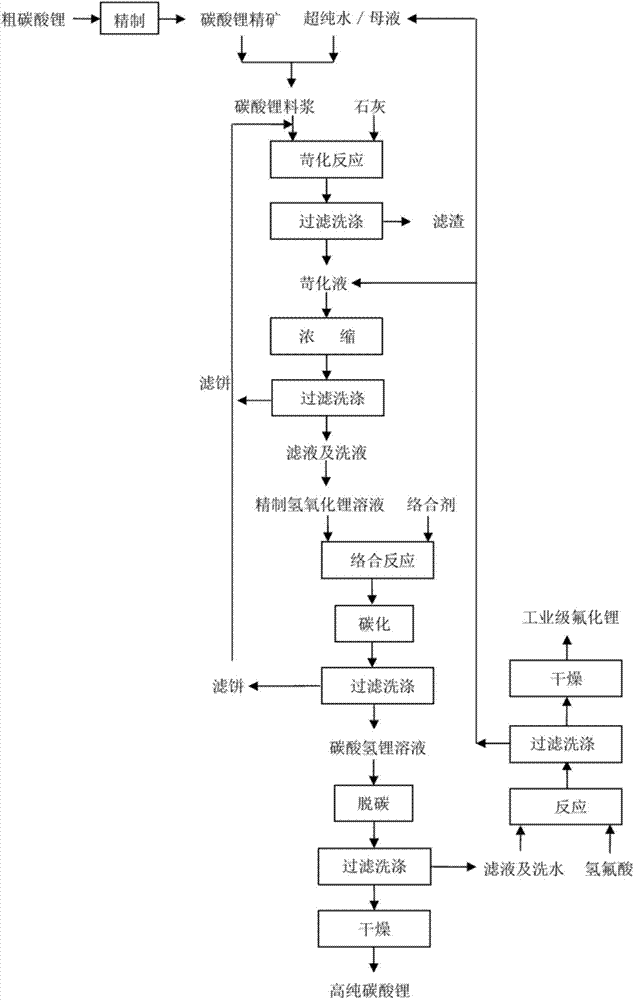

Method for preparing high-purity lithium carbonate with co-production of lithium fluoride by employing crude lithium carbonate

ActiveCN104326495ASolve the single preparation raw materialSolve the costProductsReagentsLithium hydroxideCarbonization

The invention discloses a method for preparing high-purity lithium carbonate with co-production of lithium fluoride by employing crude lithium carbonate. The method includes following steps: (1) preparing the crude lithium carbonate into lithium carbonate concentrate; (2) preparing the lithium carbonate concentrate into a slurry material with addition of lime and performing filtration to obtain a crude lithium hydroxide solution; (3) concentrating and filtering the crude lithium hydroxide solution, adding a complexing agent to remove impurity metal ions to obtain a refined lithium hydroxide solution; (4) feeding CO2 into the refined lithium hydroxide solution for carbonization and performing filtration to obtain a lithium bicarbonate solution; and (5) heating the lithium bicarbonate solution, performing a filtering and washing process, drying a filter cake to obtain the high-purity lithium carbonate, mixing the filtrate and a washing liquid with addition of hydrofluoric acid, performing a filtering and washing process, and then drying the filter cake to obtain the lithium fluoride. By means of the method, impurity ions in the high-purity lithium carbonate is in the trace-amount grade. The quality of the high-purity lithium carbonate is better in an industrial requirement in YS / T546-2008. Problems of poor quality, low lithium yield and high production cost in preparation of the high-purity lithium carbonate from salt lake lithium are solved.

Owner:河南省氟基新材料科技有限公司

Process for producing lithium carbonate from concentrated lithium brine

ActiveUS20140334997A1Cell electrodesLithium carbonates/bicarbonatesMetal impuritiesPhysical separation

Disclosed are methods for a simplified process for preparing lithium carbonate from concentrated lithium brine which can be used for battery grade, pharmaceutical and other high purity grade applications. Impure lithium carbonate is precipitated from lithium concentrated brine, preferably lowered in magnesium, subsequently suspended in aqueous solution and reacted with carbon dioxide to form dissolved lithium bicarbonate. The insoluble impurities are filtered and the dissolved boron and metal impurities such calcium, magnesium and iron are physically separated from the lithium bicarbonate solution using ion selective mediums or other selective processes. Lithium carbonate is then subsequently precipitated.

Owner:OROCOBRE

Method for preparing lithium fluoride

The invention relates to a method for preparing lithium fluoride, which is characterized by comprising the following steps of: mixing high-purity lithium carbonate with pure water, and introducing carbon dioxide gas to carry out the carburization reaction for obtaining a lithium bicarbonate solution; precisely filtering the lithium bicarbonate solution; introducing hydrofluoric acid gas into the lithium bicarbonate solution, stirring to carry out the neutralization reaction, and controlling the pH value to be 0.5-3 to prepare lithium fluoride slurry; centrifugally separating the lithium fluoride slurry to separate solid from liquid of the lithium fluoride slurry; and drying the separated solid lithium fluoride to obtain a finished product. The method of the invention has the advantage of simple technology; the prepared lithium fluoride has the advantages of high purity, good liquidity, no alkaline impurities and neutral state; and the product can achieve the lithium fluoride grade of battery levels.

Owner:GANFENG LITHIUM CO LTD

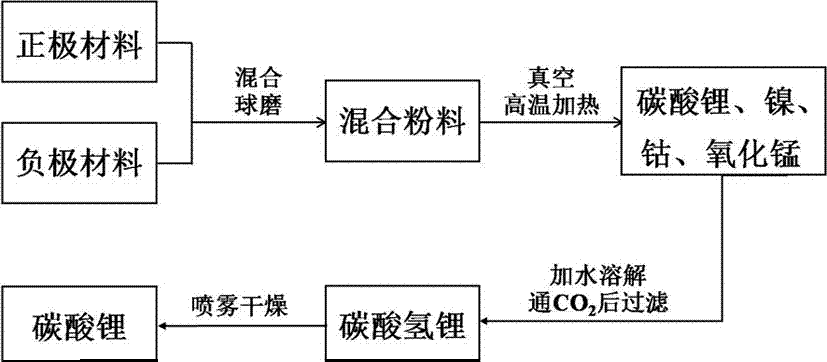

Method for preparing lithium carbonate and ternary precursor by recycling waste ternary lithium battery

ActiveCN112374511ACannot be recycled effectivelyImprove leaching rateWaste accumulators reclaimingNickel compoundsMetallic lithiumManganese

The invention discloses a method for preparing lithium carbonate and a ternary precursor by recycling a waste ternary lithium battery, and belongs to the field of solid waste recycling. Graphite and abinder carried in black powder obtained after pretreatment of a waste ternary battery are adopted as reducing agents, and the structure of the ternary material is destroyed through self-reduction phase inversion; lithium carbonate is converted into lithium bicarbonate which is easy to leach with water by adopting a carbonation water leaching method, so as to realize the preferential leaching of lithium; and sulfuric acid leaching is directly performed on the material subjected to lithium extraction without adding a reducing agent to obtain a nickel-cobalt-manganese solution. Copper, iron, calcium and other impurities in the solution are deeply removed through an impurity removal procedure, the content of aluminum and magnesium in the solution is controlled, then nickel, cobalt and manganese in the solution are extracted into an organic phase through synchronous extraction, a nickel sulfate solution, a cobalt sulfate solution and a manganese sulfate solution are obtained after reverseextraction is conducted through sulfuric acid, and a high-quality ternary positive electrode material precursor can be prepared after the metal proportion is adjusted. The method provided by the invention has the advantages of high recovery rate of valuable metals including lithium, nickel, cobalt and manganese, short flow, good product quality, economy and environment-friendliness.

Owner:UNIV OF SCI & TECH BEIJING

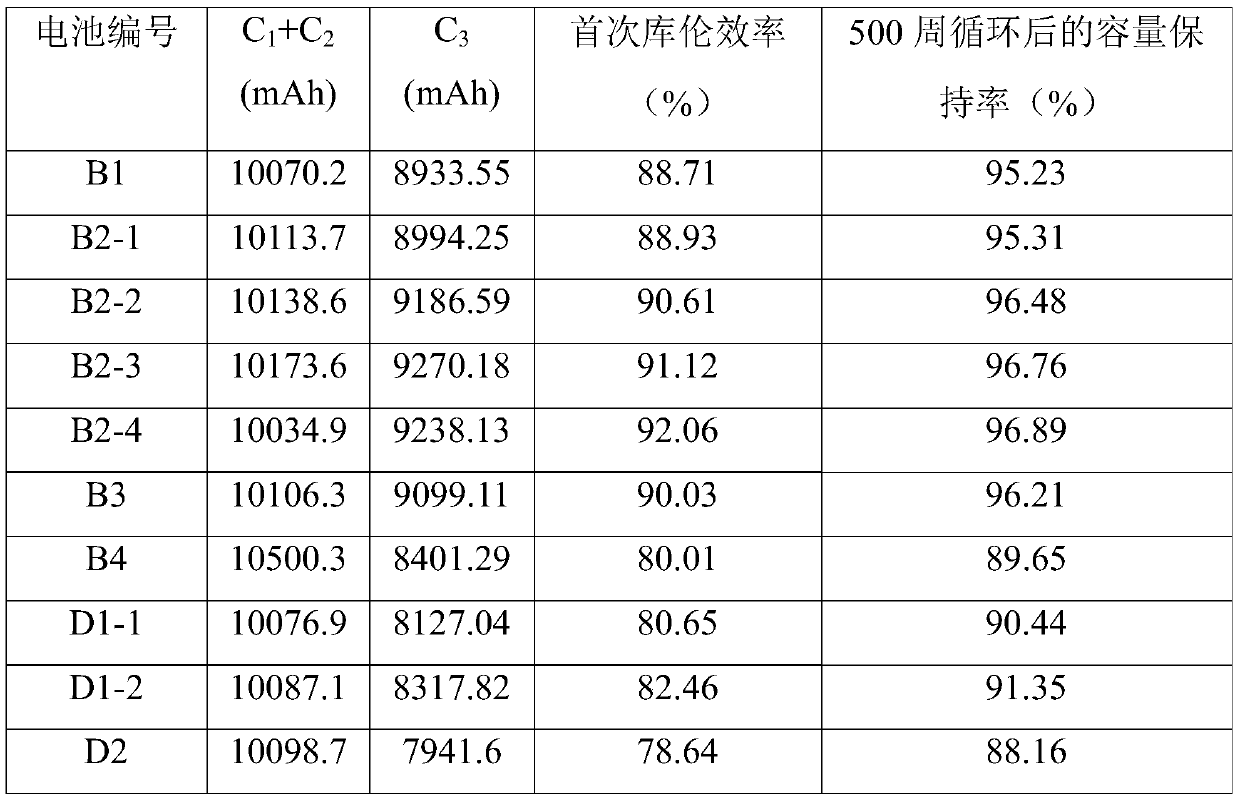

Method for lithium supplement of lithium ion battery negative electrode plate, lithium-supplement negative electrode plate and lithium ion battery

InactiveCN109888192AImprove the first Coulombic efficiencyHigh cycle capacity retentionElectrode manufacturing processesSecondary cellsElectrolytic agentElectrical battery

The invention relates to the field of lithium ion batteries, in particular to a method for lithium supplement of a lithium ion battery negative electrode plate, a lithium-supplement negative electrodeplate and a lithium ion battery. The method for the lithium supplement of the lithium ion battery negative electrode plate comprises the step of drying the negative electrode plate and a lithium hydrogencarbonate solution after contact to obtain the lithium-supplement negative electrode plate. The invention also provides the lithium ion battery fabricated by the lithium-supplement negative electrode plate. The lithium ion battery is obtained by assembly and formation of the lithium-supplement negative electrode plate, a positive electrode plate, a separator and an electrolyte. According to the method for lithium supplement of the lithium ion battery negative electrode plate, the employed lithium hydrogencarbonate solution (lithium source) is not toxic, the problem of safety does not exist, the method can be performed without protection of inert gas, and industrial production is facilitated; and moreover, the lithium ion battery provided by the invention employs the negative electrodeplate subjected to lithium supplement (namely, the negative electrode plate comprising lithium carbonate on a surface) and a lithium carbonate-containing electrolyte, the negative electrode plate andthe electrolyte are jointly matched, and the initial coulombic efficiency and the cycle capacity retention rate of the battery are greatly improved.

Owner:沁新集团(天津)新能源技术研究院有限公司

Method for preparing lithium carbonate from waste and old trinary lithium ion battery electrode power material

InactiveCN108011150AIncrease contentHigh purityWaste accumulators reclaimingBattery recyclingElectrical batteryLithium-ion battery

The invention relates to a recovery process of a waste and old trinary lithium ion battery, in particular to a method for preparing lithium carbonate from a waste and old trinary lithium ion battery electrode power material. By using the method, the waste and old trinary lithium ion battery electrode power material is treated through steps of material mixing, calcination, lithium bicarbonate production and spray drying. The prepared lithium bicarbonate has high content, high purity and high recovery rate. The process route is a green and environment-friendly process; the environment compatibility is high.

Owner:XUCHANG UNIV

Method for extracting lithium carbonate from coal ashes

The invention relates to the technical field of preparation of lithium carbonate. A method for extracting lithium carbonate from coal ashes provided by the invention comprises the following steps: crushing and grinding coal ash filter cakes to obtain coal ash powder; putting the coal ash powder into a reaction kettle, mixing with water, and stirring evenly, so as to obtain coal ash slurry; sealing the coal ash slurry in a reaction kettle, and introducing a carbon dioxide gas, so as to obtain a lithium bicarbonate mixed liquid; filtering the lithium bicarbonate mixed liquid for the first time, so as to obtain a first filter residue and a lithium bicarbonate liquid; putting the first filter residue into hot water, and carrying out hot melting, so as to obtain a lithium carbonate mixed hot liquid; filtering the lithium carbonate mixed hot liquid to obtain a lithium carbonate hot liquid and a second filter residue; mixing the lithium bicarbonate liquid with the lithium carbonate hot liquid, and carrying out crystallizing treatment, so as to obtain lithium bicarbonate crystal and a lithium bicarbonate liquid; adding alkali carbonate or a dilute hydrochloric acid liquid to the lithium bicarbonate liquid, and filtering to obtain a filtered material; and calcining the filtered material and lithium carbonate crystal, so as to obtain lithium carbonate.

Owner:宋英宏

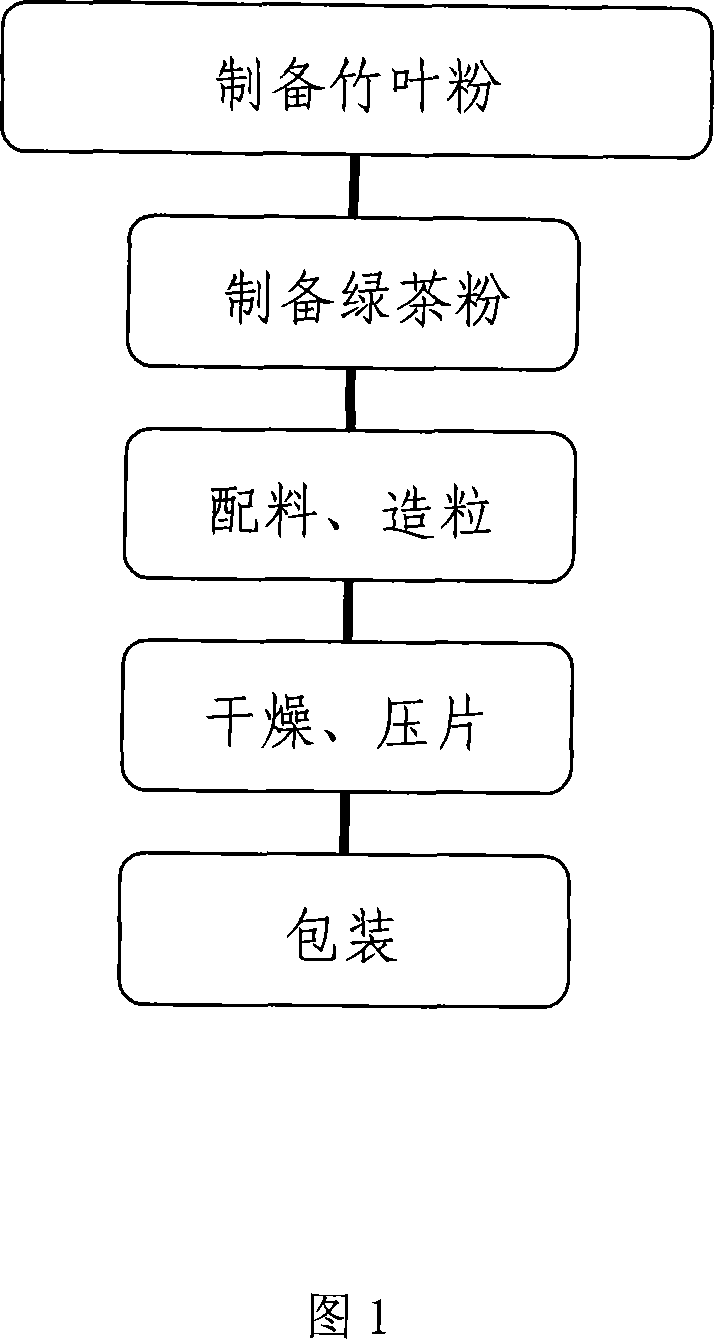

Method for preparing bamboo leaf green tea effervescent tablets

InactiveCN101040643APromote absorptionGood for healthPre-extraction tea treatmentFood preparationSodium bicarbonateAdditive ingredient

The invention discloses a method for preparing bamboo green tea effervescent sheet, comprising that a, preparing bamboo extractive powder, b, preparing green tea extractive powder, c, preparing materials, particle making, d, vacuum drying, and pressing. The invention washes bamboo and green tea, and breaks their cells into 30-50micrometer slurry, to be processed via alcohol extraction, vacuum concentration, atomization drying, and vacuum nitrogen feeding package into bamboo powder and green tea powder, to be mixed uniformly with baking soda, lithium bicarbonate, acid agent, sweetener, malt extract, dolomol, cane sugar powder and alcohol solution, to be granulated via two-step method, vacuum dried and pressed, to be packed as single press or multi press. Compared with general tea preparation, the invention can hold more functional components of tea and bamboo, with quick soluble property and absorption and easy take.

Owner:SHANGHAI INST OF TECH

Method for detecting content of residual free lithium in lithium iron phosphate/carbon composite material

ActiveCN105842389AAccurate measurementEasy to operateChemical analysis using titrationCarbon compositesLithium iron phosphate

The invention discloses a method for detecting the content of residual free lithium in a lithium iron phosphate / carbon composite material, and belongs to the technical field of lithium content determination method. A pH control stepwise titration method is adopted, the residual free lithium element in the lithium iron phosphate / carbon composite material is accurately determined, and the existing form of lithium carbonate or lithium bicarbonate of the free lithium element is effectively distinguished. The detection method has the advantages of being simple to operate, small in error of detection results, more scientific and reasonable, and accurate, can accurately give out the existing form of the free lithium element, and has important industrial value.

Owner:ZHEJIANG RICHPOWER TECH

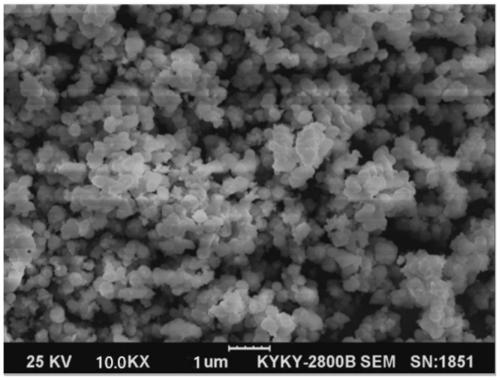

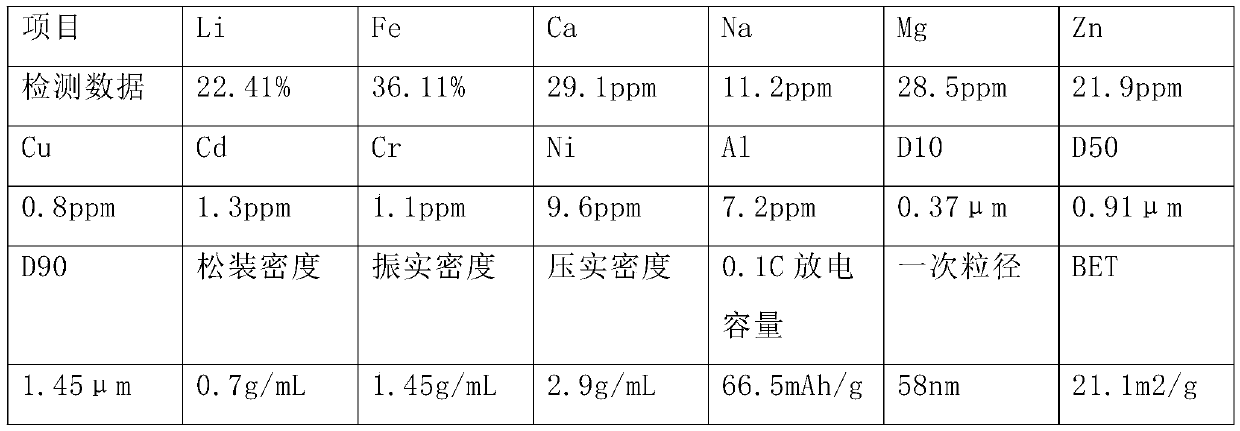

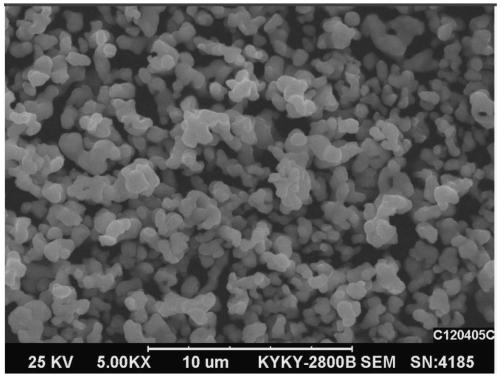

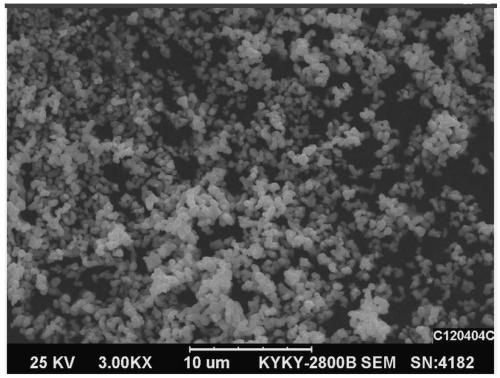

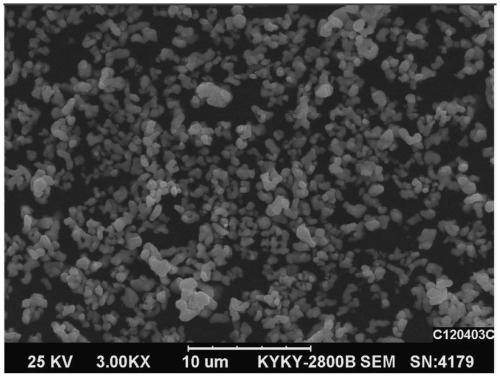

Preparation method for high-purity submicron lithium carbonate

ActiveCN105399115AImprove conversion efficiencyShorten the production cycleLithium carbonates/bicarbonatesPhysical chemistryIon exchange

The invention relates to the technical field of chemical separation and purification, especially to a preparation method for high-purity submicron lithium carbonate. The preparation method comprises the following steps: dissolving a crude lithium carbonate product in high-purity water to prepare lithium carbonate slurry; allowing the lithium carbonate slurry to enter a rotary packed bed and introducing CO2 gas into the rotary packed bed so as to prepare lithium bicarbonate liquid; allowing the lithium carbonate liquid to successively pass through a pretreated calcium-magnesium ion exchange resin apparatus and boron ion exchange resin apparatus so as to allow a second solution to be formed after removal of impurities containing calcium, magnesium and boron in the lithium bicarbonate liquid; uniformly mixing the second solution with a dispersant so as to form a third solution and adding the third solution into the rotary packed bed for a reaction so as to produce lithium carbonate precipitate; and drying the lithium carbonate precipitate so as to obtain a high-purity submicron lithium carbonate product. The preparation method employs crude lithium carbonate of the lithium salt industry as a raw material for preparation of the high-purity submicron lithium carbonate; and the raw material is more widely and easily available and cost for the raw material is greatly reduced.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Method for preparing battery lithium carbonate by continuously carbonizing industrial-grade lithium carbonate

PendingCN114477245AEmission reductionImprove utilization efficiencyLithium carbonates/bicarbonatesPhysical chemistryCarbonization

The invention discloses a method for preparing battery lithium carbonate through continuous carbonization of lithium carbonate, which comprises the following steps: preparing industrial grade lithium carbonate and battery water into slurry according to a solid-liquid ratio of 1: 23-1: 27, putting the slurry into a first-stage carbonization kettle according to a certain flow rate, and enabling the slurry to sequentially enter a second-stage carbonization kettle and a third-stage carbonization kettle through an overflow port to be subjected to carbonization reaction with introduced carbon dioxide gas, a lithium bicarbonate solution is obtained; the carbonized lithium bicarbonate solution is subjected to precise filtration, insoluble substances are removed, it is ensured that SS is smaller than or equal to 5 mg / L, ion adsorption is conducted through an ion exchange device, and a purified lithium bicarbonate solution is obtained; and conveying the lithium bicarbonate solution into a pyrolysis kettle for pyrolysis to obtain a lithium carbonate precipitate, and filtering, washing and drying the obtained lithium carbonate precipitate to obtain battery lithium carbonate. According to the method provided by the invention, the carbonization efficiency of lithium carbonate is improved, the emission of carbon dioxide is effectively reduced, energy is saved, and the method has relatively high practical value.

Owner:宁夏天霖新材料科技有限公司

Preparation method of aluminum-doped lithium manganate

PendingCN110336016AEvenly dopedWide applicabilityCell electrodesLi-accumulatorsChlorideManganese(II,III) oxide

The invention belongs to the technical field of preparation and modification of lithium manganate, in particular to a preparation method of aluminum-doped lithium manganate. The method comprises the following steps: adding water and ammonium chloride solution to manganese powder and then introducing air for reaction; adding mixed solution of ammonia water and ammonium chloride and aluminum chloride solution in turn in the reaction process, and carrying out filtering, washing and drying after reaction to obtain aluminum-doped trimanganese tetraoxide powder; adding the obtained powder to clarified lithium bicarbonate solution and obtaining amorphous Li-Mn-Al-O powder after heating reaction; and calcining the powder at high temperature to obtain aluminum-doped lithium manganate. In the method, the aluminum-doped lithium manganate is produced by reacting the trimanganese tetraoxide uniformly doped with aluminum with lithium bicarbonate solution, which improves the mixing uniformity of lithium carbonate and trimanganese tetraoxide and the doping uniformity of aluminum in the lithium manganate and greatly improves the capacity and cycle stability of the lithium manganate. Moreover, non-high-purity lithium carbonate can be carbonated and pyrolyzed to produce high-purity lithium carbonate as a lithium source, and the goals of low cost and high performance are achieved.

Owner:SINOSTEEL NANJING NEW MATERIALS RES INST CO LTD +1

Preparation method of nano lithium ferrite

The invention discloses a preparation method of nano lithium ferrite. The preparation method comprises: preparing a ferrous solution and a lithium bicarbonate solution; adding a base solution into a reaction kettle; adding the ferrous solution, the lithium bicarbonate solution and an acid-base regulator into the reaction kettle, and reacting to obtain slurry; transferring the slurry into a high-pressure reaction kettle, stirring reaction for 3-5 min at the temperature of 220-250 DEG C under pressure of 0.6-0.9 MPa, after cooling and pressure relief, taking out the material, filtering, and washing to obtain a precipitate; putting the precipitate into a roller bed furnace, calcining for 5-8 h at the temperature of 400-500 DEG C, introducing air in the calcining process, and maintaining the flow velocity of gas in the calcining furnace at 2-3 m / S, and then cooling the calcined material, carrying out air flow crushing, carrying out grading by virtue of a grading wheel, and screening to remove iron, so as to obtain the nano lithium ferrite. The preparation method is simple in process and low in cost, and the obtained nano lithium ferrite is large in specific surface area and uniform inparticle size distribution.

Owner:王柯娜

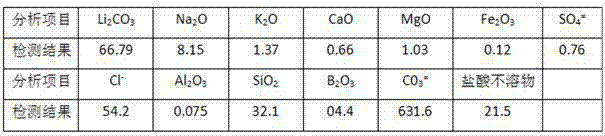

Utilization method of chloride type salt lake brine

The invention discloses a utilization method of chloride type salt lake brine for extracting ultra-high purity lithium carbonate. The method comprises taking chloride type salt lake brine as original solution, preparing lithium chloride concentrated solution by evaporation and concentration, purifying, using ammonium bicarbonate water slurry to precipitate lithium carbonate, dispersing by ultrasonic and washing lithium carbonate, then converting into lithium bicarbonate solution, centrifugally separating and decarbonizing to obtain the ultra-high purity lithium carbonate. By modification to the conventional technical processes and parameters and without the introduction of additional expensive purification steps such as ion exchange resin / membrane, the product purity can reach 99.999wt% and the main impurity total amount will not exceed 0.001wt%.

Owner:JIANGSU HAILONG LITHIUM IND TECH

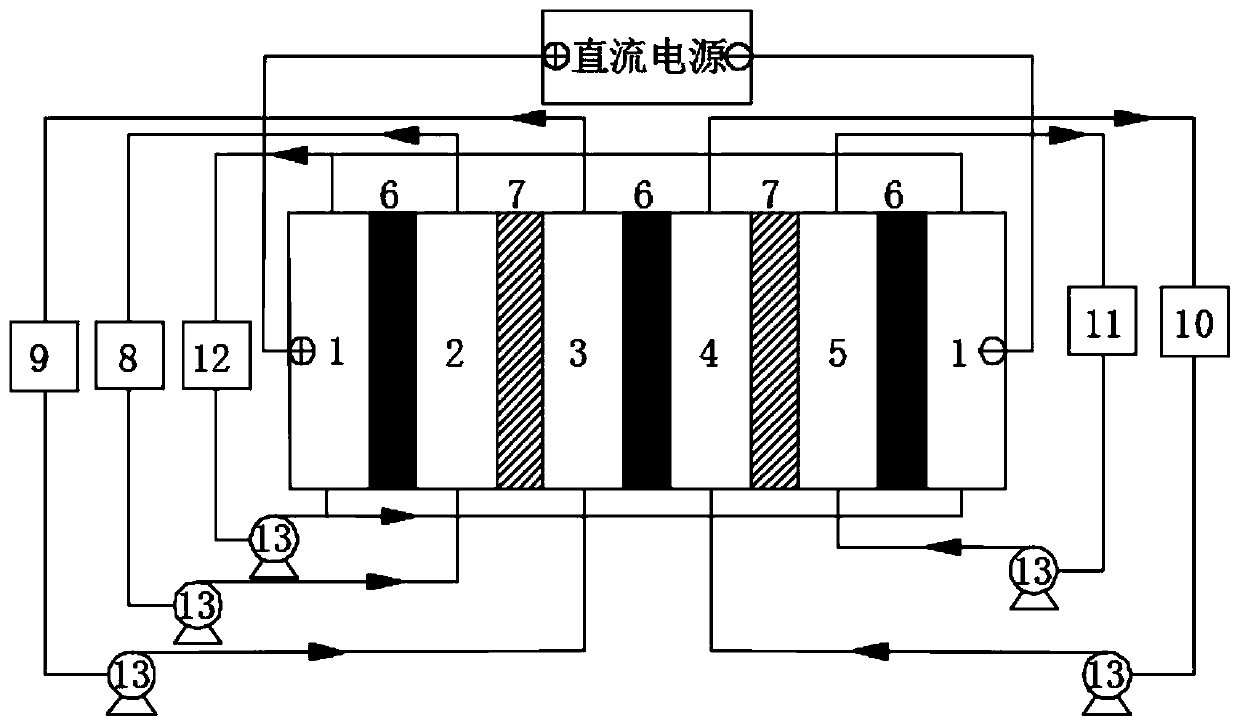

Method for preparing lithium chloride by using four-compartment replacement reaction electrodialysis

PendingCN110395749ASimple pretreatment processHigh purityLithium halidesElectrodialysisLithium chlorideLithium chloride preparation

The invention discloses a method for preparing lithium chloride by using four-compartment replacement reaction electrodialysis. A lithium salt solution, such as lithium sulfate, lithium carbonate or lithium bicarbonate, and a sodium chloride solution are fed into a feeding compartment II and a feeding compartment IV of a four-compartment replacement reaction electrodialysis device, so that under the action of electric field force, lithium ions in the feeding compartment II and chloride ions in the feeding compartment IV respectively pass through the cation exchange membrane and the anion exchange membrane, and a lithium chloride solution is obtained in the product compartment III; in addition, anions in the feeding compartment II and sodium ions in the feeding compartment IV pass through acation exchange membrane and an anion exchange membrane respectively, and a sodium salt solution is obtained in the product compartment I. According to the process, the pretreatment process of the raw materials is simplified, a large amount of hydrochloric acid does not need to be consumed, some impurity ions in the raw materials are removed while lithium carbonate is prepared, the purity of lithium chloride is improved, the difficulty of the aftertreatment process is reduced, and the method is a low-consumption, environment-friendly and recyclable lithium chloride preparation method.

Owner:SHANDONG UNIV OF SCI & TECH

Preparation method of phosphorus-doped lithium nickel cobalt ferrite

ActiveCN111533184AHigh reactivityImprove compactnessCell electrodesLi-accumulatorsAir atmosphereO-Phosphoric Acid

The invention discloses a preparation method of phosphorus-doped lithium nickel cobalt ferrite. The preparation method comprises the steps: adding a nickel-cobalt solution into an ammonium bicarbonatesolution, reacting, filtering and washing to obtain nickel-cobalt carbonate precipitate; adding the nickel-cobalt carbonate precipitate into a phosphoric acid solution, and stirring for reaction to obtain a phosphate radical doped nickel-cobalt precipitate; adding the phosphate radical doped nickel-cobalt precipitate into a polyethylene glycol solution and a lithium bicarbonate solution, stirring, slurrying, carrying out spray drying, and carrying out primary calcination to obtain a primary calcined material; adding ferrous salt and lithium salt into the primary calcined material, then addingwater, adding an ammonium carbonate solution and an acid solution after grinding and levigating are conducted, filtering, washing and drying, and obtaining a reaction material; and carrying out high-temperature calcination on the reaction material in an air atmosphere to obtain a secondary calcined material, carrying out jet milling on the secondary calcined material, screening to remove iron, and carrying out vacuum packaging to obtain the phosphorus-doped lithium nickel cobalt ferrite. The conductivity can be improved through phosphorus-doped lithium nickel cobalt oxide so that the structure stability is better, and the product capacity and the cycle performance are excellent.

Owner:蒋达金

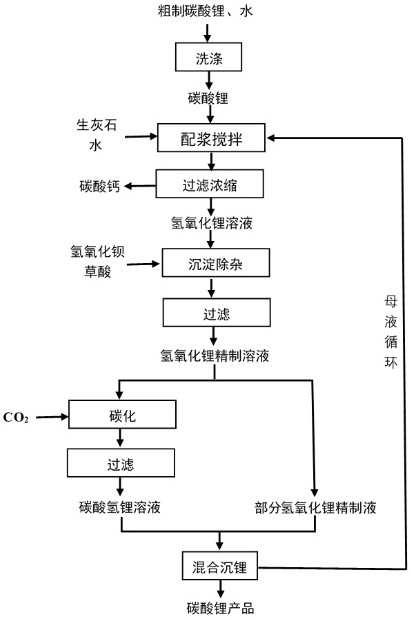

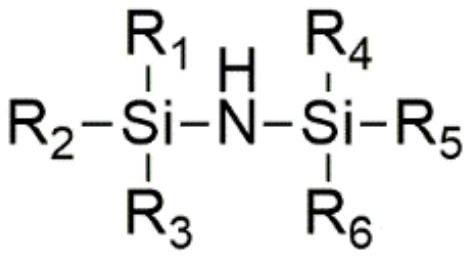

Method for producing high-purity lithium carbonate by causticizing and carbonizing coarse lithium carbonate lime

PendingCN114105172ALow costStep closeLithium carbonates/bicarbonatesProductsGas liquid reactionLithium hydroxide

The invention discloses a method for producing high-purity lithium carbonate by causticizing and carbonizing coarse lithium carbonate lime, which comprises the following steps: 1) adding water into the coarse lithium carbonate to remove soluble salt, stirring the separated solid with water and quicklime to react, and carrying out solid-liquid separation to obtain a lithium hydroxide solution; 2) concentration; 3) adding an impurity removal agent into the concentrated solution, stirring for reaction, and performing solid-liquid separation to obtain a refined solution; 4) absorbing carbon dioxide by one part of the refined solution, carbonizing, and filtering to obtain a lithium bicarbonate solution; and 5) mixing and reacting the lithium bicarbonate solution with the other part of the refined solution to obtain the high-purity lithium carbonate. According to the invention, the traditional gas-liquid reaction process of carbonization and lithium precipitation of carbon dioxide absorbed by lithium hydroxide is converted into liquid-liquid reaction, the tolerance of impurities in the solution can be increased, the crystallization is mild, the purity and granularity of the product are easy to control, the inclusion of the impurities is not easy to form, the washing procedure is reduced, the procedures of ion exchange and lithium bicarbonate pyrolysis are omitted, and the production cost is reduced. The investment cost and the evaporation load are greatly reduced, and large profits can be achieved.

Owner:FUZHOU UNIV

Method for manufacturing battery grade lithium carbonate by industrial grade lithium carbonate

InactiveCN107804861AImprove conversion efficiencyShort conversion efficiencyLithium carbonates/bicarbonatesEthylenediamineResource utilization

The invention discloses a method for manufacturing battery grade lithium carbonate by industrial grade lithium carbonate. The method includes the steps: dissolving the industrial grade lithium carbonate in distilled water to prepare lithium carbonate slurry; uniformly mixing ethylenediamine tetraacetic acid and sodium hydroxide solution to obtain ethylenediamine tetraacetic acid and sodium hydroxide mixed solution; feeding the lithium carbonate slurry into a rotating packed bed, leading CO2 gas into the rotating packed bed and performing carbonization reaction to obtain feed liquid; adding theethylenediamine tetraacetic acid and sodium hydroxide mixed solution into the feed liquid, and sufficiently stirring the mixed solution and the feed liquid to obtain mixed feed liquid; performing solid-liquid separation on the mixed feed liquid to obtain lithium bicarbonate solution; adding the lithium bicarbonate solution into a negative pressure device, decomposing lithium bicarbonate and precipitating the battery grade lithium carbonate. Compared with the prior art, the method is simple in process, convenient in operation, beneficial to batch production, short in reaction time, high in conversion efficiency, efficient in resource utilization and wide in application prospect.

Owner:大余县旭日矿业科技有限公司

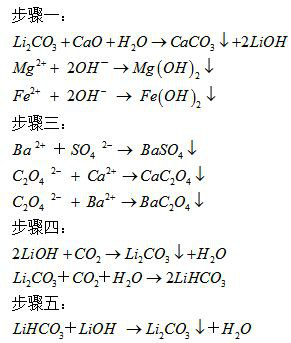

Preparation method of lithium tetrafluoro (oxalato) phosphate and lithium difluoro (oxalato) phosphate

InactiveCN111690010AEfficient removalEasy to separateGroup 5/15 element organic compoundsOXALIC ACID DIHYDRATESilazane

The invention discloses a preparation method of lithium tetrafluoro (oxalato) phosphate and lithium difluoro (oxalato) phosphate. The method comprises the following steps: in a nitrogen atmosphere, adding silazane into an oxalic acid solution, uniformly stirring, dropwise adding a lithium hexafluorophosphate solution according to a molar ratio of the dropwise adding amount of lithium hexafluorophosphate to oxalic acid of 1: (0.8-1.2), and reacting to obtain lithium tetrafluoro (oxalato) phosphate; or adding silazane into an oxalic acid solution, dropwise adding the lithium hexafluorophosphatesolution after uniform stirring, wherein the molar ratio of the dropwise adding amount of lithium hexafluorophosphate to oxalic acid is 1: (1.8-2.4), and obtaining lithium difluorobis (oxalate) phosphate after reaction. The reaction route and reaction conditions are safe, environmentally friendly, economical and capable of achieving industrialization, generated by-products are lithium bicarbonateand lithium fluoride, separation is easy, no corrosive gas is generated, and the safety of the whole technological process is improved.

Owner:香河昆仑新能源材料股份有限公司

Method for quickly depositing lithium carbonate from lithium bicarbonate solution

ActiveCN101182012AIncrease sedimentation rateHigh recovery rateCarbonate preparationHydrogenOrganic solvent

The invention provides a method for rapidly precipitating lithium carbonate from lithium bicarbonate solution. The method adopts a heatable negative pressure device, uses water-soluble organic solvents such as ethanol, propanol, etc., controls the temperature at 80-180°C, and stirs under the condition of negative pressure in the container at 0.01-0.10MPa to carry out isovolumic reaction, so that bicarbonate Lithium decomposes, precipitates lithium carbonate, and the precipitated mother liquor can be recycled and reused. The present invention not only overcomes the problems of "wall-hanging effect" of precipitation and "concentration entrainment effect" of water-soluble impurity ions in the ordinary evaporation and precipitation process, but also accelerates the precipitation rate: the precipitation process only takes about 20 minutes, which is faster than the ordinary evaporation and precipitation method. 2 to 3 times; the precipitation rate of lithium is improved: the single precipitation rate of lithium carbonate reaches more than 87%, and the total lithium recovery rate reaches more than 94%.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Technological method for recycling lithium from lithium-containing waste liquid of medicine and synthetic plastics industries

ActiveCN105129826ASolve the problem of saving resourcesSolve environmental problemsLithium halidesLithium carbonates/bicarbonatesPlastics industryDecomposition

The invention discloses a technological method for recycling lithium from lithium-containing waste liquid of medicine and synthetic plastics. The technological method comprises the following steps of: (1) preparing feedstocks; (2) evaporating and concentrating the feedstocks so as to obtain crude lithium carbonate; (3) drying the crude lithium carbonate; (4) calcinating the dried lithium carbonate so as to obtain crude powdery lithium carbonate; (5) adding water into the crude powdery lithium carbonate so as to pulpify the crude powdery lithium carbonate, and introducing CO2 into the lithium carbonate slurry so as to acidify the lithium carbonate slurry; (6) performing resin purification on the acidified lithium carbonate slurry so as to obtain lithium bicarbonate purified liquid; (7) heating the lithium bicarbonate purified liquid for decomposition and washing and separating the liquid so as to obtain wet pure lithium carbonate; and (8) drying the wet pure lithium carbonate so as to obtain powdery pure lithium carbonate; or acidifying the wet pure lithium carbonate, then concentrating and crystallizing the acidified lithium carbonate, and drying the crystallized lithium carbonate so as to obtain the powdery pure lithium carbonate. The technological method disclosed by the invention is simple in process, high in recycling rate, controllable in cost, and easy to popularize and apply in industrial production. Through the recycling of the lithium-containing waste liquid resources in the medicine and synthetic plastics industry, a national precious rare resource is saved.

Owner:江西环锂新能源科技有限公司

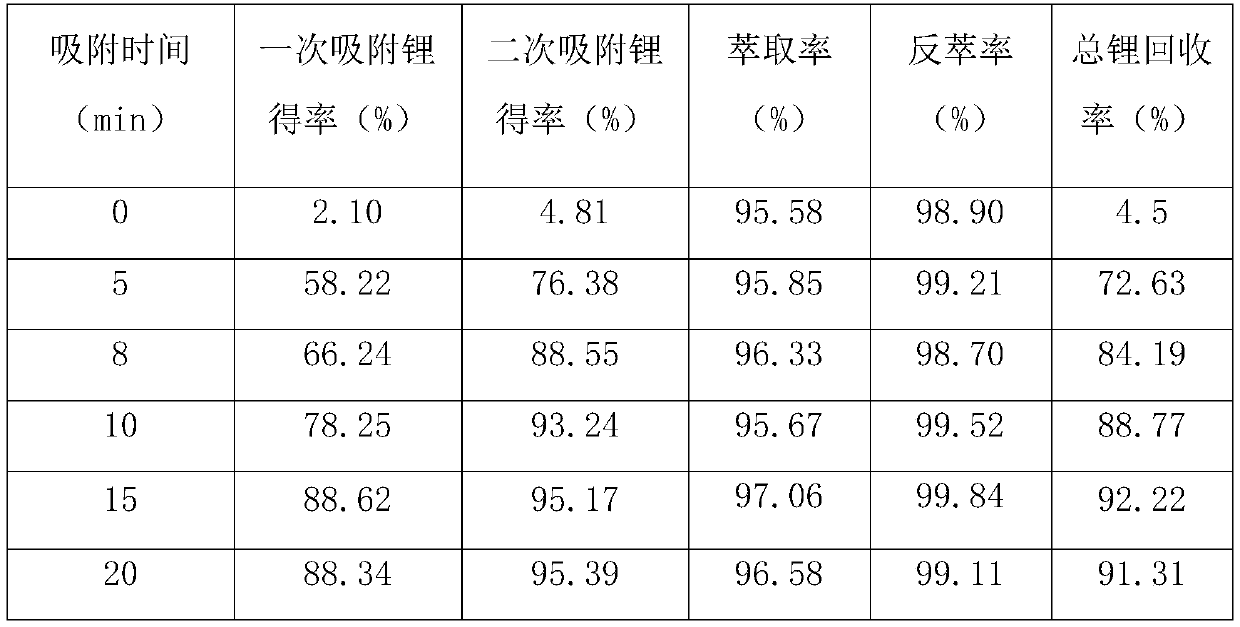

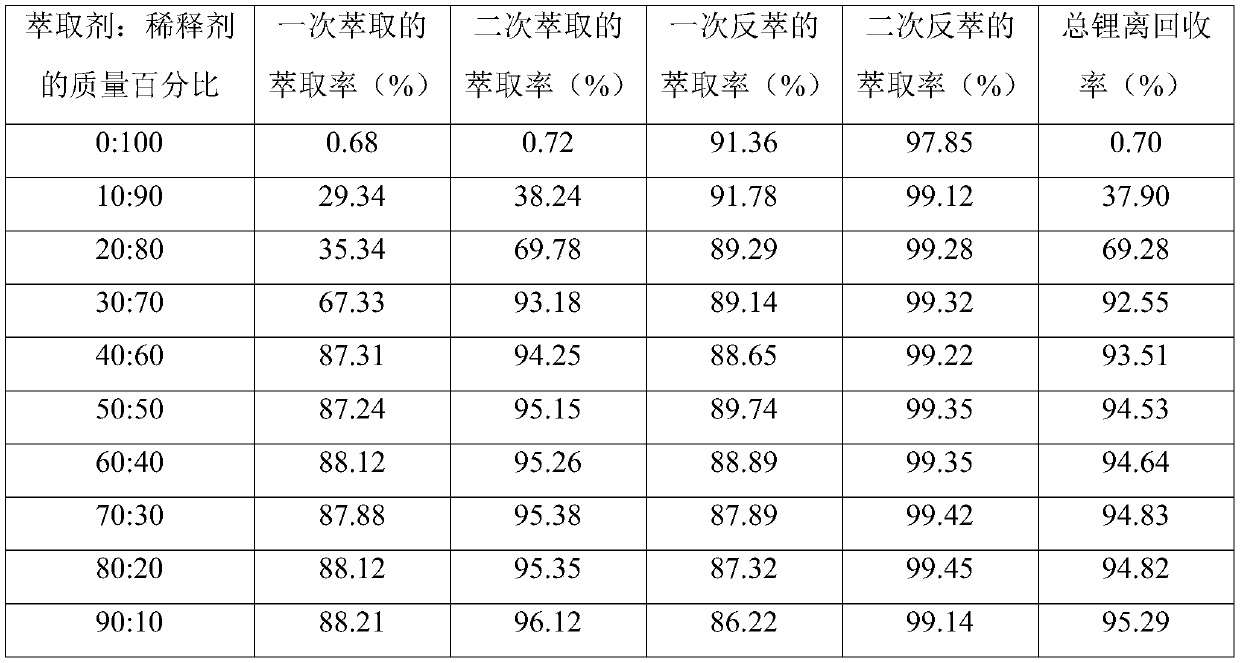

Method for extracting lithium from water with high magnesium-lithium ratio and preparing lithium carbonate

PendingCN111410216AAvoid incomplete precipitationAvoid lostMultistage water/sewage treatmentWater/sewage treatment by heatingPhysical chemistryLithium bicarbonate

The invention belongs to the technical field of chemical engineering. In order to solve the problem that efficient and cheap production of lithium carbonate cannot be achieved through an existing process, the invention provides a method for extracting lithium from water with the high magnesium-lithium ratio and preparing lithium carbonate, an adsorption-extraction method is adopted for extractinglithium ions and preparing high-purity lithium carbonate. The method comprises the steps of firstly, introducing water containing lithium into an adsorbent to be adsorbed and desorbed; adding a certain amount of alkali into the desorption solution to remove impurities such as magnesium; then uniformly mixing the desorbed liquid after impurity removal with an extraction agent according to a certainproportion, and carrying out phase splitting to obtain an extraction liquid; mixing the extracting solution with a stripping agent, and carrying out phase splitting to obtain lithium bicarbonate; andfinally, heating and decomposing the obtained lithium bicarbonate, crystallizing and separating out, washing and drying to obtain high-yield and high-purity battery-grade lithium carbonate. Accordingto the method, the lithium ions can be efficiently extracted in an environment-friendly manner under the condition that the magnesium-lithium ratio is greater than 500:1; energy consumption is low, purity is high, selectivity is good, the recovery rate is high, and cyclic continuous production can be achieved.

Owner:孟元

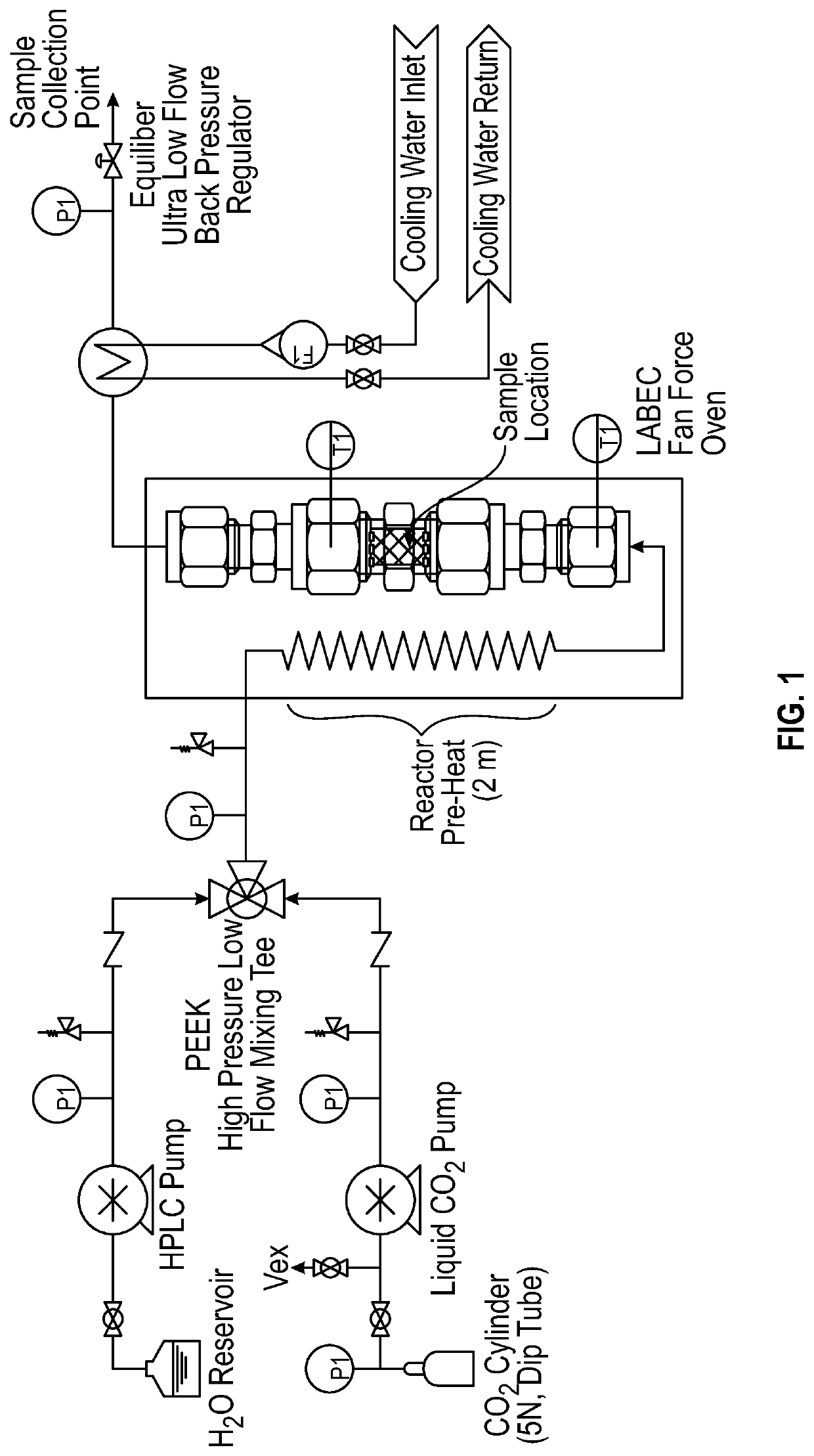

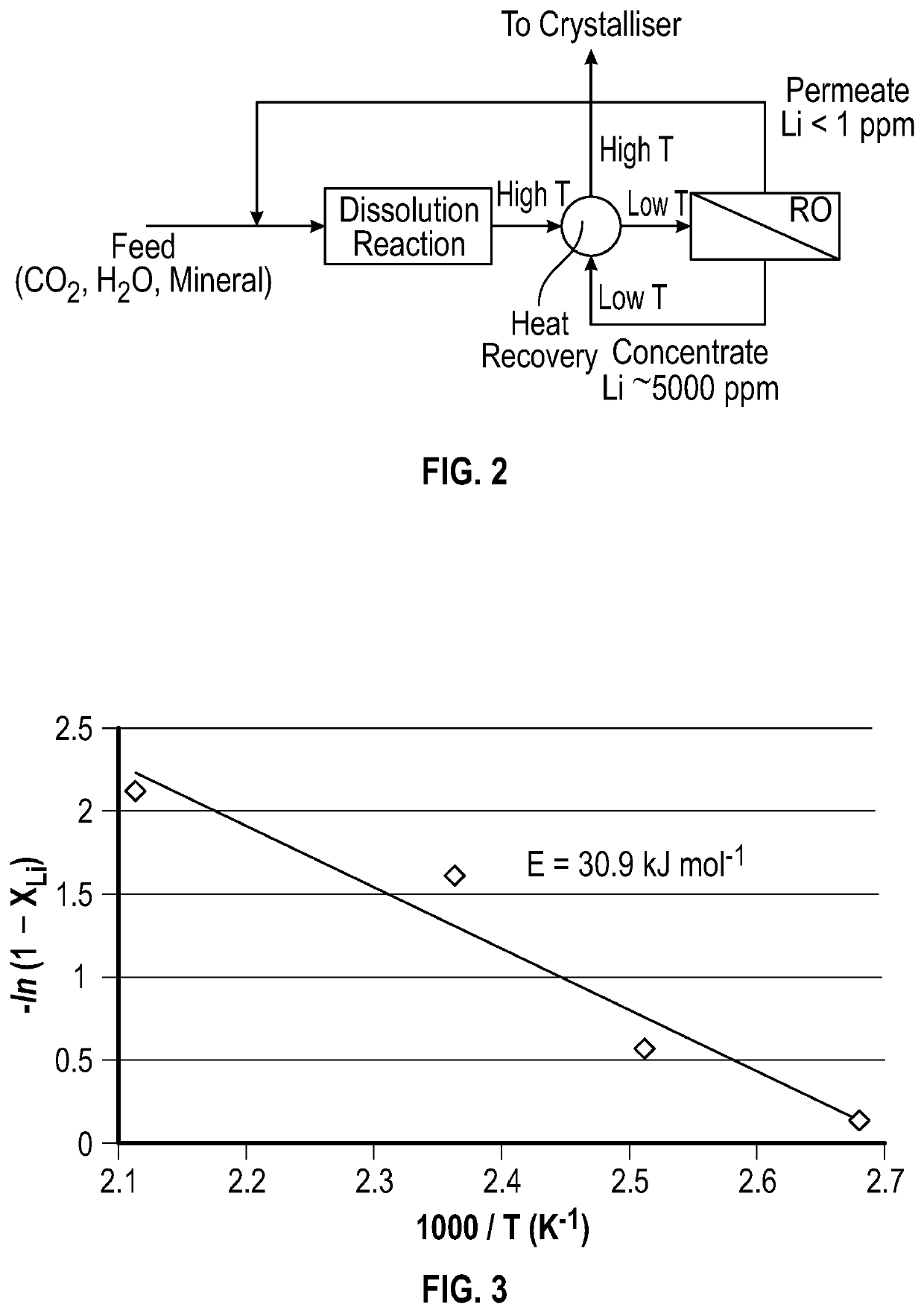

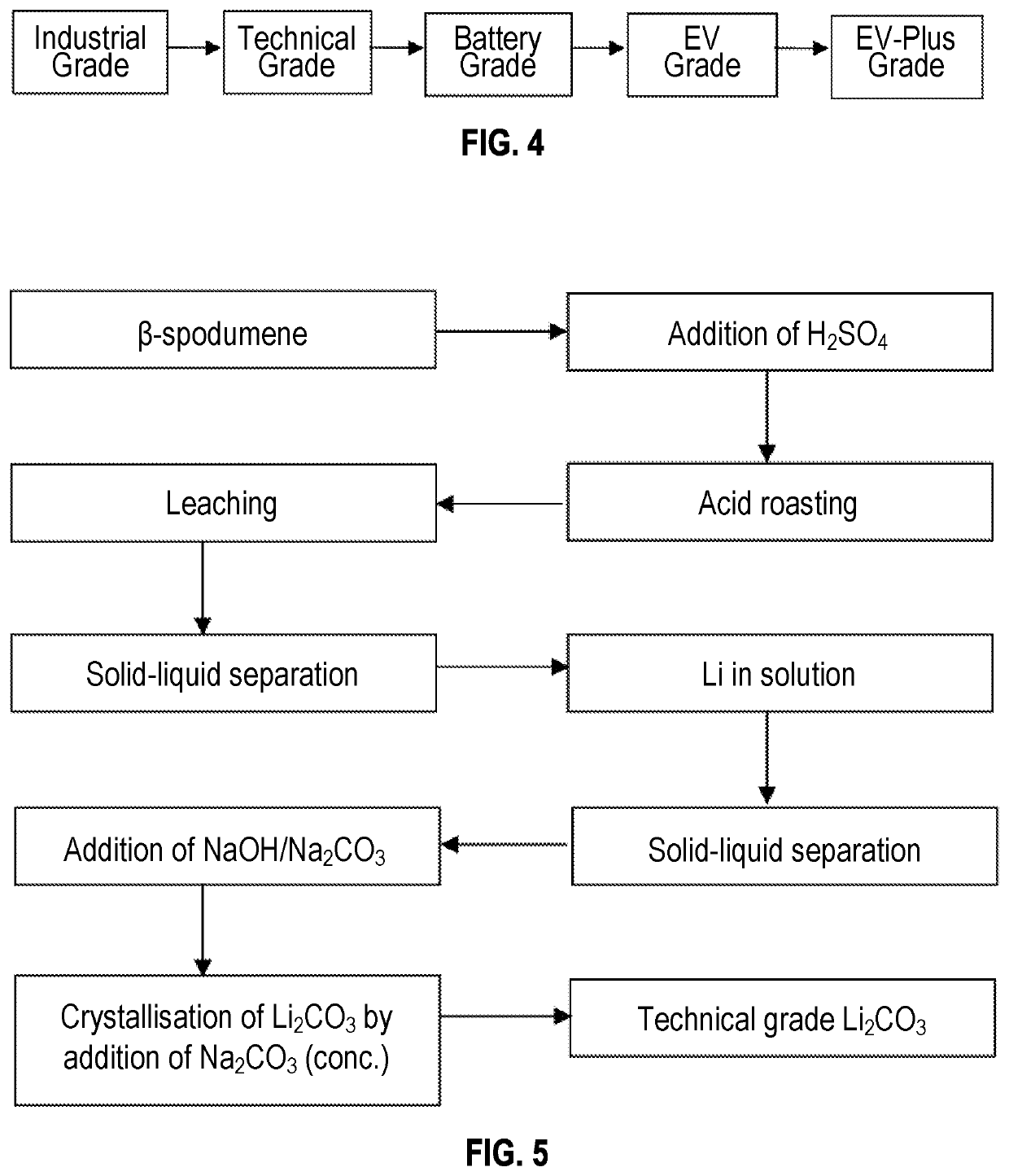

Lithium extraction method

ActiveUS11371116B2Process efficiency improvementSolid solvent extractionPhysical chemistryEngineering

According to the present invention there is provided a method for the extraction of lithium from one or more lithium-containing ores such as spodumene, the inventive method comprising the steps of: milling said ore / s to a predetermined average particle size; optionally calcining the milled ore; further optionally performing a secondary milling step; providing an aqueous suspension of the one or more lithium-containing ores at a predetermined solids concentration; subjecting the one or more lithium-containing ores to an aqueous extraction medium defined by a predetermined partial pressure of CO2, a predetermined extraction temperature, over a predetermined time; and obtaining technical grade lithium carbonate / lithium bicarbonate therefrom. Optional concentration and / or precipitation / purification steps may follow.

Owner:NOVALITH TECH PTY LTD

A method for comprehensive recovery of valuable metals from waste lithium-ion battery materials

ActiveCN106129511BEfficient recyclingHigh recovery rateWaste accumulators reclaimingProcess efficiency improvementLithiumManganese

The invention discloses a method for comprehensively recovering valuable metals from a waste lithium-ion battery material. The method is characterized by comprising the steps of mixing a waste lithium-ion battery positive electrode material with a reducing agent, or mixing simply crushed whole battery with a carbon reducing agent; carrying out reducing roasting treatment at the temperature of 500-750 DEG C; firstly carbonizing and leaching a roasted product through CO2 to obtain a lithium bicarbonate water solution for preparing an Li2CO3 product; and leaching valuable elements of cobalt, nickel, manganese and the like from liquid leached residues through oxidation acid leaching or oxidation ammonia leaching, carrying out extracting and purifying and then preparing the corresponding compound product. The method is simple in technology and short in flow; the reagent cost is low; and valuable metal elements of lithium, the cobalt, the nickel, the manganese and the like in the waste lithium-ion battery material can be efficiently recovered.

Owner:GUANGDONG GUANGHUA SCI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com