Method for preparing bamboo leaf green tea effervescent tablets

A technology of effervescent tablets and green tea, which is applied in the field of preparation of effervescent tablets of bamboo leaf green tea, can solve problems such as inconvenient consumption, and achieve the effects of convenient consumption, improvement of human immunity, and easy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

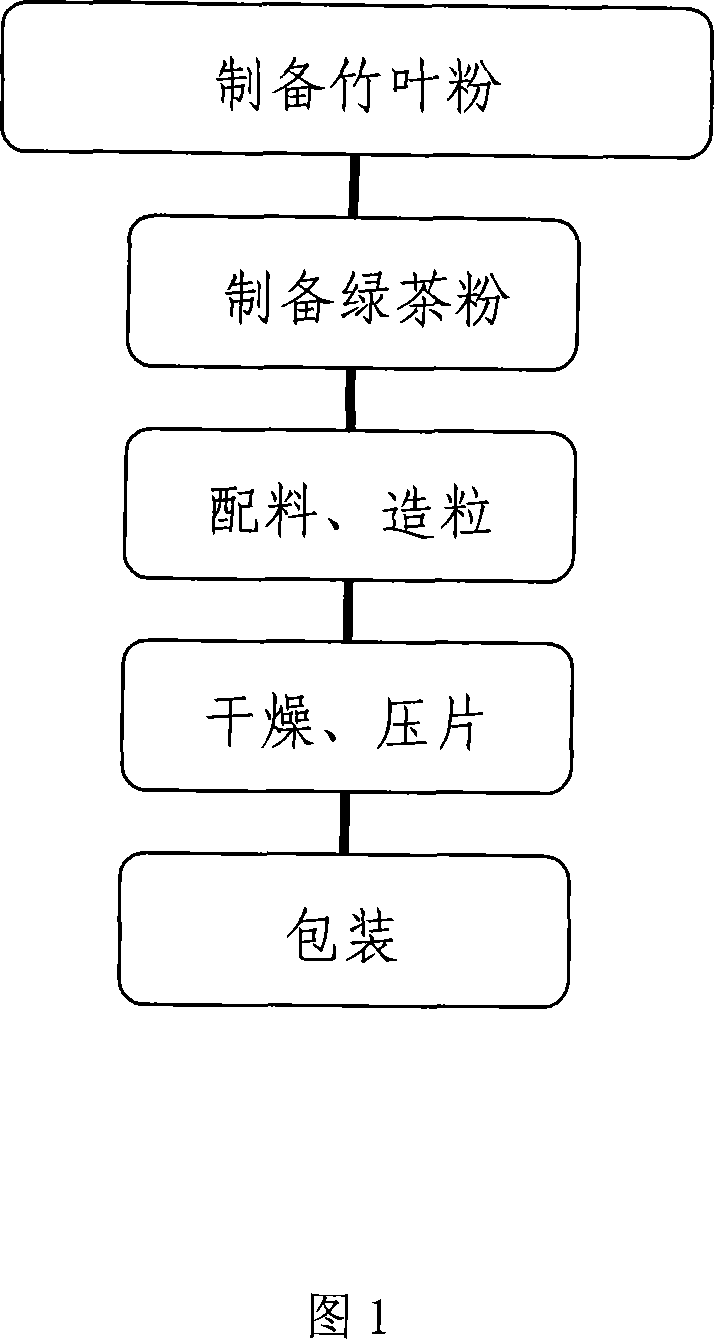

[0016] Further detailed description of the present invention: as shown in Figure 1, the preparation method of bamboo leaf green tea effervescent tablet of the present invention is as follows: a kind of preparation method of bamboo leaf green tea effervescent tablet comprises the following steps:

[0017] a. Preparation of bamboo leaf extract powder

[0018] Clean bamboo leaves, dry them at 40°C-70°C for 6-12 hours, mix dry bamboo leaves and ethanol (concentration: 70% (w / w)) in a ratio of 1:5-20, and process them under high-speed shearing. In the machine, the bamboo leaves are subjected to cell wall breaking and micronization treatment, crushed into a slurry with a fineness of 30-50 μm, extracted at a temperature of 60-80°C for 60-120min, and then at a temperature of 40-60°C and a vacuum degree of 0.59 Under the condition of ~0.86MPa, vacuum concentrate until the dry solids reach more than 40% (w / w), and finally use the spray drying method to dry the concentrate, control the i...

Embodiment 1

[0027] Preparation of Bamboo Leaf Extract Liquid Powder

[0028] Clean the bamboo leaves, dry 200g of the bamboo leaves at a temperature of 50°C for 10h, mix the dried bamboo leaves 80g with 400ml 70% (w / w) ethanol solution, and carry out cell wall breaking and Micronize it to crush it into a slurry with a fineness of 30-50 μm, extract it at a temperature of 60-80°C for 60 minutes, and then concentrate it in vacuum until the dry solid reaches 40 at a temperature of 40-60°C and a vacuum degree of 0.59-0.86MPa. % (w / w), and finally adopt the spray drying method to dry its concentrate, control the air inlet temperature at 50-110°C, the air outlet temperature at 50-70°C, and the moisture content of the bamboo leaf extract powder after drying is ≤5%;

[0029] Preparation of green tea extract powder

[0030] Clean the green tea, dry 100g of green tea at a temperature of 50°C for 8 hours, mix 50g of dry green tea with 250ml of 70% (w / w) ethanol solution, and carry out cell wall brea...

Embodiment 2

[0038] Preparation of Bamboo Leaf Extract Liquid Powder

[0039]Clean the bamboo leaves, dry 100g bamboo leaves at a temperature of 50°C for 10h, mix 40g of dry bamboo leaves with 800ml 70% (w / w) ethanol solution, and carry out cell wall breaking and Micronize it to crush it into a slurry with a fineness of 30-50μm, extract it at a temperature of 60-80°C for 120min, and then concentrate it in vacuum until the dry solid reaches 40 at a temperature of 40-60°C and a vacuum degree of 0.59-0.86MPa. % (w / w), and finally adopt the spray drying method to dry its concentrate, control the air inlet temperature at 50-110°C, the air outlet temperature at 50-70°C, and the moisture content of the bamboo leaf extract powder after drying is ≤5%;

[0040] Preparation of green tea extract powder

[0041] Clean the green tea, dry 50g of green tea at a temperature of 50°C for 8 hours, mix 25g of dry green tea with 750ml of 70% (w / w) ethanol solution, and carry out cell wall breaking and miniatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com