Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

477results about "Lithium halides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation of complex fluoride and complex fluoride phosphor

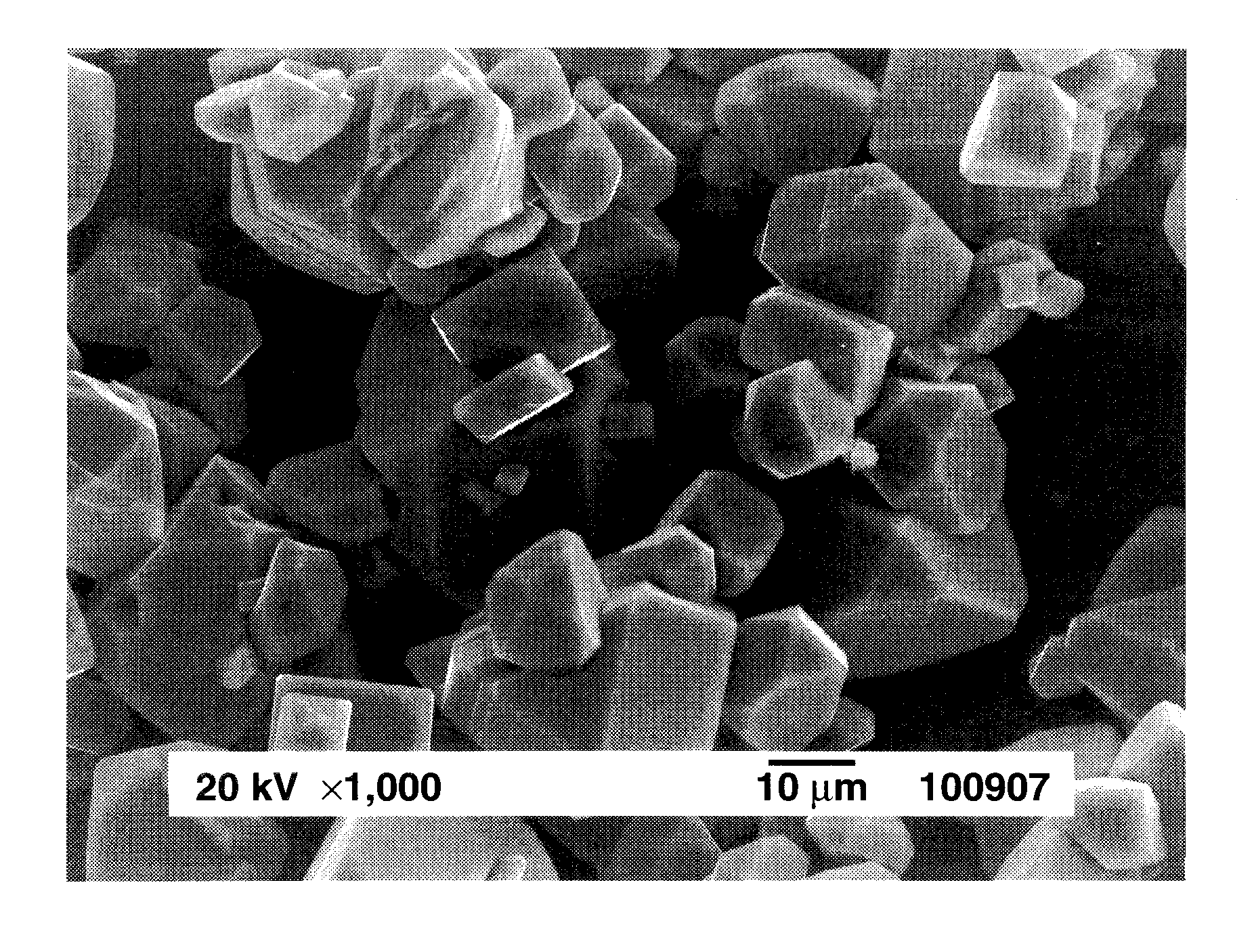

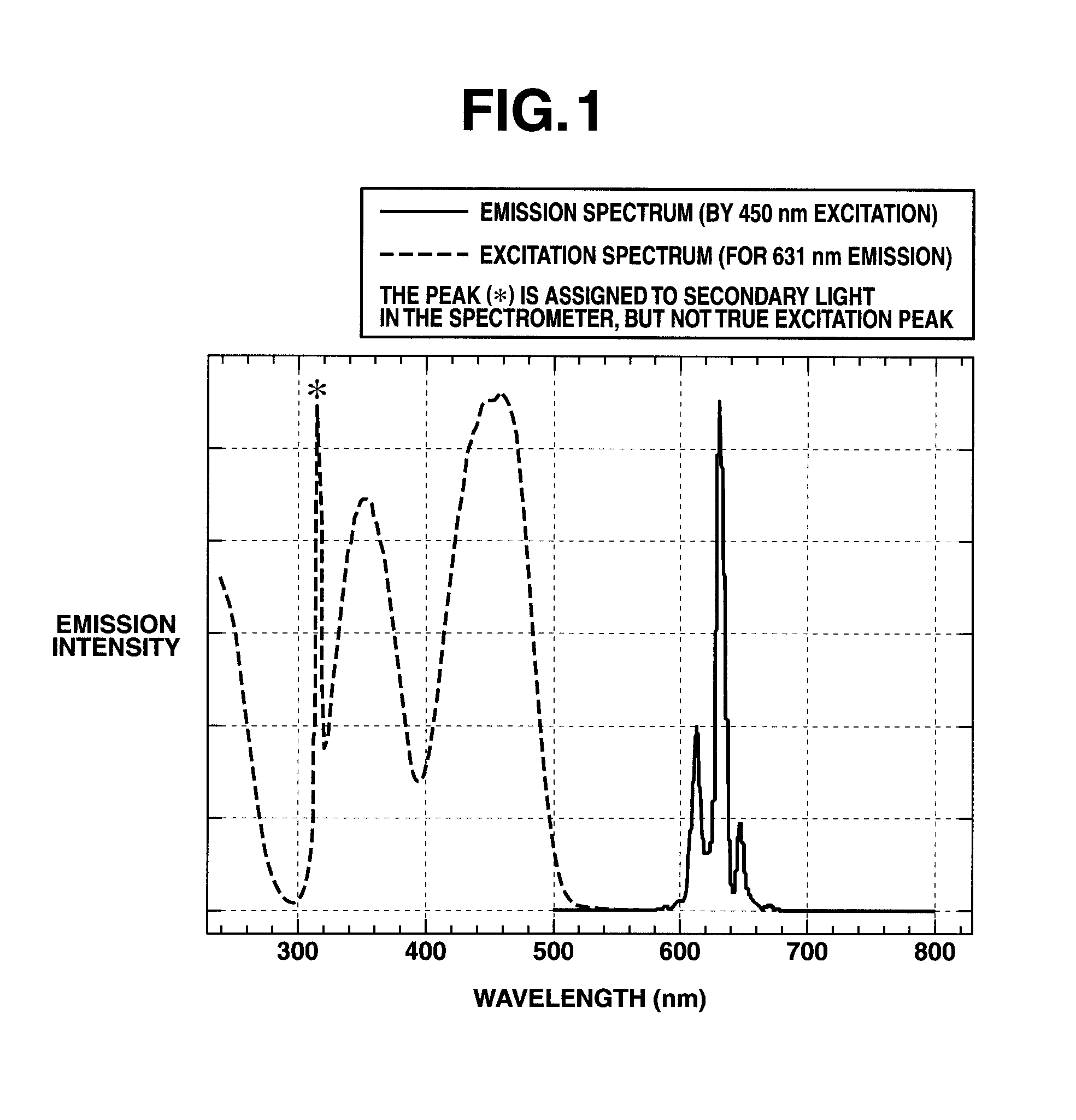

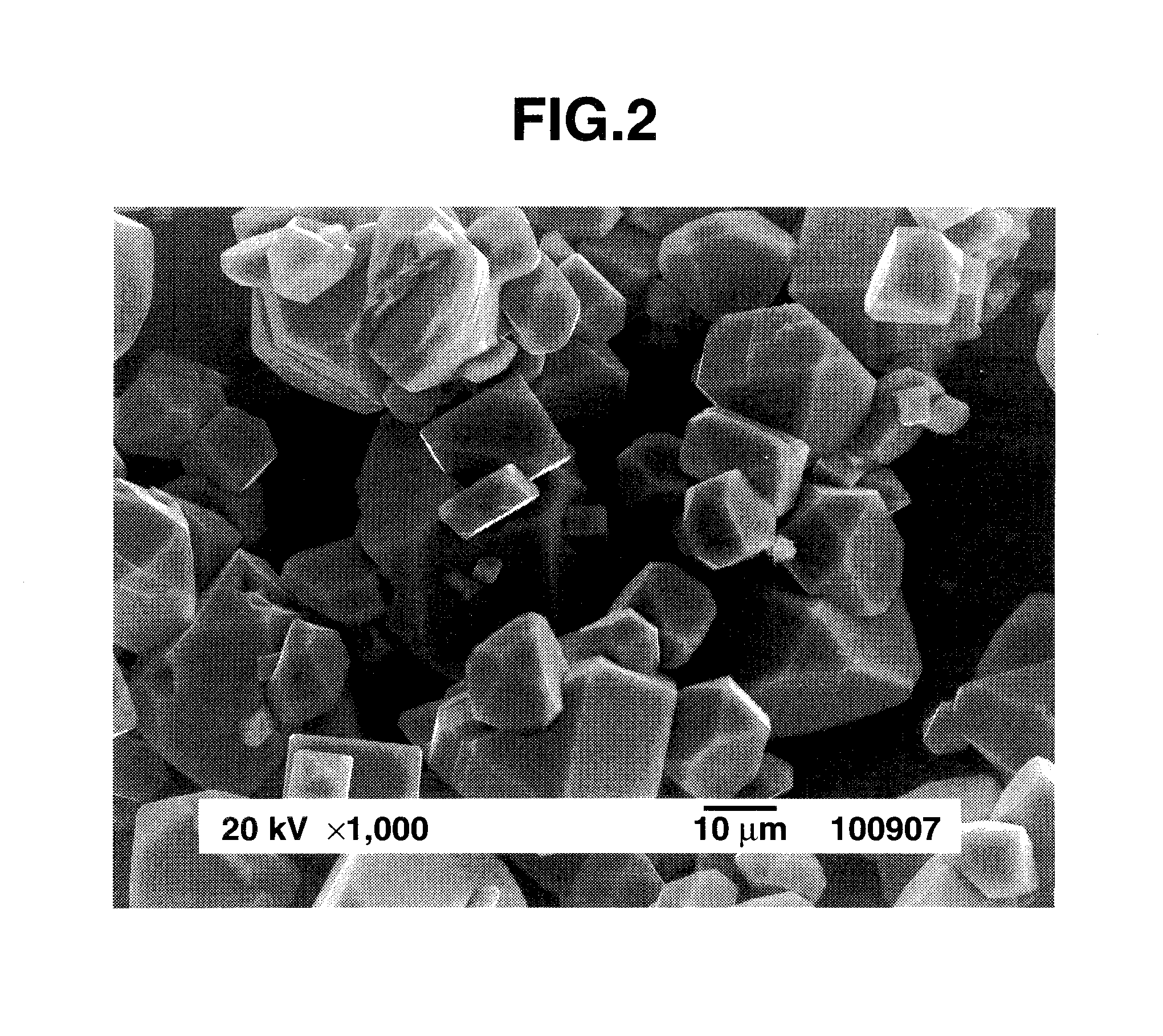

ActiveUS20120256125A1Uniform sizeSatisfactory emissive propertyTin compoundsSilicon halogen compoundsPhysical chemistryFluoride

A complex fluoride A2MF6 wherein M is a tetravalent element Si, Ti, Zr, Hf, Ge or Sn, A is an alkali metal Li, Na, K, Rb or Cs is prepared by providing a first solution containing a fluoride of M, providing a second solution containing a compound of A and / or the compound of A in solid form, mixing the first solution with the second solution and / or the solid for reacting the fluoride of M with the compound of A, and recovering the resulting solid product via solid-liquid separation.

Owner:SHIN ETSU CHEM IND CO LTD

Method for separating magnesium and concentrating lithium from brine in salt lake

ActiveCN1626443AHighly selective extractionEfficient separationMagnesium halidesLithium halidesLithiumSalt lake

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

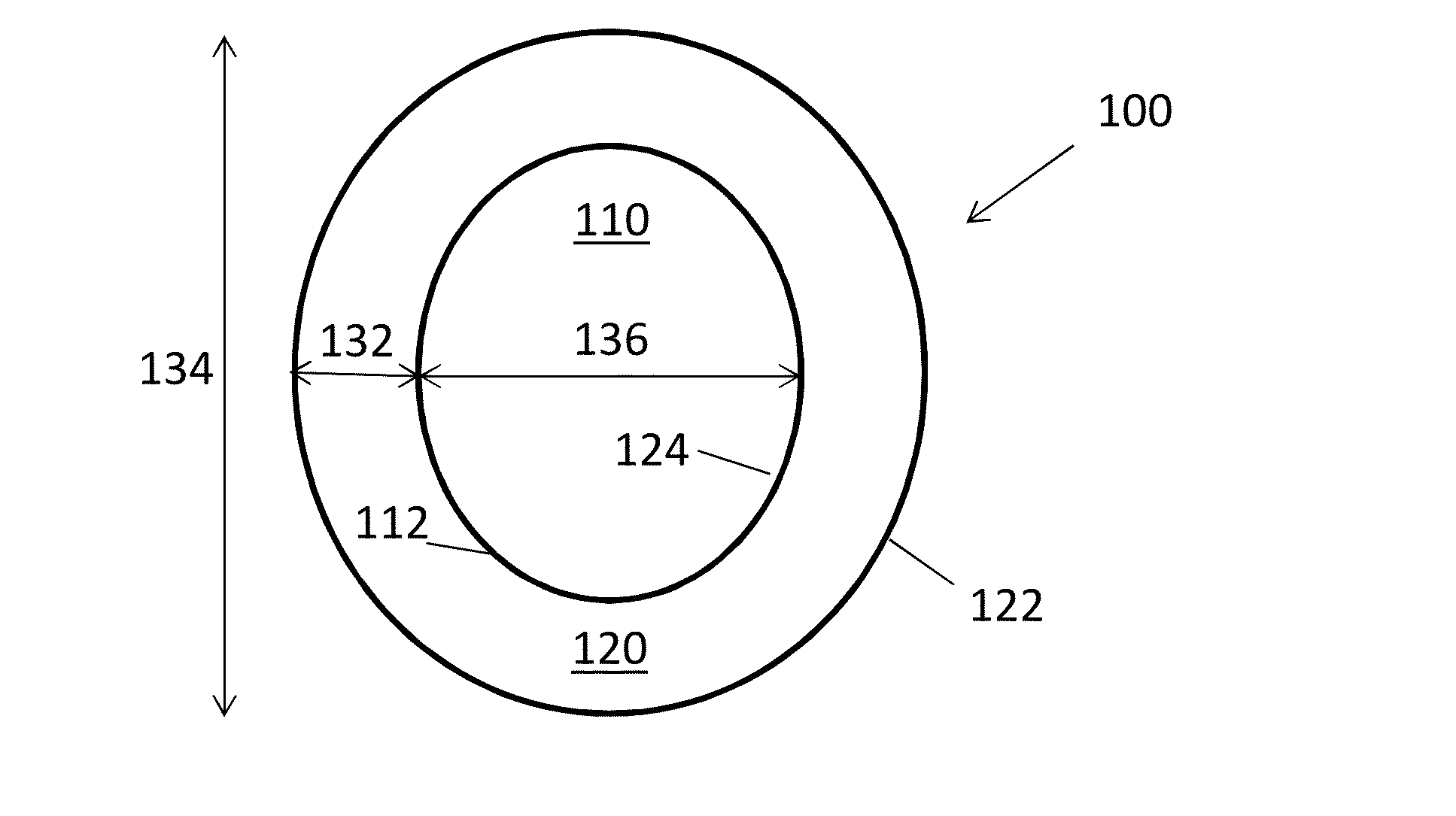

Stabilized lithium composite particles

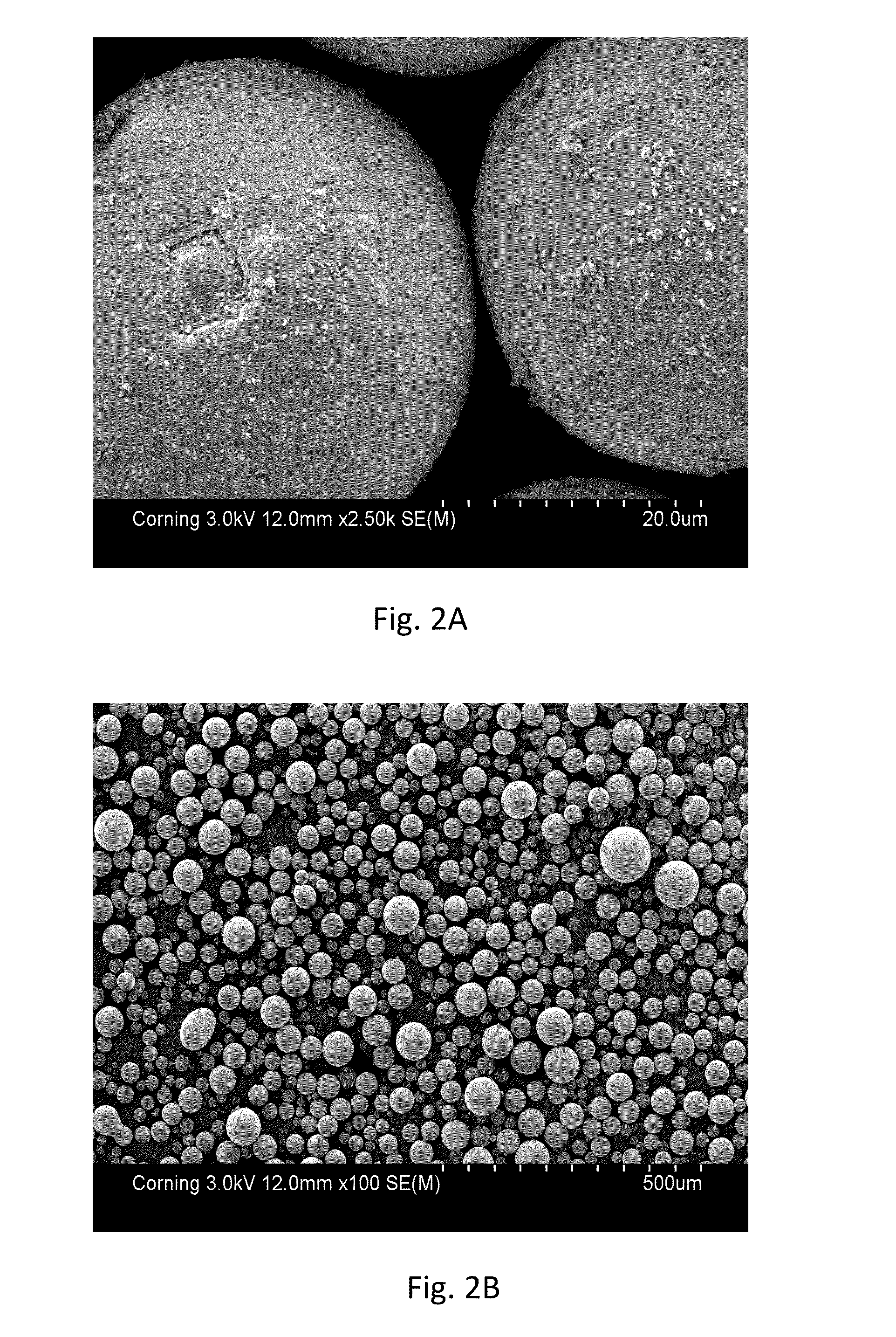

Stabilized lithium particles include a lithium-containing core and a coating of a complex lithium salt that surrounds and encapsulates the core. The coating, which is a barrier to oxygen and water, enables the particles to be handled in the open air and incorporated directly into electrochemical devices. The coating material is compatible, for example, with electrolytic materials that are used in electrochemical cells. The average coated particle size is less than 500 microns.

Owner:CORNING INC

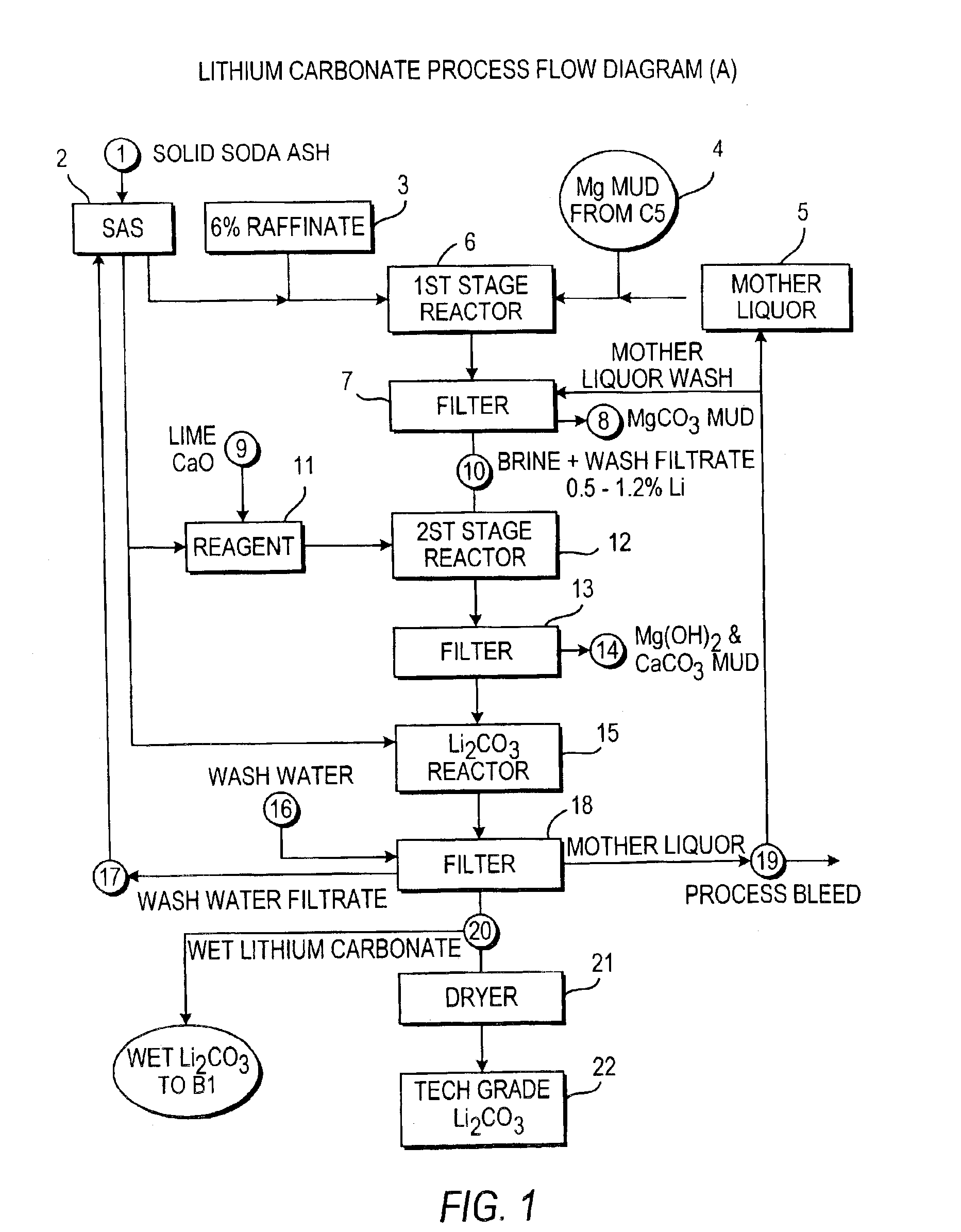

Production of lithium compounds directly from lithium containing brines

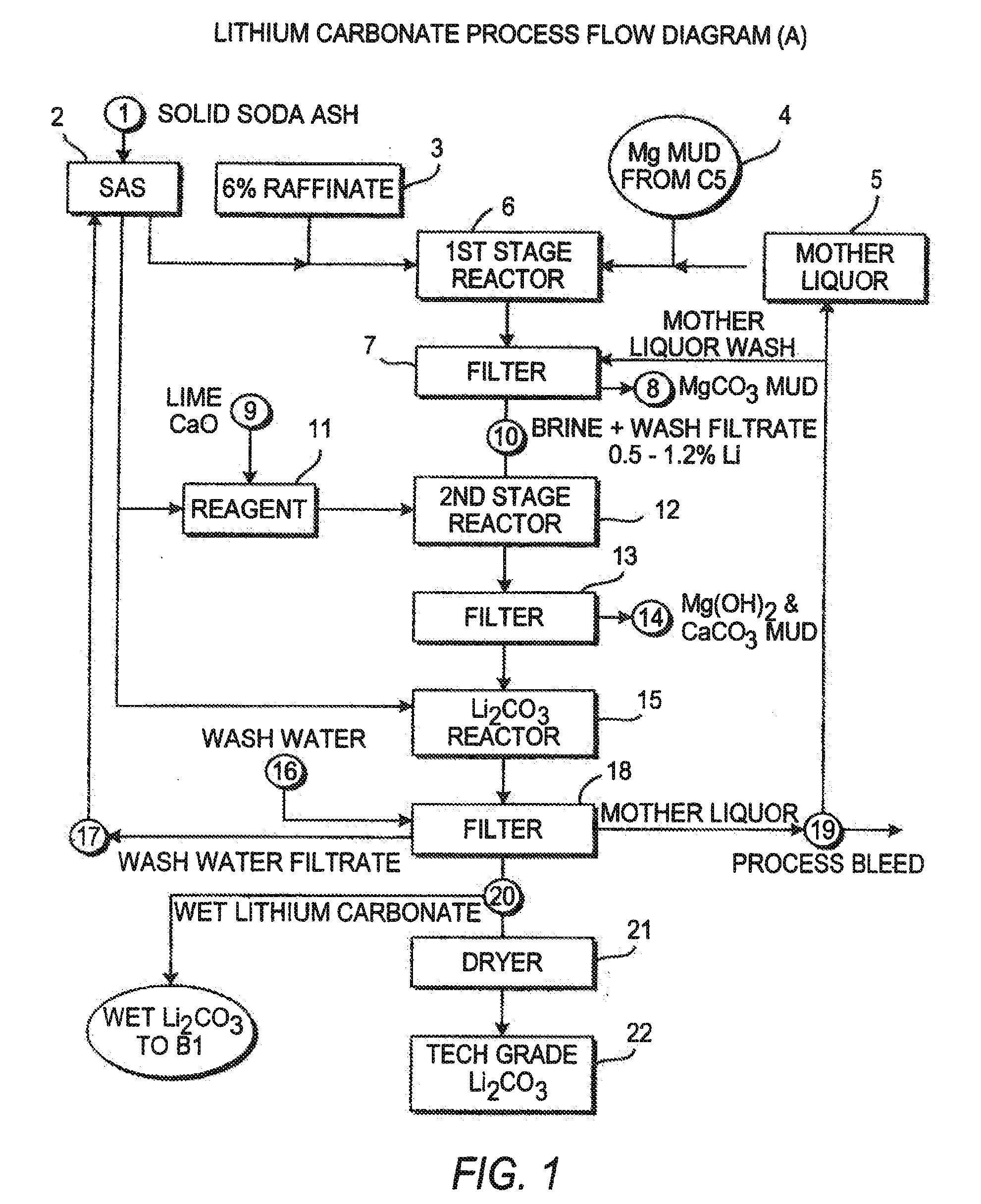

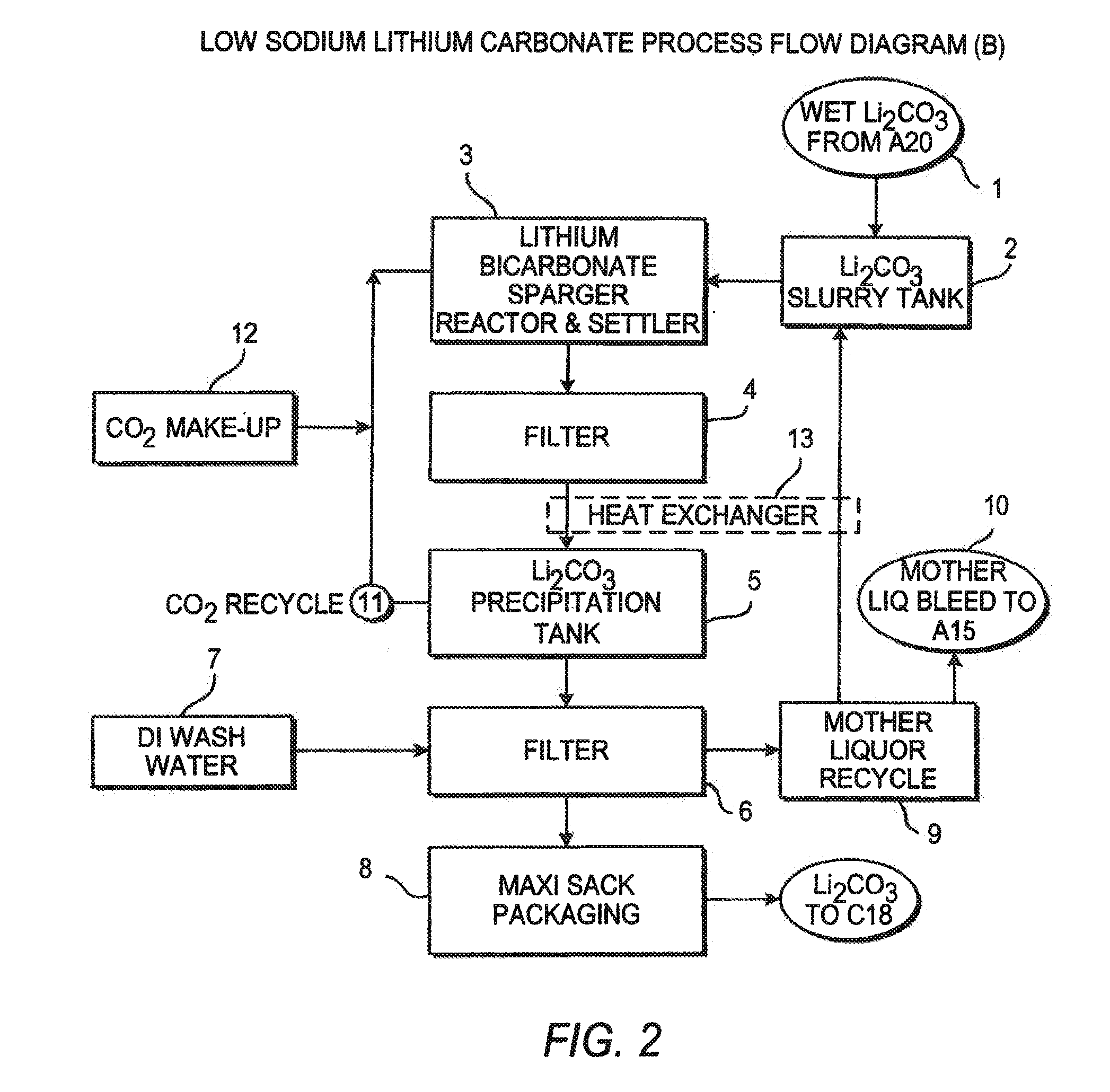

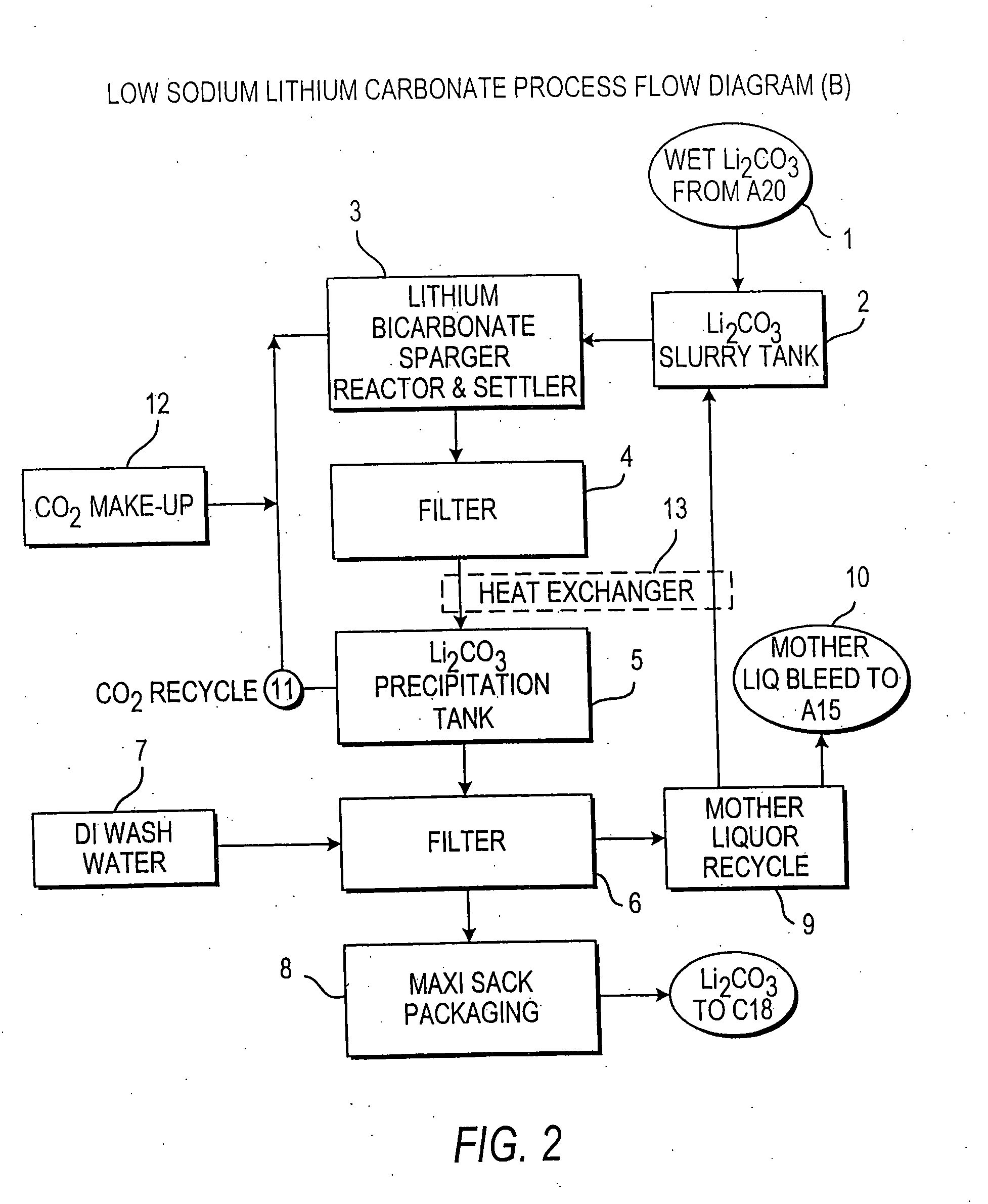

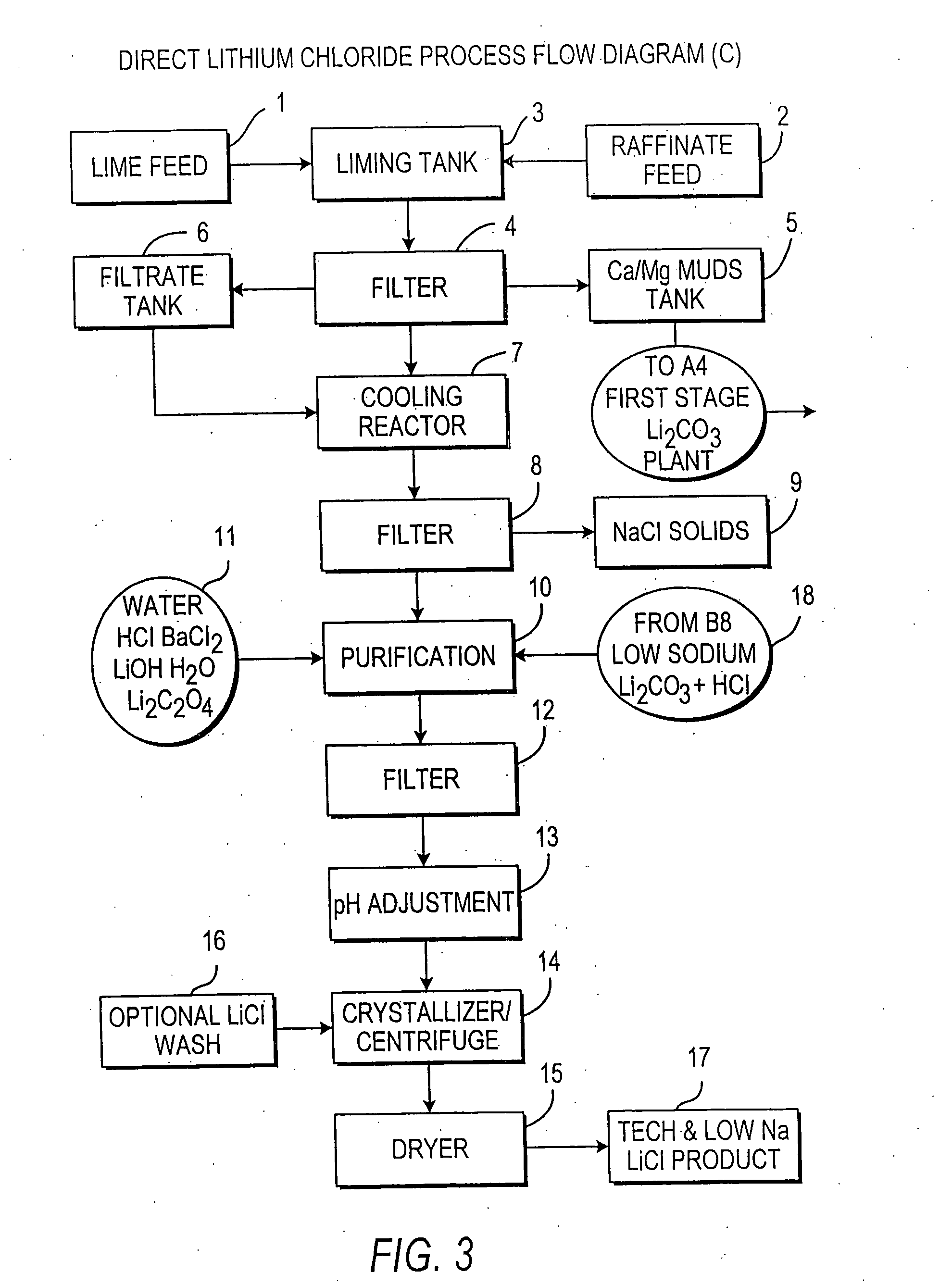

InactiveUS20060115396A1Promote absorptionConstant liquid volumeCalcium/strontium/barium carbonatesCalcium/strontium/barium sulfatesLithium chlorideLithium carbonate

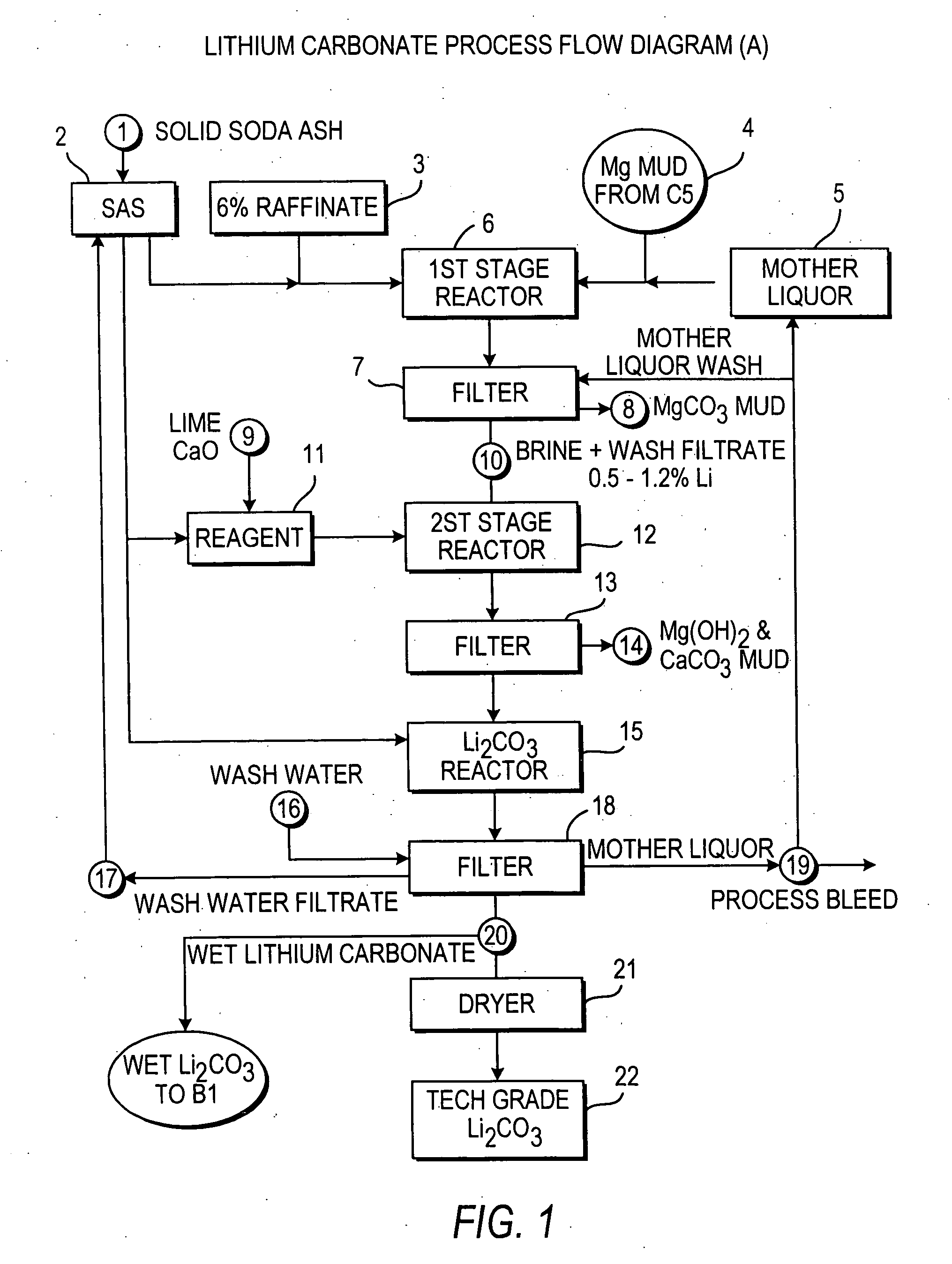

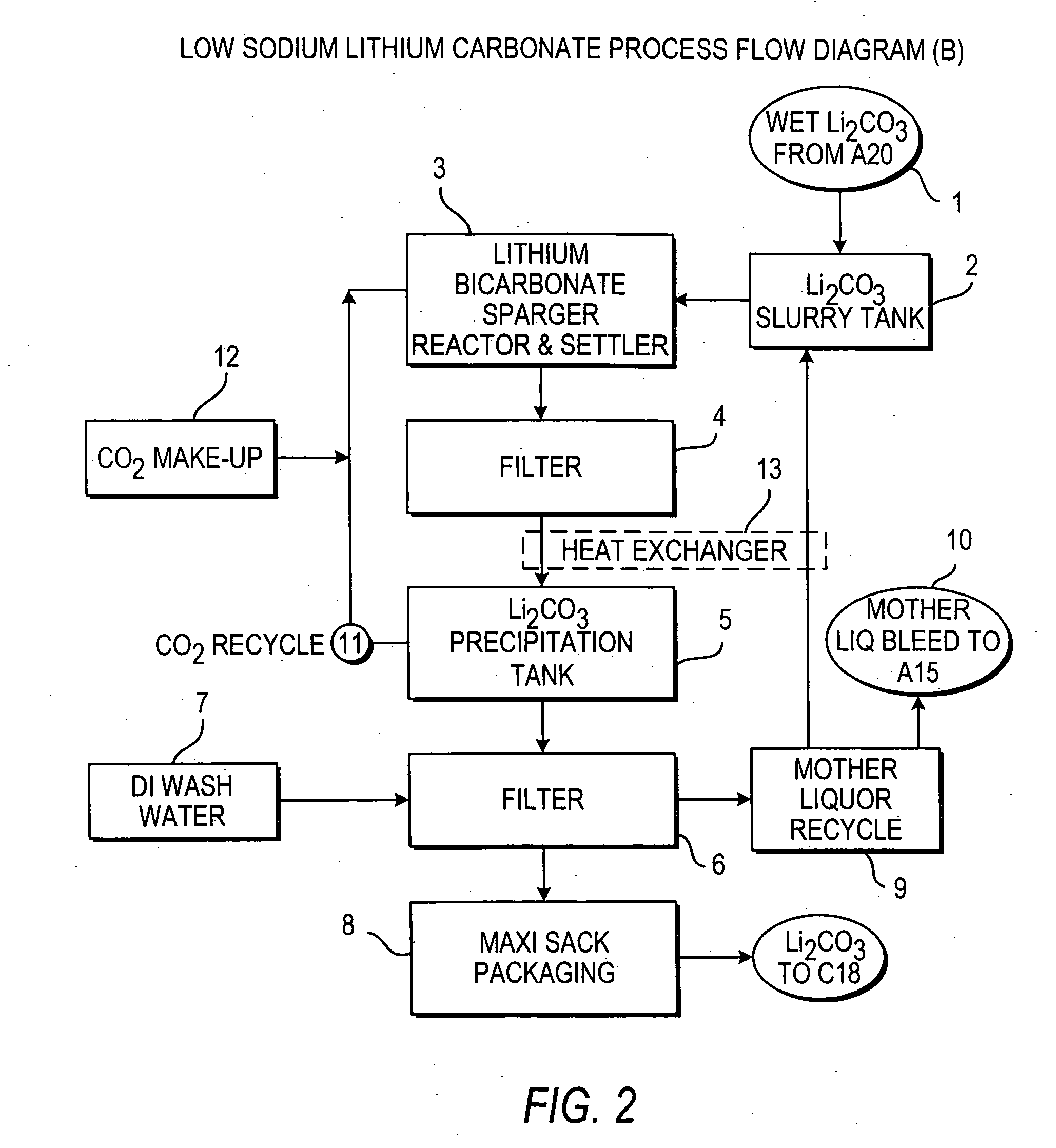

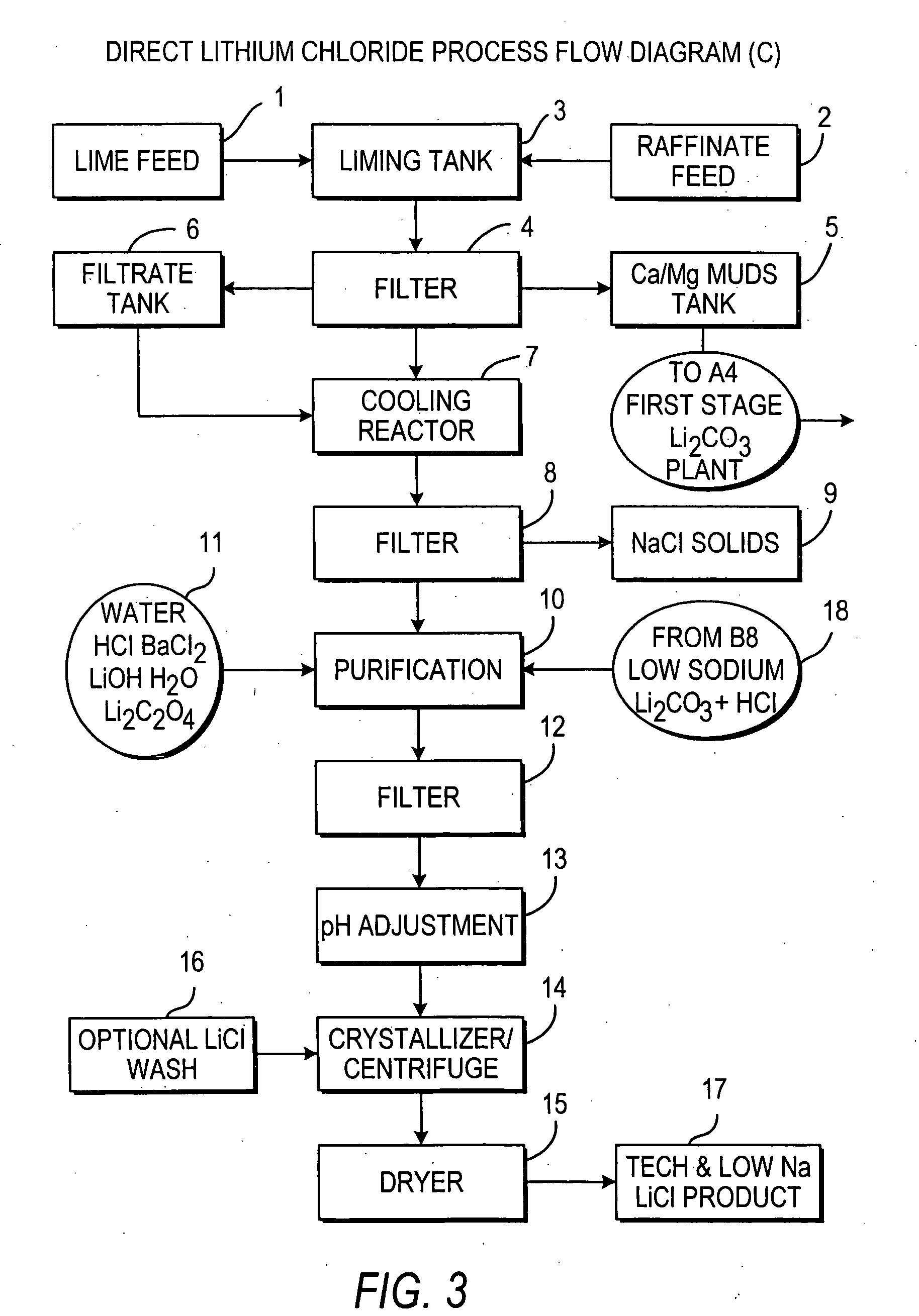

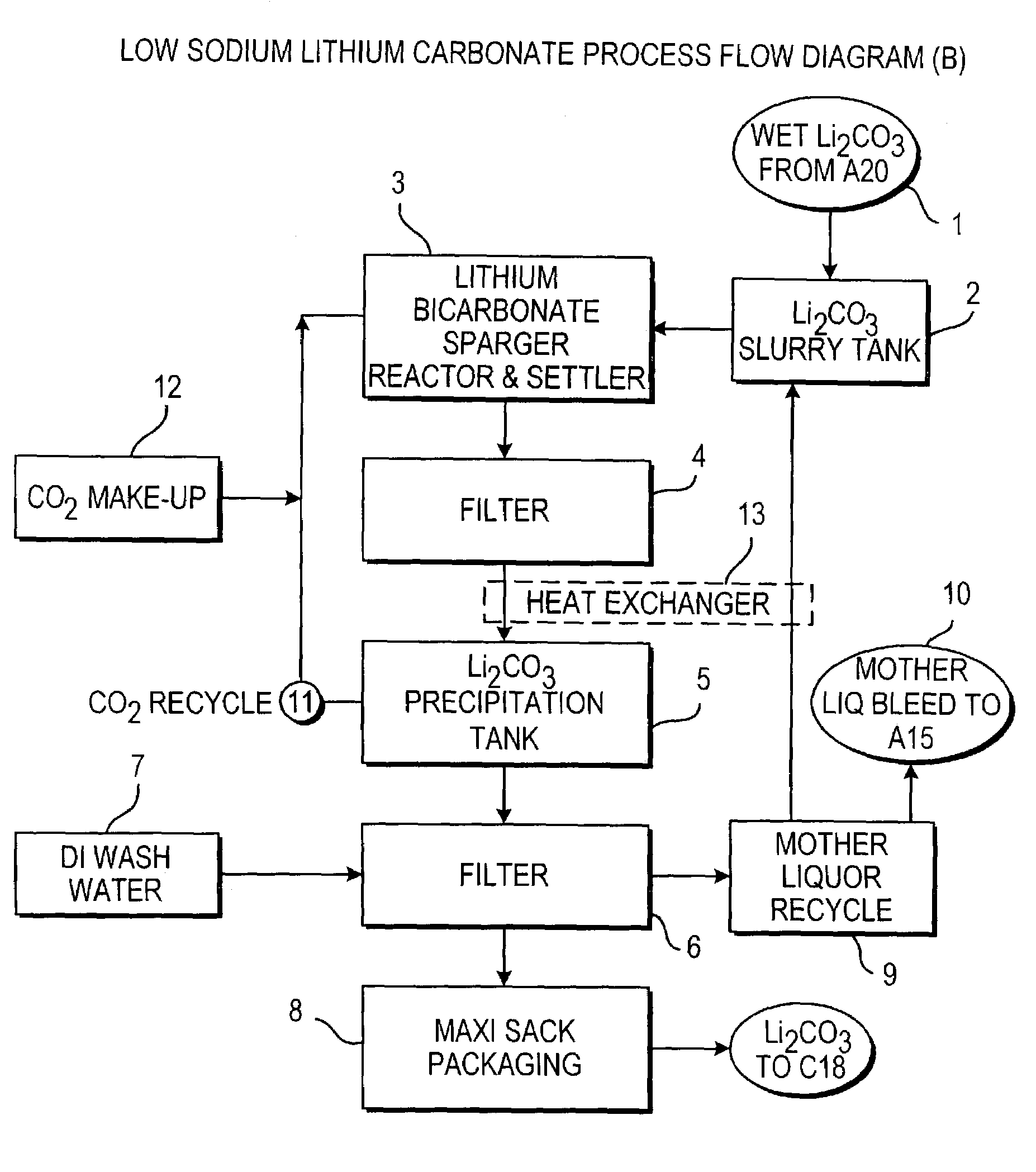

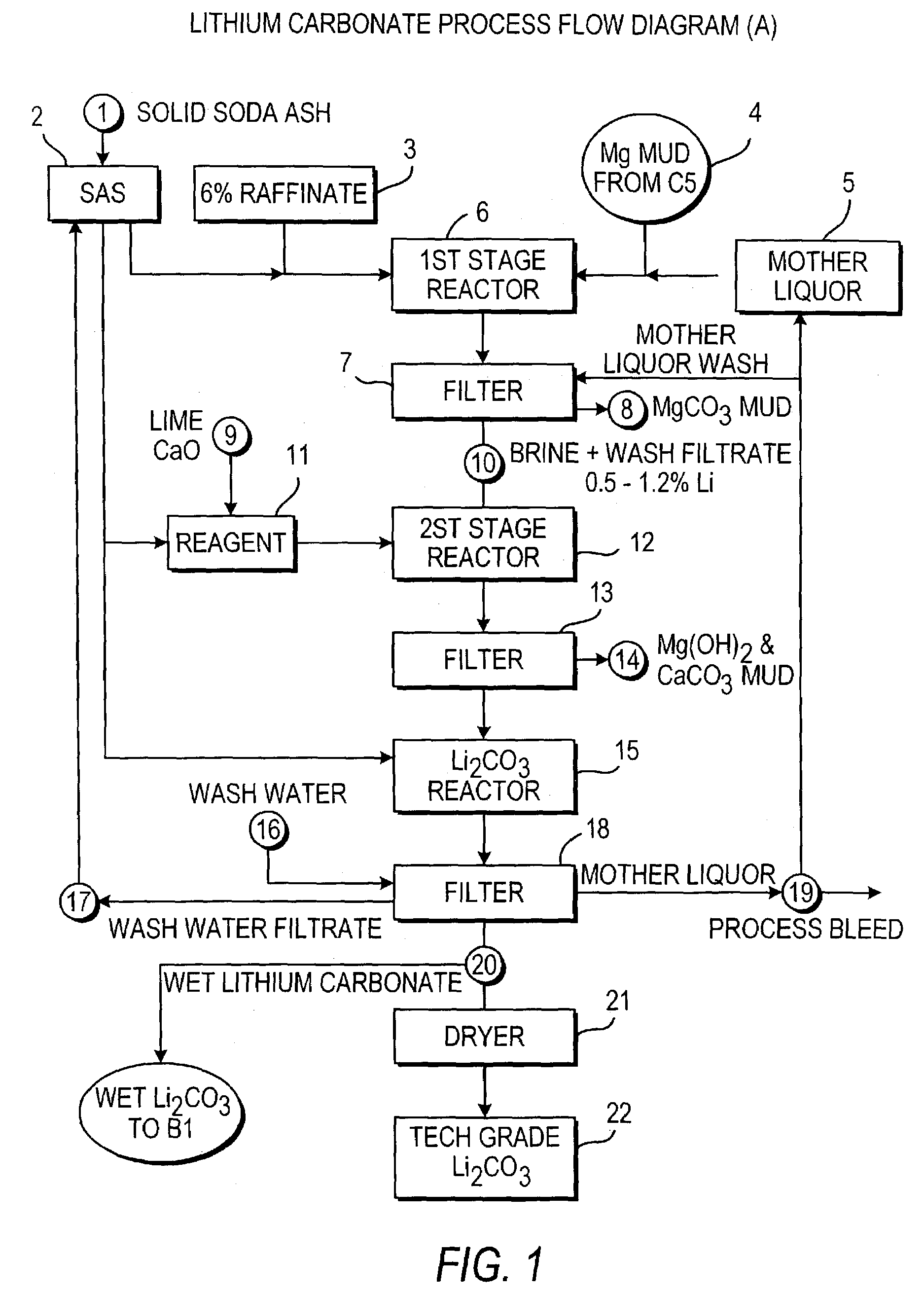

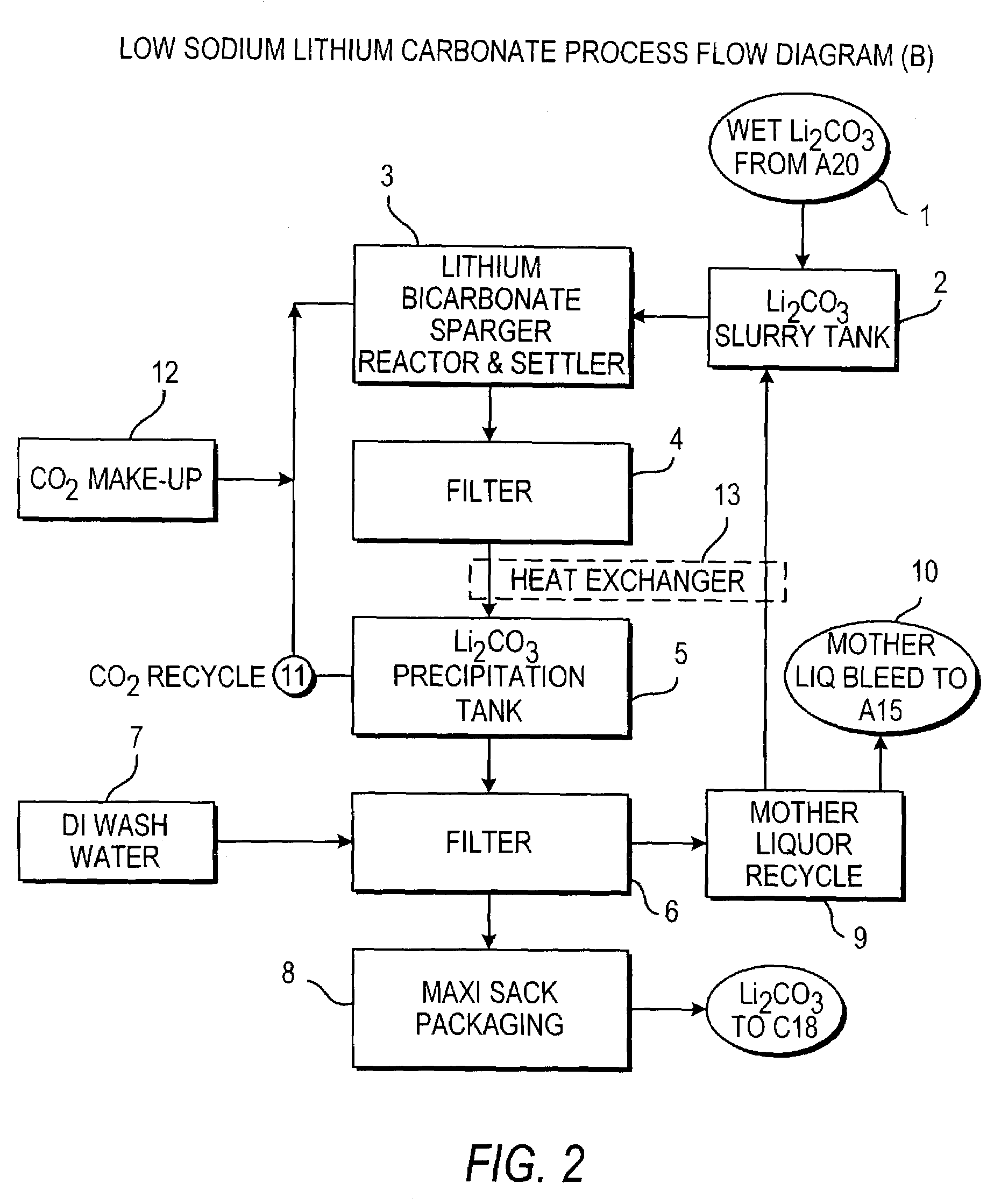

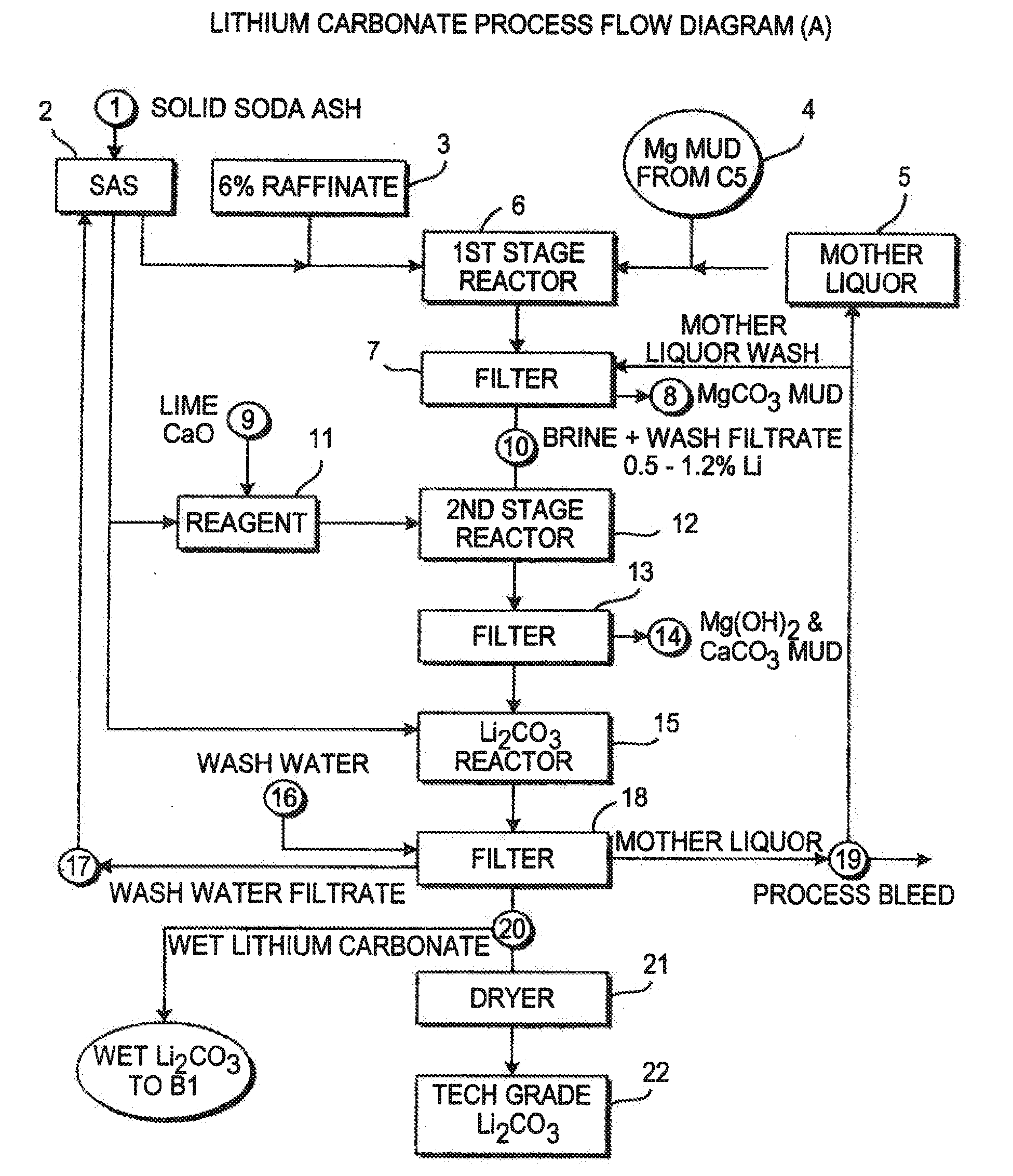

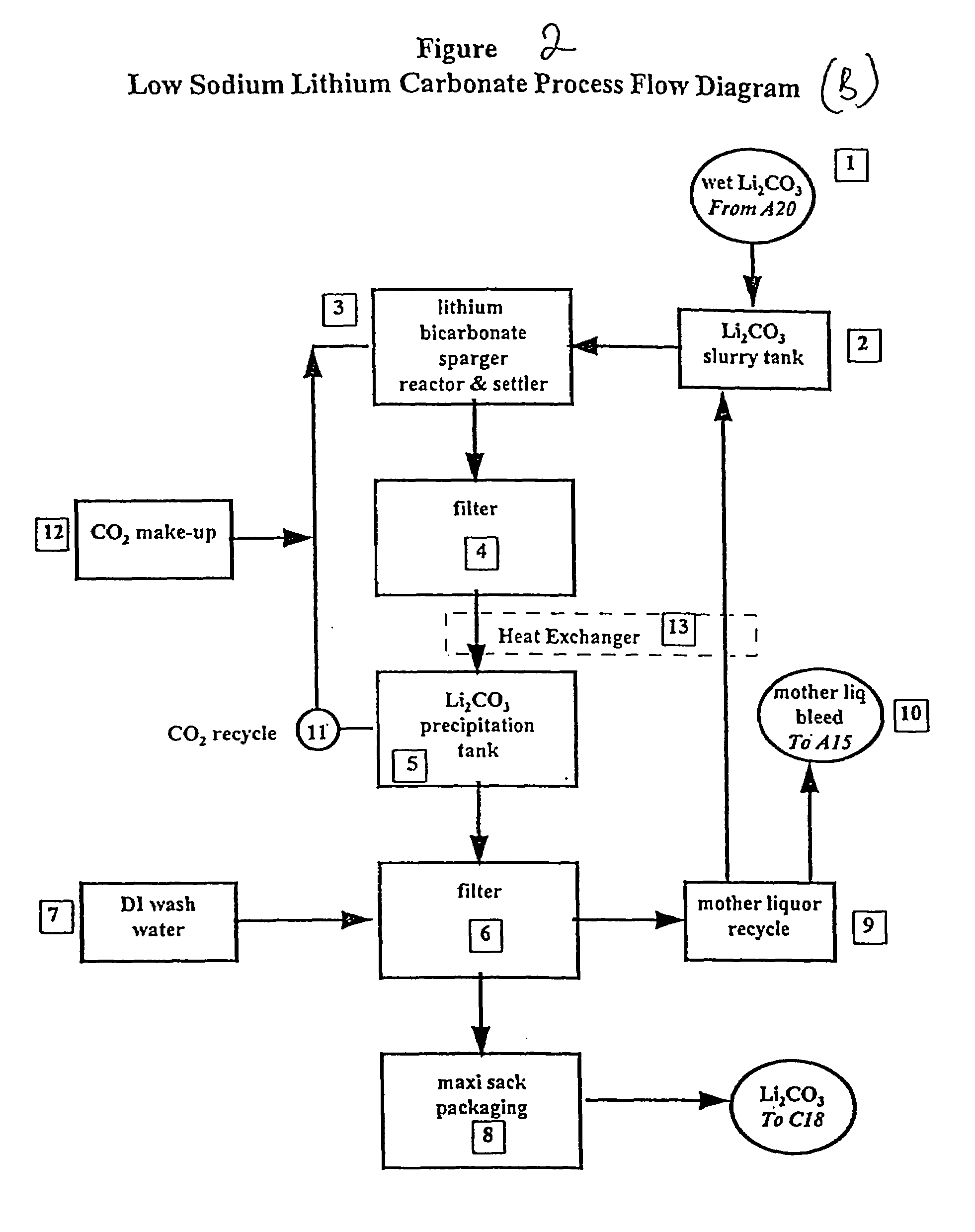

Methods and apparatus for the production of low sodium lithium carbonate and lithium chloride from a brine concentrated to about 6.0 wt % lithium are disclosed. Methods and apparatus for direct recovery of technical grade lithium chloride from the concentrated brine are also disclosed.

Owner:BORYTA DANIEL ALFRED +2

Production of lithium compounds directly from lithium containing brines

InactiveUS7157065B2Reduce in quantityPromote absorptionCalcium/strontium/barium carbonatesChemical/physical/physico-chemical processesSlurryLithium compound

A continuous process for directly preparing high purity lithium carbonate from lithium containing brines by preparing a brine containing about 6.0 wt % lithium and further containing other ions naturally occurring in brines; adding mother liquor containing carbonate to precipitate magnesium; adding a solution of CaO and sodium carbonate to remove calcium and any residual magnesium; precipitating lithium carbonate from the purified brine by adding soda ash solution; filtering to obtain solid lithium carbonate; preparing an aqueous slurry of the lithium carbonate and introducing carbon dioxide gas at a temperature from at least minus 10 to +40° C.; passing the lithium bicarbonate solution through a filter to clarify the solution; introducing said filtered lithium bicarbonate solution into a reactor and adjusting the temperature of the solution to from 60–100° C. to precipitate ultra-pure lithium carbonate.

Owner:ROCKWOOD LITHIUM INC

Production of lithium compounds directly from lithium containing brines

InactiveUS20110123427A1Reduce in quantityPromote absorptionVarying alkali metal carbonate water contentRubidium/caesium/francium compoundsLithium chlorideLithium carbonate

Methods and apparatus for the production of low sodium lithium carbonate and lithium chloride from a brine concentrated to about 6.0 wt % lithium are disclosed. Methods and apparatus for direct recovery of technical grade lithium chloride from the concentrated brine are also disclosed.

Owner:ROCKWOOD LITHIUM INC

Production of lithium compounds directly from lithium containing brines

InactiveUS20070160516A1Promote absorptionConstant liquid volumeCrystallization separationCarbonate/bicarbonate preparationLithium chlorideLithium carbonate

Methods and apparatus for the production of low sodium lithium carbonate and lithium chloride from a brine concentrated to about 6.0 wt % lithium are disclosed. Methods and apparatus for direct recovery of technical grade lithium chloride from the concentrated brine are also disclosed.

Owner:ROCKWOOD LITHIUM INC

Method for separating magnesium from lithium and extracting lithium from brine

InactiveCN101538057ASolve the difficult technical problems of filtrationSimple technical processMultistage water/sewage treatmentSolution crystallizationFiltrationHigh energy

The invention provides a method for separating magnesium from lithium and extracting the lithium from high magnesium-lithium ratio brine (brine from a saline lake, from underground and from an oil-gas field). The method comprises: sodium salt and potassium and magnesium mixed salt are separated from the brine by evaporation of a saltpan; after boron extraction, sodium hydroxide is used for precipitating Mg<2+> from obtained old brine, and crystallized Mg(OH)2 is obtained by modification and precipitation condition control; filtration and separation are carried out to remove the Mg(OH)2 to realize separation of magnesium and lithium; after filtered mother solution is vaporized and concentrated for 2-4 times, Na2SO4 and NaCl are separated by crystallization, and pure caustic soda can be added to form lithium carbonate from lithium; or the operation of further evaporation is carried out until Na2SO4 and NaCl are separated by multiple times of natural evaporation or forced evaporation concentration and multiple times of cooling crystallization; the operations of evaporation and concentration are carried out until LiCl saturation, and LiCl products can be prepared after the operation of cooling crystallization is carried out. Compared with the prior art for separating the magnesium from the lithium and extracting the lithium from the brine, the method obtains the crystallized Mg(OH)2 by modification and precipitation condition control, solves the existing technical problem of hard filtration of Mg(OH)2, solves the defects of high energy consumption, complex process and high cost of the existing calcination method, and solves the fundamental defects of low Li<2+> recovery ratio and complex technical process of the traditional precipitation method. The Li<2+> recovery ratio ranges from 85-93%, Mg<2+> removal ratio is more than 99.5%, and the method solves the problem of extracting Li<+> and Mg<2+> from high-magnesium and low-lithium brine with Mg<2+> / Li<+>>=20 mass ratio.

Owner:钟辉

Coordinate extracting system for extracting lithium from salt lake brine with extraction method

The invention relates to a coordinate extracting system for extracting lithium from salt lake brine with extraction method, which comprises the following steps of (1) acidity of raw material liquid adjustment: adding hydrochloric acid to the salt lake brine to adjust the pH value of the raw material liquid to 1 to 5 so that the raw material liquid is obtained; (2) extracting lithium: carrying out three-stage extraction on the raw material liquid obtained in step (1) by using TBP-BA-FeCl3 solvent naphtha as an extracting agent to obtain an organic phase; (3) organic phase washing: carrying out three-stage washing to the organic phase obtained in the step (2) by using the hydrochloric acid as a washing agent; (4) organic phase reextraction: carrying out three-stage extraction on the organic phase obtained in the step (3) by using hydrochloric acid as a reextraction agent to obtain lithium chloride solution. The invention has the advantages of simple technique, easy control, low reextraction acidity, low requirements on reextraction equipment materials and concentration of lithium in the material brine, and no need of evaporation concentration of thin lithium solution, thereby saving energy, reducing consumption, decreasing the production cost, and simultaneously improving the total recovery rate of the lithium effectively.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

Method and device for extracting bitten lithium chloride

The invention relates to a method and a device for extracting bitten lithium chloride. The method specifically comprises the steps: 1, adsorbing lithium ions by bittern in a lithium-containing salt lake old brine pool through an aluminum salt adsorbing agent, desorbing by using water to obtain a desorbing solution; 2, filtering the desorbing solution by using a coarse filter; 3, filtering permeate of the coarse filter by using a nanofiltration membrane to obtain permeate of the nanofiltration membrane; 4, concentrating the permeate of the nanofiltration membrane by using a reverse osmosis membrane to obtain a reverse osmosis concentrated solution; and 5, carrying out baysalt or evaporating on the reverse osmosis concentrated solution to obtain lithium-containing concentrated brine. According to the method, the problems that the concentration multiple in a reverse osmosis station can not be increased, the baysalt efficiency is low and a plenty of reagents are consumed in precipitation in a conventional process for extracting lithium from brine can be solved, and the obtained lithium chloride solution is high in yield and high in purity.

Owner:JIANGSU JIUWU HITECH

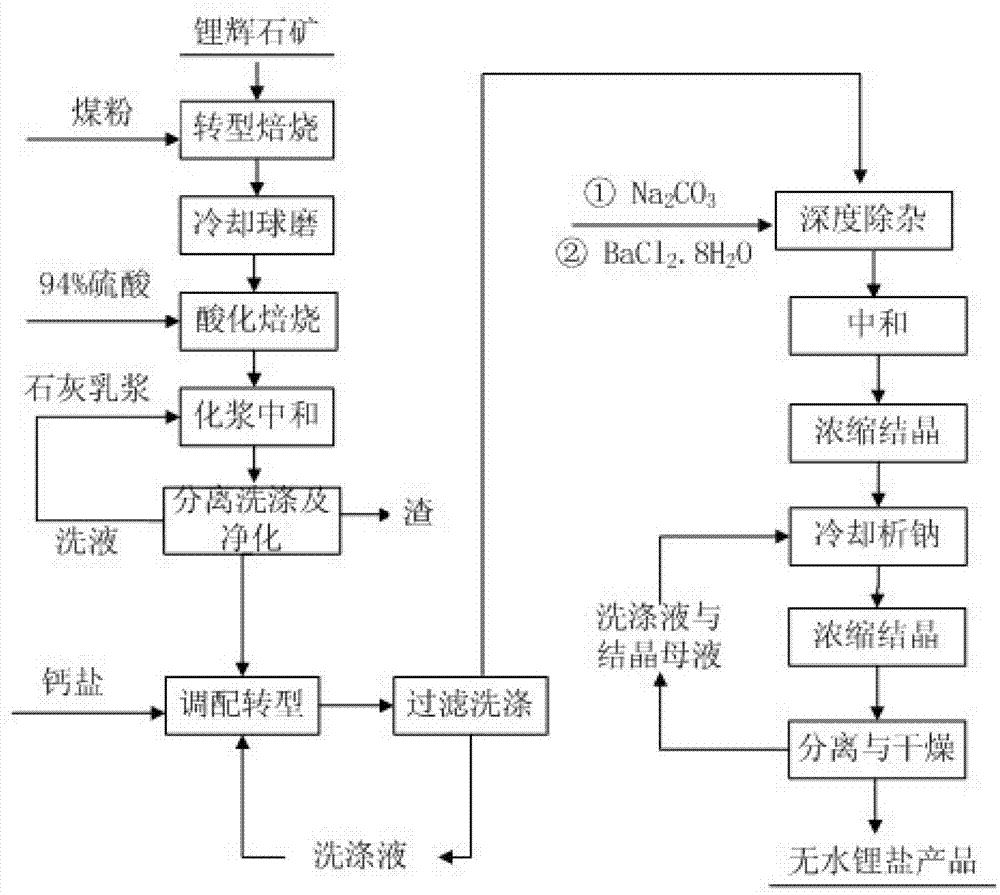

Method for preparing lithium salts from lithium extracted from spodumene

InactiveCN102765734AShort processEasy to operateLithium halidesLithium nitratesResource utilizationImpurity

The invention discloses a method for preparing lithium salts from lithium extracted from spodumene, which comprises the following steps: a. transforming and roasting; b. cooling and ball milling; c. acidifying and roasting; d. slurrying and neutralizing; e. separating, washing and purifying; f. blending and transforming; g. filtering and washing; h. deep impurity removing; i. neutralizing; j. concentrating and crystallizing; k. cooling to precipitate sodium; l. concentrating and crystallizing; and m. separating and drying. The method disclosed by the invention has the advantages of short technical process, low energy consumption, simple operation steps, low production cost and high resource utilization ratio.

Owner:GANFENG LITHIUM CO LTD

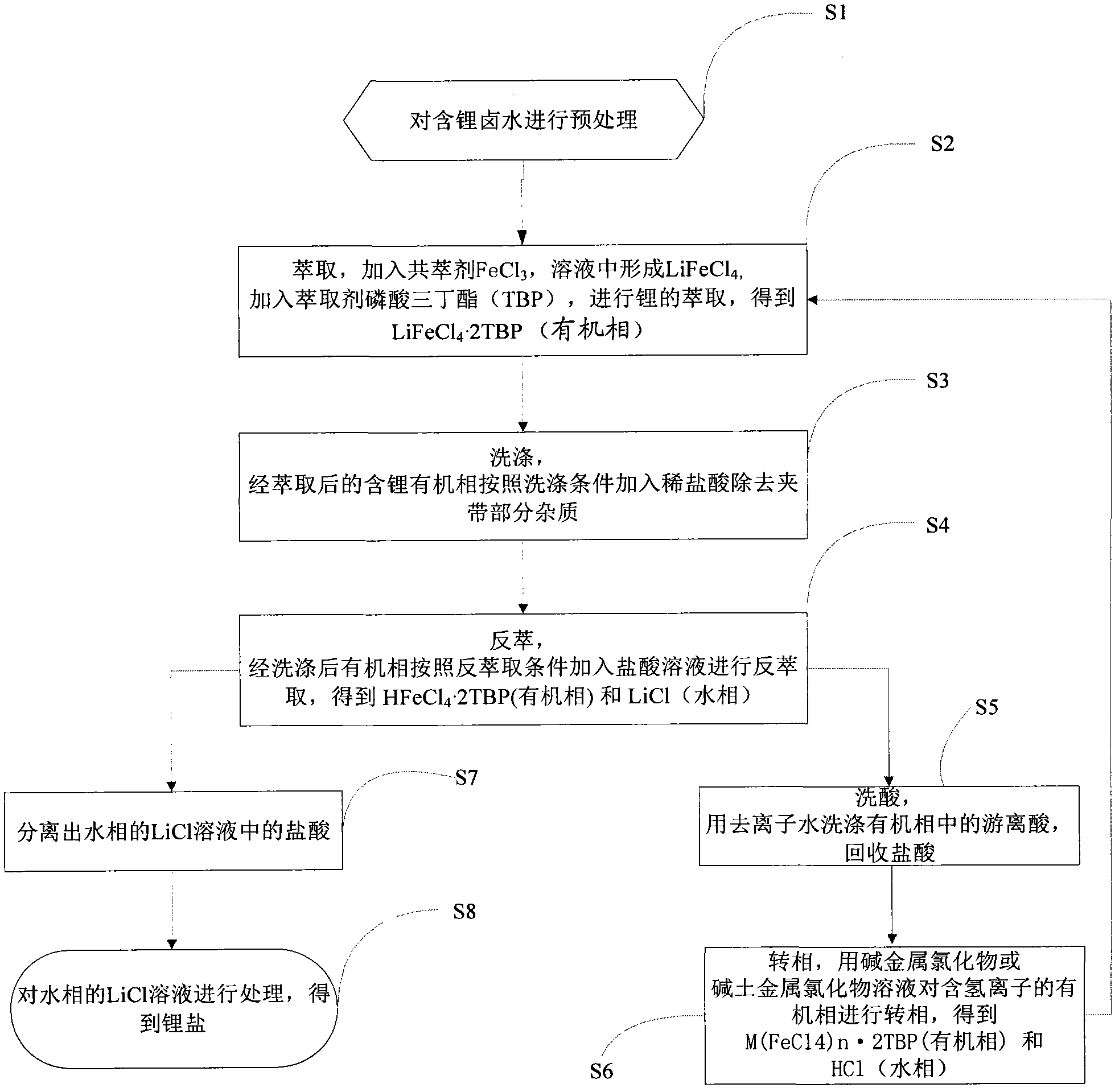

Method for extracting lithium salt from lithium brine

InactiveCN102992358AIncrease profitAvoid hydrolysisLithium halidesLithium carbonates/bicarbonatesLithiumAlkaline earth metal

The invention provides a method for extracting lithium salt from lithium brine. The method comprises the following steps: extraction step: adding a co-extracting agent FeCl3 and an extraction agent tributyl phosphate (TBP) to lithium brine to extract lithium so as to obtain an organic phase LiFeCl4.2TBP and a water phase raffinate; reverse extraction step: adding a hydrochloric acid liquor to the organic phase LiFeCl4.2TBP for reverse extraction to obtain organic phase LiFeCl4.2TBP and water phase LiCl; and phase inversion step: inversing phase for the organic phase LiFeCl4.2TBP containing hydrogen ions by a liquor of alkali chloride, alkaline earth chloride or a mixture MCln (n is greater than or equal to 1) as a phase inversion agent to obtain an organic phase M(FeCl4)n.2TBP. According to the method for extracting lithium salt from lithium brine provided by the invention, the production cost of extracting lithium salt can be lowered.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

Preparation method of lithium fluoride

InactiveCN102030344AHigh yieldYield over 97%, high purityLithium halidesHydrofluoric acidLithium hydroxide

The invention provides a preparation method of lithium fluoride, which comprises the following steps: (1) introducing carbon dioxide into water, then adding the raw material lithium carbonate to obtain a lithium bicarbonate solution, then adding a precipitant, introducing carbon dioxide until the pH of the solution is 8-9, filtering, and collecting the lithium bicarbonate solution; and (2) adding hydrofluoric acid to the filtrate obtained in the step (1), carrying out fluoridation, then adding a lithium hydroxide solution, regulating the pH of the system to be 7-7.5, then filtering, collecting the filter cake, and drying to obtain the product lithium fluoride. In the invention, the industrial grade lithium carbonate is used, the total yield of the technical process achieves more than 97%, the purity is as high as 99.9% or above, and the impurity content in the product is as low as 80PPm or below.

Owner:SHANGHAI CHINA LITHIUM INDAL

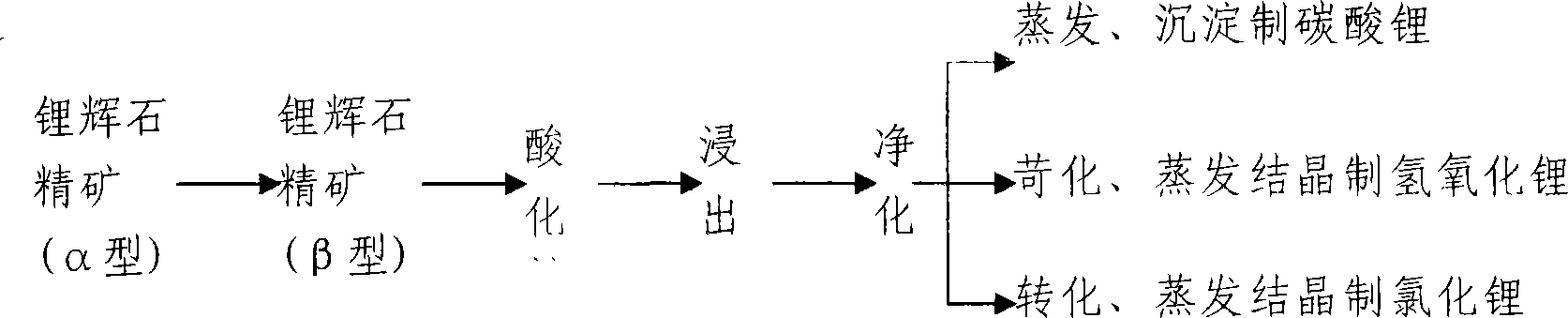

Novel method for spodumene calcining transformation

InactiveCN101224900AEvenly heatedFast heat transferChemical industryLithium halidesLithium chlorideLithium hydroxide

The invention relates to a method for producing lithium carbonate, lithium hydroxide and lithium chloride with spodumene. Aiming at the defect of the calcination transformation technology of the spodumene concentrate, the invention provides a new method of the fluidization and dynamic calcination transformation of the spodumene concentrate: the spodumene concentrate from a concentration plant is dried and milled to granules with the granularity of minus 250 meshes to minus 350 meshes; then a fluidization dynamic calcinator is adopted to carry out high temperature calcination transformation to the concentrate, the material temperature is controlled between 900 and 1200 DEG C; because the material in the furnace is fluidized and transfers heat and is delivered in the form of air delivery with hot air, the process is rapid in heat transfer rate, high in efficiency and short in calcination time, which overcomes the technical defect of the existing calcination technology that the material is easy to be agglomerated and avoids cooling and ball-milling procedures. When the calcined material is treated by the procedures of leaching, purging, filtering, etc., the obtained filtrate (raw material liquid) can be utilized for producing products such as lithium carbonate, lithium hydroxide, lithium chloride and so on by adopting existing different technologies.

Owner:钟辉

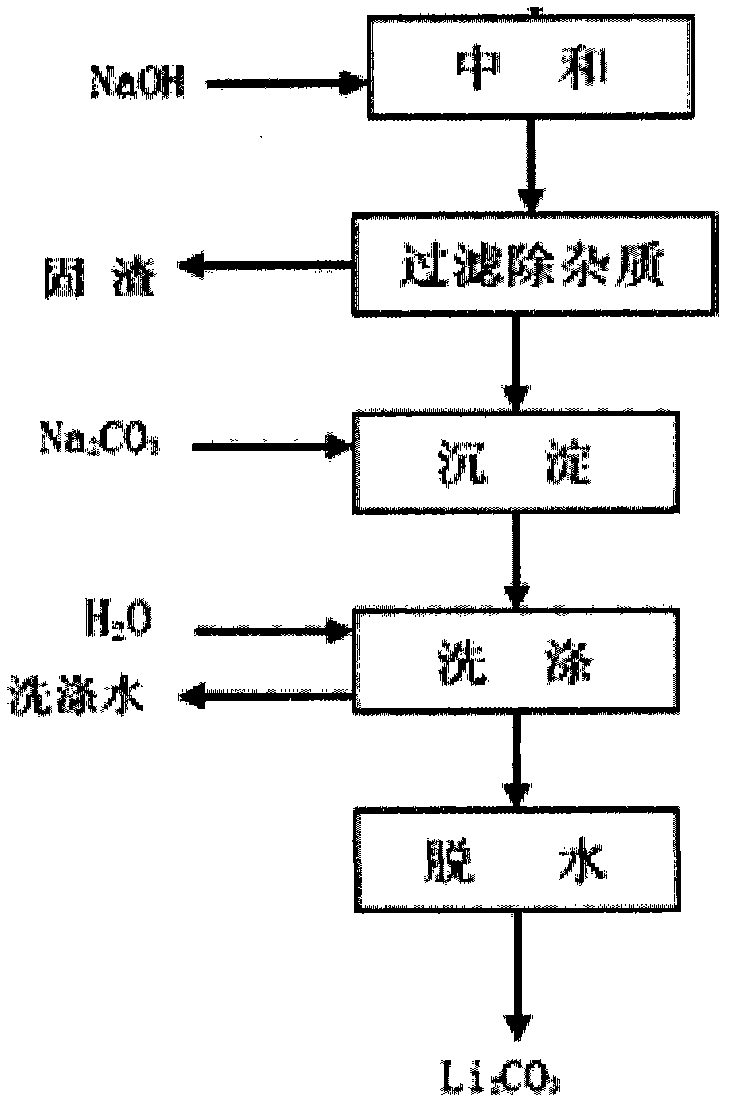

Method for preparing high-purity lithium carbonate and other available byproducts from salt lake brine

InactiveCN101712481ATake advantage ofCalcium/strontium/barium carbonatesLithium halidesLithium chlorideLithium carbonate

The invention relates to a method for preparing high-purity lithium carbonate and other available byproducts from salt lake brine. The method comprises the following steps: (1) separating potassium and sodium by exposing salt in a salt field, (2) separating boron by an acidification method, (3) separating magnesium by a sedimentation method, (4) separating calcium by the sedimentation method, (5) preparing lithium chloride, and (6) preparing the lithium carbonate. The preparation method of the invention can purify the potassium, sodium, boron, magnesium and calcium ions respectively besides obtaining the lithium carbonate product of which the purity is over 99.5 percent so as to fully utilize the salt lake brine resource.

Owner:DALIAN LICHANG NEW MATERIAL CO LTD

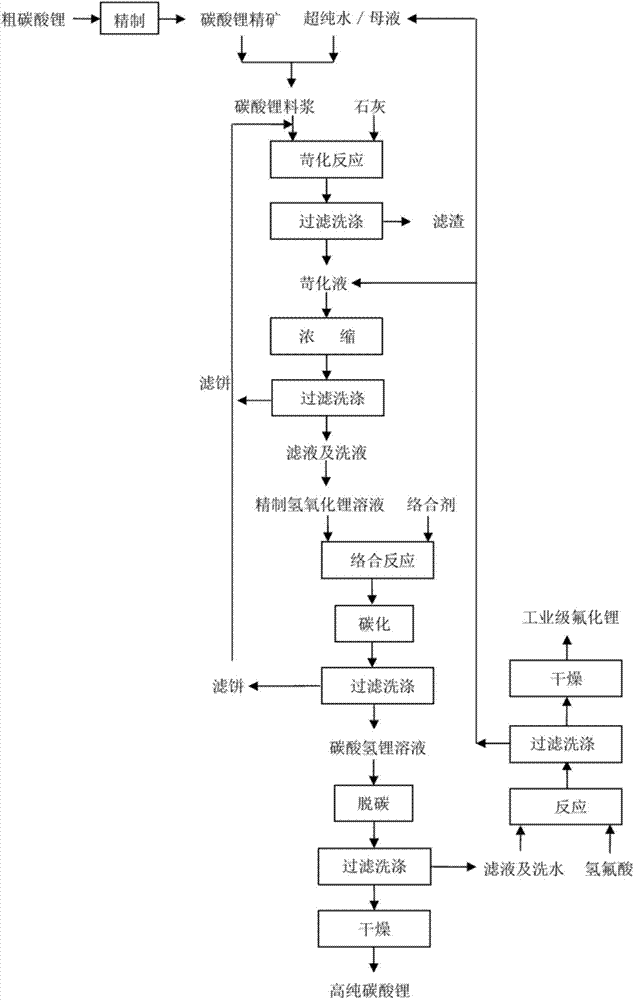

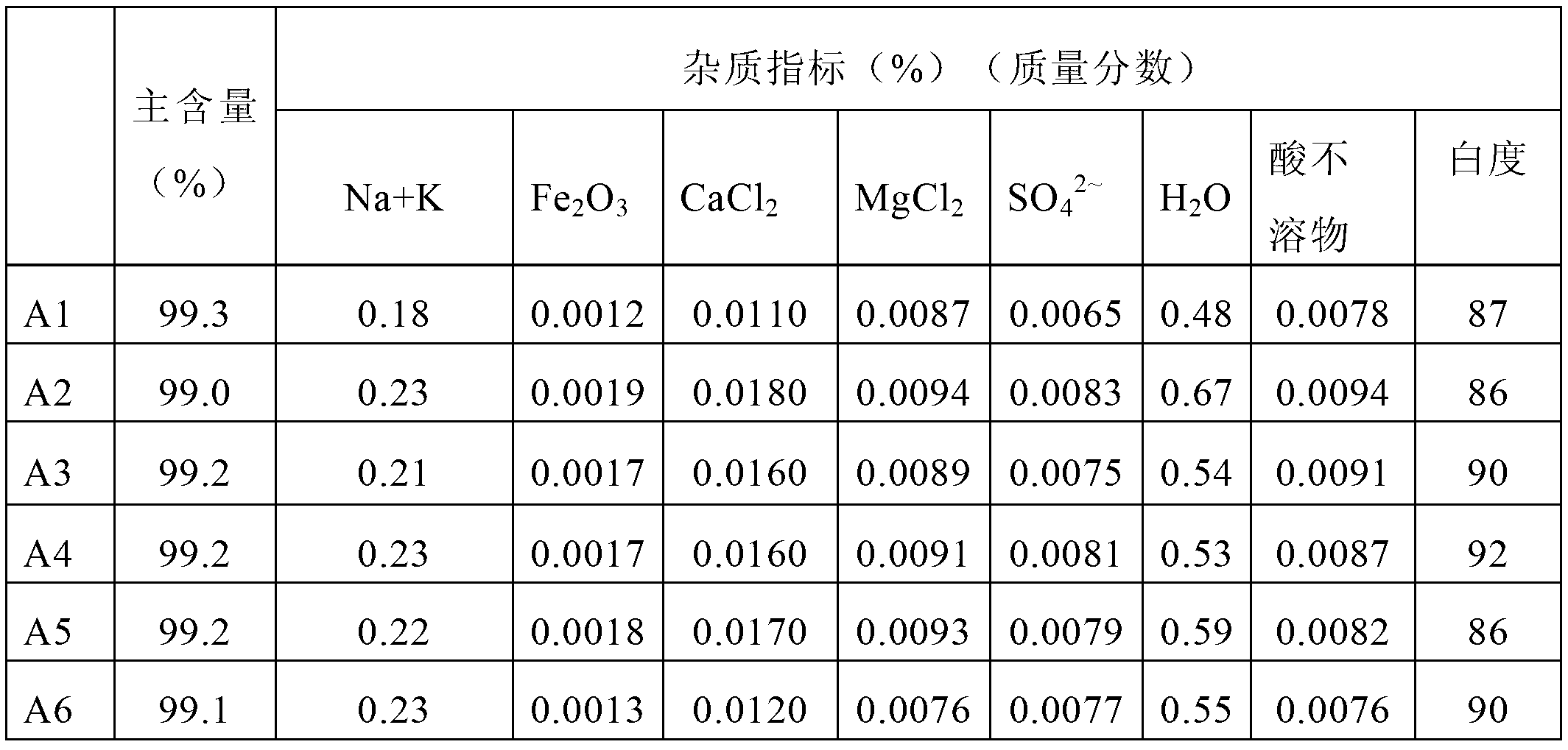

Method for preparing high-purity lithium carbonate with co-production of lithium fluoride by employing crude lithium carbonate

ActiveCN104326495ASolve the single preparation raw materialSolve the costProductsReagentsLithium hydroxideCarbonization

The invention discloses a method for preparing high-purity lithium carbonate with co-production of lithium fluoride by employing crude lithium carbonate. The method includes following steps: (1) preparing the crude lithium carbonate into lithium carbonate concentrate; (2) preparing the lithium carbonate concentrate into a slurry material with addition of lime and performing filtration to obtain a crude lithium hydroxide solution; (3) concentrating and filtering the crude lithium hydroxide solution, adding a complexing agent to remove impurity metal ions to obtain a refined lithium hydroxide solution; (4) feeding CO2 into the refined lithium hydroxide solution for carbonization and performing filtration to obtain a lithium bicarbonate solution; and (5) heating the lithium bicarbonate solution, performing a filtering and washing process, drying a filter cake to obtain the high-purity lithium carbonate, mixing the filtrate and a washing liquid with addition of hydrofluoric acid, performing a filtering and washing process, and then drying the filter cake to obtain the lithium fluoride. By means of the method, impurity ions in the high-purity lithium carbonate is in the trace-amount grade. The quality of the high-purity lithium carbonate is better in an industrial requirement in YS / T546-2008. Problems of poor quality, low lithium yield and high production cost in preparation of the high-purity lithium carbonate from salt lake lithium are solved.

Owner:河南省氟基新材料科技有限公司

Preparation of lithium carbonate from lithium chloride containing brines

ActiveUS9034294B1Chloride preparationSolid sorbent liquid separationLithium carbonateLithium hydroxide

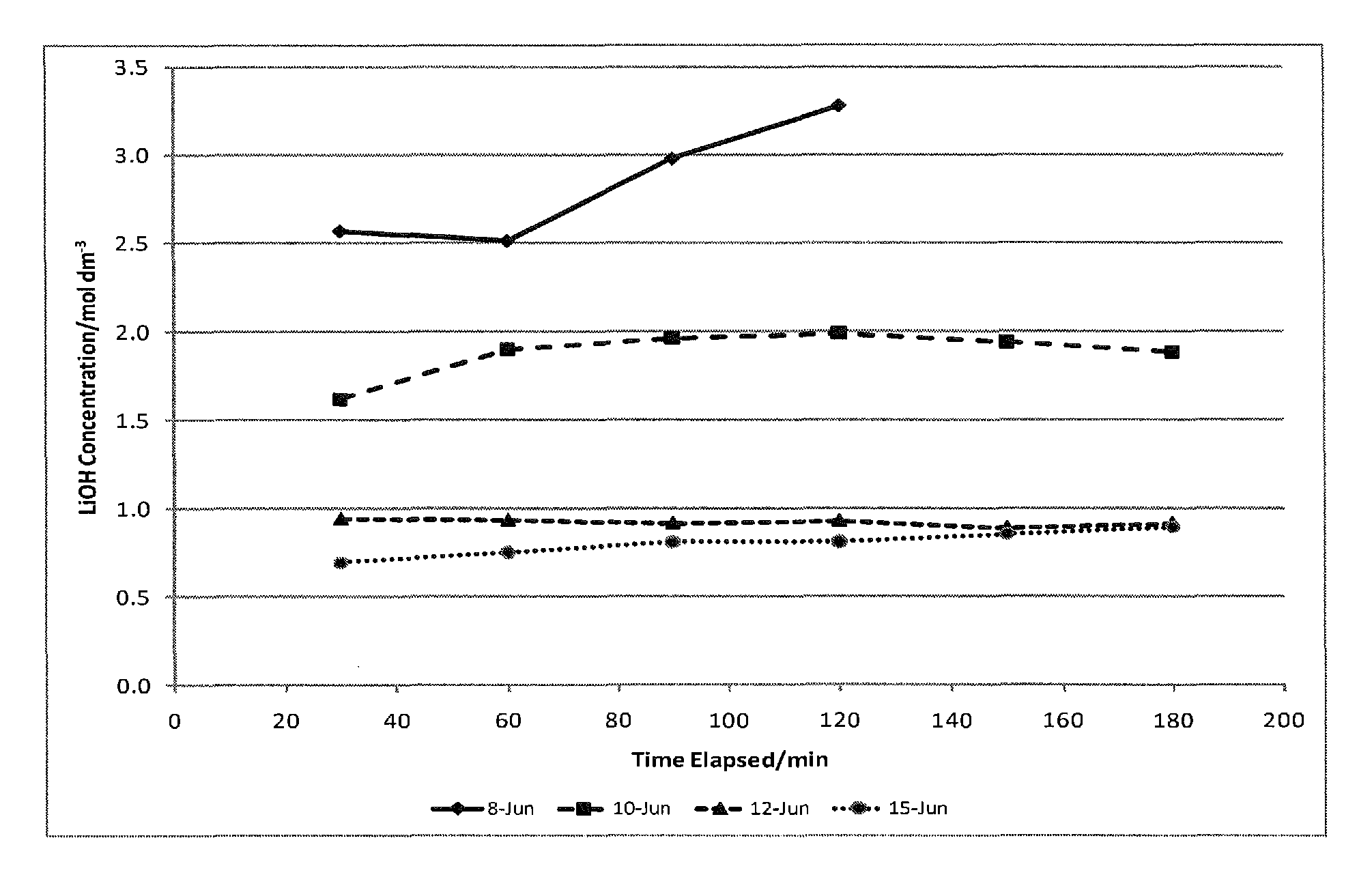

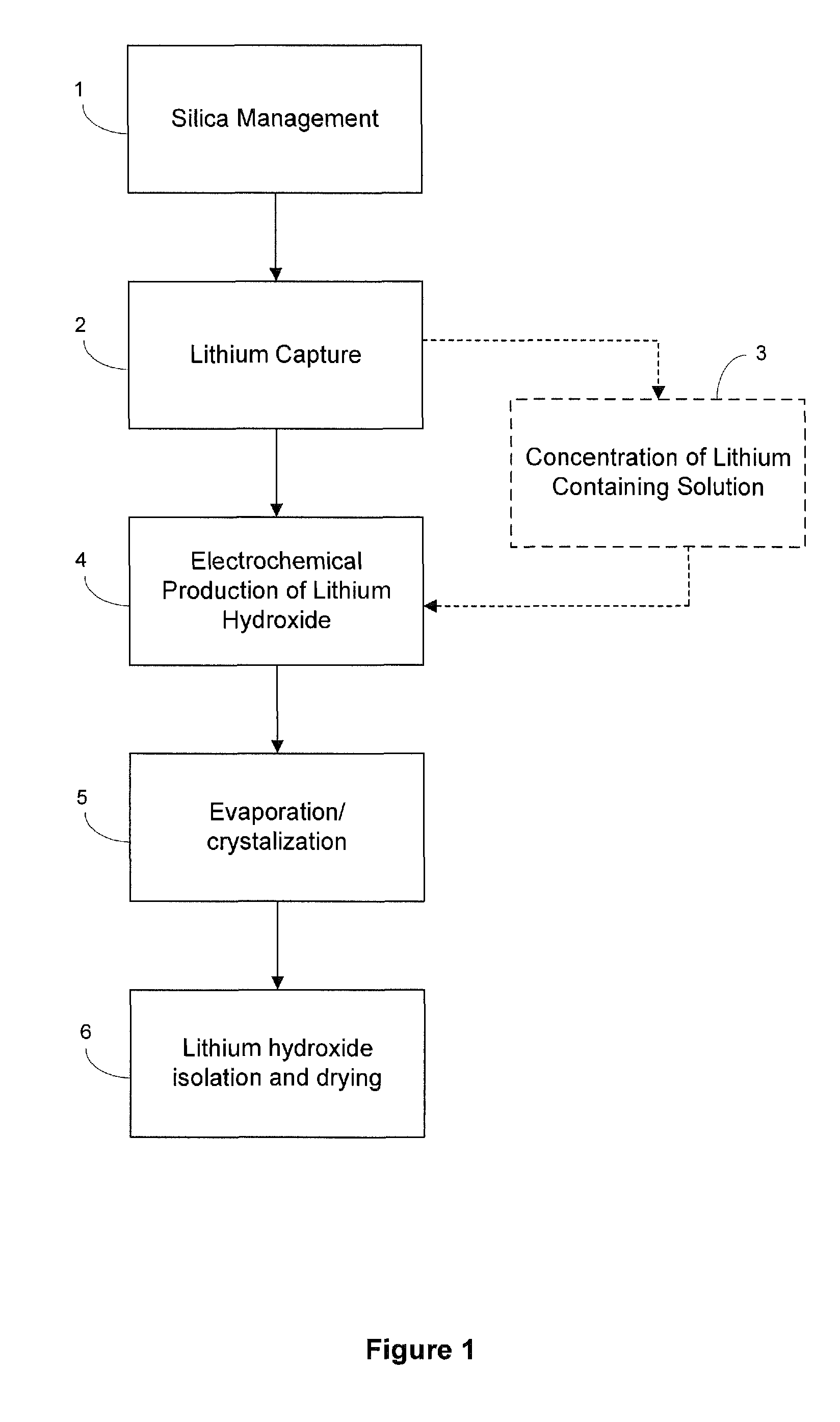

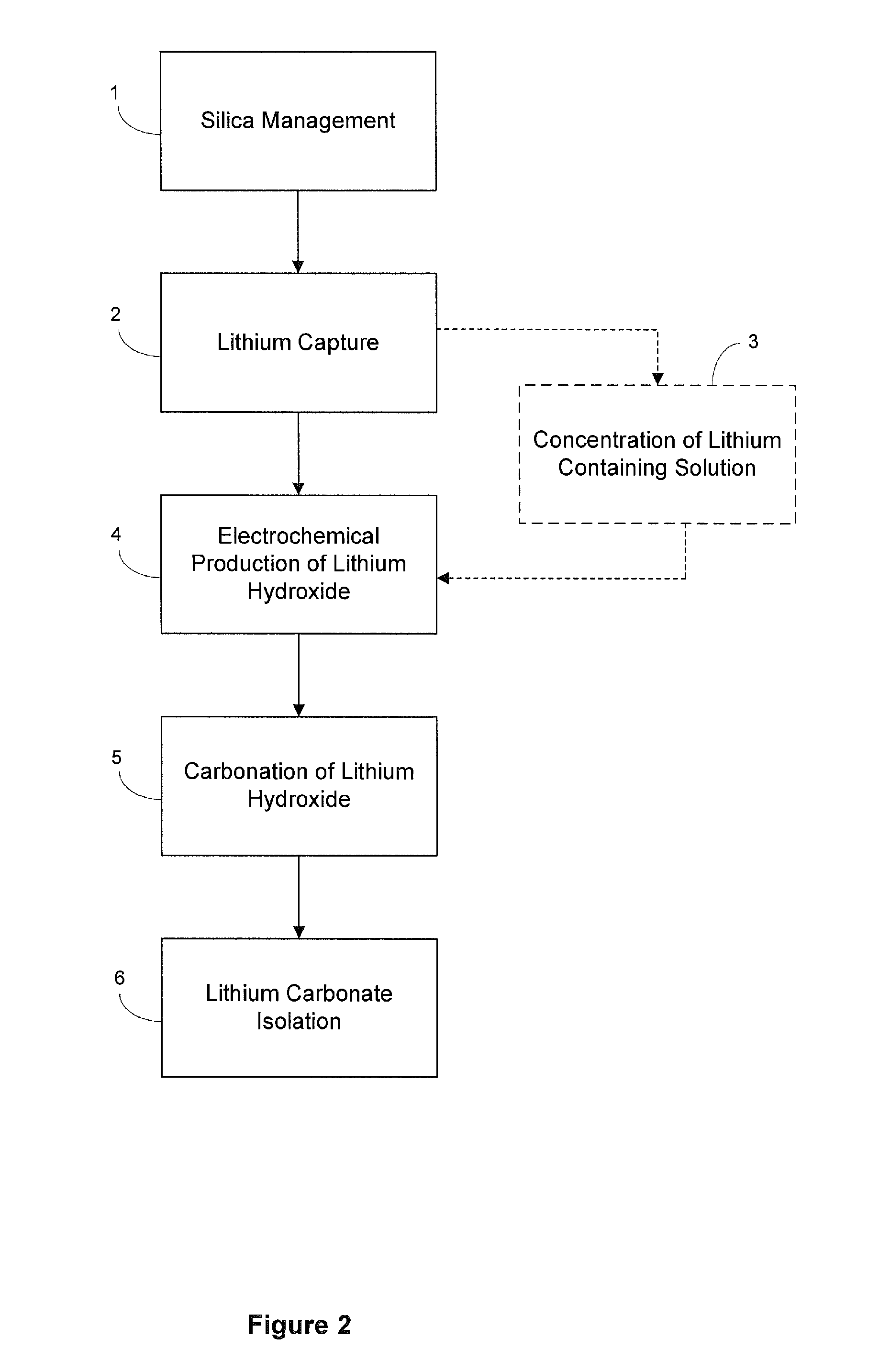

This invention relates to a method for the preparation of lithium carbonate from lithium chloride containing brines. The method can include a silica removal step, capturing lithium chloride, recovering lithium chloride, supplying lithium chloride to an electrochemical cell and producing lithium hydroxide, contacting the lithium hydroxide with carbon dioxide to produce lithium carbonate.

Owner:TERRALITHIUM LLC

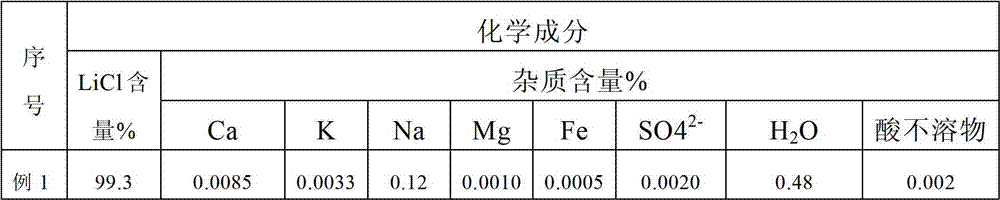

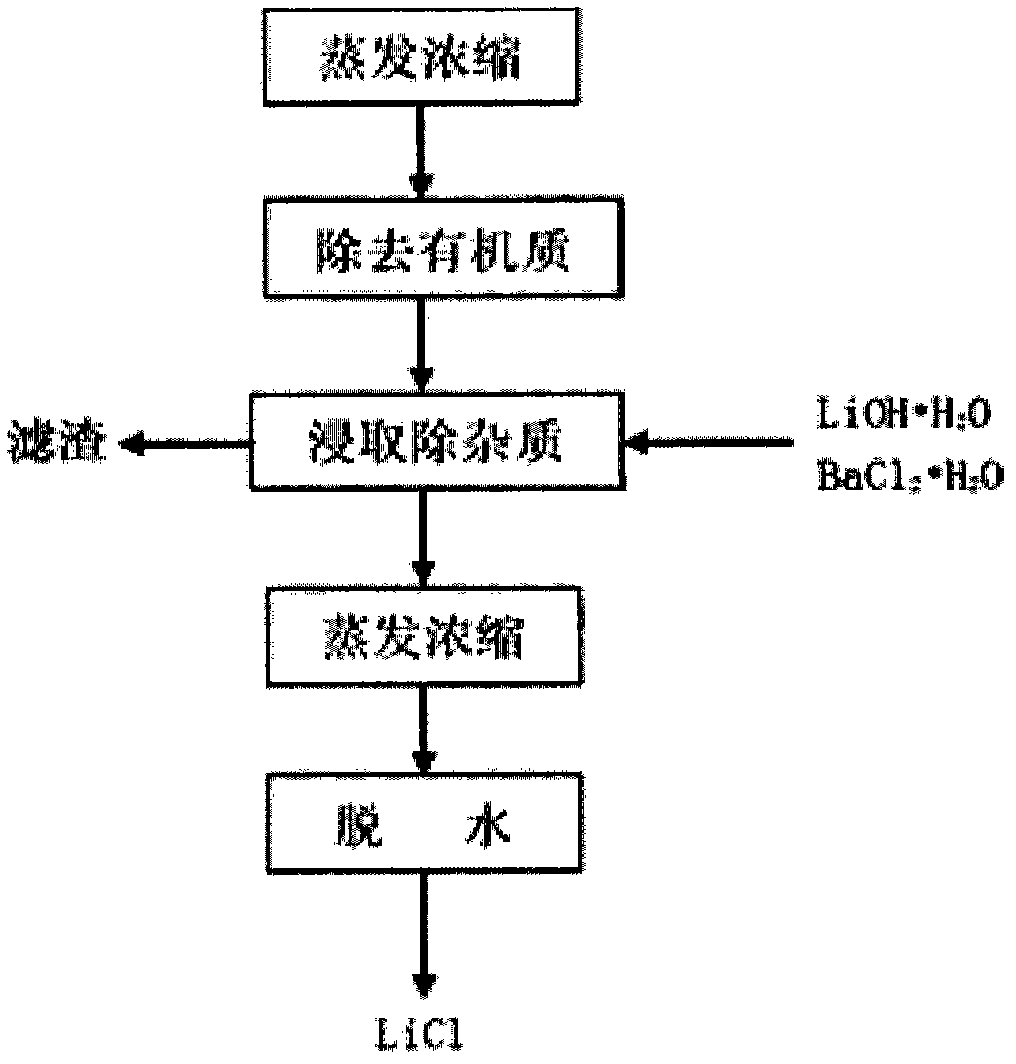

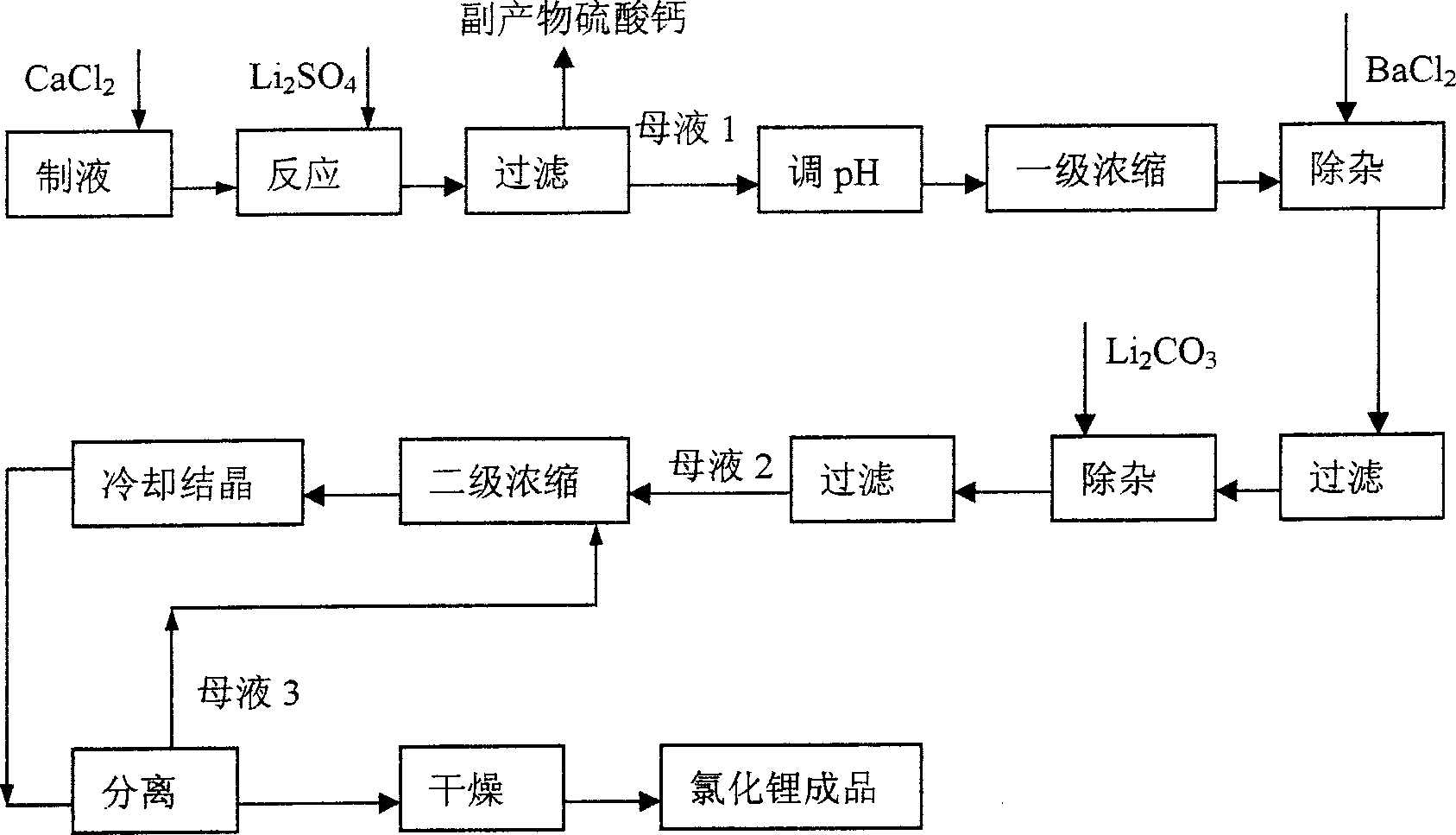

Method for preparing lithium chloride free from water

This invention discloses a method for preparing anhydrous LiCl. The method comprises: (1) adding CaCl2 to Li2SO4 solution to obtain LiCl and CaSO4; (2) filtering and washing to remove CaSO4 and obtain LiCl solution; (3) concentrating, adding BaCl2 solution, reacting, filtering and washing to remove SO42-; (4) adding LiCO3 solution, reacting, filtering and washing to remove Ba2+ and Ca2+; (5) concentrating, cooling, crystallizing, separating and drying to obtain anhydrous LiCl. The method has such advantages as simple process, easy operation, low energy and water consumption, low Li loss, and high LiCl yield.

Owner:JIANGSU RONGHUI GENERAL LITHIUM IND CO LTD

Recovery of lithium compounds from brines

InactiveUS6936229B1Reduce in quantityCalcium/strontium/barium carbonatesCrystallization separationLithium chlorideLithium carbonate

Methods and apparatus for the production of low sodium lithium carbonate and lithium chloride from a brine concentrated to about 6.0 wt % lithium are disclosed. Methods and apparatus for direct recovery of technical grade lithium chloride from the concentrated brine are also disclosed.

Owner:ROCKWOOD LITHIUM INC

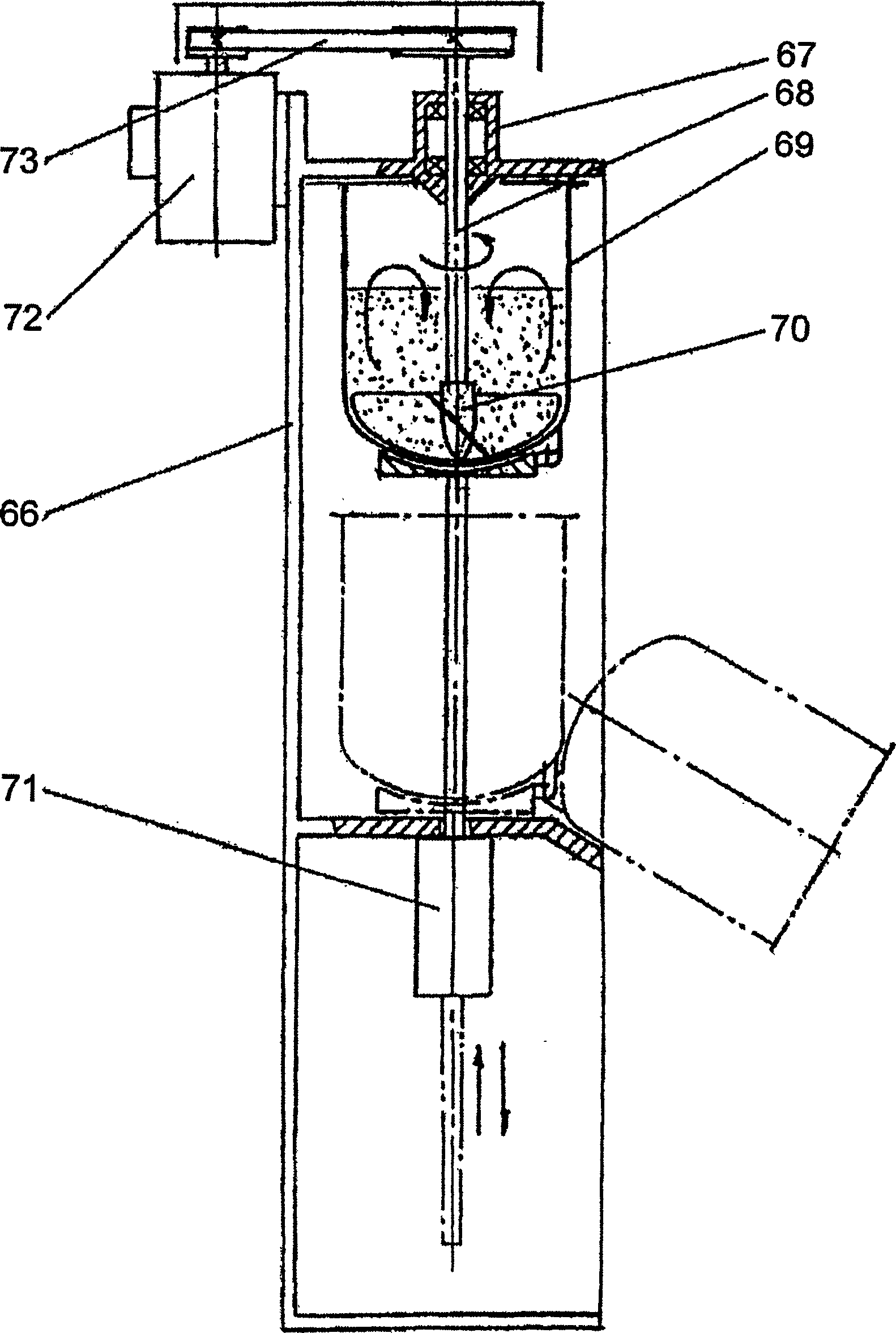

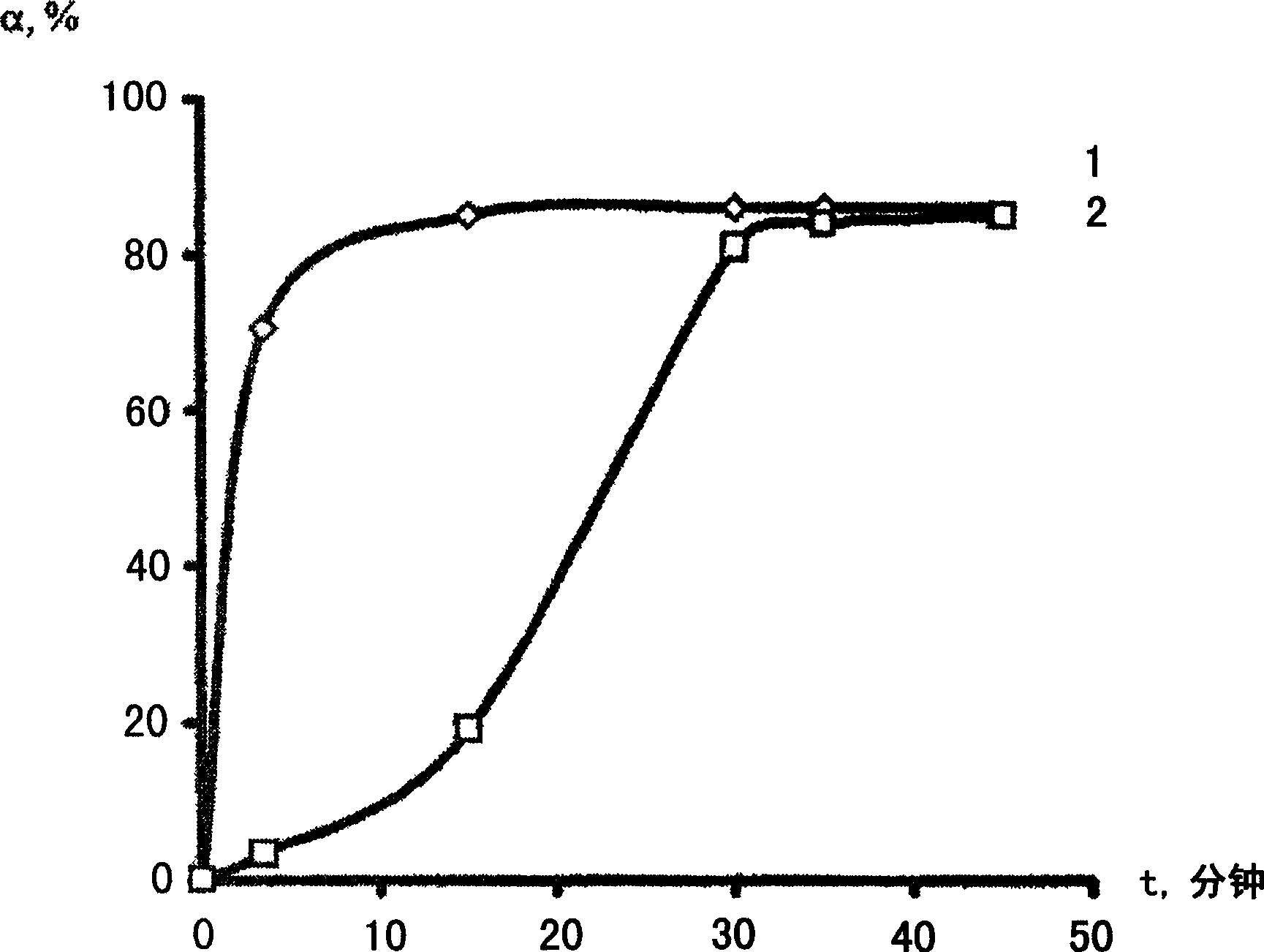

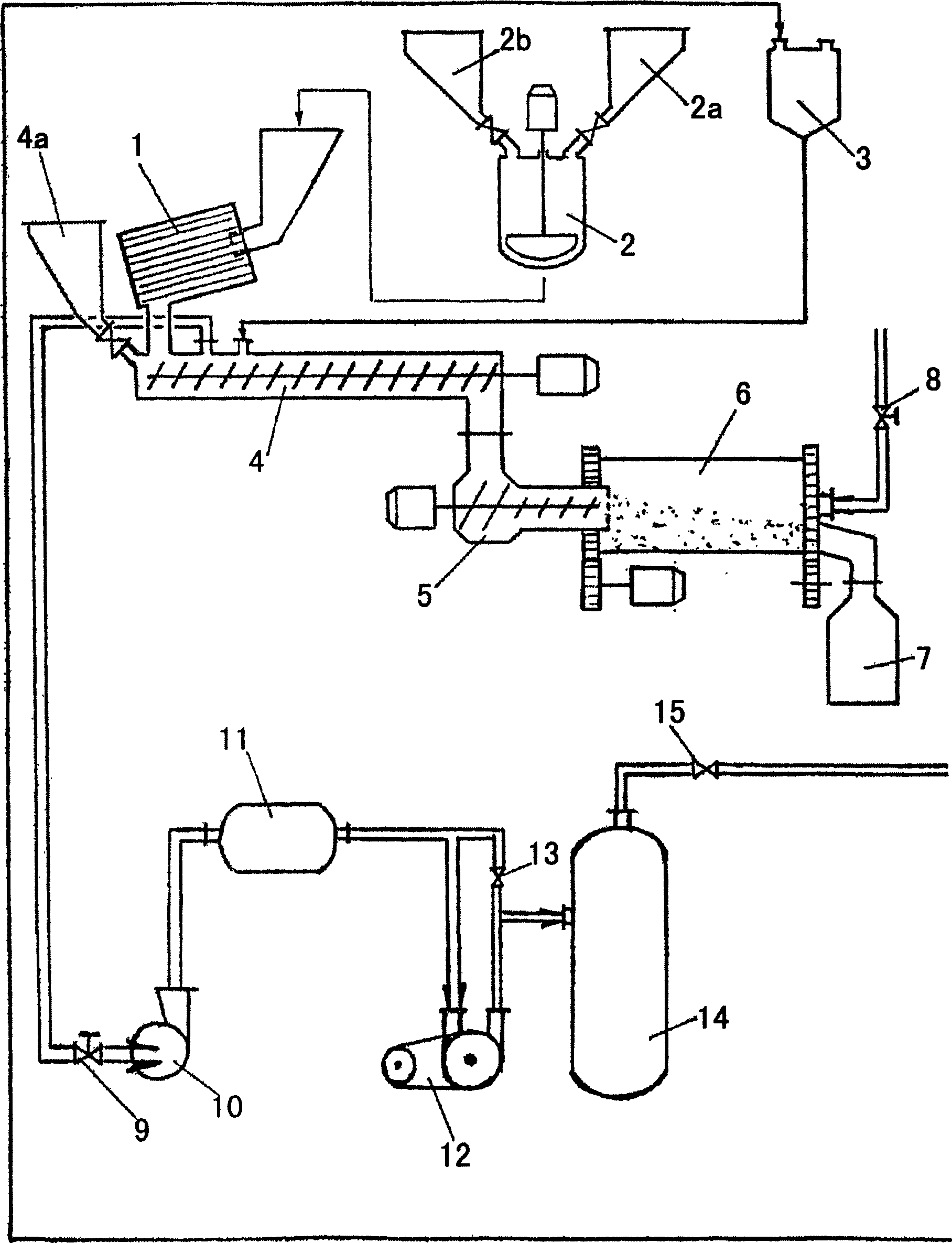

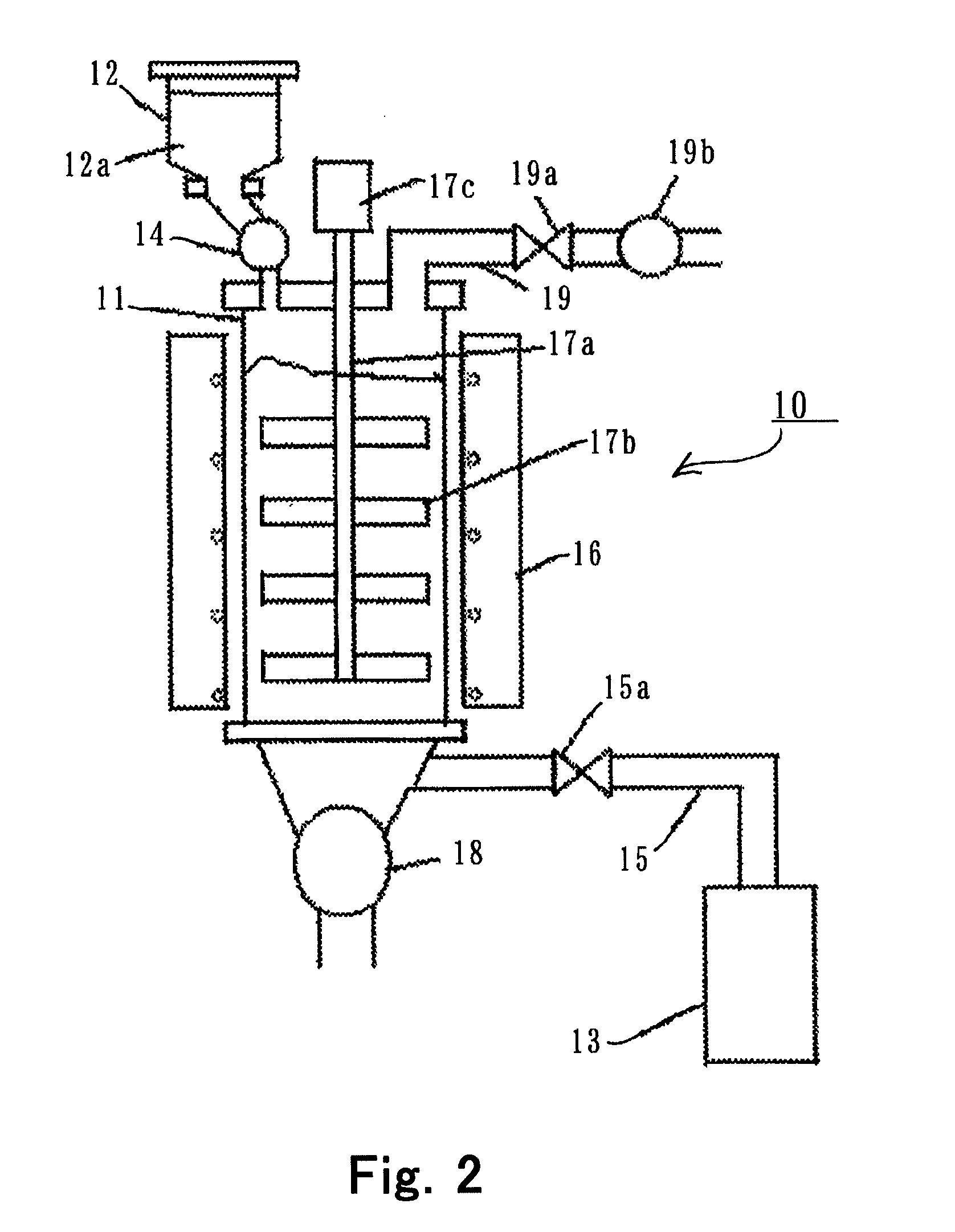

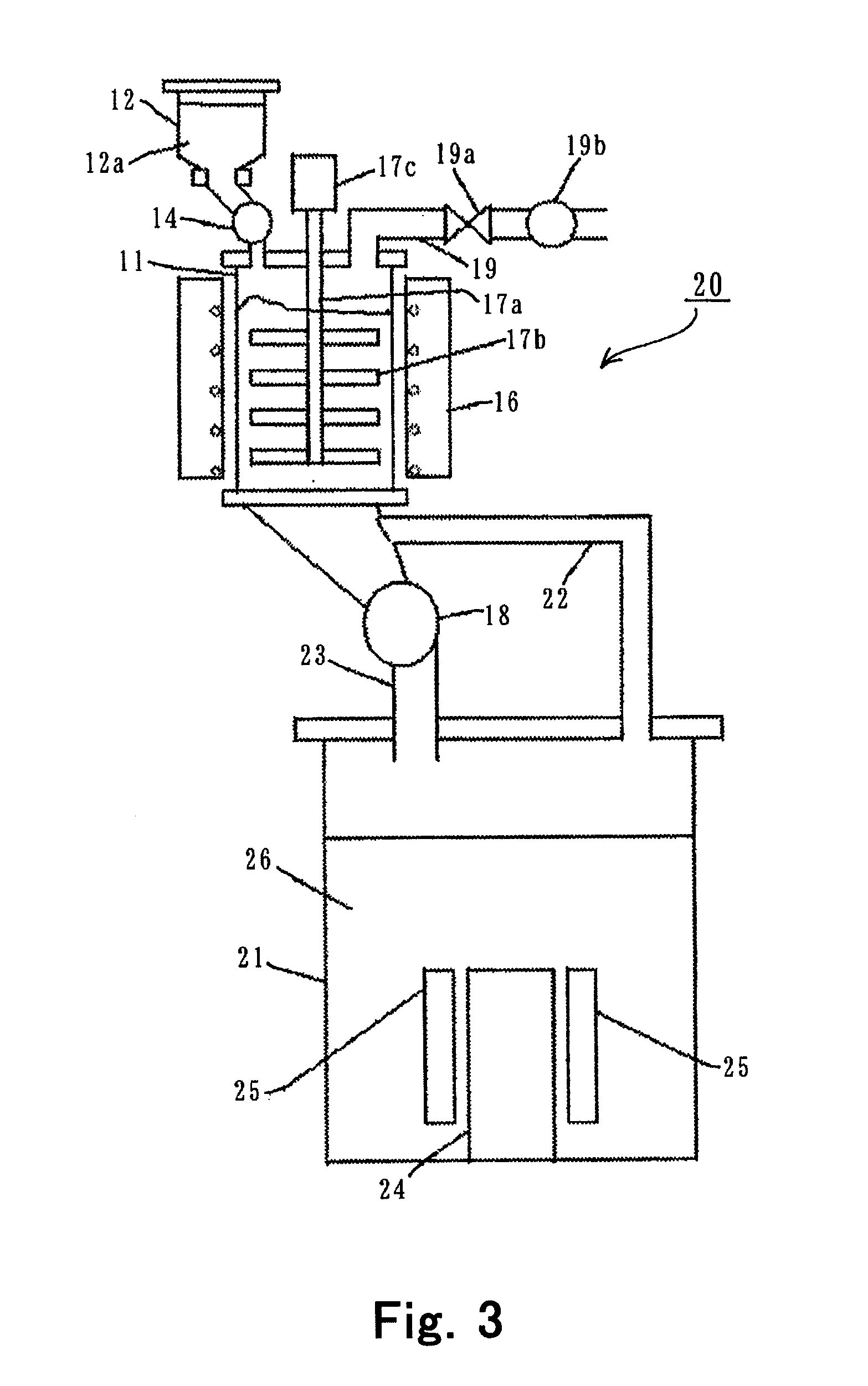

Method for producing granulated sorbents and installation for carrying out the method

The invention relates to a method for producing granulated sorbents, and to an installation for carrying out the method. The aim of the invention is to obtain the chloride form of the double hydroxide of aluminium and lithium as LiCL2AI / OH)3 nH2O (DHAL-CL) in a waste-free solid phase of aluminium hydroxide and lithium salts in a mixer, with subsequent continuous activation of crystalline DHAL-CI in a centrifugal mill activator in order to obtain a defectuous material structure. The product obtained is mixed with chlorinated polyvinyl chloride as a binding agent and with liquid methylene chloride. The granulation is carried out by extruding the paste produced and refining the same in the granulator. The methylene chloride produced is collected by an organic liquid absorbent having a high boiling point. The methylene chloride steam is guided out of the material flow in the carrier gas flow in the manner of an ideal displacement in the counter-current of the contact phases. The methylene chloride recuperation is carried out in two steps according to the thermal method, during the heating of the absorbent used. The inventive method is characterised by essentially reduced environmental impact in relation to prior art, due to the closed material circuits used. The granulated sorbent is especially suitable for the selective extraction of lithium from chloride salt lye of any mineralization, with an extraction degree of 95 %.

Owner:青海盐湖蓝科锂业股份有限公司

Lithium ion battery and positive electrode material thereof

InactiveCN108075111AReduce residual lithium on the surfaceLarge specific surface areaSecondary cellsPositive electrodesPhysical chemistryLithium-ion battery

The invention discloses a lithium ion battery and a positive electrode material thereof. The general chemical formula of the positive electrode material of the lithium ion battery is LiNixM[1-x]O2, wherein x is greater than or equal to 0.5 but smaller than 1; the M is one or more of Co, Mn, Al, Mg, Ti and Zr; the specific surface area of the positive electrode material of the lithium ion battery is 0.2 to 0.6m<2> / g; the surface lithium residue quantity is 200 to 1000 ppm. Compared with the prior art, the positive electrode material of the lithium ion battery is prepared through solid phase reaction; the surface lithium residue quantity of the material can be obviously reduced; the specific surface area increase of the positive electrode material of the lithium ion battery in the reaction process can also be avoided. The circulation stability of the positive electrode material of the lithium ion battery is good; the preparation method is simple; the implementation is easy; the production cost is low; good application prospects are realized. The invention also discloses the lithium ion battery.

Owner:CONTEMPORARY AMPEREX TECH CO

Method for extracting lithium salt from spodumene by soda ash pressure leach method

ActiveCN103183366AImprove resource utilizationSimple processProcess efficiency improvementLithium halidesResource utilizationChemistry

The invention discloses a method for extracting lithium salt from spodumene by a soda ash pressure leach method. The method comprises the following technological process: (1) roasting and transforming; (2) cooling and grinding; (3) size mixing; (4) pressure leaching; and (5) cooling and decompressing. The method is characterized by further comprising the following technological process: (6) pressure filtering and separating; (7) acidifying and transforming; (8) separating and washing; (9) condensing and separating out sodium; (10) evaporating and crystallizing; (11) centrifugal separation; and (12) drying. The method for extracting lithium salt from spodumene by the soda ash pressure leach method provided by the invention is simple in process, low in cost and high in resource utilization rate.

Owner:GANFENG LITHIUM CO LTD +1

Method for producing lithium fluorosulfonate, lithium fluorosulfonate, nonaqueous electrolytic solution, and nonaqueous electrolytic solution secondary battery

ActiveUS20140038062A1High yieldLower internal impedanceCell electrodesOrganic electrolyte cellsElectrolytic agentPhysical chemistry

The present invention relates to a method for producing lithium fluorosulfonate which comprises reacting a lithium salt and fluorosulfonic acid in a nonaqueous solvent, wherein the lithium salt is a lithium salt not generating water through the reaction step.

Owner:MU IONIC SOLUTIONS CORP +1

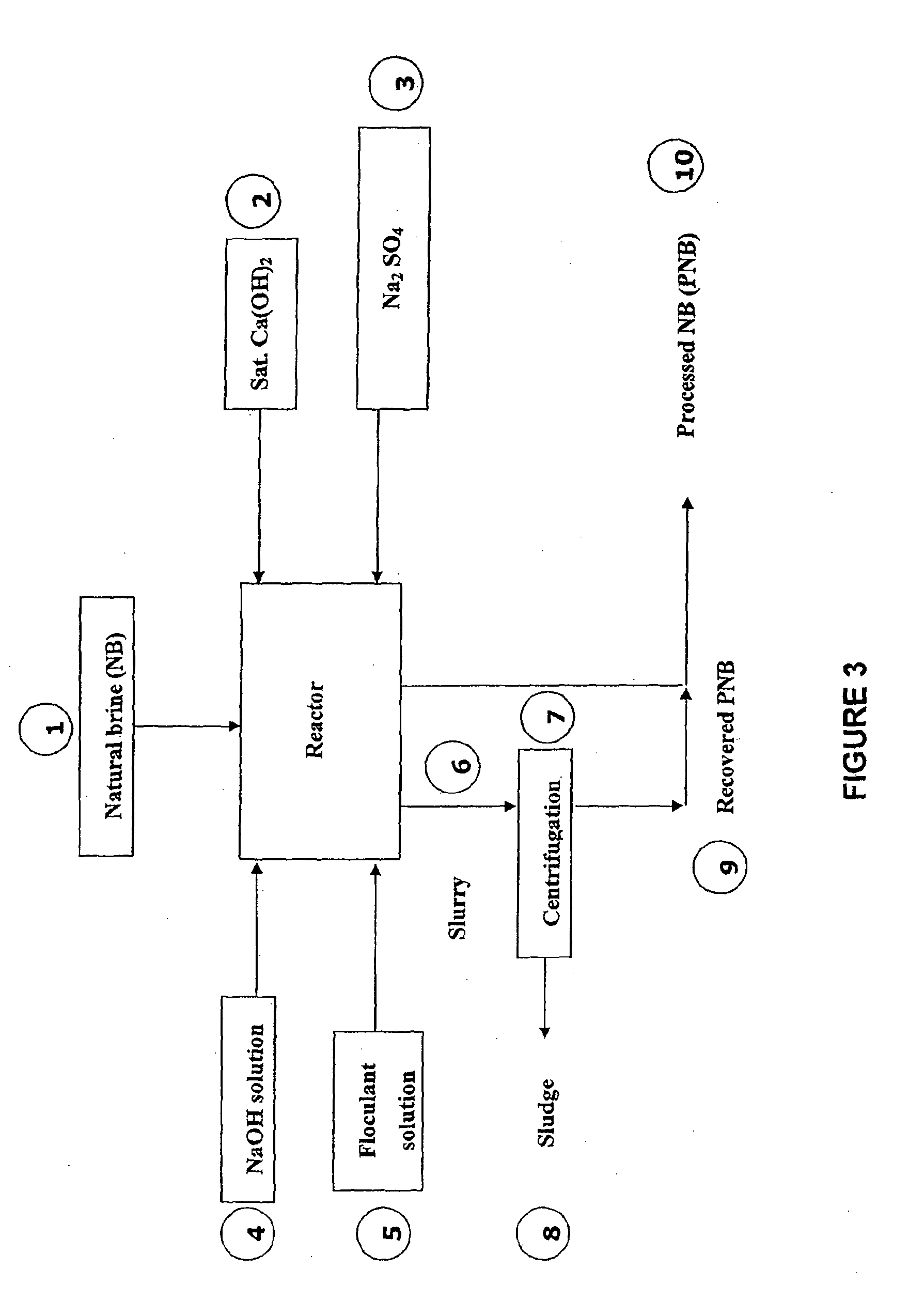

Process for recovering lithium from a brine

InactiveUS20110300041A1Reduce contentOther chemical processesRubidium/caesium/francium compoundsLithium chlorideLithium carbonate

There is disclosed herein a process for recovering lithium from an impure natural or industrial brine, the process comprising adjusting the pH of a feed brine containing lithium to a value of no less than 11.3 and separating the waste solids and a solution containing lithium values. The solution may be further concentrated and treated to obtain lithium carbonate and a lithium chloride solution suitable for obtaining electrolytic grade lithium chloride.

Owner:RINCON LITHIUM

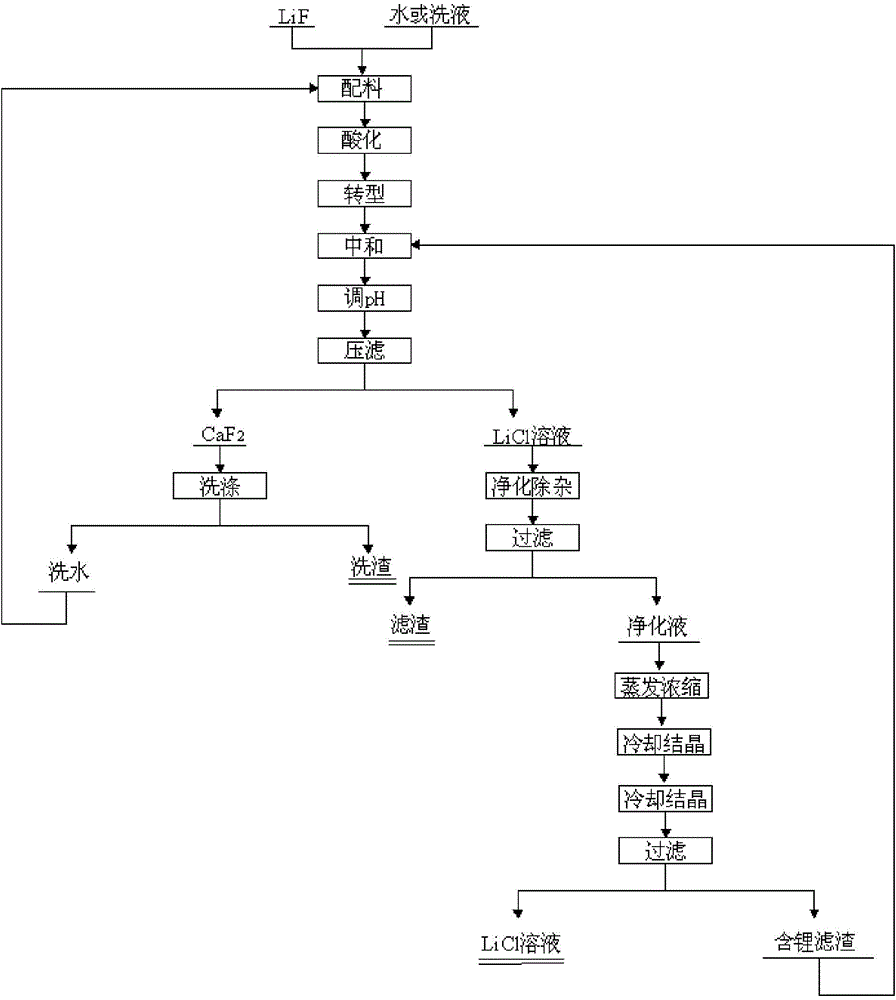

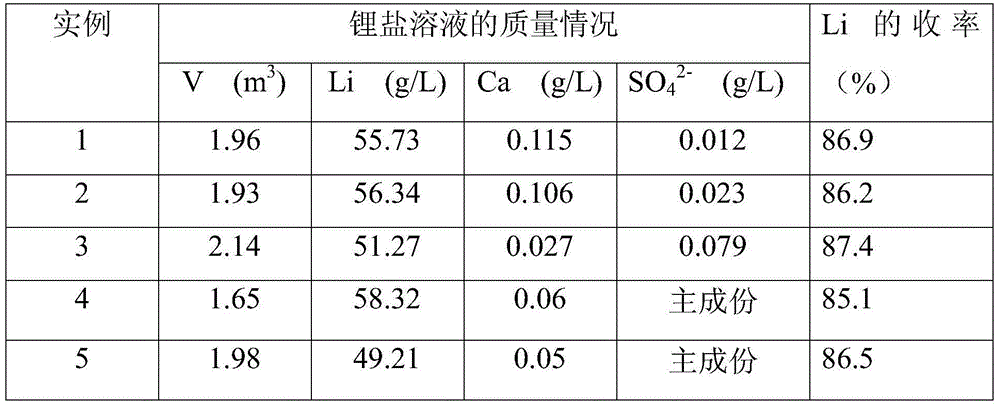

Method for preparing lithium salt through recycling lithium fluoride-containing waste material material

ActiveCN104787784AReduce pollutionSolve the problem of inability to efficiently and environmentally friendly process lithium fluoride-containing wasteLithium halidesPotassiumEvaporation

The invention relates to a method for preparing a lithium salt through recycling a lithium fluoride-containing waste material, wherein the method comprises the following steps: (1) ingredient preparation: putting the lithium fluoride-containing waste material and pure water or washing water into a reaction kettle to prepare a slurry; (2) acidification: adding an inorganic acid into the reaction kettle, and regulating the pH of the slurry; (3) transformation: adding a calcium salt into the reaction kettle, and transforming; (4) neutralization: adding calcium carbonate or calcium hydroxide to neutralize excess inorganic acid; (5) pH adjustment: adding an alkali, and regulating the pH of the solution; (6) filter pressing and washing; (7) purification and impurity removal: adding soluble carbonate and BaCl2 into the filtrate, and removing Ca<2+> and SO4<2->; and (8) evaporation concentration and sodium potassium precipitation to obtain a pure lithium salt solution. The treatment problem of the lithium fluoride-containing waste material is solved, environmental pollution is reduced, lithium resources are efficiently recycled to prepare the lithium salt, the recovery rate of lithium is high, and the lithium salt production costs are low.

Owner:GANFENG LITHIUM CO LTD

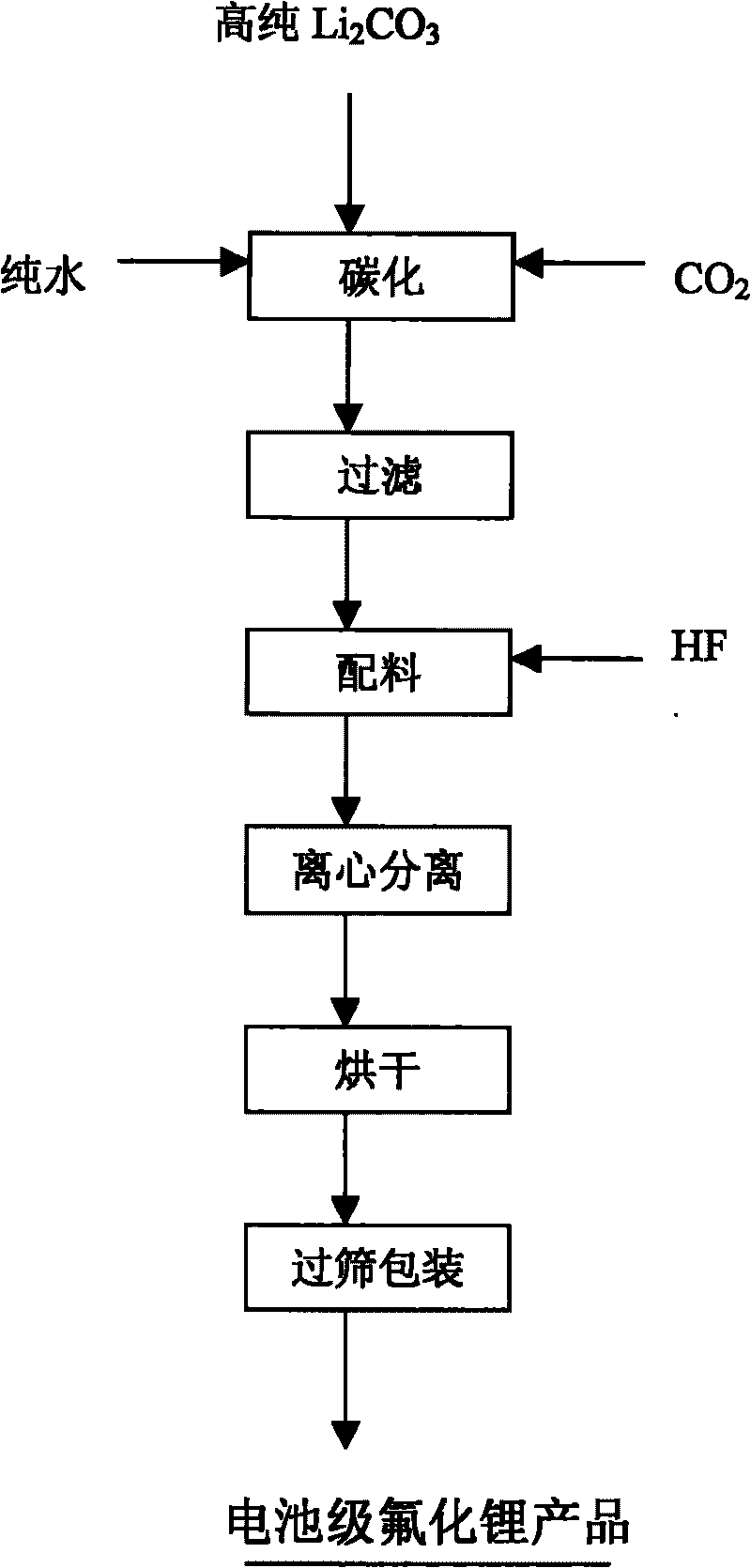

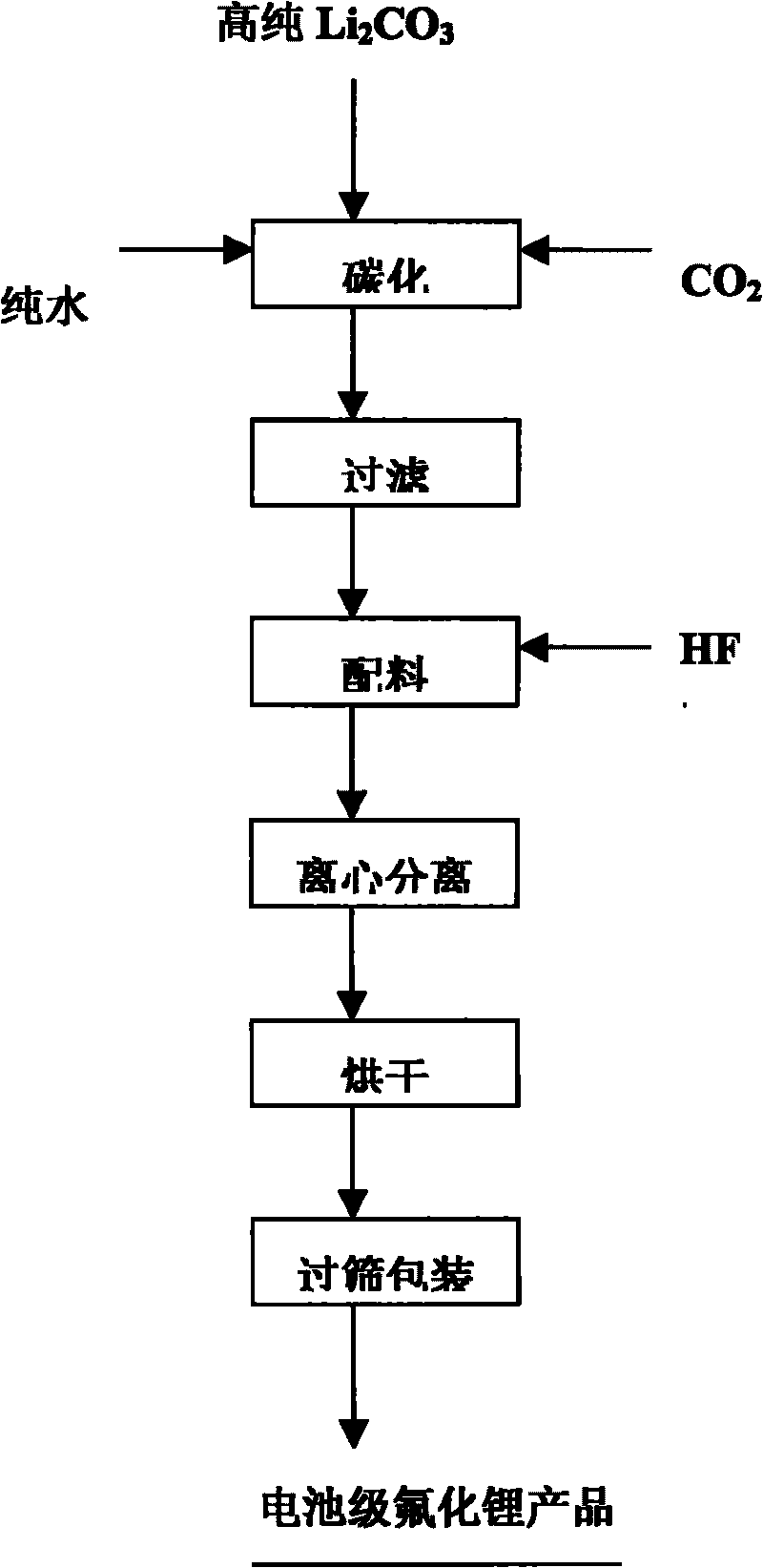

Method for preparing lithium fluoride

The invention relates to a method for preparing lithium fluoride, which is characterized by comprising the following steps of: mixing high-purity lithium carbonate with pure water, and introducing carbon dioxide gas to carry out the carburization reaction for obtaining a lithium bicarbonate solution; precisely filtering the lithium bicarbonate solution; introducing hydrofluoric acid gas into the lithium bicarbonate solution, stirring to carry out the neutralization reaction, and controlling the pH value to be 0.5-3 to prepare lithium fluoride slurry; centrifugally separating the lithium fluoride slurry to separate solid from liquid of the lithium fluoride slurry; and drying the separated solid lithium fluoride to obtain a finished product. The method of the invention has the advantage of simple technology; the prepared lithium fluoride has the advantages of high purity, good liquidity, no alkaline impurities and neutral state; and the product can achieve the lithium fluoride grade of battery levels.

Owner:GANFENG LITHIUM CO LTD

Production of lithium compounds directly from lithium containing brines

InactiveUS6921522B2Promote absorptionConstant liquid volumeCalcium/strontium/barium carbonatesCalcium/strontium/barium sulfatesLithium chlorideLithium carbonate

Methods and apparatus for the production of low sodium lithium carbonate and lithium chloride from a brine concentrated to about 6.0 wt % lithium are disclosed. Methods and apparatus for direct recovery of technical grade lithium chloride from the concentrated brine are also disclosed.

Owner:ROCKWOOD LITHIUM INC

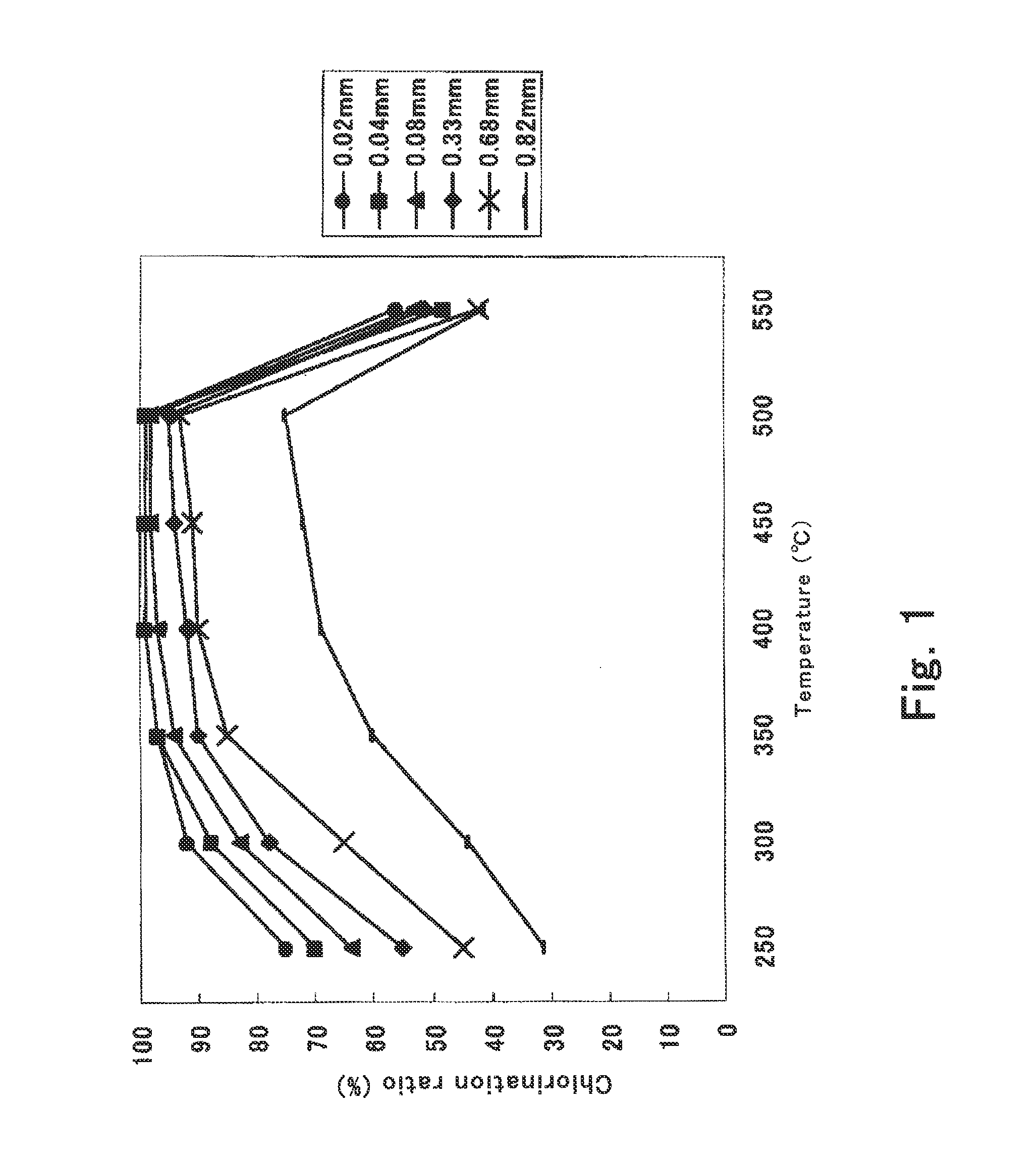

Process for producing metallic lithium

ActiveUS20130001097A1Efficient productionSafe and efficientLithium halidesMetallic lithiumLithium chloride

Provided is a safe and efficient method for producing lithium metal which facilitates efficient production of anhydrous lithium chloride without corrosion of the system materials by chlorine gas or molten lithium carbonate, and which allows production of lithium metal by molten salt electrolysis of the produced anhydrous lithium chloride as a raw material. The method includes the steps of (A) contacting and reacting lithium carbonate and chlorine gas in a dry process to produce anhydrous lithium chloride, and (B) subjecting the raw material for electrolysis containing the anhydrous lithium chloride to molten salt electrolysis under such conditions as to produce lithium metal, wherein the chlorine gas generated by the molten salt electrolysis in step (B) is used as the chlorine gas in step (A) to continuously perform steps (A) and (B).

Owner:SANTOKU CORP

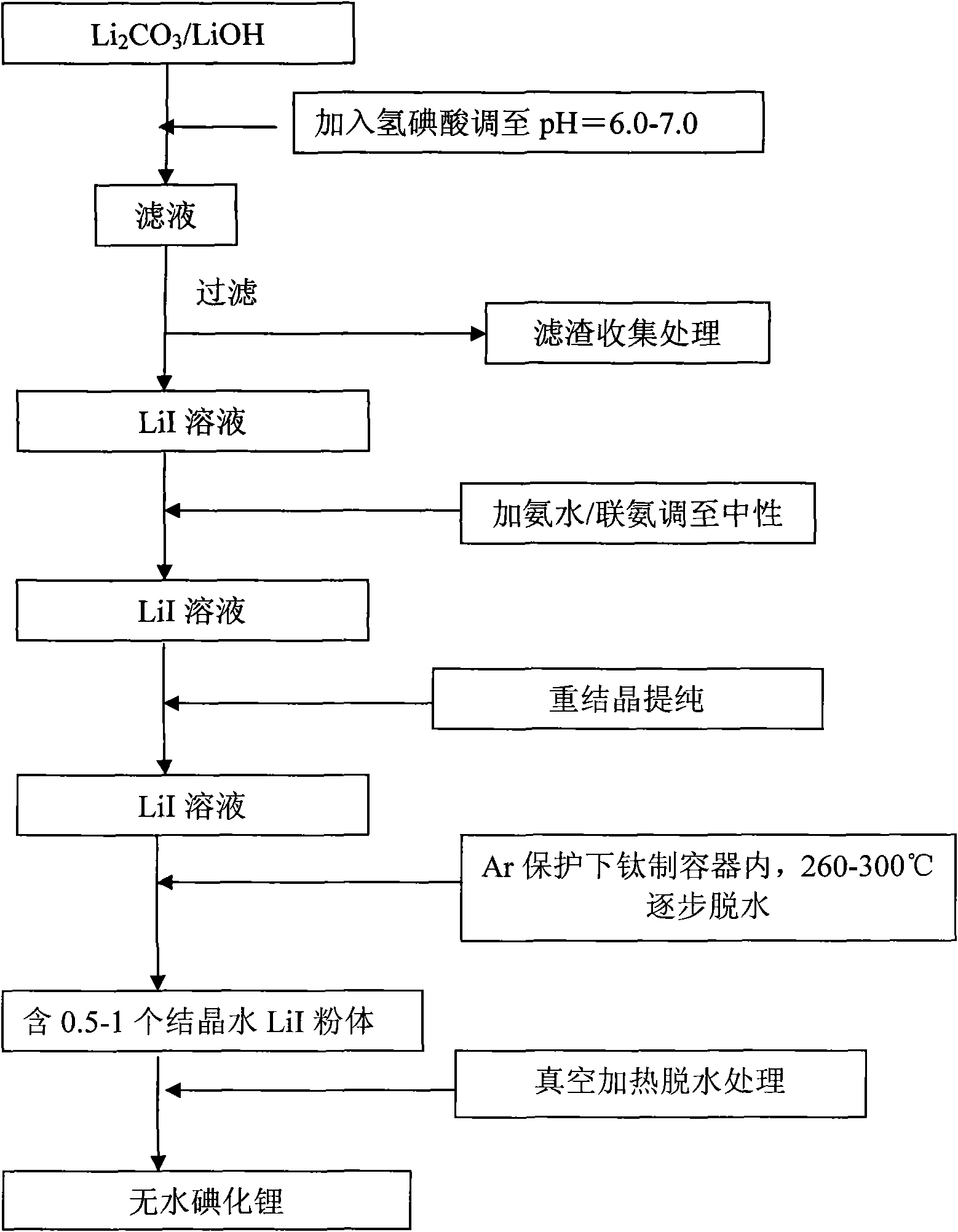

Methods for preparing anhydrous lithium iodide and scintillation crystal doped with lithium iodide

ActiveCN101565192AEasy to operateSimple processPolycrystalline material growthFrom frozen solutionsBridgman methodScintillation crystals

The invention discloses a method for preparing an anhydrous lithium iodide, comprising the following operation steps of: dehydrating the lithium iodide water solution to the lithium iodide powders containing 0.5-1 crystal water; and subsequently carrying out heating and dehydration treatment in vacuum to obtain the anhydrous lithium iodide. The invention also discloses a method for preparing a scintillation crystal doped with the lithium iodide, comprising the following operation steps of: dehydrating the lithium iodide water solution to the lithium iodide powders containing 0.5-1 crystal water; mixing the lithium iodide powder with the doped compound; subsequently carrying out heating and dehydration treatment in vacuum; and subsequently carrying out crystal growth under a vacuum state by adopting a Bridgman method, thus obtaining the scintillation crystal doped with the lithium iodide. The method for preparing the anhydrous lithium iodide has simple operation and no environmental pollution and is easy for large-scale industrial production; the method for preparing the scintillation crystal doped with the lithium iodide has simple process, is not easy to be oxidized at high temperature during the preparation process and can produce the high-quality scintillation crystal doped with the lithium iodide in batches.

Owner:上海新漫传感科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com