Methods for preparing anhydrous lithium iodide and scintillation crystal doped with lithium iodide

A scintillation crystal, lithium iodide technology, applied in chemical instruments and methods, lithium halide, crystal growth and other directions, can solve the problems of high cost, difficult to control conditions, environmental pollution, etc., and achieve high temperature oxidation resistance, no environmental pollution, purity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation of embodiment 1 anhydrous lithium iodide

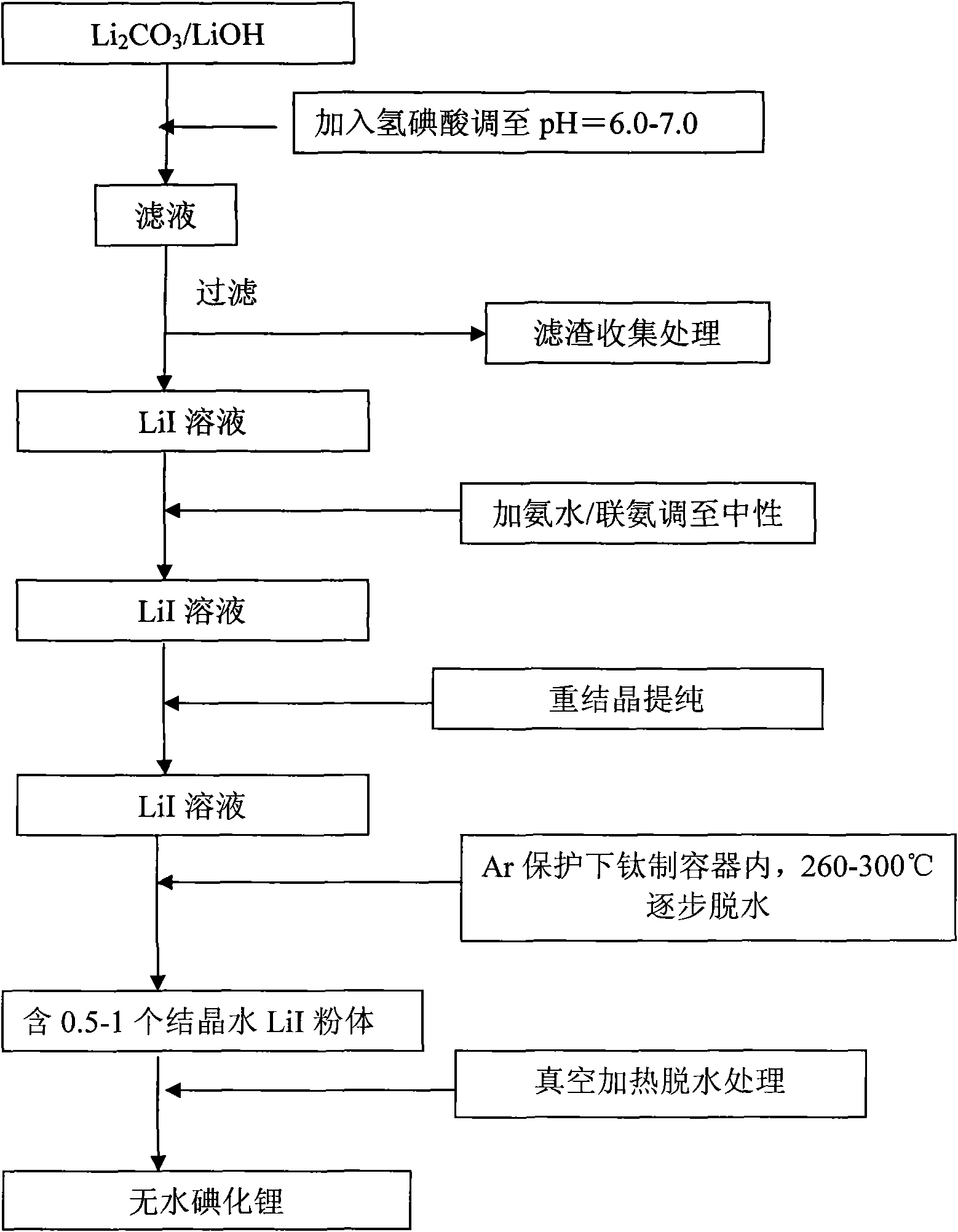

[0028] The operation step of preparing anhydrous lithium iodide comprises as follows (referring to appendix figure 1 ):

[0029] (1) get purity and be that lithium carbonate 100g of 99.999% is placed in the beaker of 2000ml, add about 500ml concentration again and be the analytical pure hydroiodic acid solution of 45.5%, stir and make it react fully, adjust to 6.0 to the solution pH value, then Add a small amount of ammonia water to adjust the pH value of the solution to 7.0, filter to remove impurities, then concentrate and recrystallize the filtrate, and then dissolve the obtained crystals in water to obtain a lithium iodide aqueous solution;

[0030] (2) Put the lithium iodide aqueous solution in a titanium bucket, pass argon gas into the lithium iodide aqueous solution, and heat it to 300°C at a heating rate of 5°C / min under stirring, and keep the temperature until the solution becomes Powder; the lithium ...

Embodiment 2

[0032] The preparation of embodiment 2 anhydrous lithium iodide

[0033] The operation step of preparing anhydrous lithium iodide comprises as follows:

[0034] (1) get purity and be that lithium carbonate 100g of 99.999% is placed in the beaker of 2000ml, then add about 500ml concentration and be the analytical pure hydroiodic acid solution of 45.5%, stir and make it react fully, adjust to 7.0 to the solution pH value, then Add a small amount of ammonia water to adjust the pH value of the solution to 9.0, filter to remove impurities, then concentrate the filtrate for recrystallization, and then dissolve the obtained crystals in water to obtain a lithium iodide aqueous solution;

[0035] (2) Put the lithium iodide aqueous solution in a titanium bucket, pass argon gas into the lithium iodide aqueous solution, and heat it to 260°C at a heating rate of 10°C / min under stirring, and keep the temperature until the solution becomes Powder; the lithium iodide powder is lithium iodide...

Embodiment 3

[0037] The preparation of embodiment 3 anhydrous lithium iodide

[0038] The operation step of preparing anhydrous lithium iodide comprises as follows:

[0039] (1) get purity and be that lithium carbonate 100g of 99.999% is placed in the beaker of 2000ml, then add about 500ml concentration and be the analytical pure hydroiodic acid solution of 45.5%, stir and make it react fully, adjust to 6.5 to the solution pH value, then Add a small amount of ammonia water to adjust the pH value of the solution to 8.0, filter to remove impurities, then concentrate the filtrate for recrystallization, and then dissolve the obtained crystals in water to obtain a lithium iodide aqueous solution;

[0040] (2) Put the lithium iodide aqueous solution in a titanium bucket, pass argon gas into the lithium iodide aqueous solution, and heat it to 280°C at a heating rate of 8°C / min under stirring, and keep the temperature until the solution becomes Powder; the lithium iodide powder is lithium iodide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com