Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1418results about How to "Fast heat transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

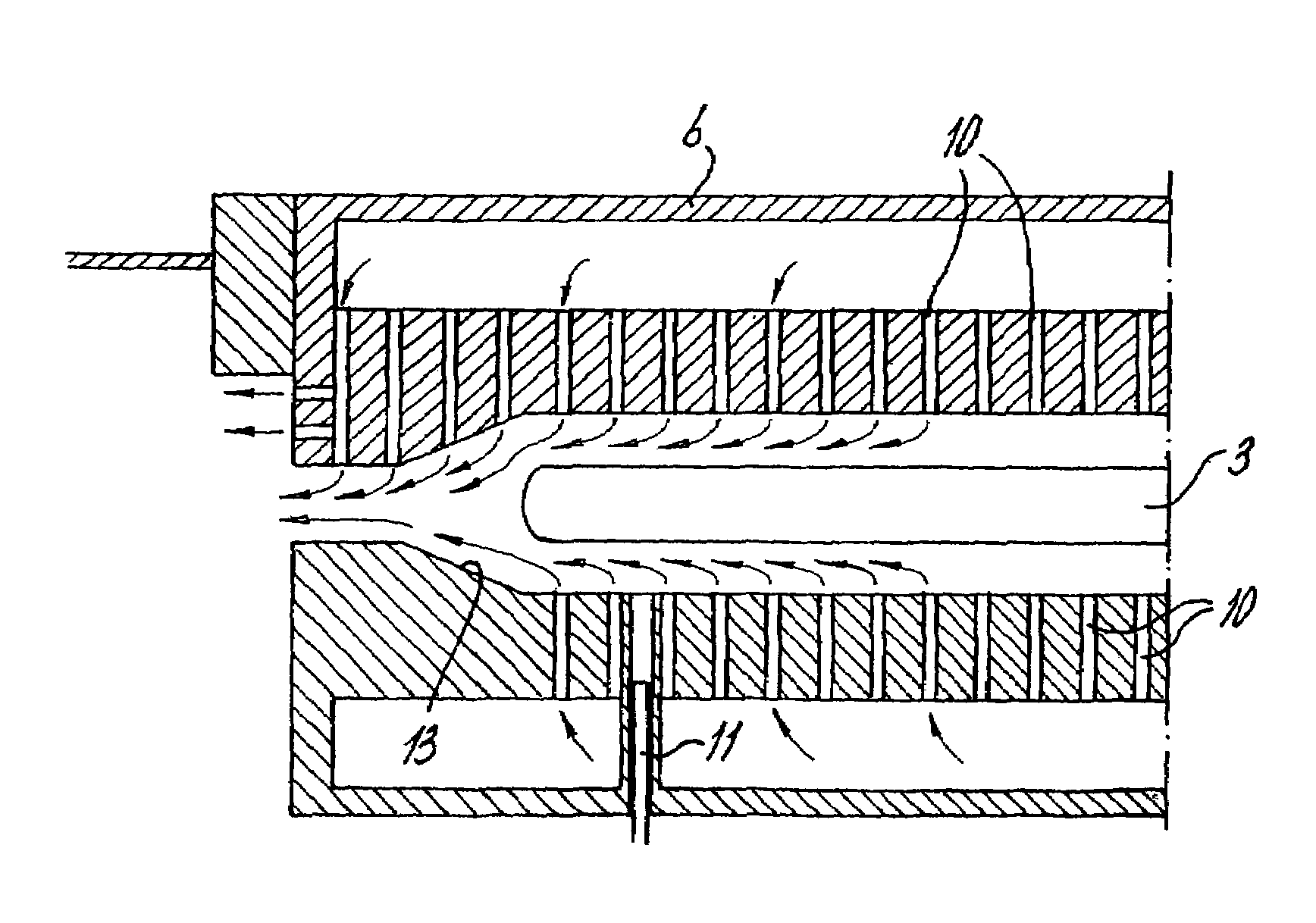

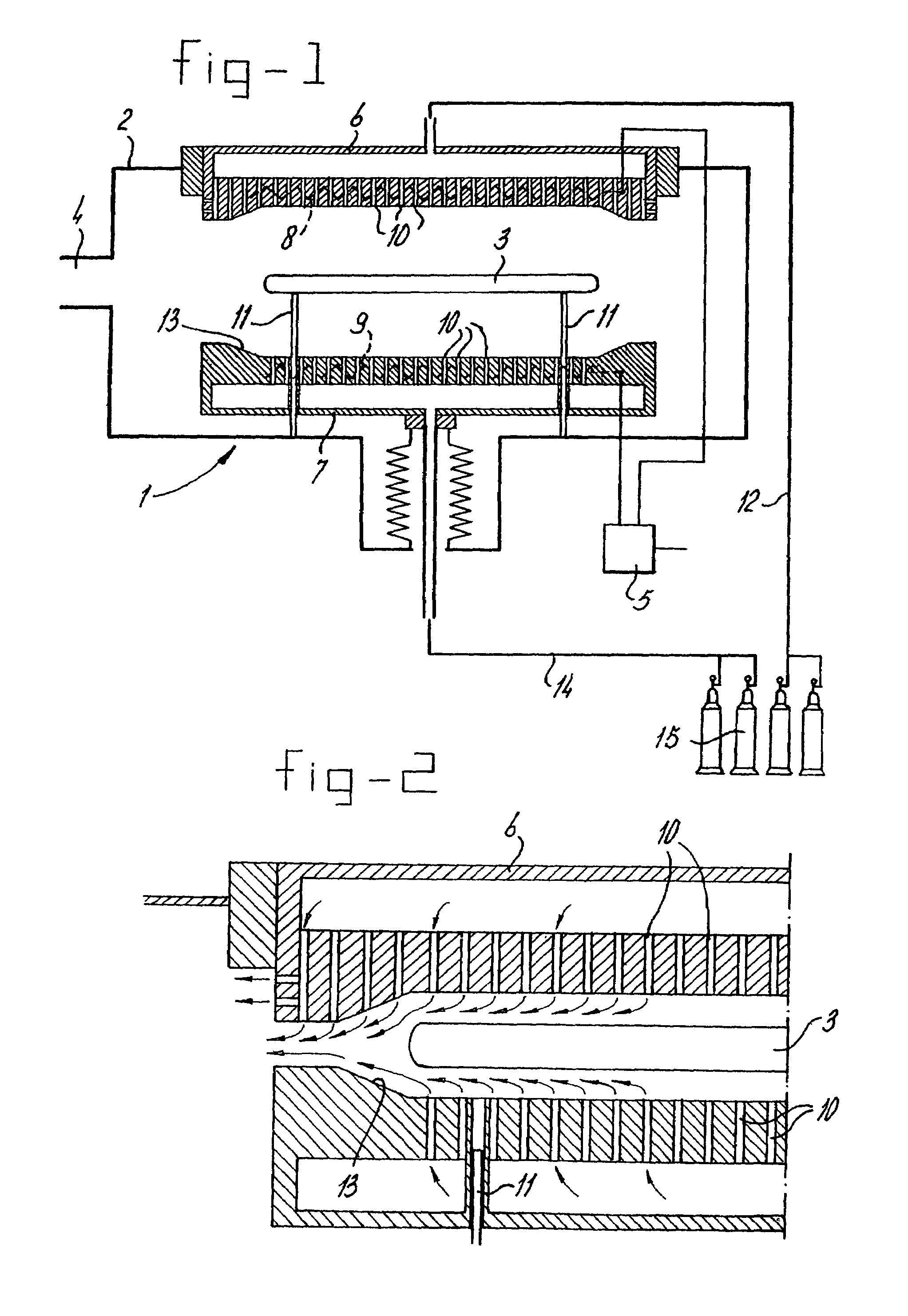

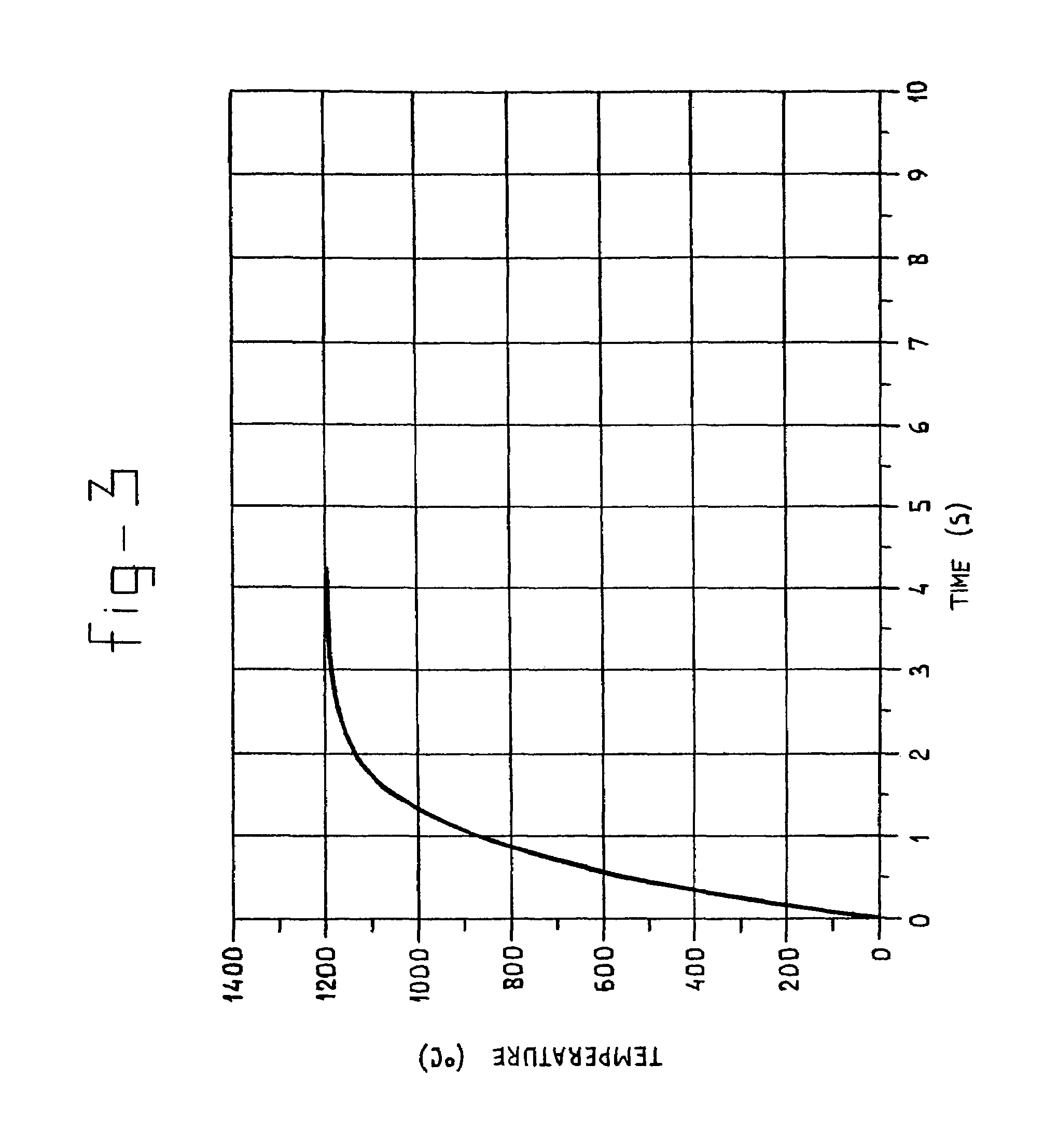

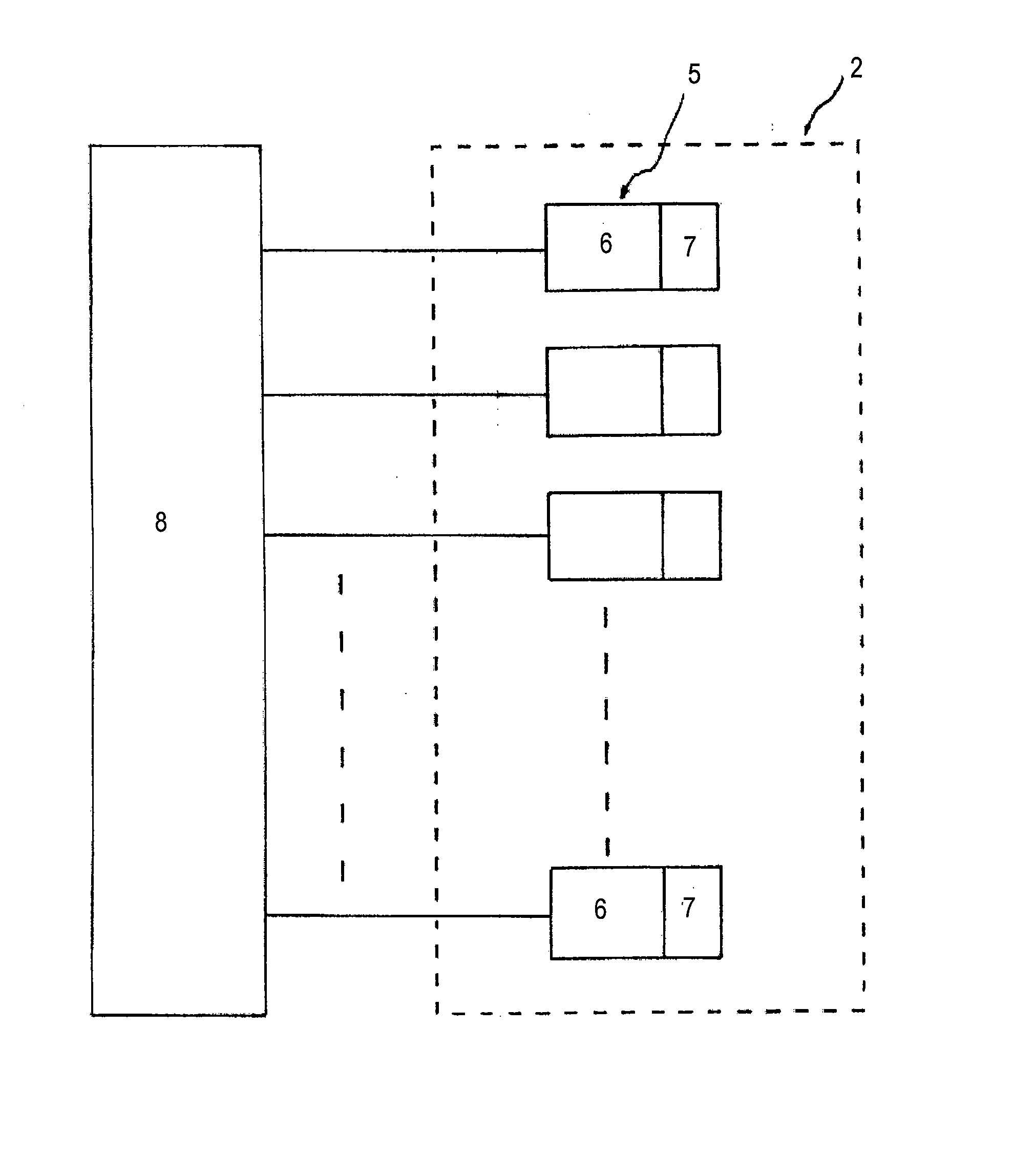

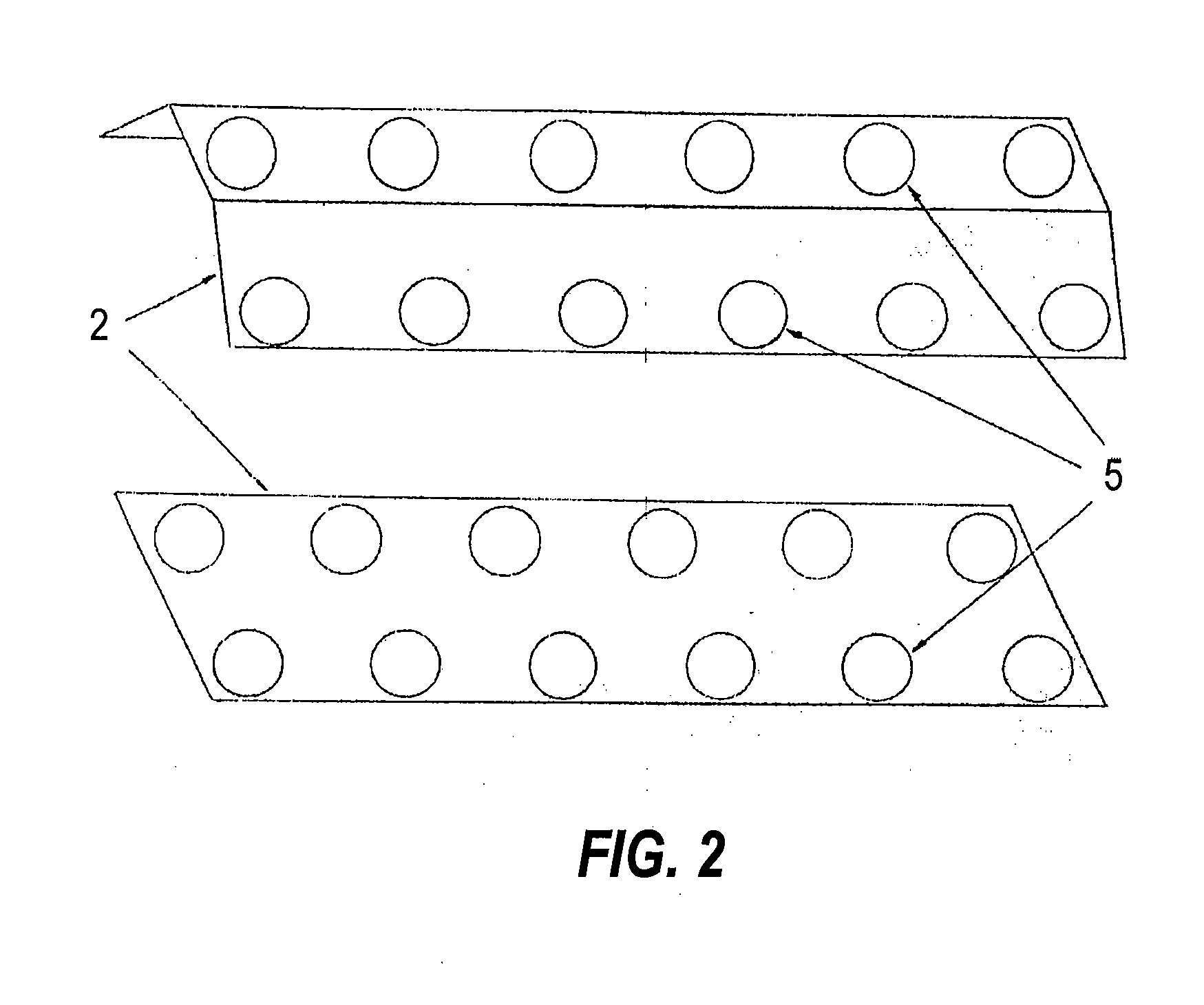

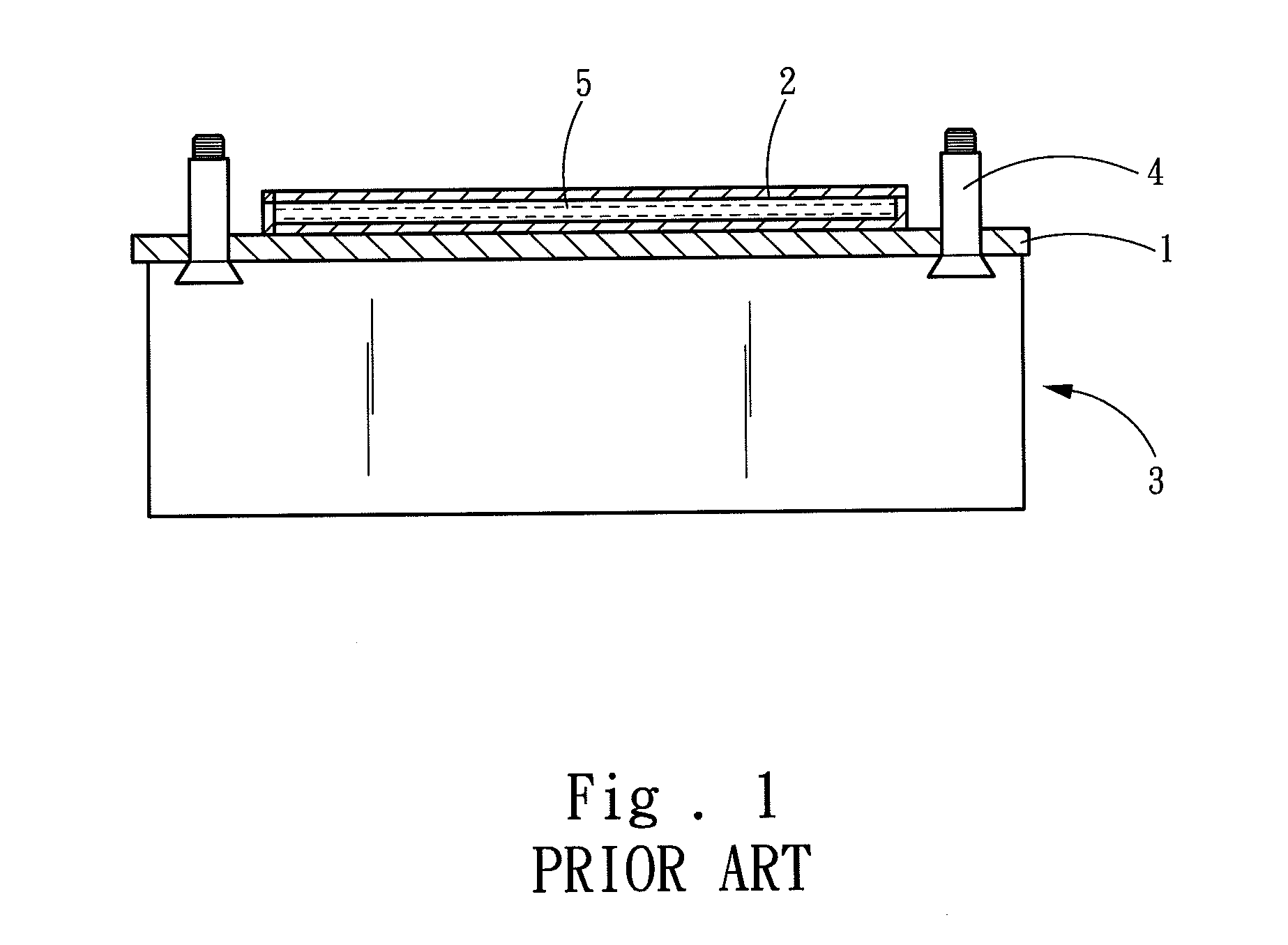

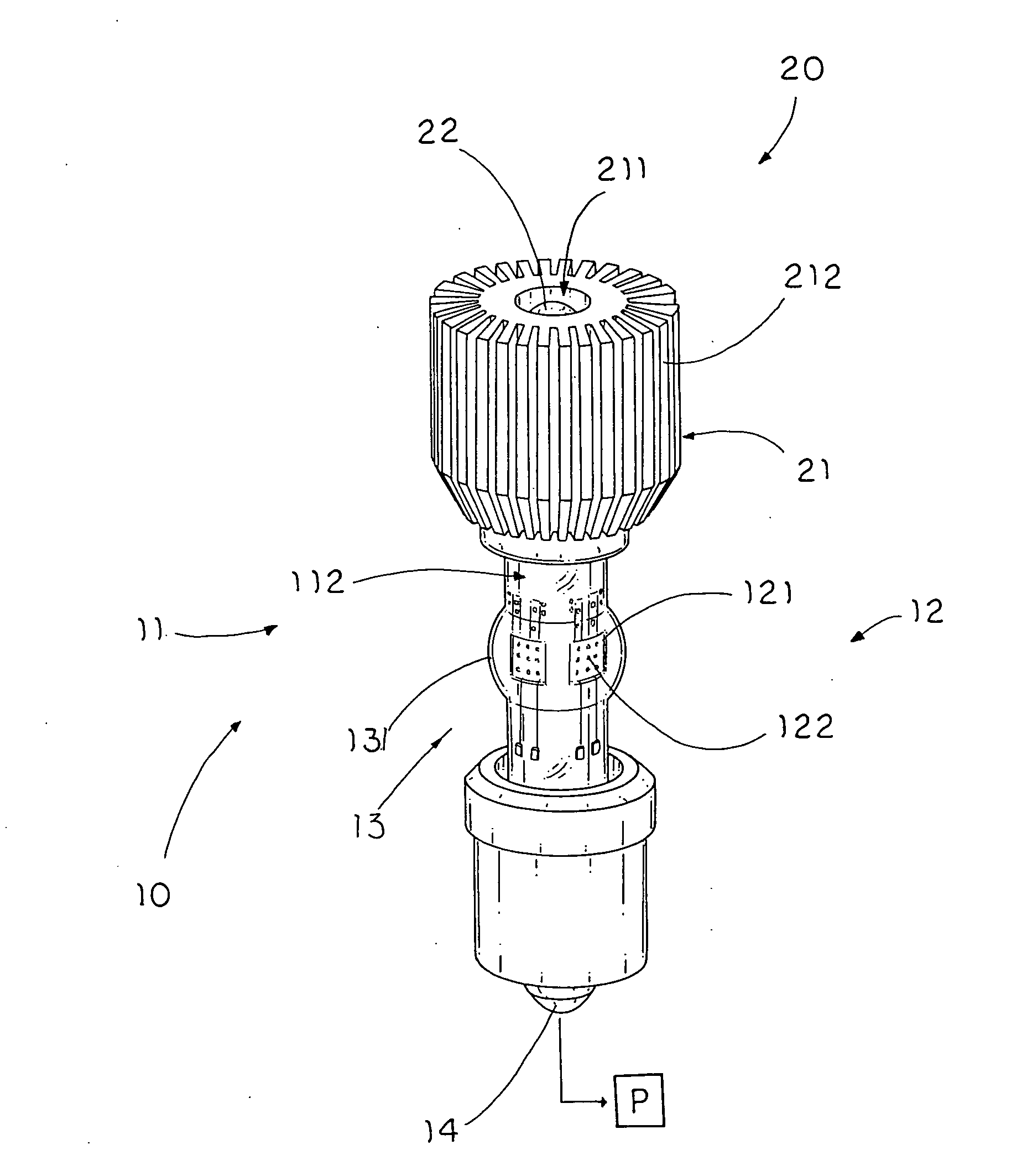

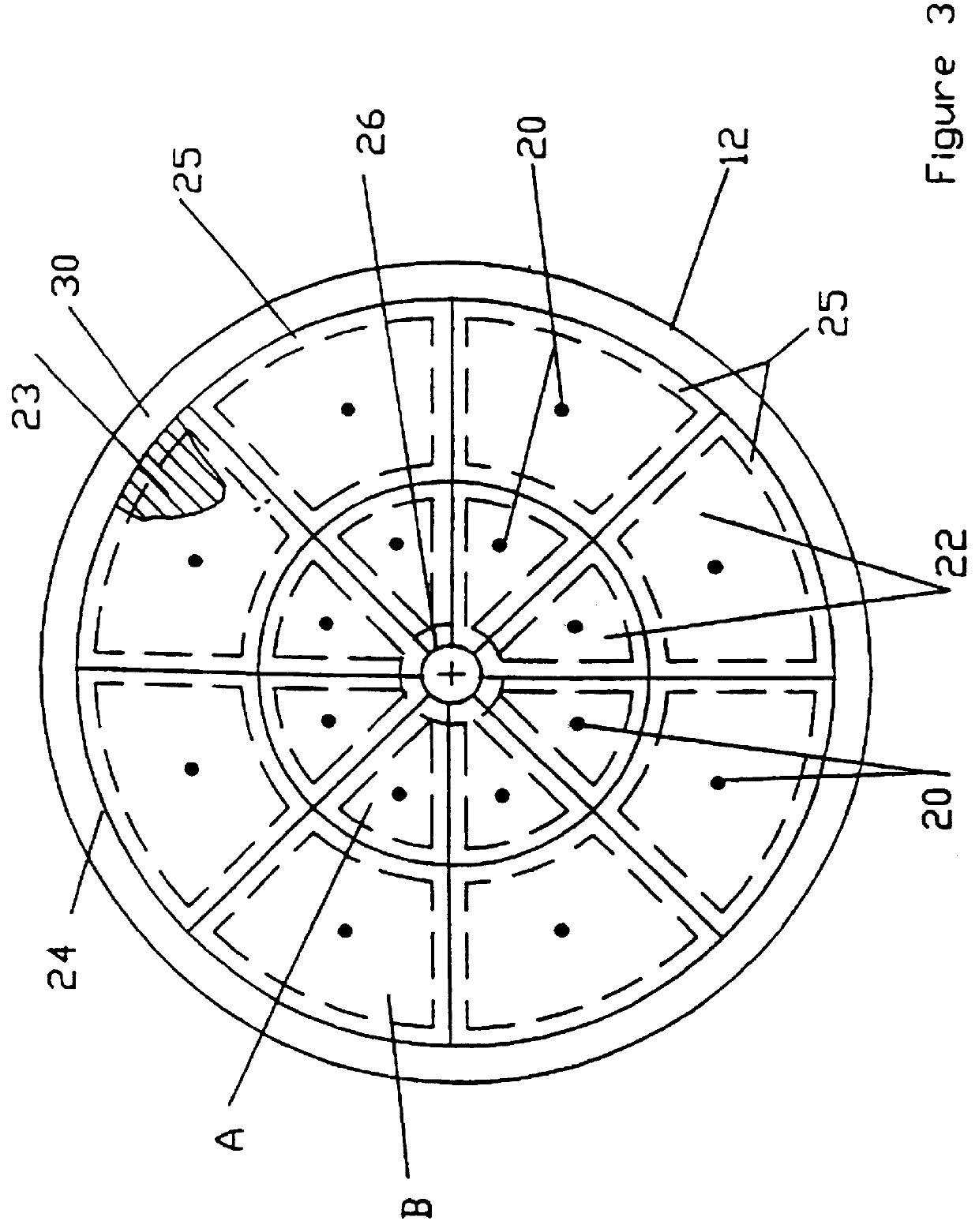

Method and apparatus for supporting a semiconductor wafer during processing

InactiveUS7312156B2Short timeIncrease temperatureSemiconductor/solid-state device manufacturingChemical vapor deposition coatingProduct gasEngineering

A semiconductor wafer is processed while being supported without mechanical contact. Instead, the wafer is supported by gas streams emanating from a large number of passages in side sections positioned very close to the upper and lower surface of the wafer. The gas heated by the side sections and the heated side sections themselves quickly heat the wafer to a desired temperature. Process gas directed to the “device side” of the wafer can be kept at a temperature that will not cause deposition on that side section, but yet the desired wafer temperature can be obtained by heating non-process gas from the other side section to the desired temperature. A plurality of passages around the periphery of the wafer on the non-processed side can be employed to provide purge gas flow that prevents process gas from reaching the non-processed side of the wafer and the adjacent area of that side section.

Owner:ASM INTERNATIONAL

Method and apparatus for supporting a semiconductor wafer during processing

InactiveUS20050037619A1Short timeIncrease temperatureSemiconductor/solid-state device manufacturingChemical vapor deposition coatingProduct gasPartial heating

A semiconductor wafer is processed while being supported without mechanical contact. Instead, the wafer is supported by gas streams emanating from a large number of passages in side sections positioned very close to the upper and lower surface of the wafer. The gas heated by the side sections and the heated side sections themselves quickly heat the wafer to a desired temperature. Process gas directed to the “device side” of the wafer can be kept at a temperature that will not cause deposition on that side section, but yet the desired wafer temperature can be obtained by heating non-process gas from the other side section to the desired temperature. A plurality of passages around the periphery of the wafer on the non-processed side can be employed to provide purge gas flow that prevents process gas from reaching the non-processed side of the wafer and the adjacent area of that side section.

Owner:ASM INTERNATIONAL

Fused glassy particulates obtained by flame fusion

InactiveUS6254981B1Efficient meltingFast heat transferSynthetic resin layered productsCellulosic plastic layered productsParticulatesSuspended particles

The disclosure describes methods for producing bulk, particulate material that includes solid, generally ellipsoidal particles. Irregularly shaped feed particles with average particle sizes of up to 25 microns on a volume basis are dispersed in at least a portion of a combustible gas mixture by application of force and / or fluidizing agents. The combustible mixture with particles in suspension is then delivered, while controlling agglomeration or re-agglomeration of the particles, to at least one flame front. There, the mixture and suspended particles are uniformly distributed across the surface(s) of and passed through the flame front(s) with a high concentration of particles in the mixture. This flame front and the resultant flame(s) with suspended particles are located in at least one "wall free" zone. In such zone(s) the flame(s) may expand while the particles are maintained in dispersion and heated, with controlled and highly efficient application of heating energy. At least partial fusion occurs within at least the surfaces of the particles at high thermal efficiencies, while agglomeration of particles during fusion is inhibited.

Owner:3M CO

At least partly fused particulates and methods of making them by flame fusion

InactiveUS6045913AEfficient meltingFast heat transferSynthetic resin layered productsCellulosic plastic layered productsEllipsoidal particleProduct gas

The disclosure describes methods for producing bulk, particulate material that includes solid, generally ellipsoidal particles. Irregularly shaped feed particles with average particle sizes of up to 25 microns on a volume basis are dispersed in at least a portion of a combustible gas mixture by application of force and / or fluidizing agents. The combustible mixture with particles in suspension is then delivered, while controlling agglomeration or re-agglomeration of the particles, to at least one flame front. There, the mixture and suspended particles are uniformly distributed across the surface(s) of and passed through the flame front(s) with a high concentration of particles in the mixture. This flame front and the resultant flame(s) with suspended particles are located in at least one "wall free" zone. In such zone(s) the flame(s) may expand while the particles are maintained in dispersion and heated, with controlled and highly efficient application of heating energy. At least partial fusion occurs within at least the surfaces of the particles at high thermal efficiencies, while agglomeration of particles during fusion is inhibited.

Owner:3M CO

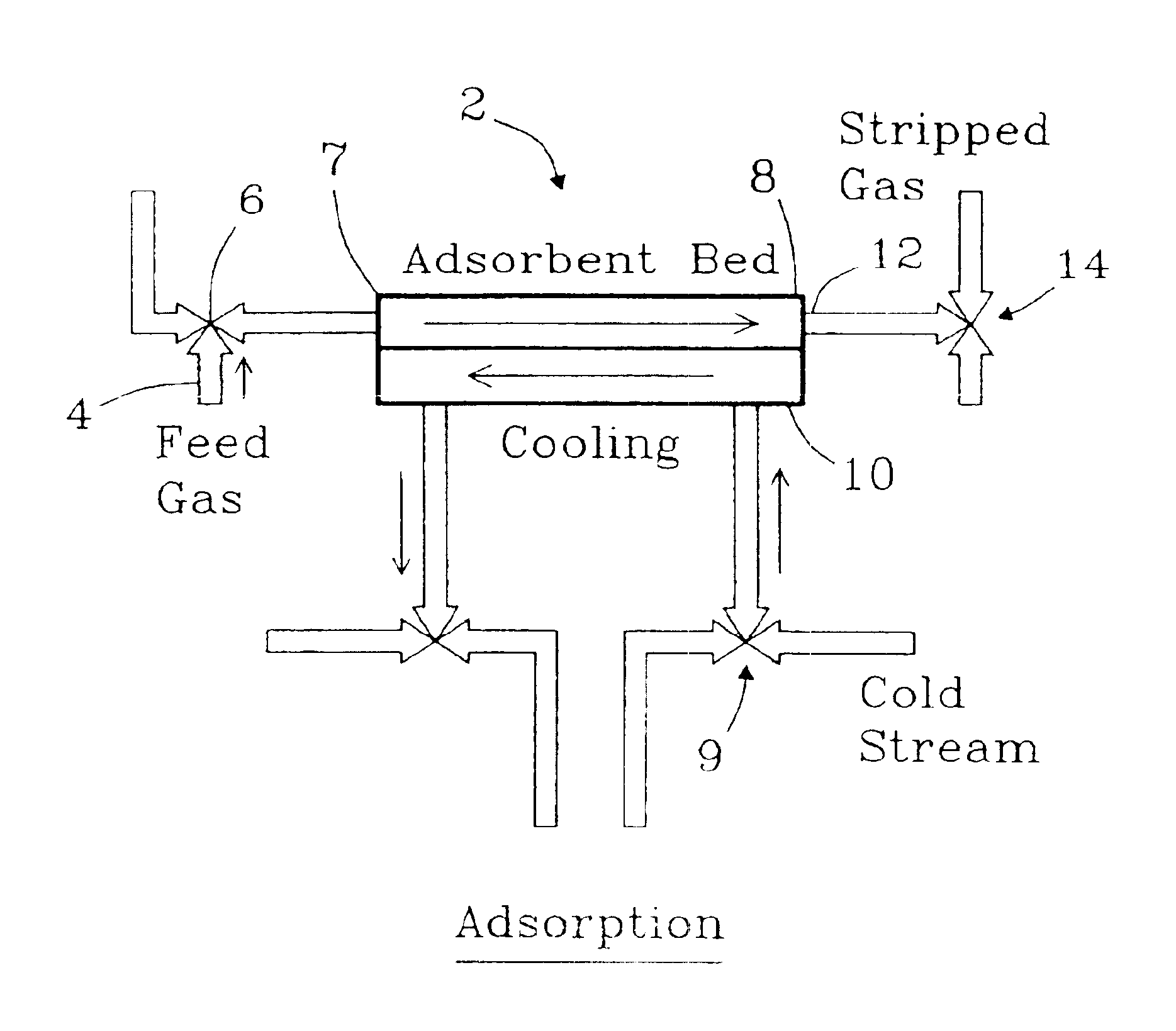

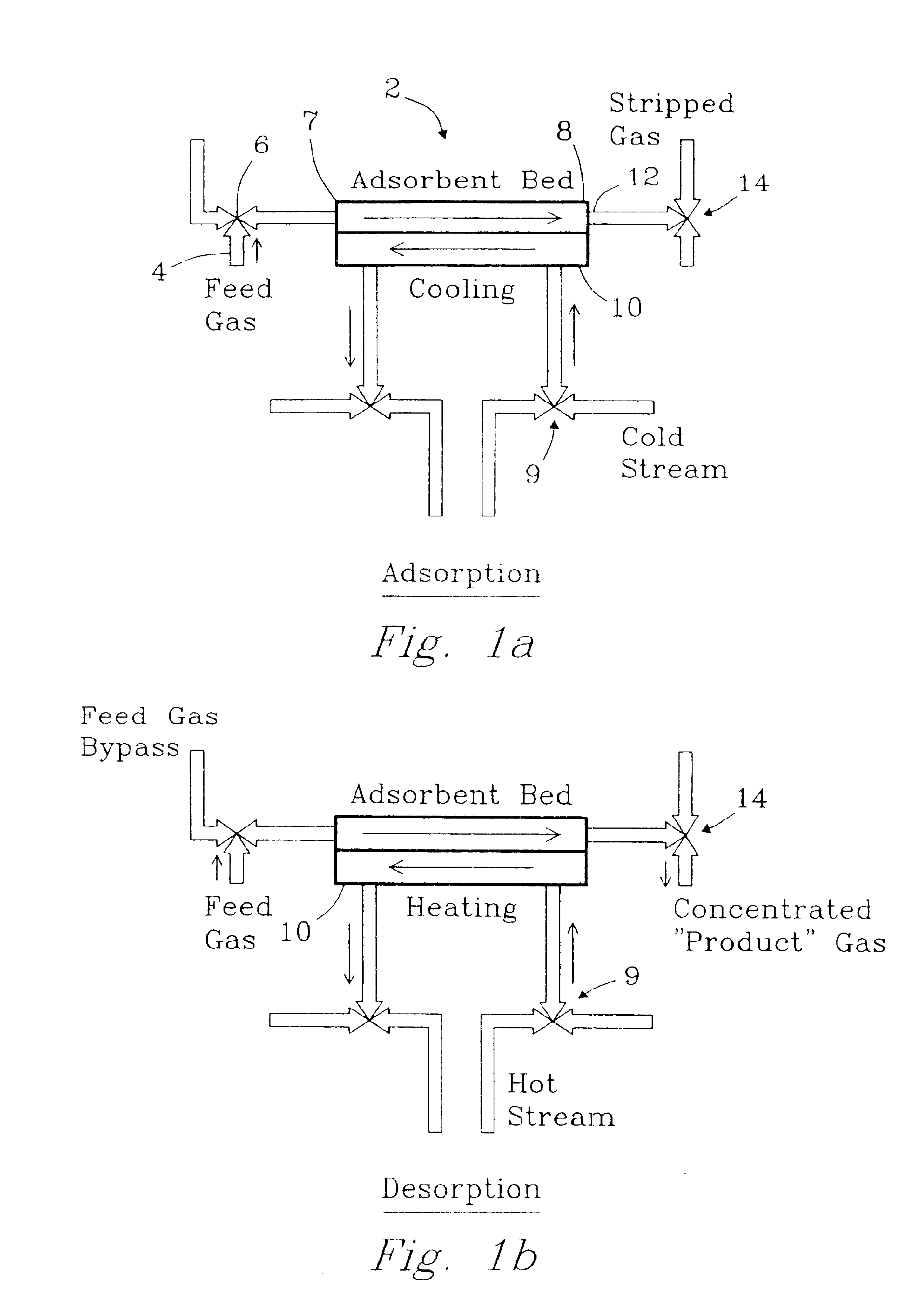

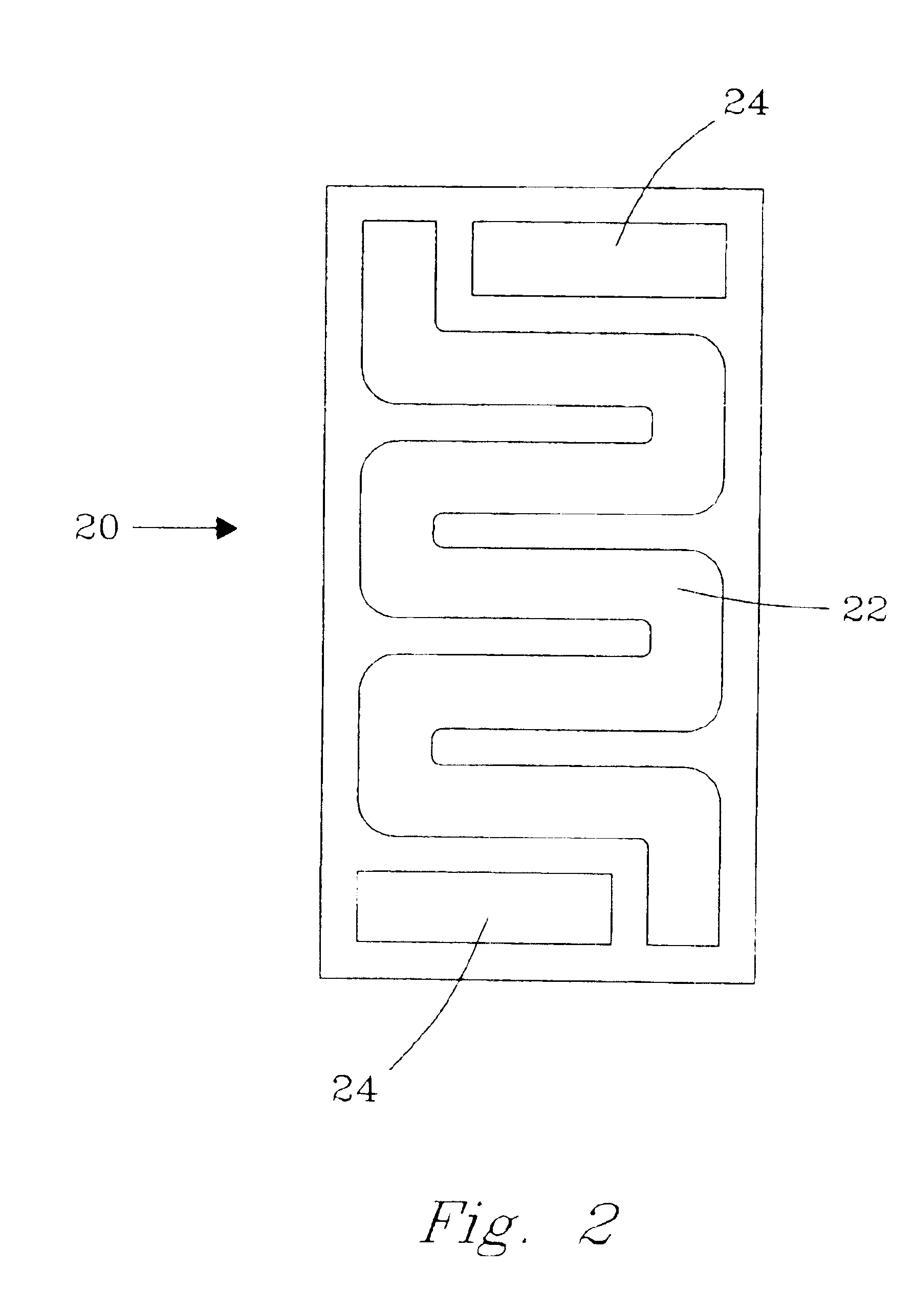

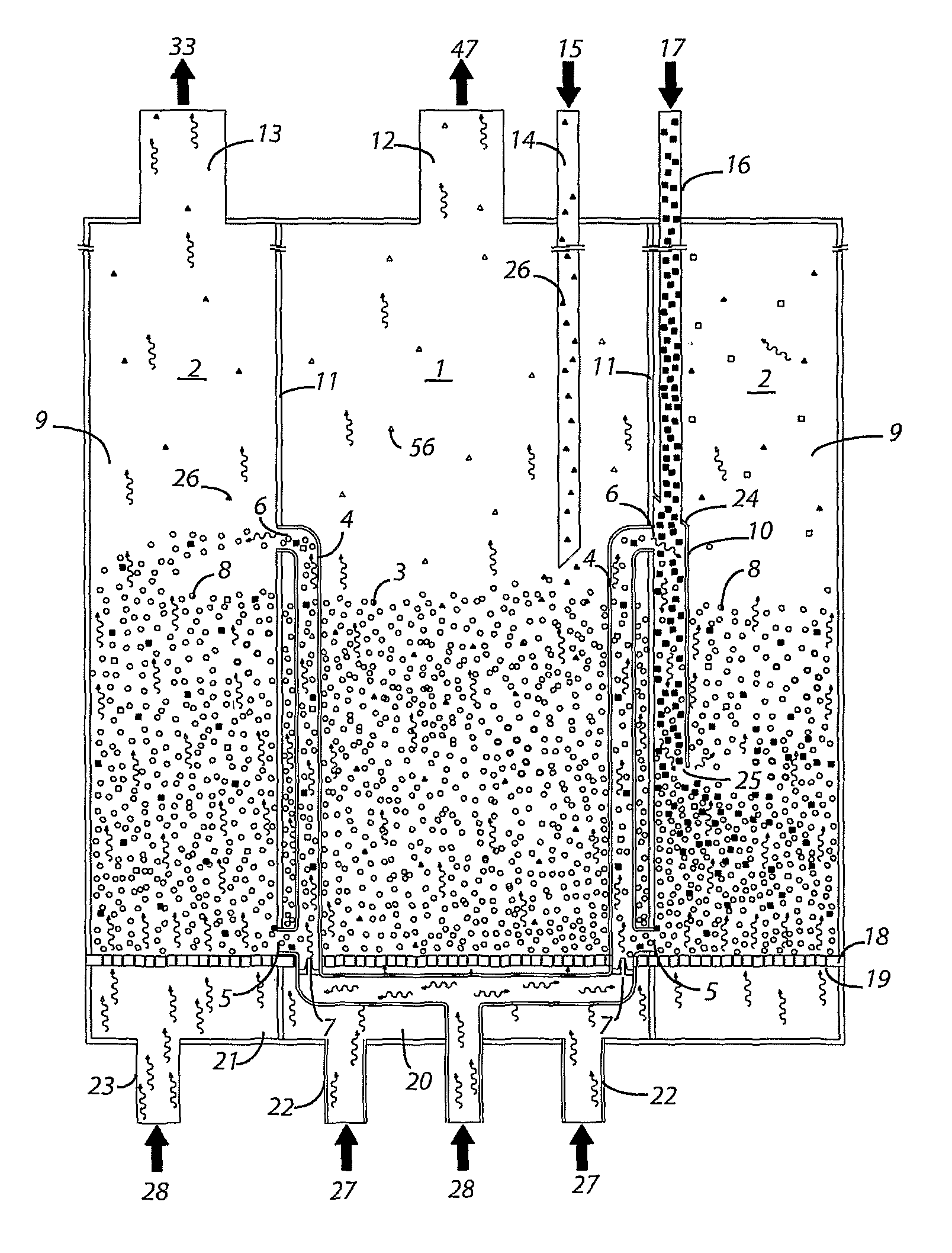

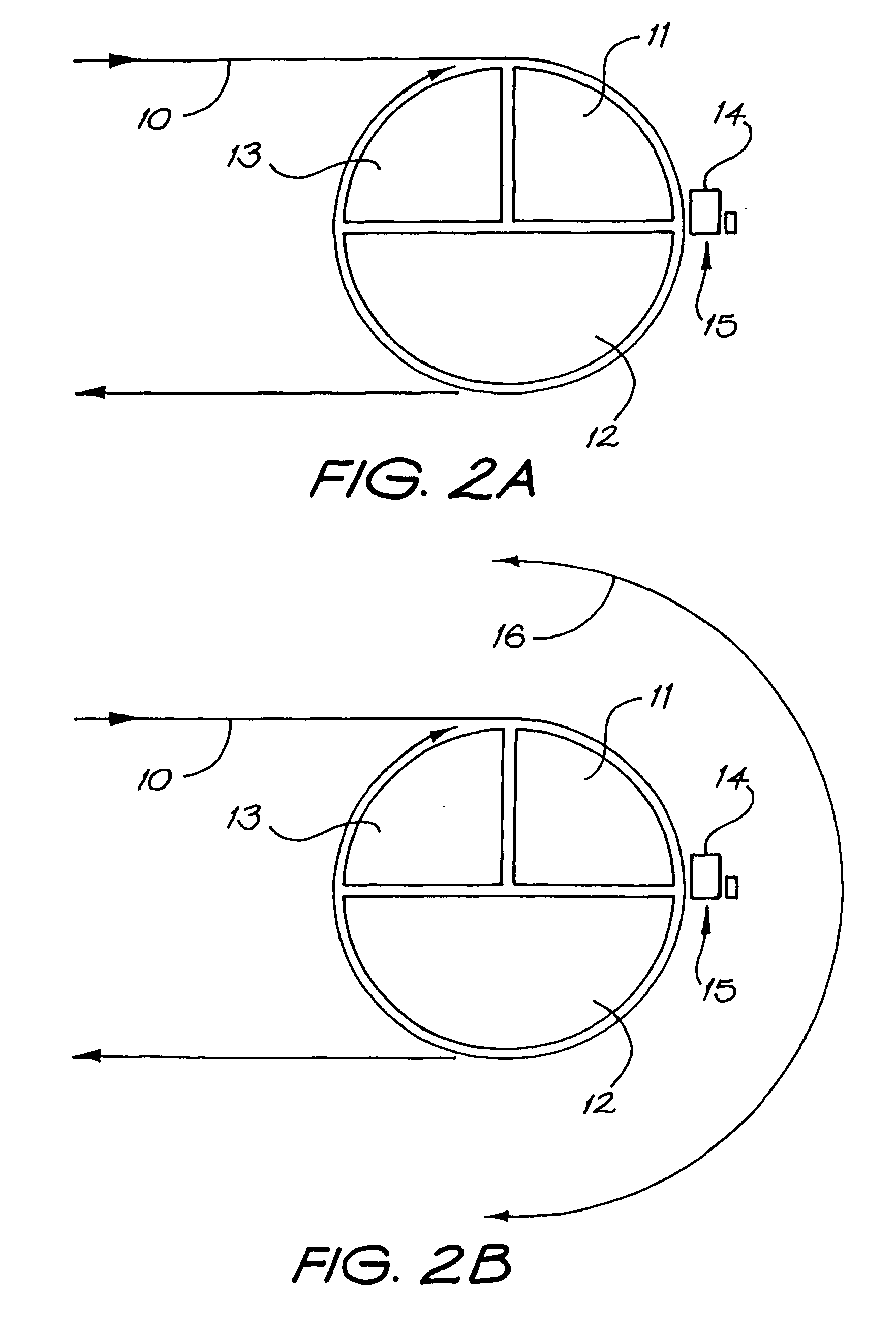

Apparatus for thermal swing adsorption and thermally-enhanced pressure swing adsorption

The present invention provides compact adsorption systems that are capable of rapid temperature swings and rapid cycling. Novel methods of thermal swing adsorption and thermally-enhanced pressure swing adsorption are also described. In some aspects of the invention, a gas is passed through the adsorbent thus allowing heat exchangers to be very close to all portions of the adsorbent and utilize less space. In another aspect, the adsorption media is selectively heated, thus reducing energy costs. Methods and systems for gas adsorption / desorption having improved energy efficiency with capability of short cycle times are also described. Advantages of the invention include the ability to use (typically) 30-100 times less adsorbent compared to conventional systems.

Owner:BATTELLE MEMORIAL INST

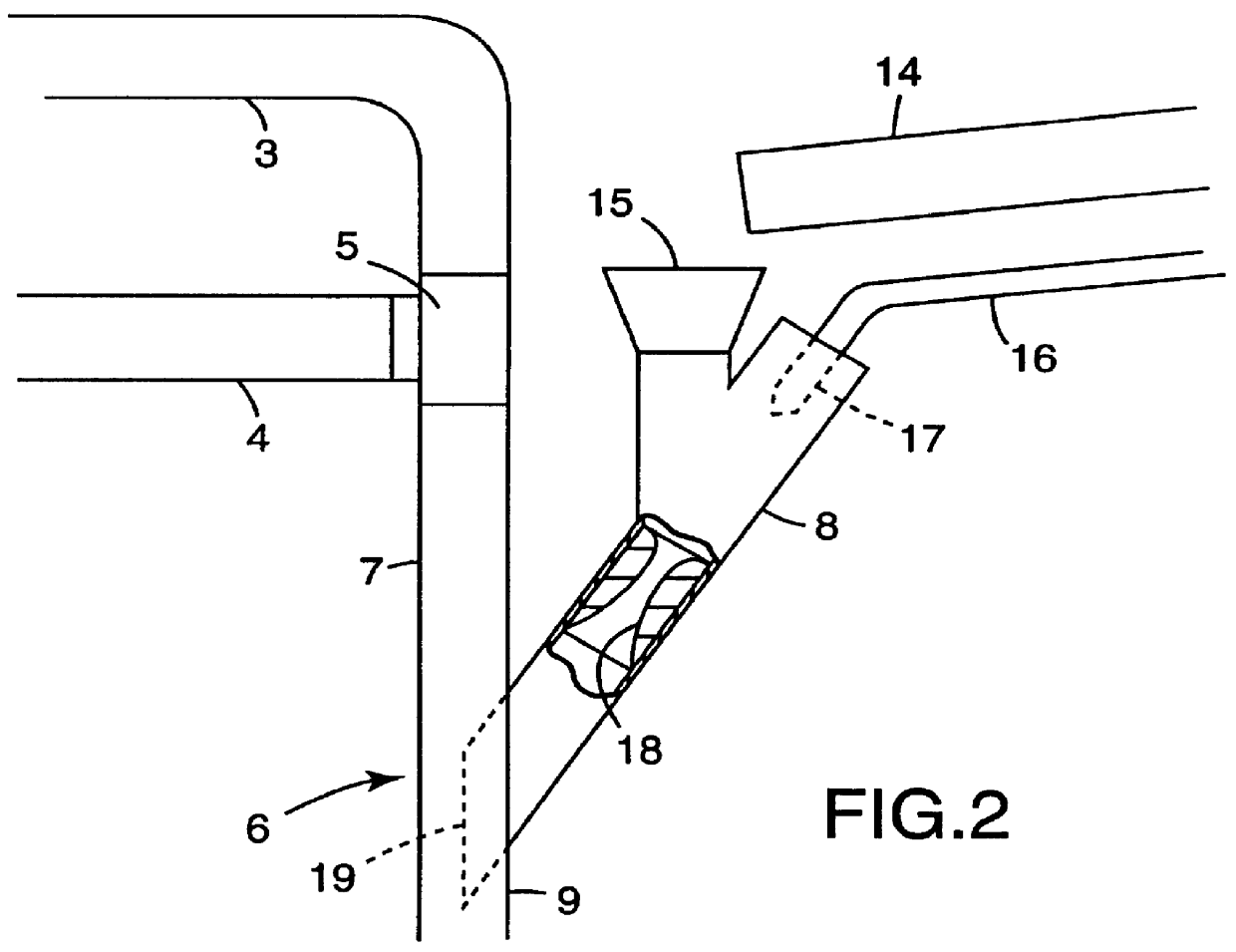

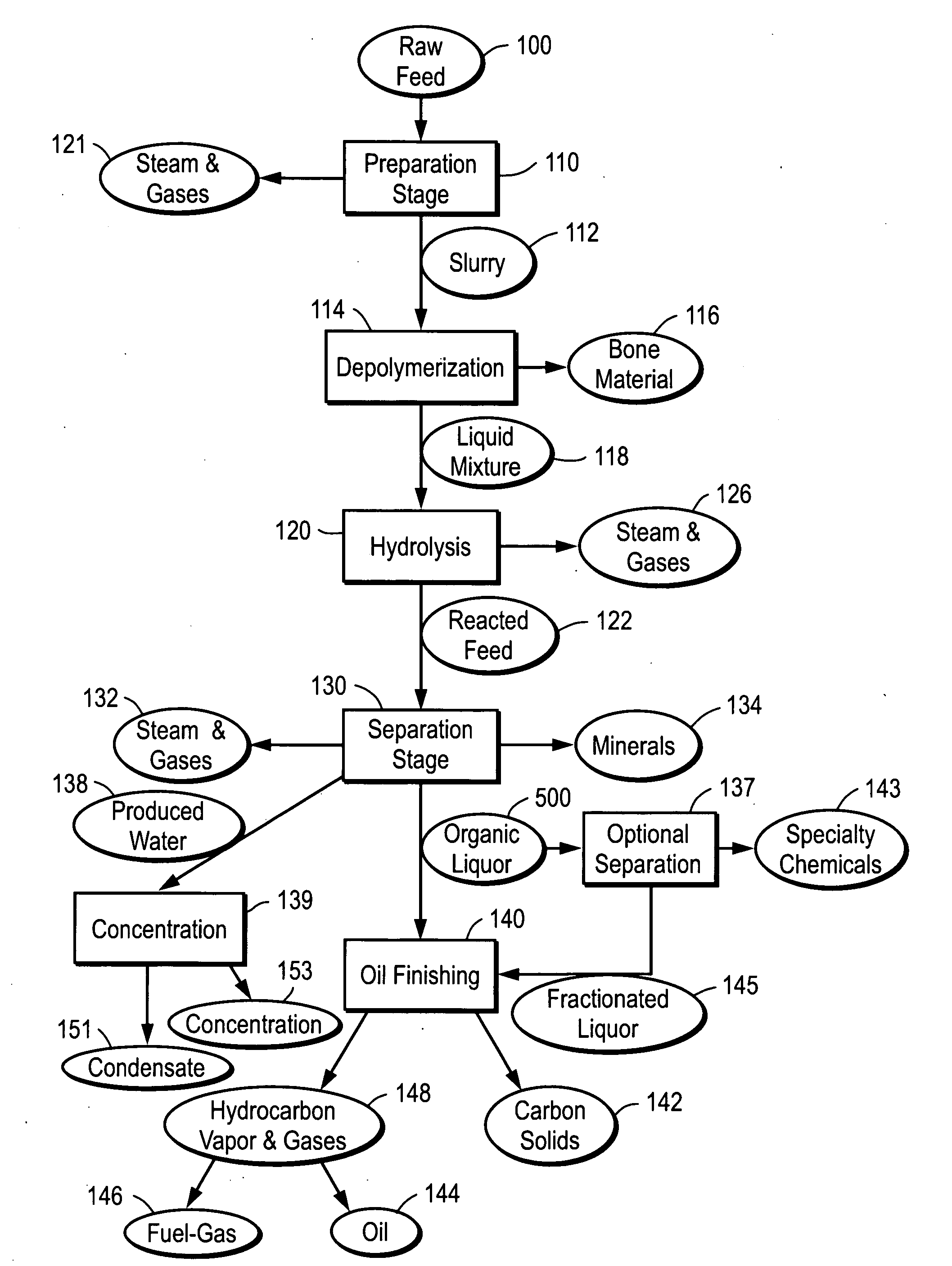

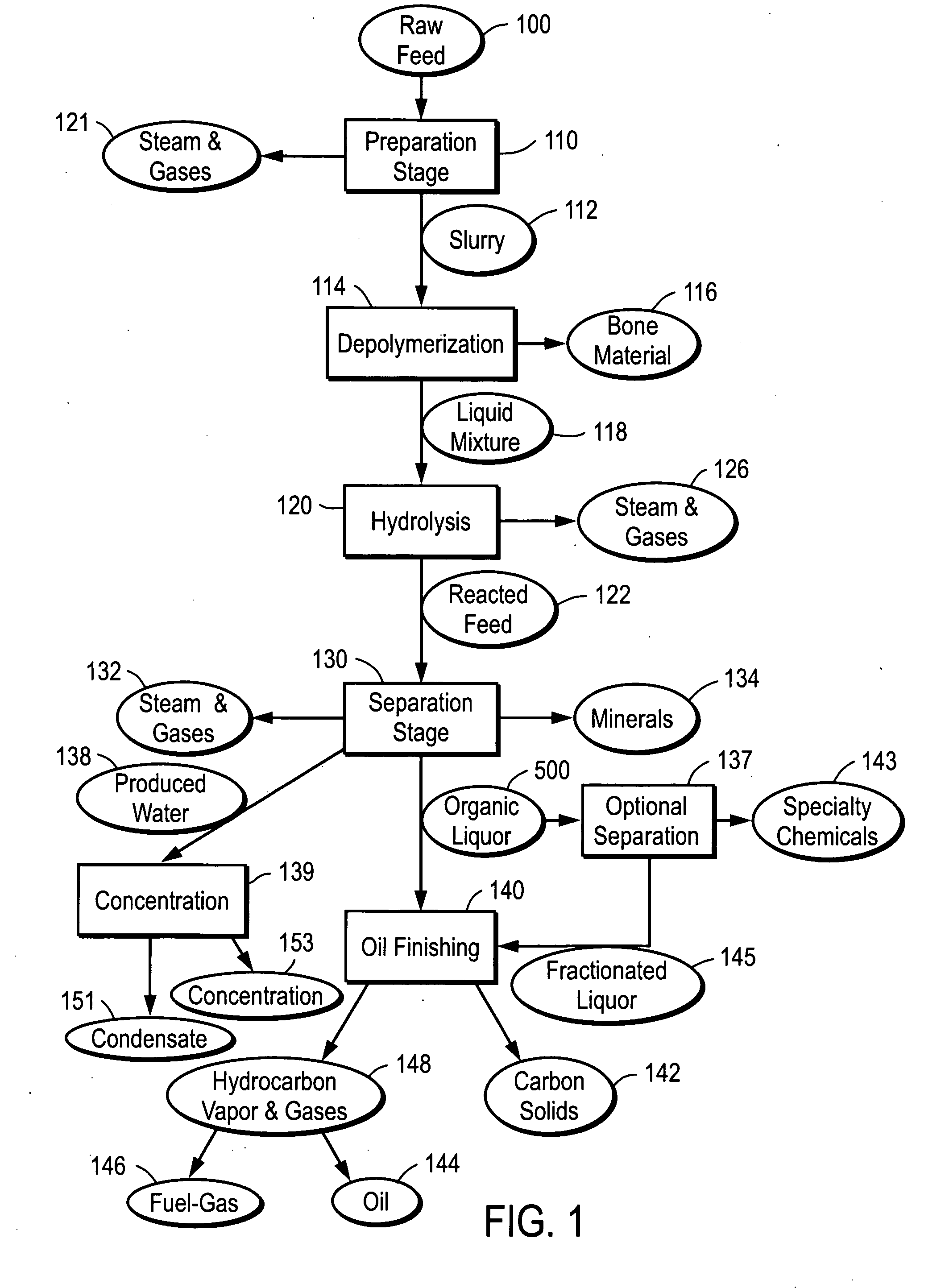

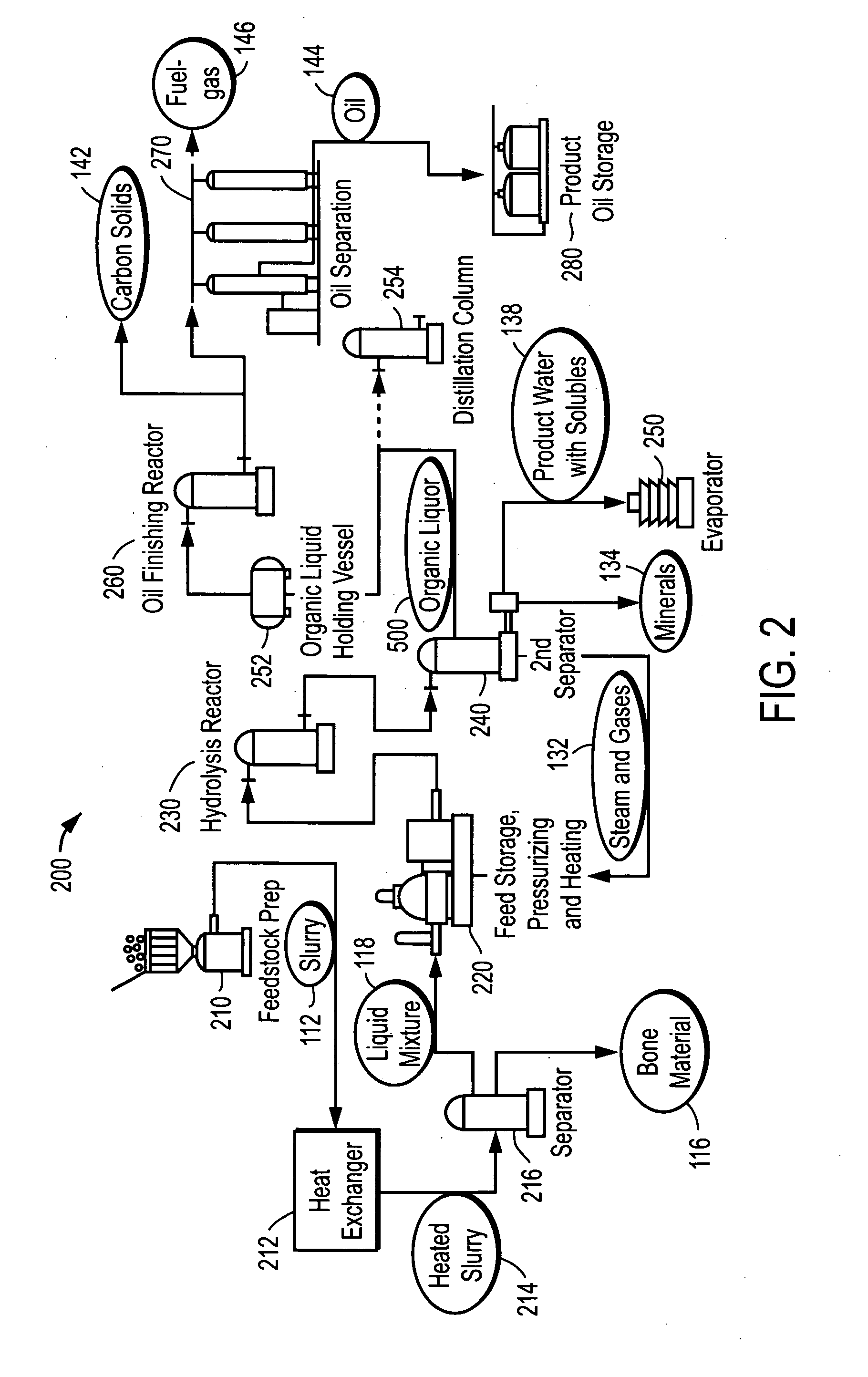

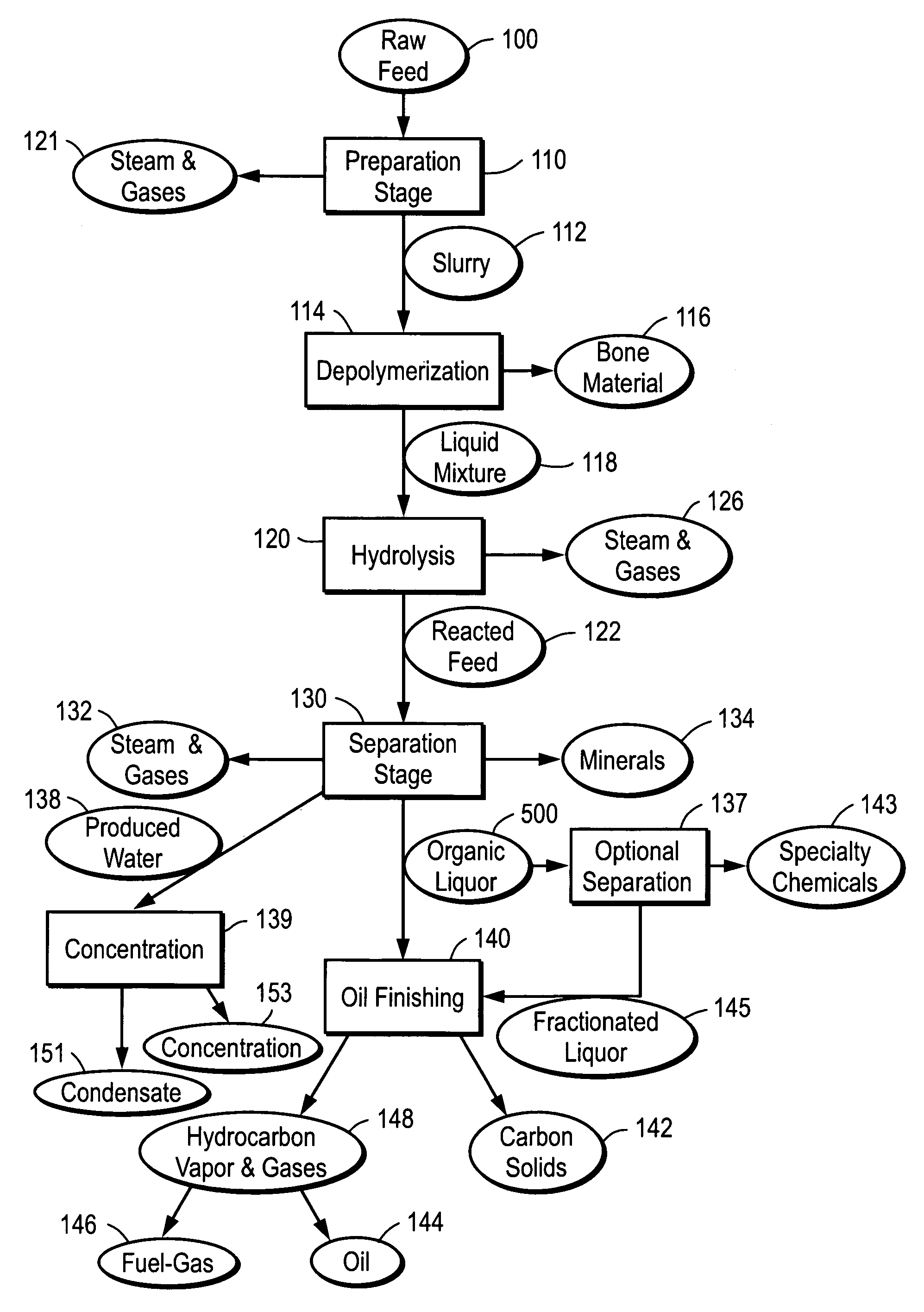

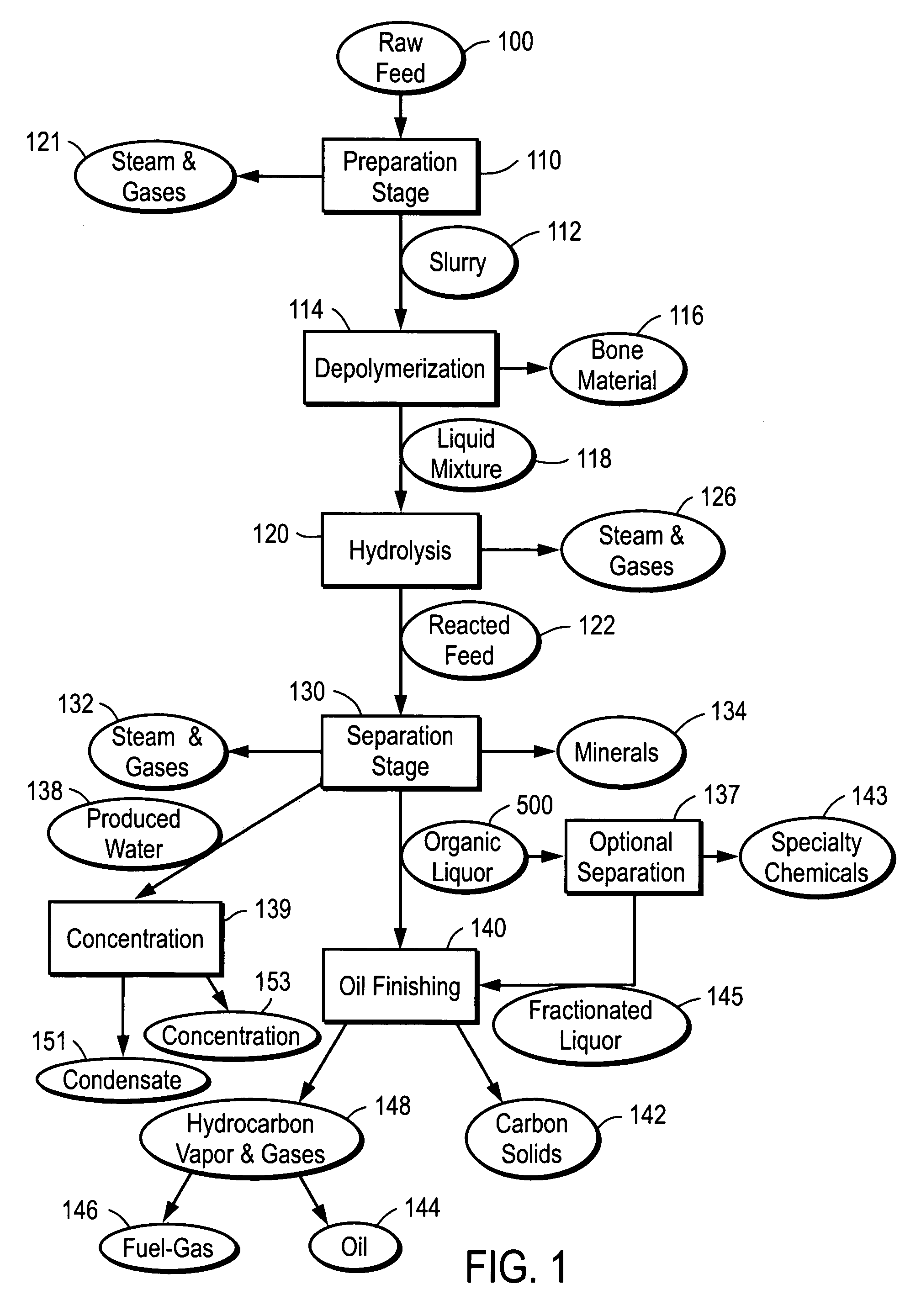

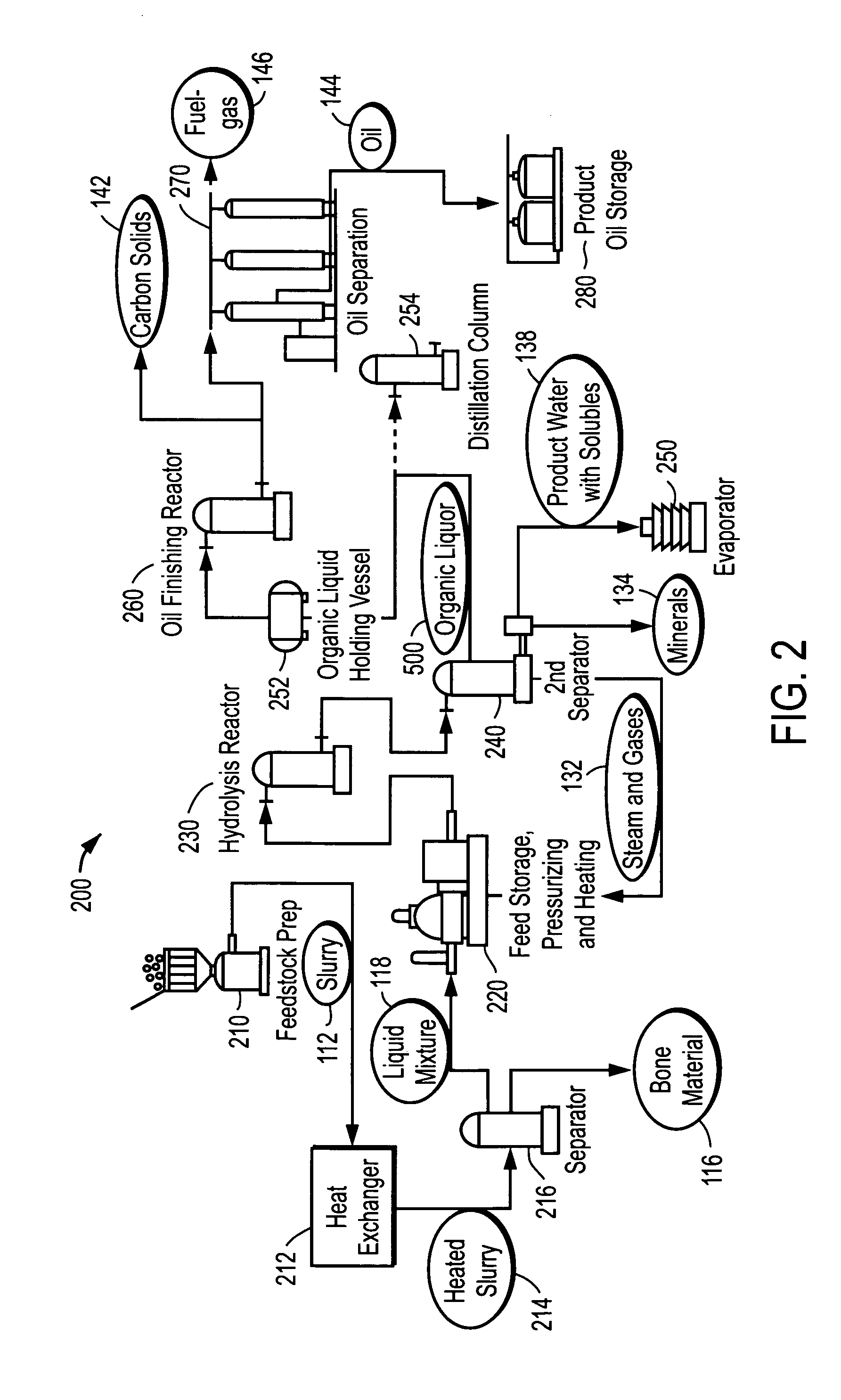

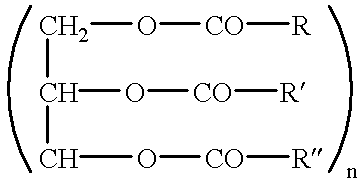

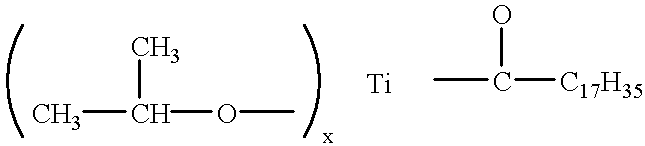

Depolymerization process of conversion of organic and non-organic waste materials into useful products

ActiveUS20070098625A1Improve energy efficiencyAcceptable costWaste based fuelLiquid hydrocarbon mixture productionDepolymerizationCost effectiveness

The present invention relates to the conversion of waste and low-value materials into useful products in reliable purities in a cost-effective and energy-efficient manner. More specifially, the invention provides processes that can handle mixed streams of various feedstocks, e.g. shredder residue, offal, animal manures, municipal sewage sludge, tires, and plastics, that otherwise have little commercial value, to useful products including gas, oil, specialty chemicals, and carbon solids. The process subjects the feedstock to heat and pressure, separates out various components, then further applies heat and pressure to one or more of those components, according to processes based on thermal or catalytic cracking. The invention further comprises an apparatus for performing a multi-stage process of converting waste materials into useful materials, and at least one oil product that arises from the process. Useful products can also be obtained or derived from materials diverted at different points of the process.

Owner:SYNPET TEKNOLOJI GELISTIRME

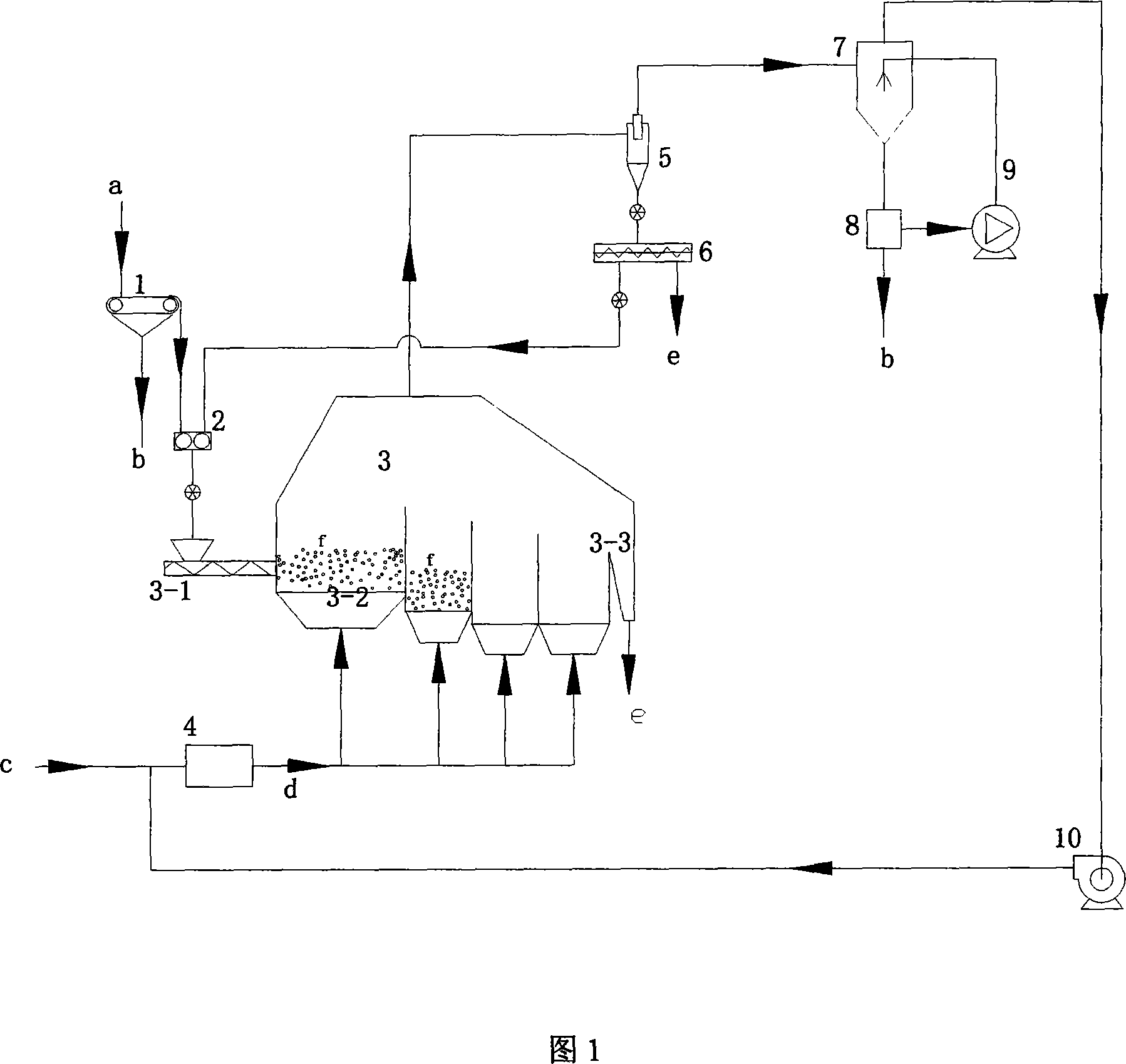

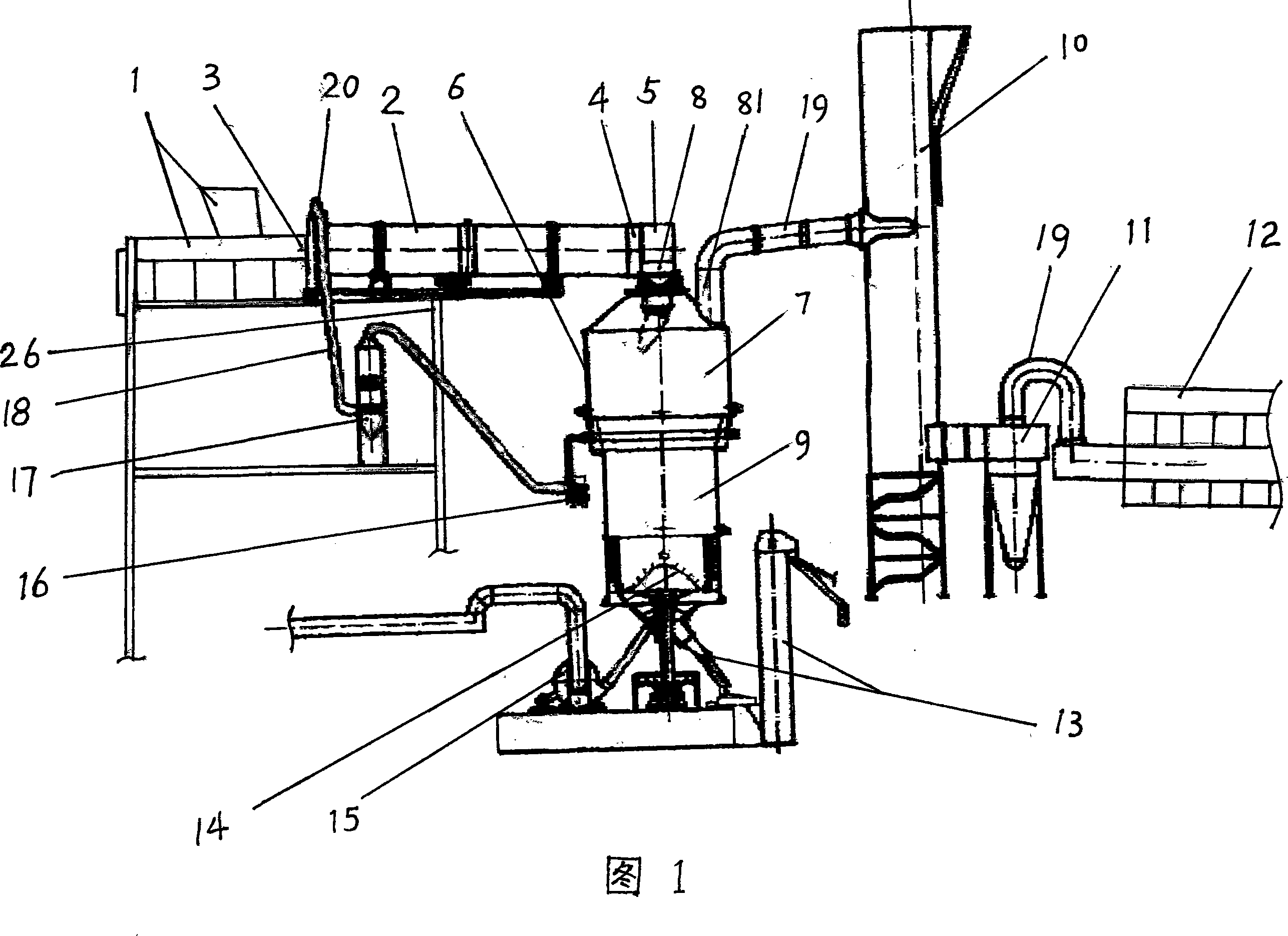

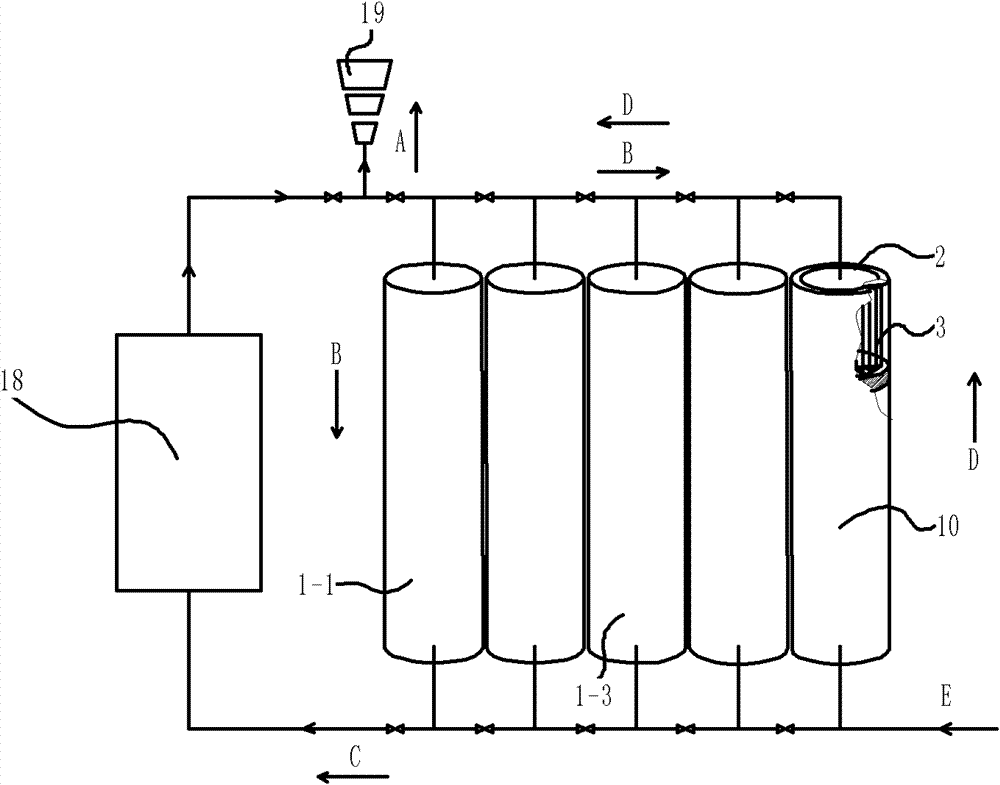

Enclosed multi-chamber fluidized bed drying method for sludge

InactiveCN101186422AUniform humidityReduce breakageSludge treatment by de-watering/drying/thickeningLiquid wasteFluidized bed drying

A closed multi-room fluidized bed sludge drying method is provided, which is a sludge drying method having the advantages of simple equipment structure, convenient operation, strong sludge adaptability, high thermal efficiency, safety, continuity, stability, etc. After the mechanically dewatered sludge is mixed with the back-mixed sludge, the mixture is dried room by room in an inert particles multi-room fluidized bed dryer (3). The first room and the second room of the inert particles multi-room fluidized bed dryer (3) adopt inert particles (f) as heat storage medium. Gas from a cyclone separator (5) goes through a spray tower (7) and returns into an air heating unit (4) through a circulating fan (10). Part of dried sludge (e) at the lower part of the cyclone separator (5) enters the inert particles multi-room fluidized bed dryer (3) through the back-mixing in a mixer (2). Waste liquid from the bottom of the spray tower (7) enters a waste liquid circulating pool (8), with part of waste liquid circulating into the spray tower (7) and part into a sewage treatment system.

Owner:SOUTHEAST UNIV

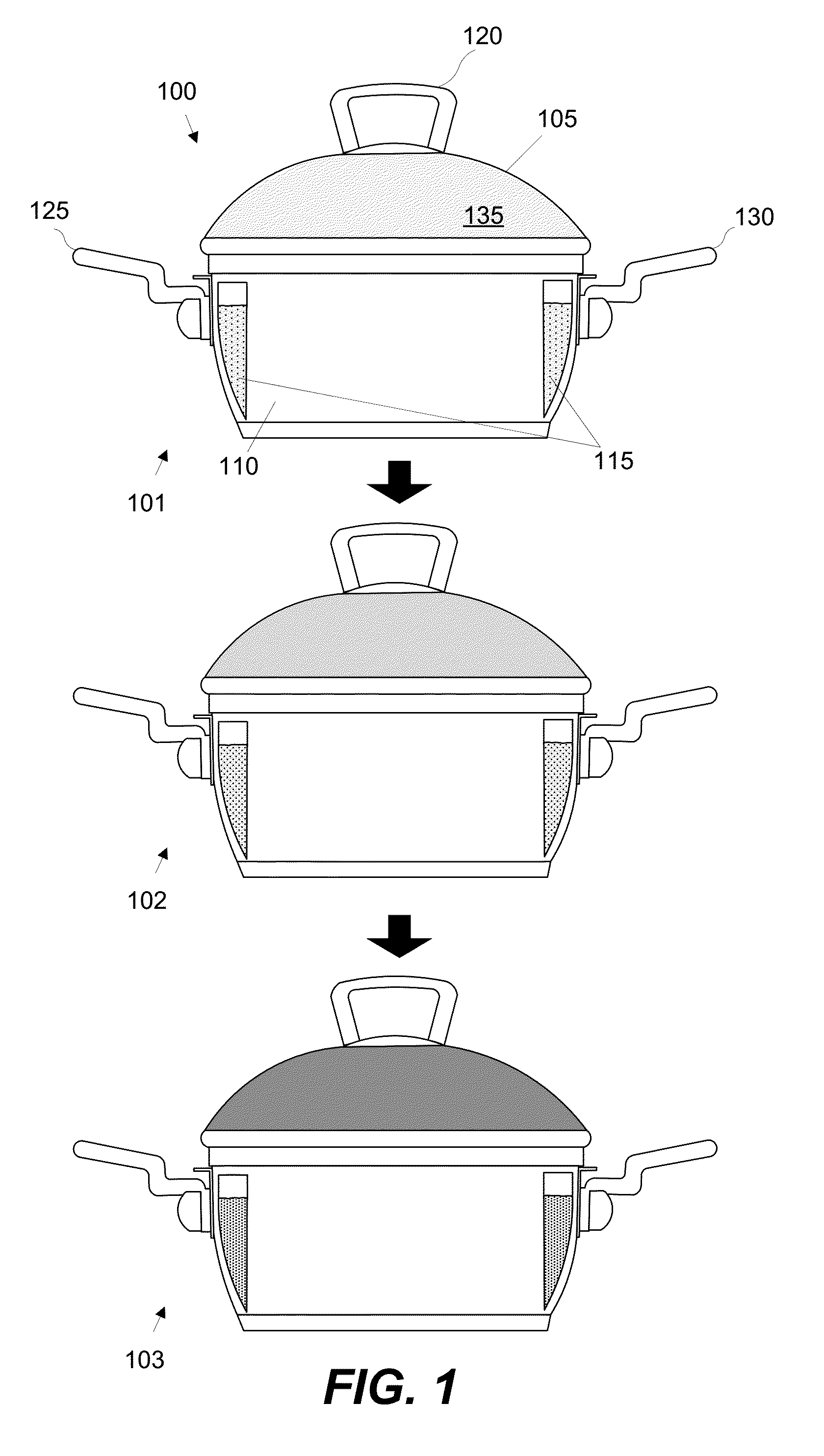

Low pressure thermodynamic cookware

InactiveUS20150313399A1Good for healthReduce stressCooking-vessel lids/coversSteam cooking vesselsEngineeringCooker

Some embodiments provide a cooking apparatus having a dual wall structure, including inner and outer shells. The inner shell is disposed adjacent the outer shell and the edges of the shells are hermetically sealed to form a cavity between the shells. In some embodiments, the cooking apparatus has a low-pressure creating lid, including a disk with an aperture, a pressure release valve installed on the aperture, and a rim that surround the disk.

Owner:PARK JONG PETER

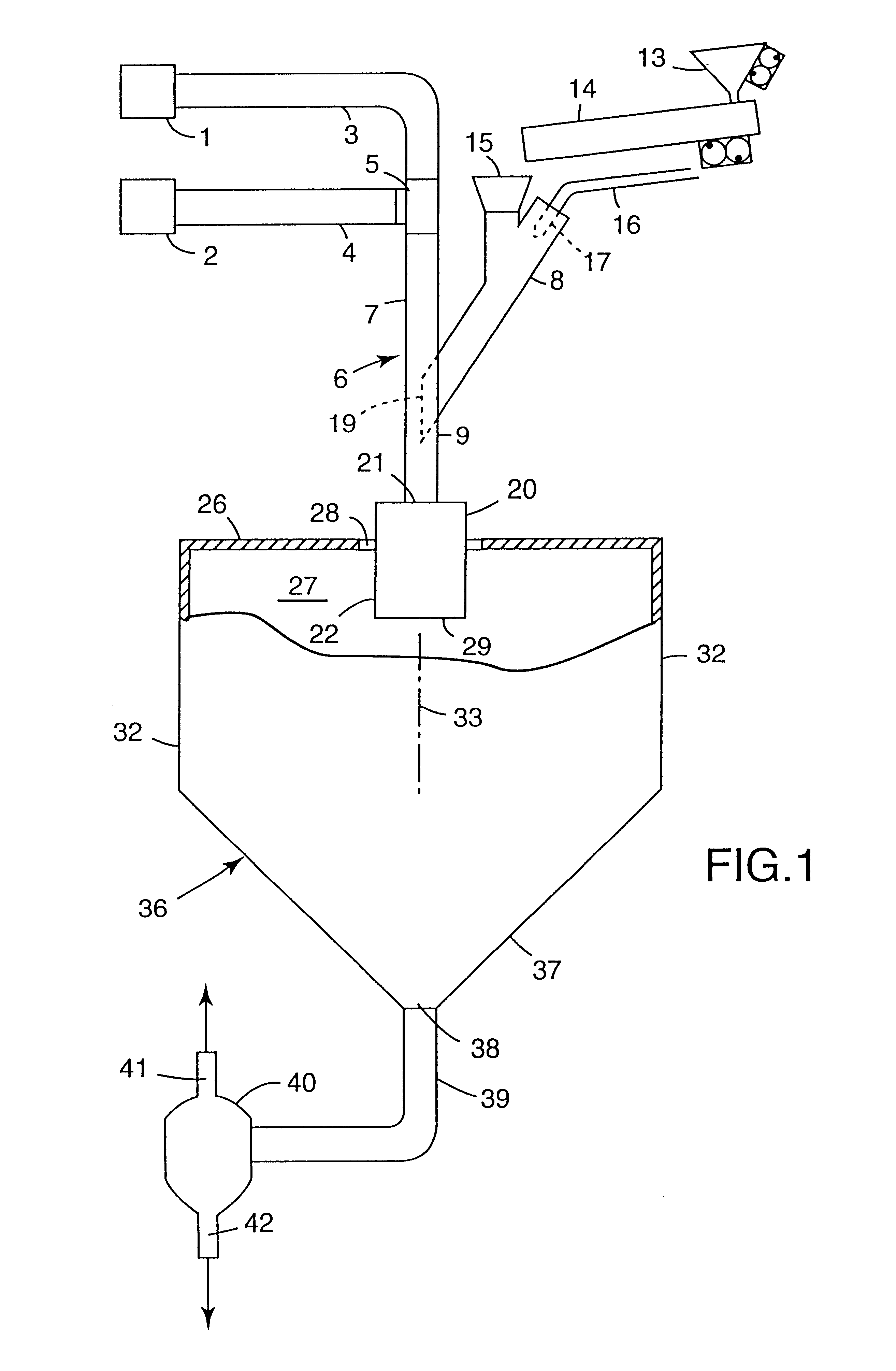

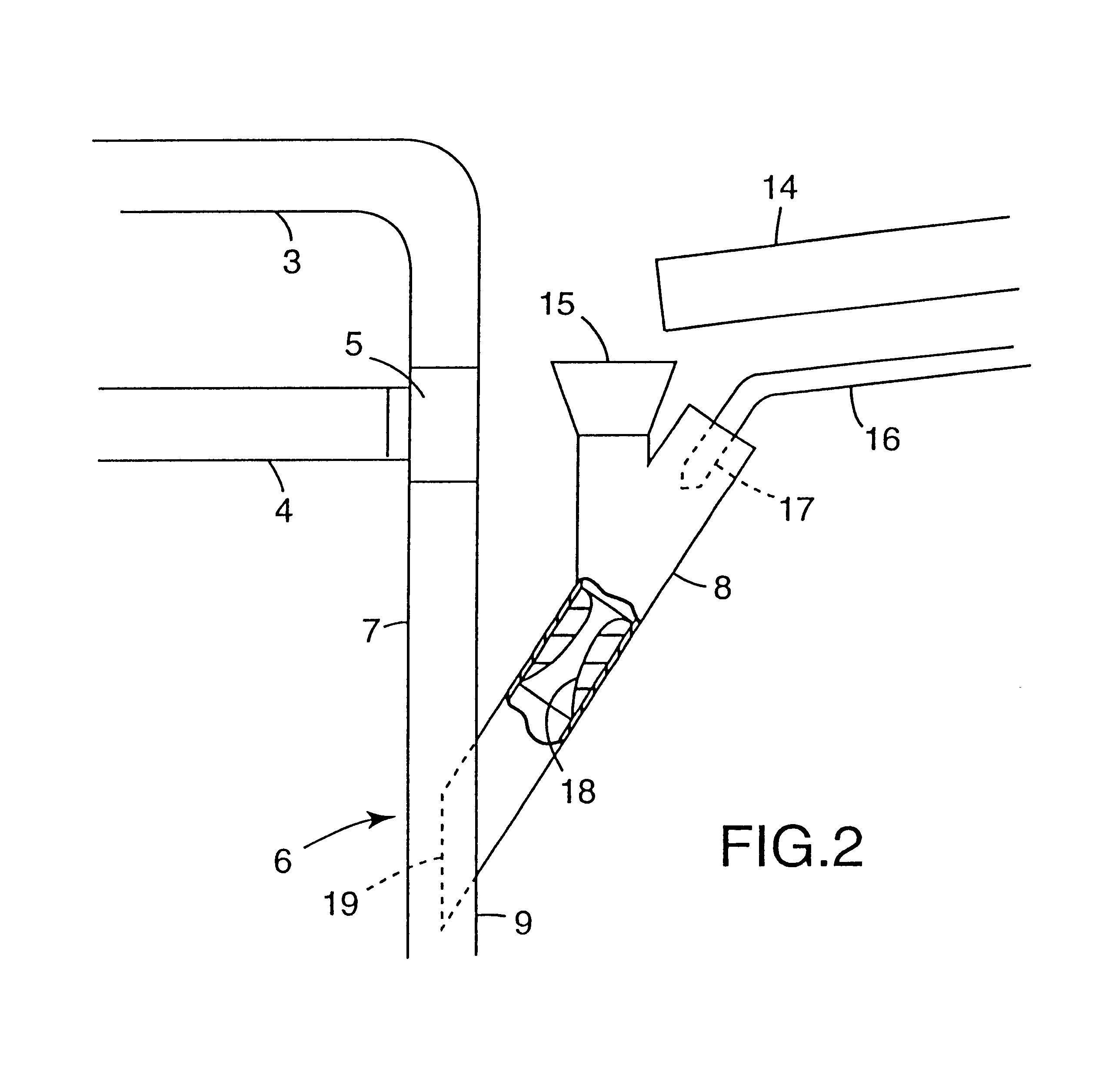

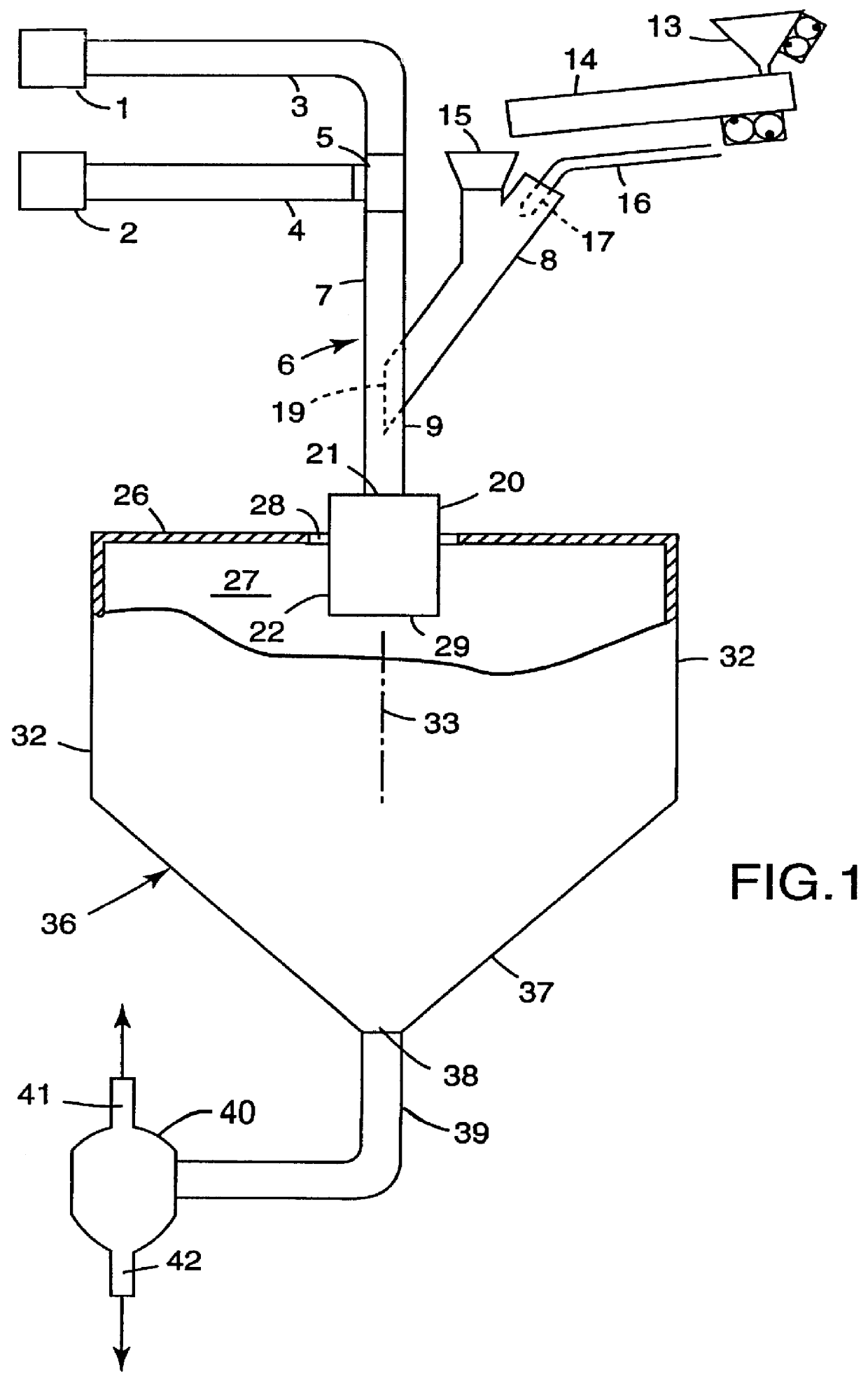

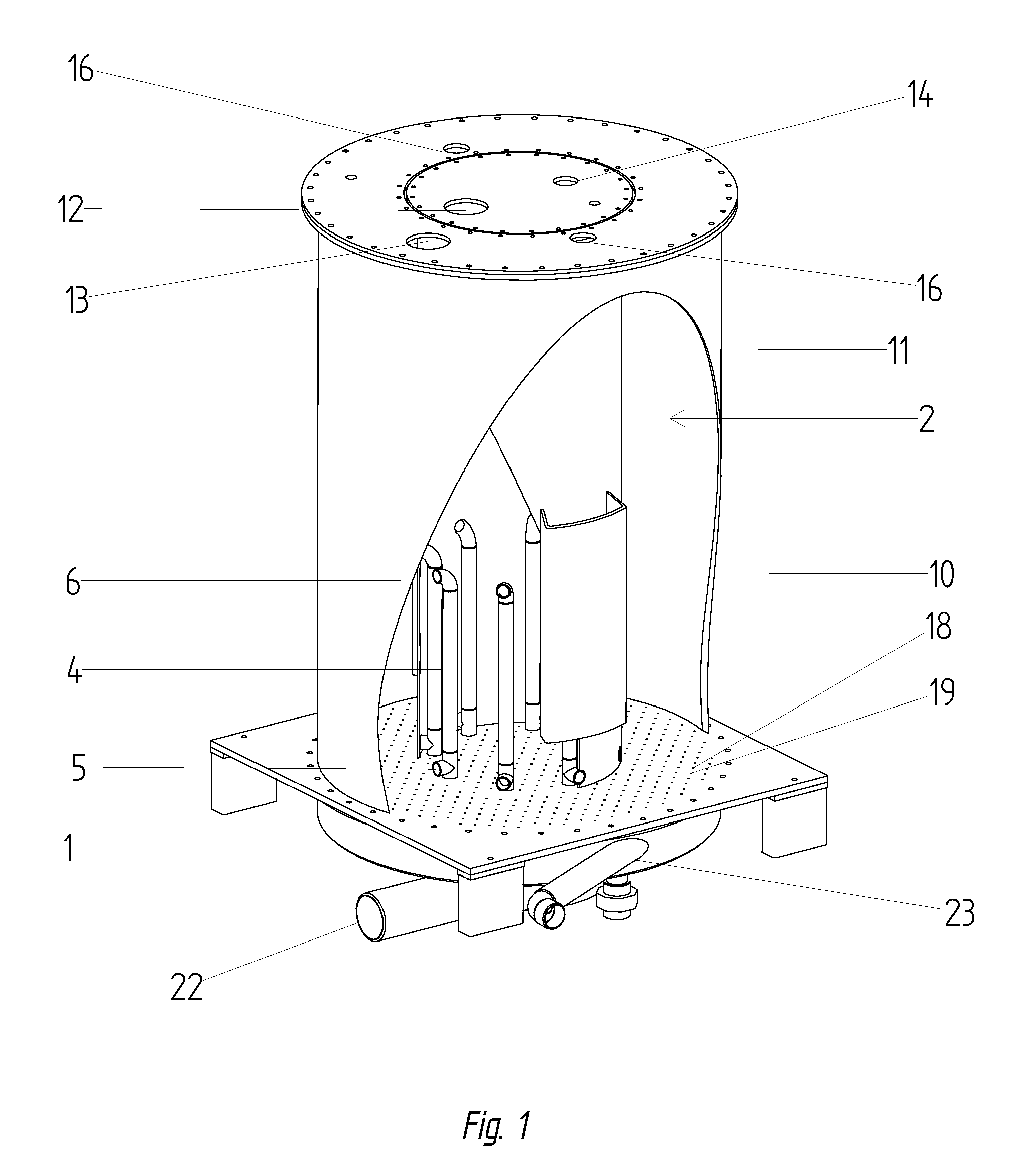

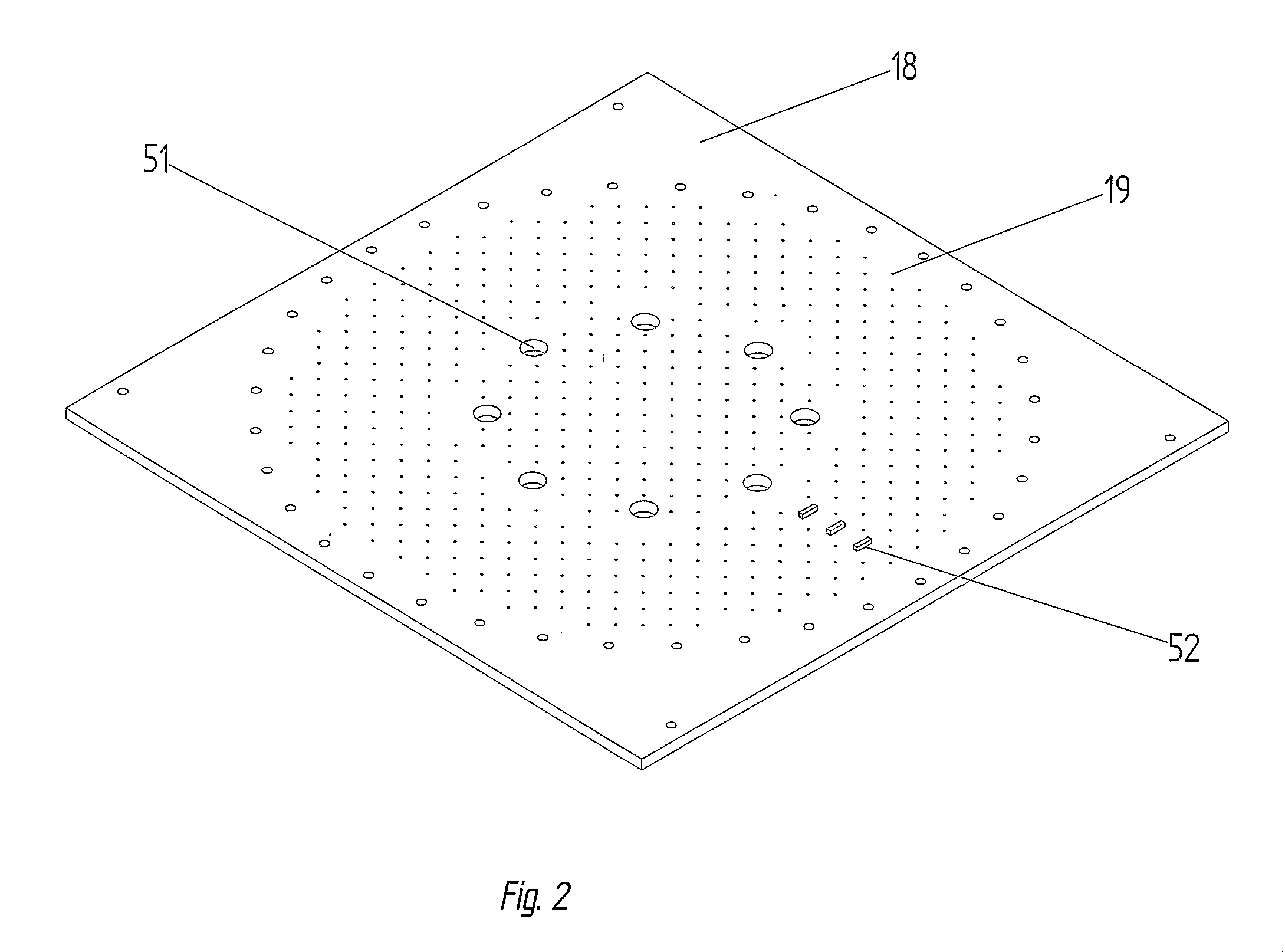

Apparatus and process for the pyrolysis of agricultural biomass

InactiveUS7943014B2Avoid cloggingPrevent escapeFluidized bed combustionCombustible gas coke oven heatingCombustion chamberFluidized bed

An integrated combustion chamber and fluidized bed pyrolysis reactor. In one embodiment, the combustion chamber is cylindrical and the pyrolysis reactor is provided annularly about the combustion chamber with an annular wall that provides a common surface for heat transfer. A lift tube in fluid communication with the pyrolysis reactor is provided within the combustion chamber for circulating biomass and an inert fluidizable media upwardly through the lift tube; this advantageously increases heat transfer and leads to more rapid pyrolysis. The media and biomass exit the lift tube into either a freeboard area of the pyrolysis reactor or into a low density region of the fluidized bed. A condensable gaseous product is produced during pyrolysis that has economic value. The apparatus and process are especially well suited to the pyrolysis of low density agricultural biomass. The apparatus is compact and particularly well suited to mobile operation.

Owner:AGRI THERM

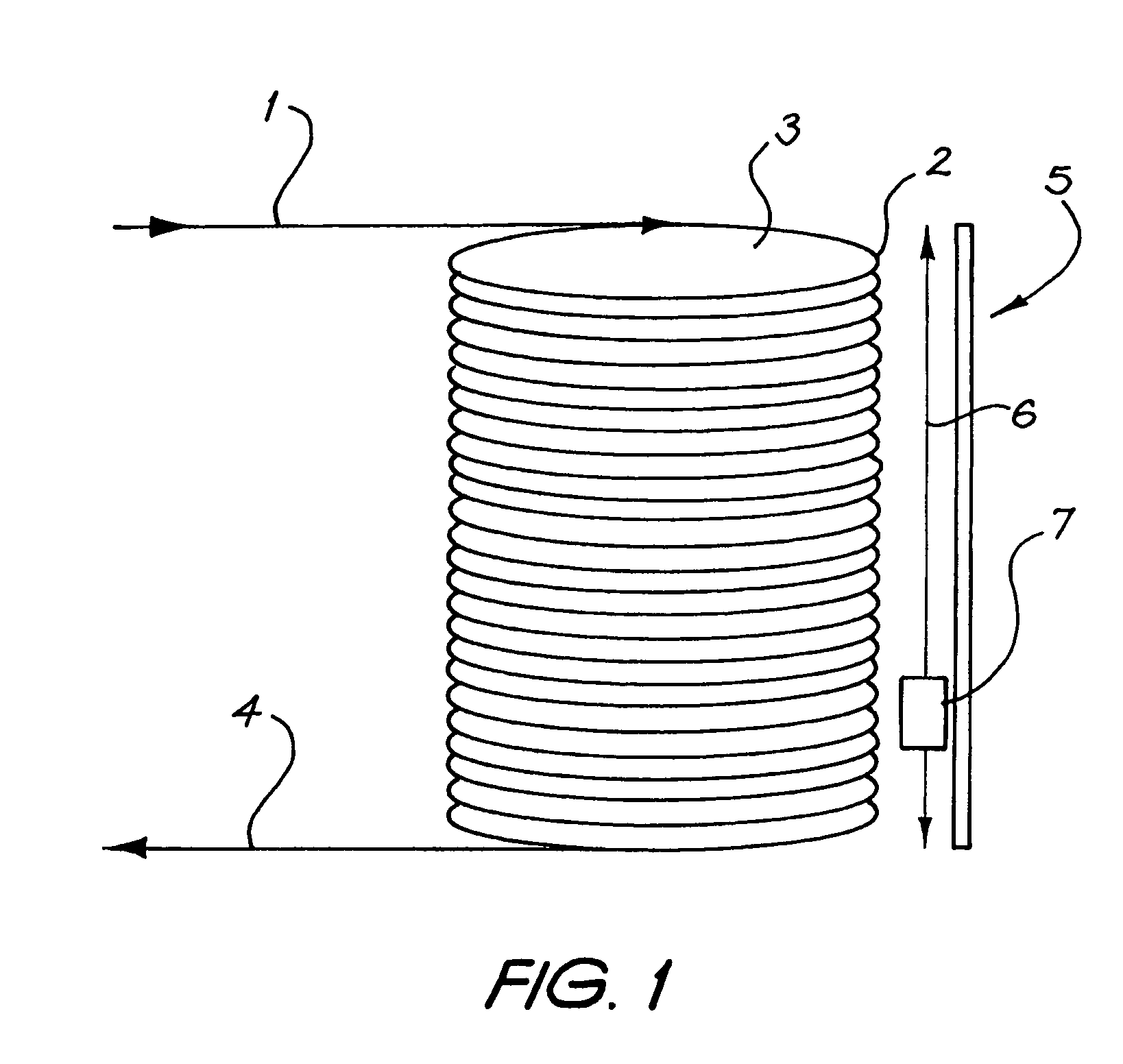

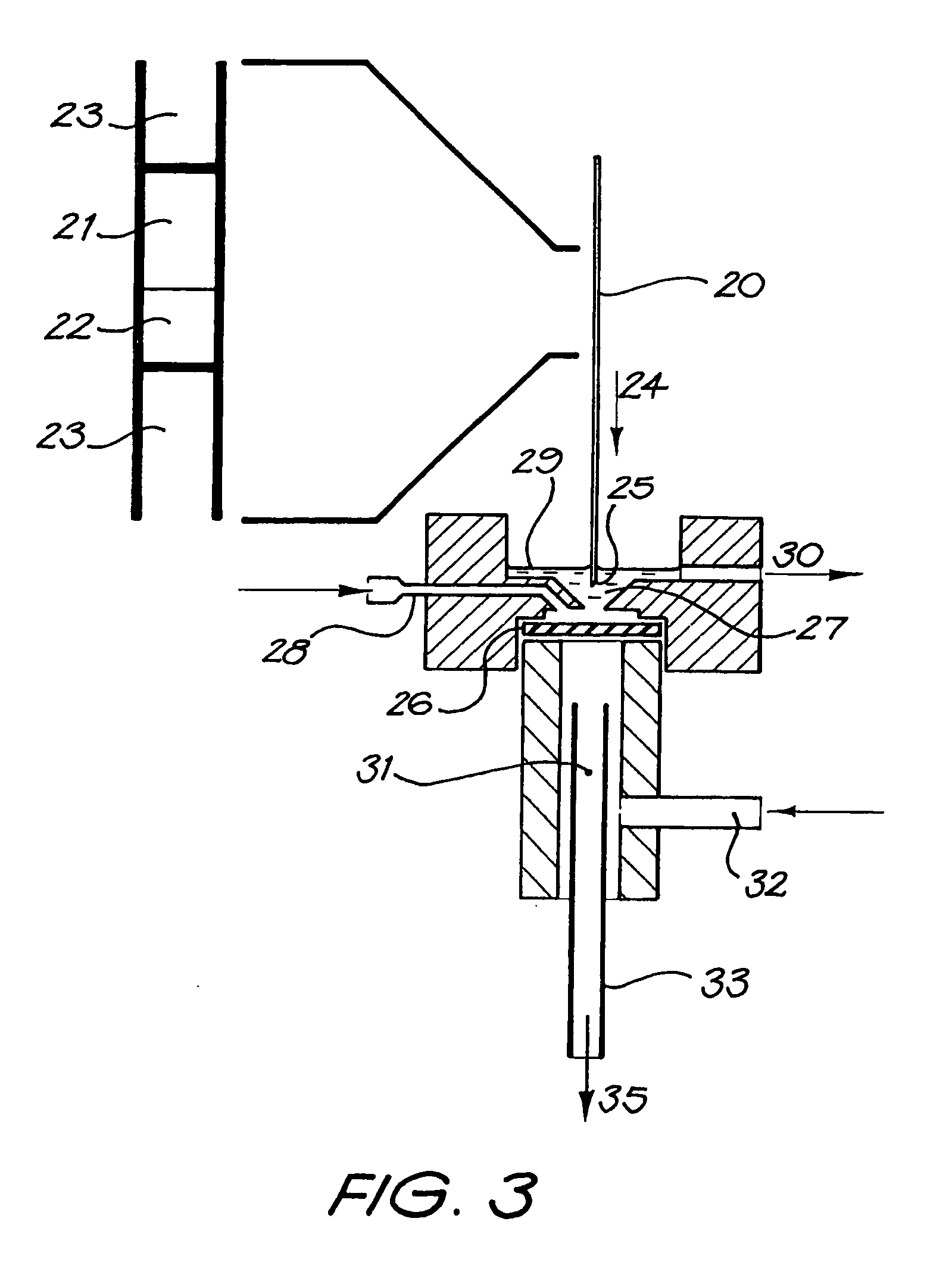

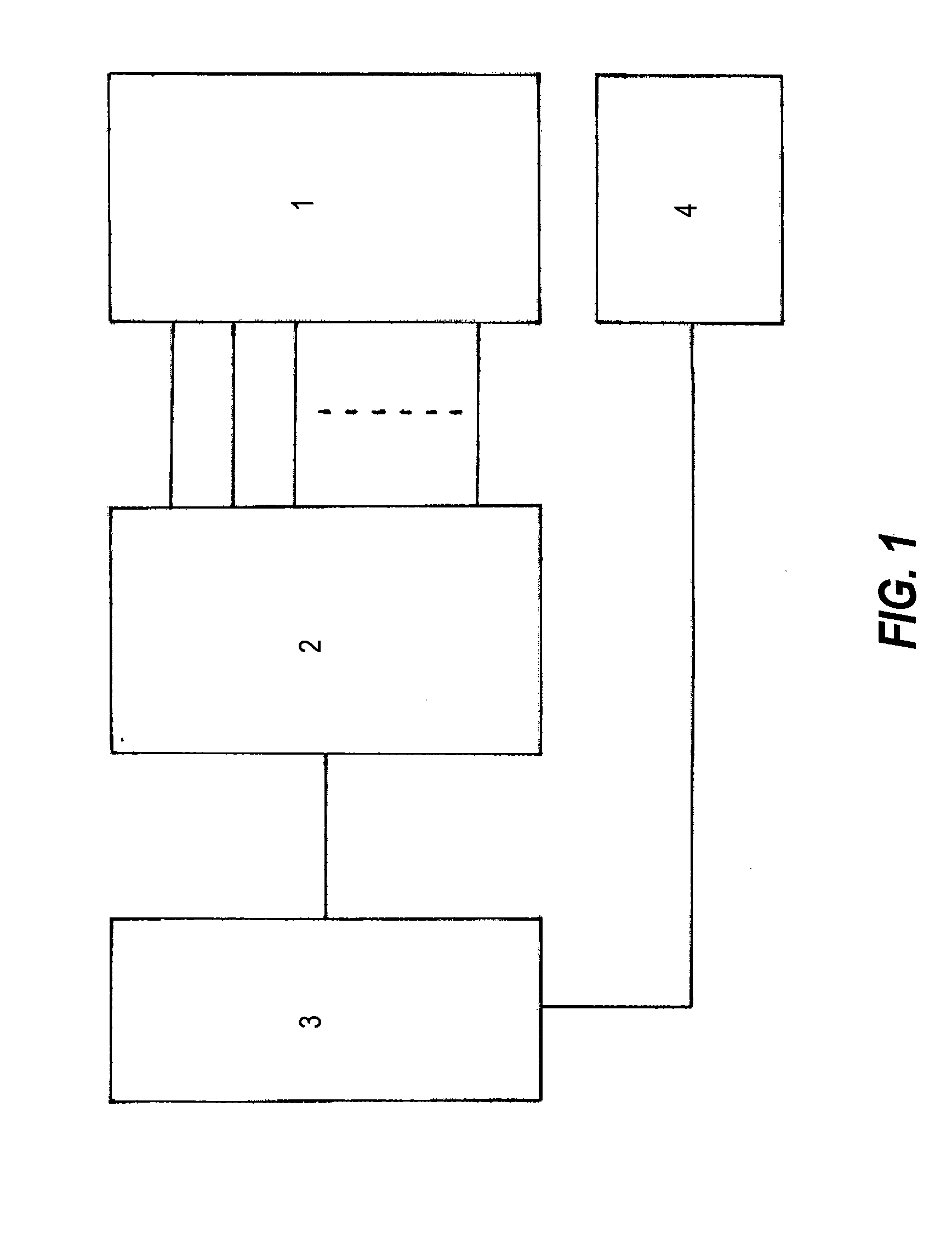

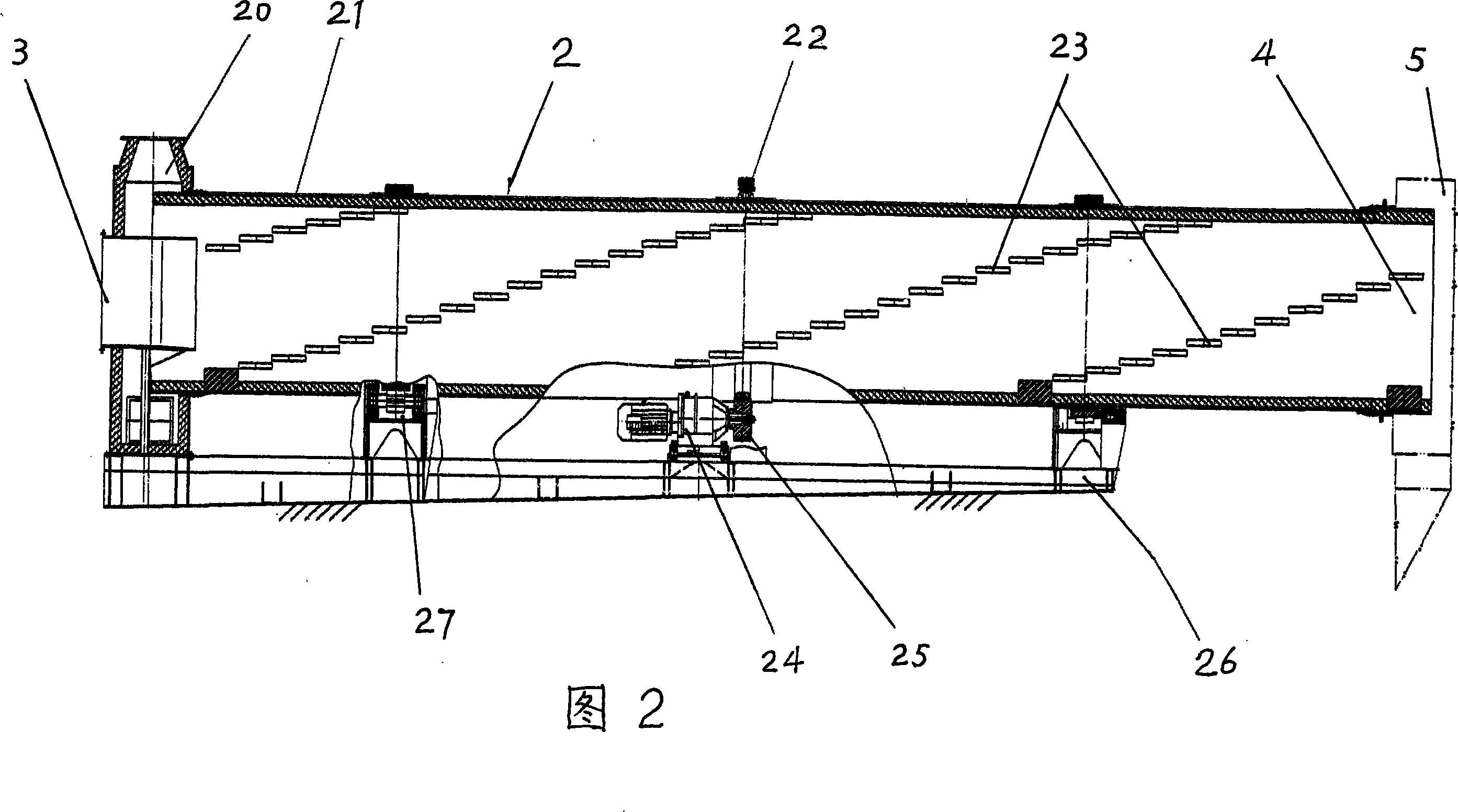

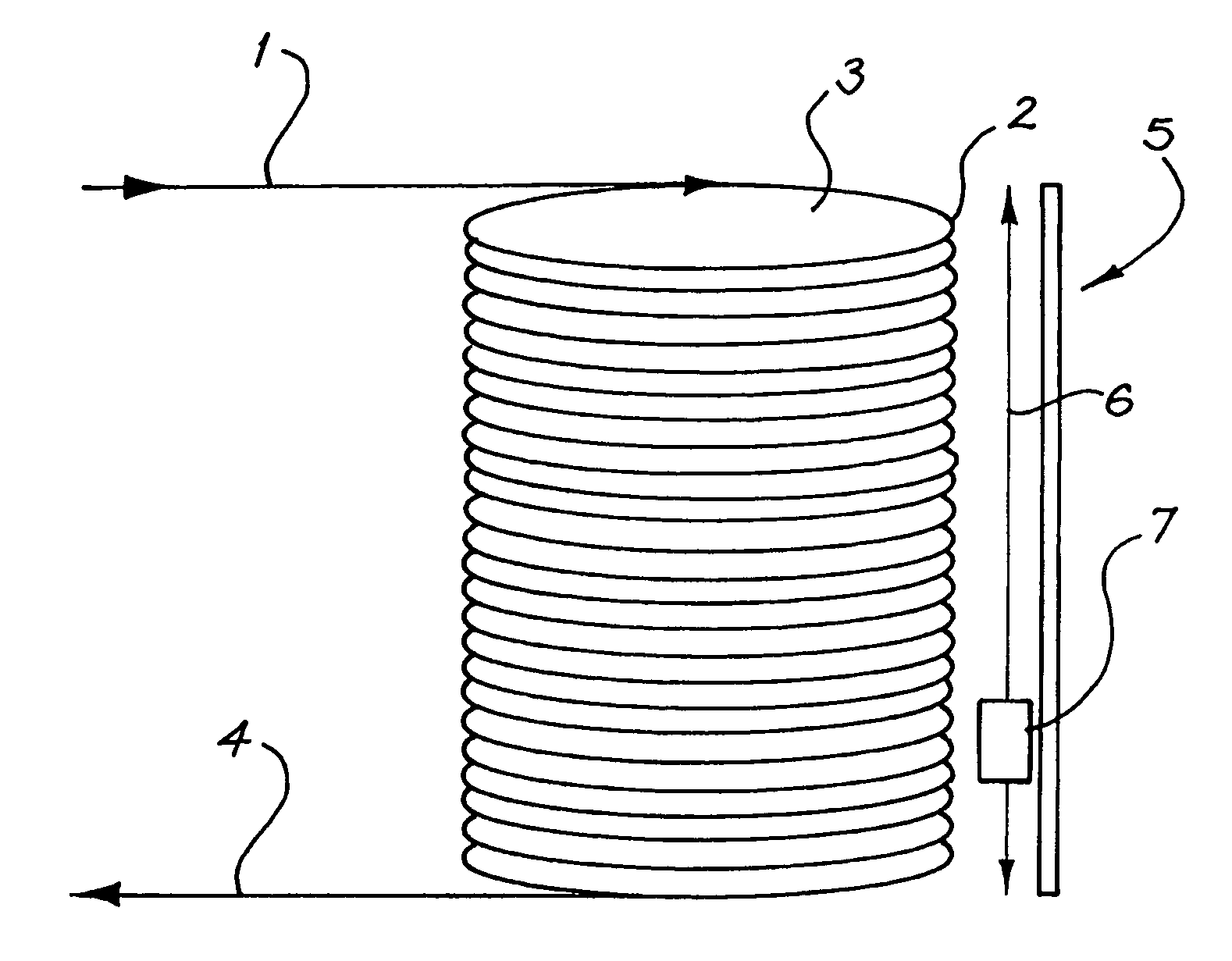

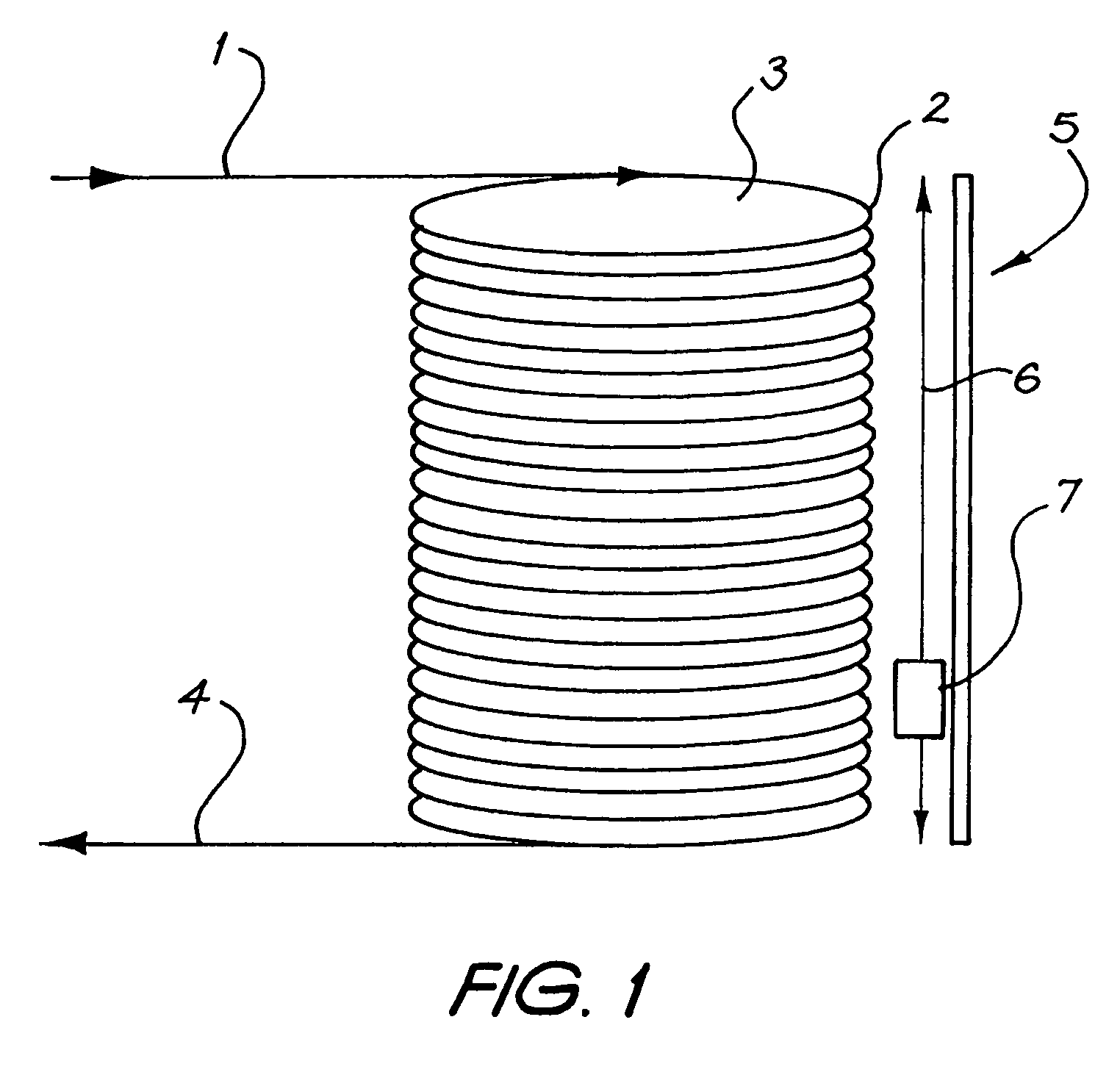

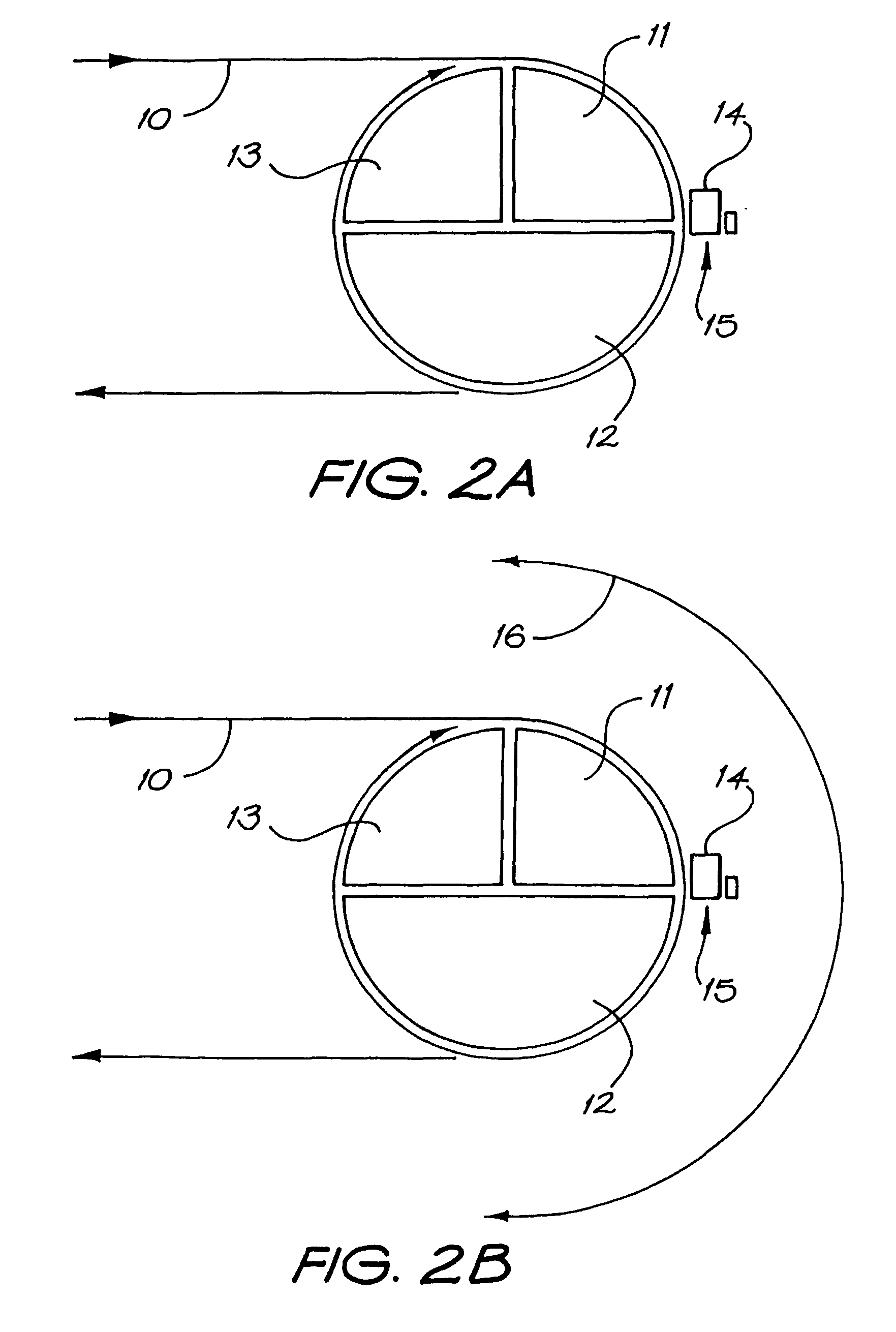

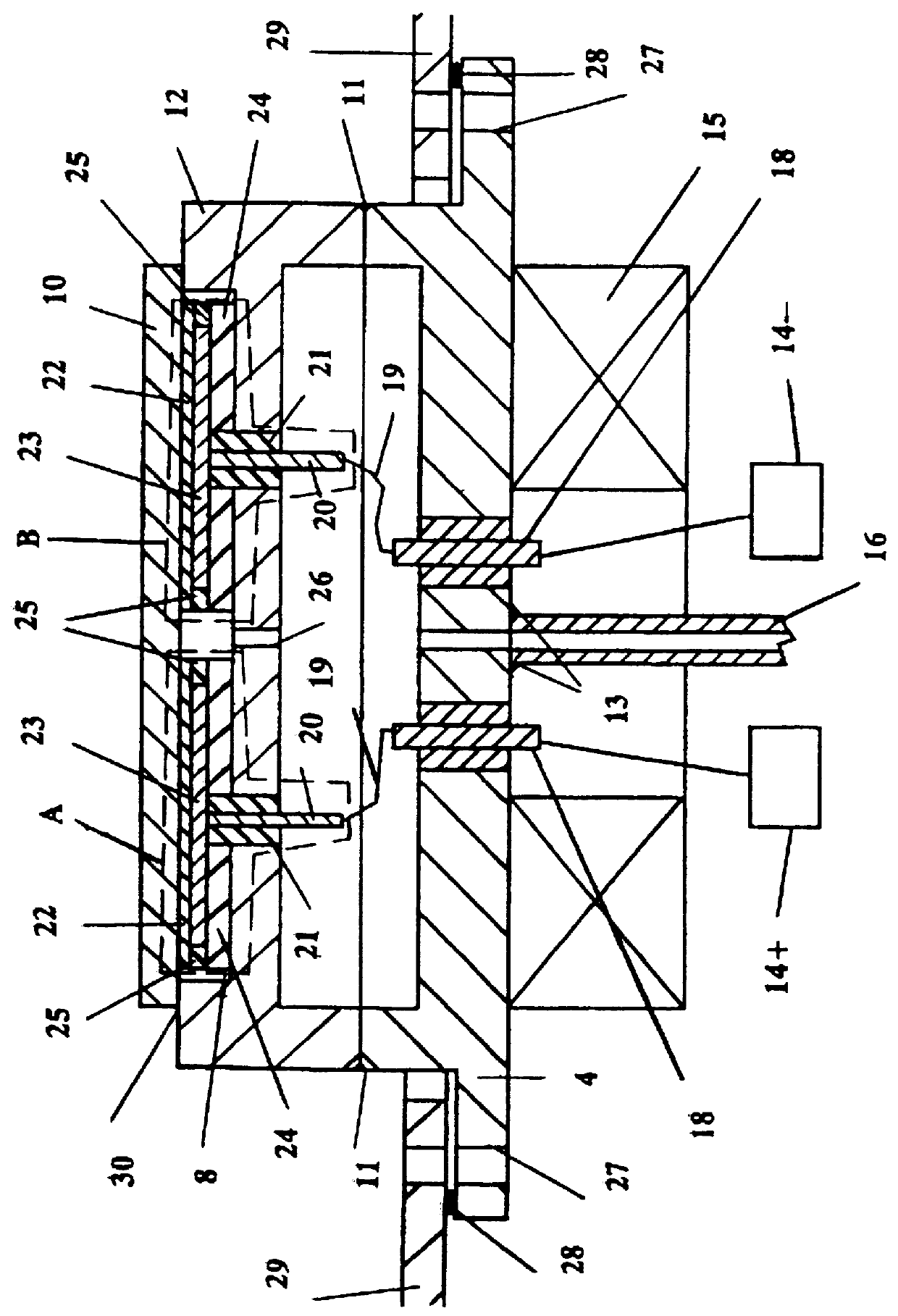

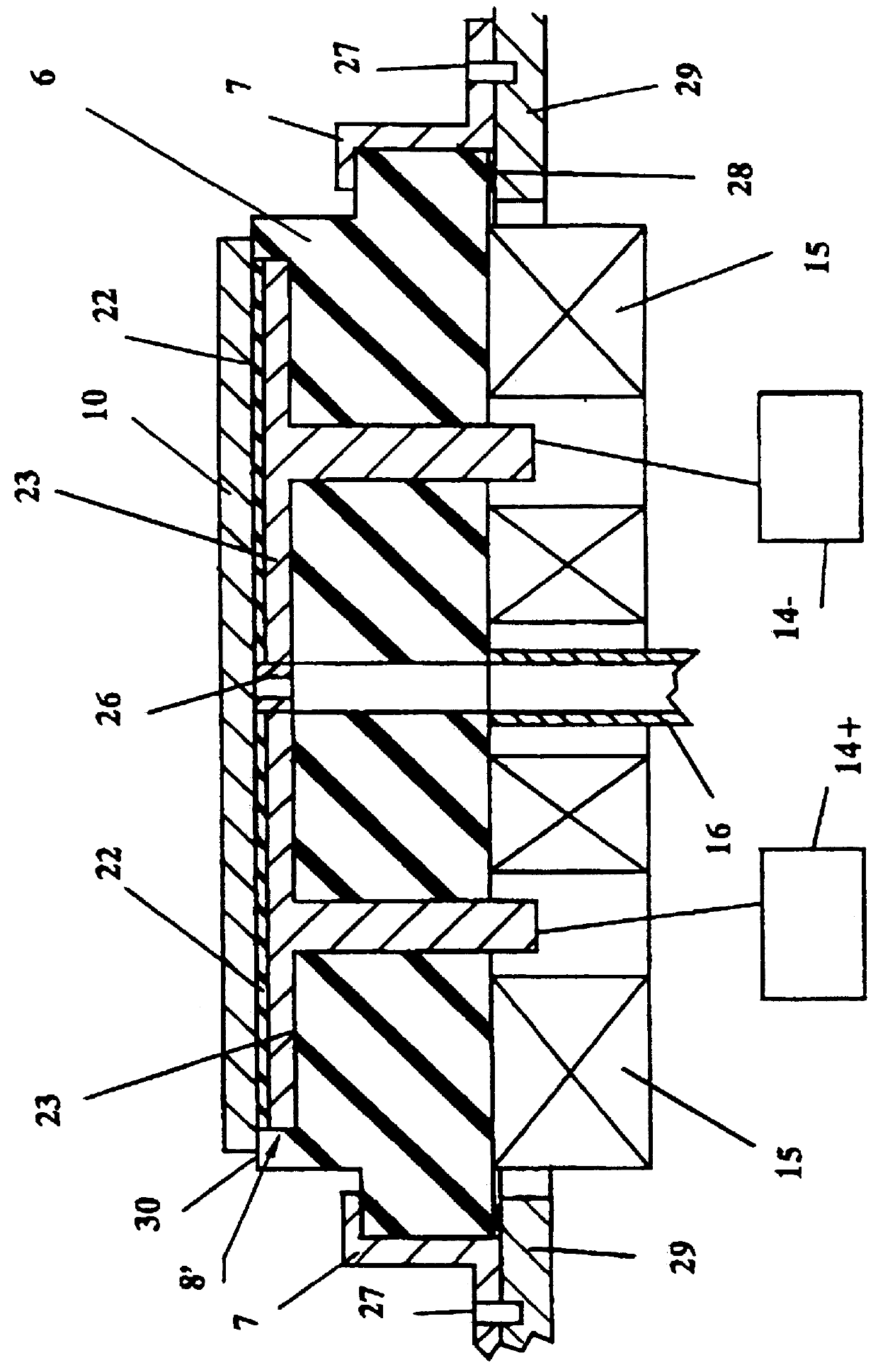

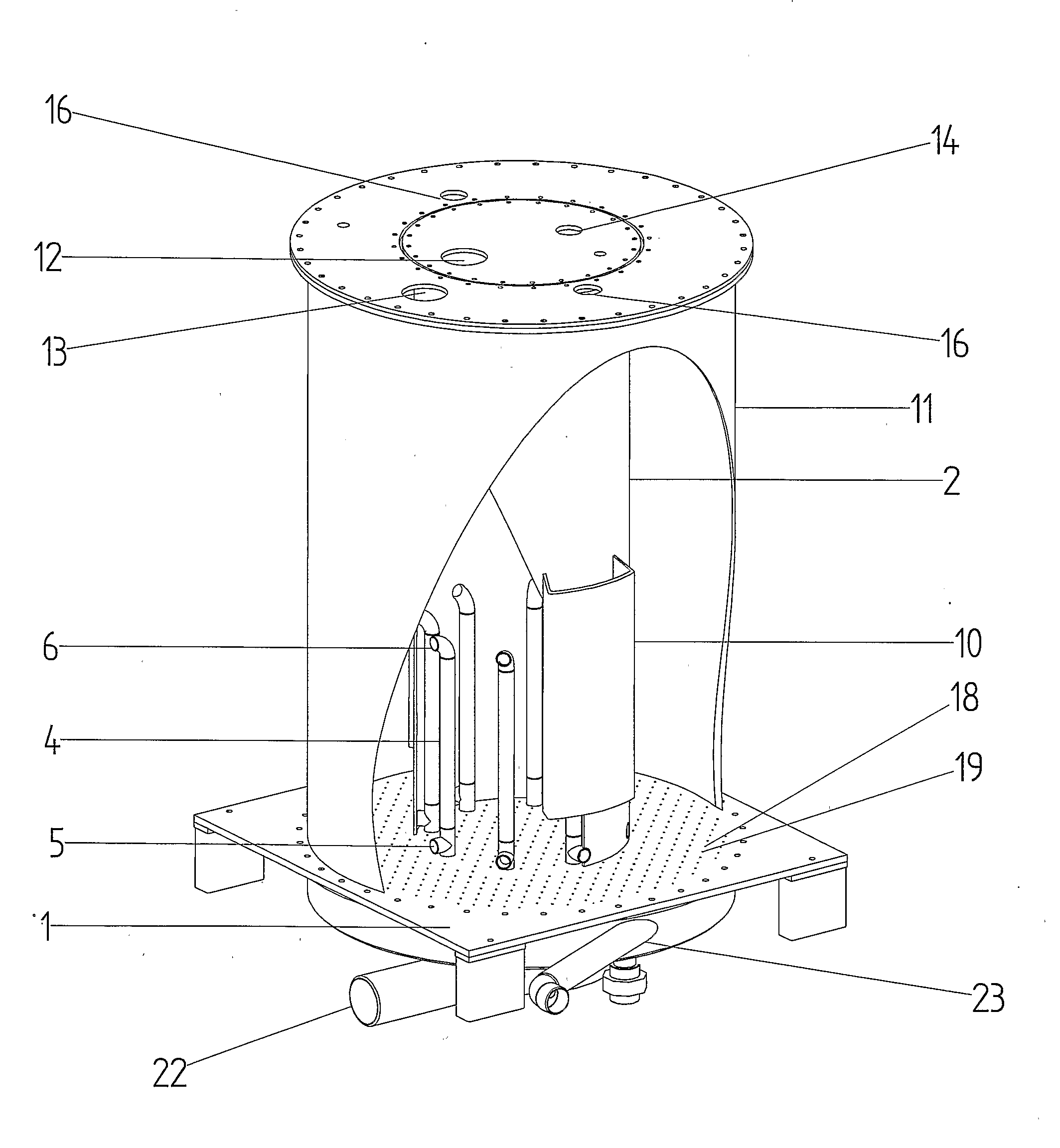

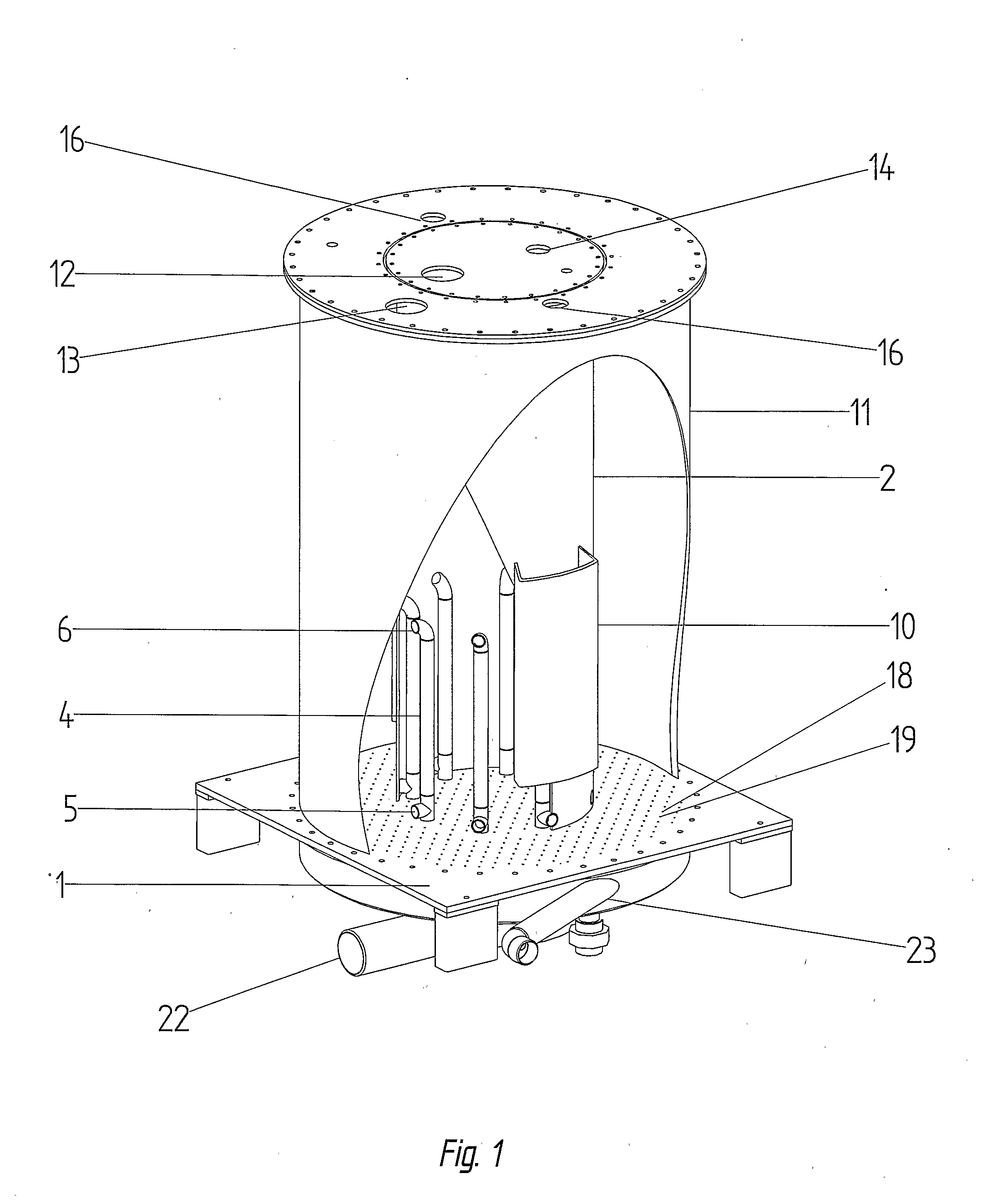

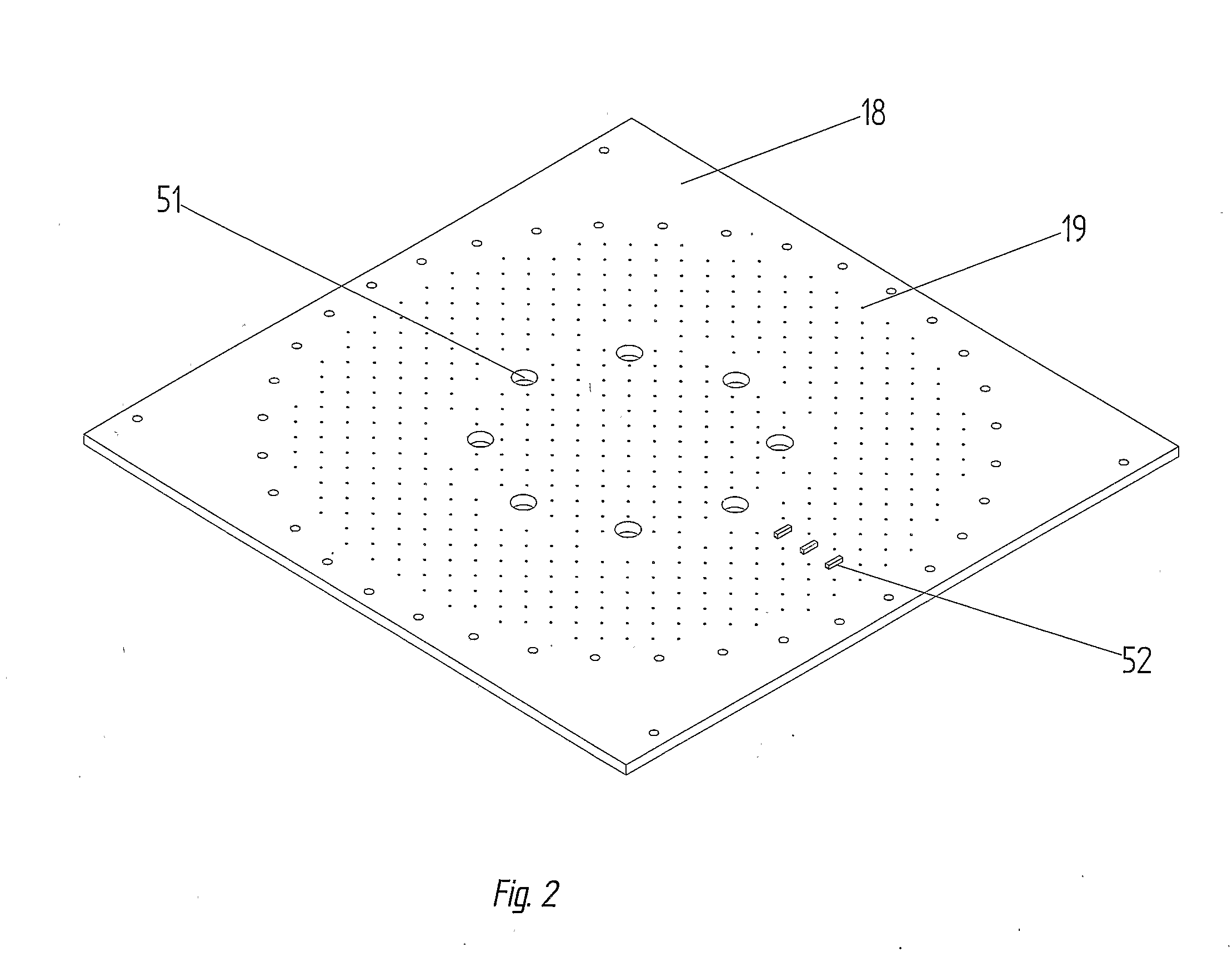

Continous flow thermal device

ActiveUS20050282206A1Avoid vaporizationMinimizing turbulent flowBioreactor/fermenter combinationsBiological substance pretreatmentsThermal contactThermal cycle

The present invention provides a thermal cycling device including: a heat exchanger body (3) having a longitudinal axis and longitudinally divided to provide at least two segments which are able to be heated to different temperatures so that said body has peripheral surfaces of different temperatures; a conduit (2) extending about said body so as to be in thermal contact with said peripheral surfaces; a first delivery device to deliver a first fluid to said conduit to cause said fluid to pass therealong and therefore change in temperature as the fluid passes said segments; and a second delivery device to deliver a second fluid to said conduit so as to flow with said first liquid and therefore also change in temperature. The fluid then leaves the device by conduit (4). The invention also is directed to an injector means for use in the thermal cycling device of this invention, comprising: a septum (26); a needle (20) which is able to pierce the septum; a reservoir (27) in fluid contact with septum (26) having an inlet (28) and an outlet (30); wherein when in use, the needle is urged through the fluid in said reservoir and then through the septum while continually purging the reservoir with said purge fluid. The present invention also includes a scanning detector (5) fitted to the outside of the heat exchange body (3) which monitors the course of reaction inside the conduit (2).

Owner:QIAGEN GMBH

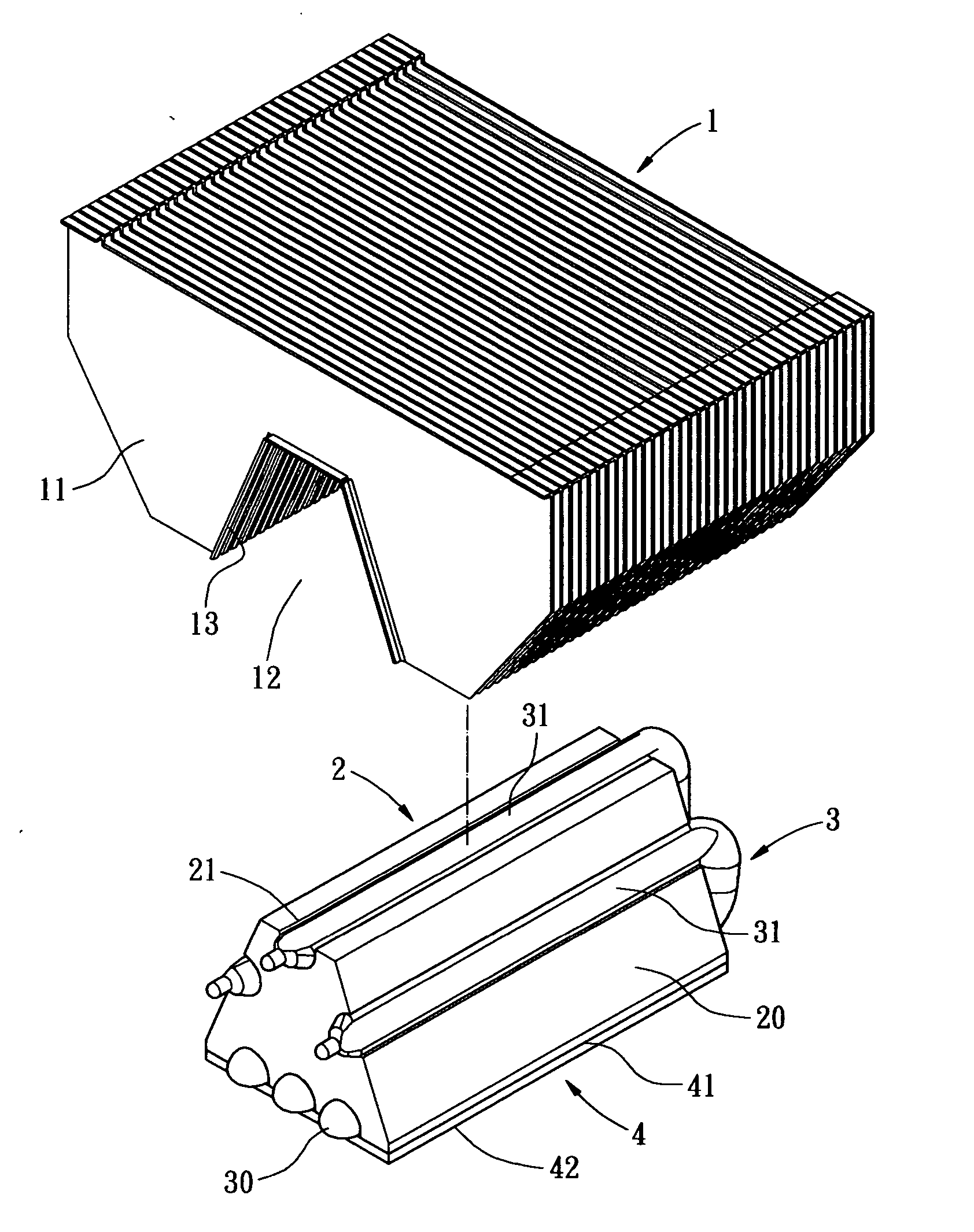

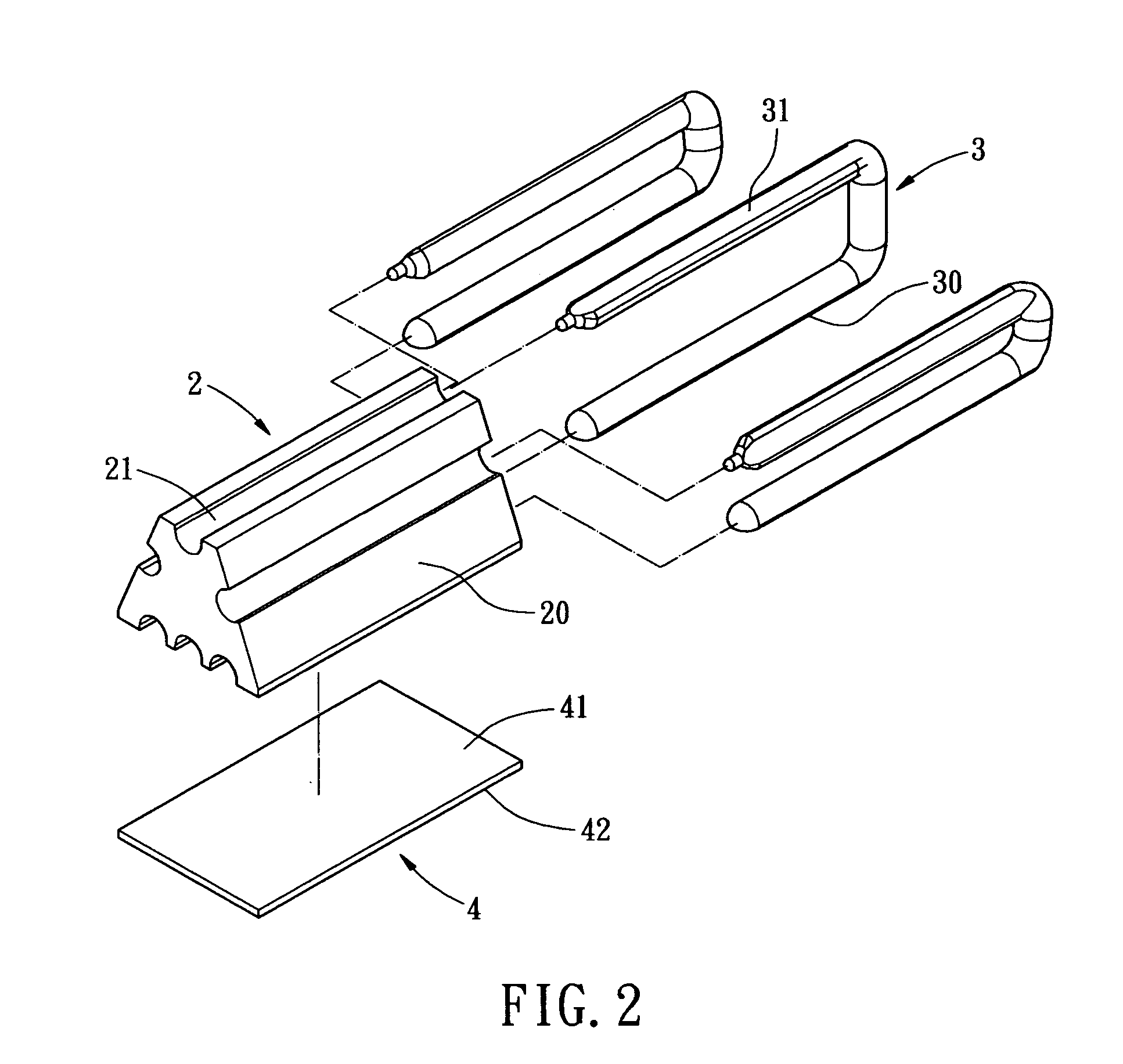

Heat pipe heat sink with holeless fin module

InactiveUS20060011329A1Fast heat transferEasy to manufactureSemiconductor/solid-state device detailsSolid-state devicesHeat conductingAdhesive

A heat pipe heat sink with a holeless fin module is disclosed in the present invention. Because of the holeless arrangement the heat pipe heat sink is much more convenient for manufacturing. The heat generated by an electrical component can quickly be transferred into the heat pipe and uniformly distributed to each of the heat dissipating fins. The heat pipe heat sink includes a heat dissipating fin module, a heat conducting member, one or more heat pipes installed on the heat conducting member, and a heat conducting plate which is thermally connected to the heat conducting member and the electrical component. The end surface of the heat conducting member with the heat pipe installed thereon is convenient for application of an adhesive because the end surface and the pipe wall of the heat pipe are exposed outside of the heat dissipating fin module before any combination takes place. The top of the heat conducting plate is attached to the bottom surface of the heat conducting member, while the bottom of the heat conducting plate is thermally connected to the top surface of an electrical component. Via the heat conducting plate, a uniform heat connection end surface is formed below the heat conducting member.

Owner:WAFFER TECH +1

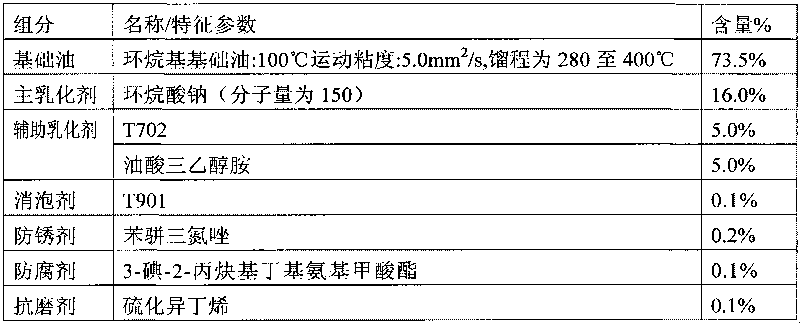

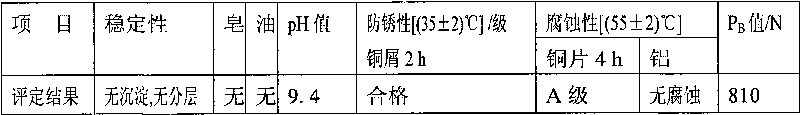

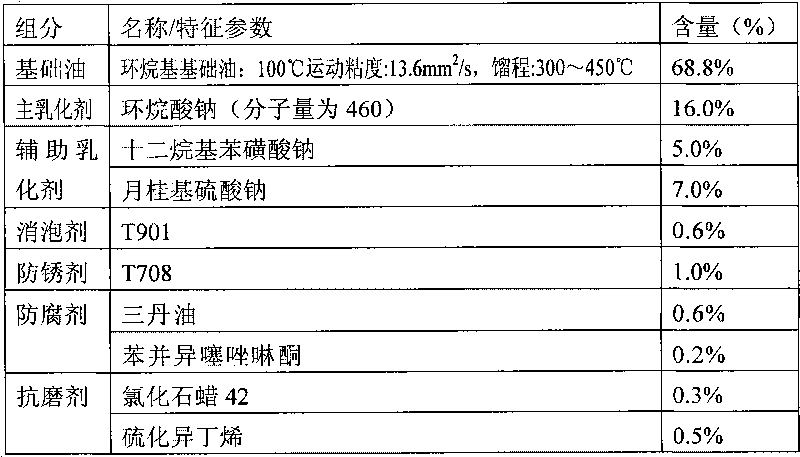

Water-based copper and aluminum wiredrawing oil composite and preparation method thereof

The invention relates to an oil-based lubricating composite and a preparation method thereof, in particular to a water-based copper and aluminum wiredrawing oil composite and a preparation method thereof. The water-based copper and aluminum wiredrawing oil composite comprises base oil, an emulsifier, an auxiliary emulsifier, a defoaming agent, a rust-proof agent, an antiseptic and an antiwear agent. The preparation method comprises the following steps of: configuring the water-based copper and aluminum wiredrawing oil composite into 3 percent to 45 percent water-based emulsion according to weight percentage; and spraying the water-based emulsion into a wiredrawing die cavity in the copper and aluminum wiredrawing process. The water-based copper and aluminum wiredrawing oil composite has the advantages of excellent lubricating property, great optimal light stability and storage stability, low cost, good cooling effect, fast heat transfer, little temperature increase in the using process, difficult combustion and easy cleaning and ensures the safety of the service environment; and in addition, a copper wire and an aluminum wire drawn by the method have the advantages of uniform wireshape, bright surfaces, difficult corrosion, good ultraviolet and storage stability and good stability.

Owner:PETROCHINA KARAMAY PETROCHEMICAL CO LTD

Microwave heating apparatus and method for whole-body or regional heating

ActiveUS20070244530A1Rapid of regionLarge amount of energyElectrotherapyMicrowave therapyWhole bodyEngineering

The invention provides a microwave heating method and apparatus for evenly heating an object, such as a person's body. The methods and apparatus involve use of microwave source (or sources) that outputs multiple microwaves that are non-correlated with each other in phase; an array of antennas that radiate substantially plane microwaves to form a pseudo uniform microwave electromagnetic field, where the microwaves are not phase-correlated, in order to eliminate non-uniform heating caused by interference. Each of the antenna array consists of multiple antenna units, each antenna unit consists of at least one microwave radiator and at least one converter that converts the spherical microwave to plane microwave. A computer based control system and a temperature monitoring subsystem can be used to adjust the output of each antenna, in order to enhance the uniform heating effect. The apparatus and method can be used to perform whole-body hyperthermia or regional hyperthermia.

Owner:HUNAN YOULI MEDICAL TECH

Depolymerization process of conversion of organic and non-organic waste materials into useful products

ActiveUS7771699B2Efficient processingSmooth connectionWaste based fuelLiquid hydrocarbon mixture productionSpeciality chemicalsDepolymerization

The present invention relates to the conversion of waste and low-value materials into useful products in reliable purities in a cost-effective and energy-efficient manner. More specifially, the invention provides processes that can handle mixed streams of various feedstocks, e.g. shredder residue, offal, animal manures, municipal sewage sludge, tires, and plastics, that otherwise have little commercial value, to useful products including gas, oil, specialty chemicals, and carbon solids. The process subjects the feedstock to heat and pressure, separates out various components, then further applies heat and pressure to one or more of those components, according to processes based on thermal or catalytic cracking. The invention further comprises an apparatus for performing a multi-stage process of converting waste materials into useful materials, and at least one oil product that arises from the process. Useful products can also be obtained or derived from materials diverted at different points of the process.

Owner:SYNPET TEKNOLOJI GELISTIRME

Thermally conductive compound and semiconductor device using the same

InactiveUS6255376B1Improve reliabilityFast heat transferSemiconductor/solid-state device detailsConductive materialPlasticizerThermal expansion

A thermally conductive compound which comprises 15 to 60 volume % of thermoplastic carrier resin consisting of a copolymer of a plasticizer with ethylene or of a polymer of the plasticizer, polyethylene and the copolymer, 40 to 85 volume % of thermally conductive filler particles dispersed in the carrier resin, and 0.5 to 5 weight % (for the filler particles) of a dispersing agent having (a) hydrophilic group(s) and (a) hydrophobic group(s). The thermally conductive compound has a high thermal conductivity and a plasticity in the range of temperatures of -40 to 50° C., and when it is interposed between an insulator body and a semiconductor element mounted thereon or between the semiconductor element and a cap, the heat generated by an operation of the semiconductor element is rapidly transferred and the thermal stress caused by the difference of coefficients of thermal expansion between the semiconductor element and the insulator body or cap is absorbed and relieved to cause no phase separation between them. The semiconductor device using the thermal compound, accordingly, is highly reliable.

Owner:KYOCERA CORP

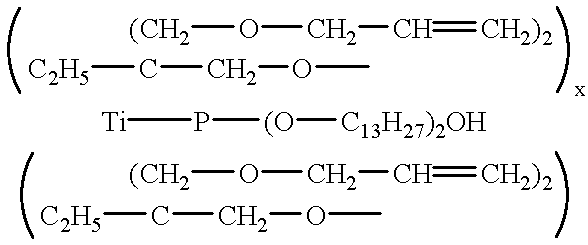

Aqueous coating with high heat-dissipation performance and preparation method thereof

InactiveCN107760128ALow densityGood thermal and electrical conductivityAnti-corrosive paintsEpoxy resin coatingsSolventChemistry

The invention relates to the technical field of novel coating preparation and in particular relates to an aqueous coating with high heat-dissipation performance which comprises the following components: 30-60 parts of aqueous resin, 1-10 parts of graphene, 10-30 parts of packing, 10-20 parts of an aid and 30-60 parts of a solvent, wherein the radial size of the graphene is 1-100 microns; and the graphene consists of 1-3 layers. The high heat-dissipation performance aqueous coating provided by the invention is good in heat dissipation effect, environmentally friendly and low in cost.

Owner:CHANGZHOU XICAI CARBON MATERIAL TECH CO LTD

Double-loop double-pyrogenation incinerator for garbage harmless treatment and its usage method

InactiveCN101101120APrevent external consumptionPlay the role of thermal insulationIncinerator apparatusRefluxCombustion chamber

The invention relates to double loop double pyrolysis incinerator and its using method. Its features are that drying apparatus is formed by horizontal rotary kiln drying device, steam separator, and fume reflux line; the feed port of the horizontal rotary kiln is connected with discharge port of the feeding device; its discharge port is connected with the feed port above secondary burning chamber. While running, part of high temperature fume of secondary burning chamber can enter the rotary kiln to process reverse drying preheat and pyrolysis for the garbage; cooled fume is inducted into the secondary burning chamber by secondary fan after dehydrating by steam separator. Compared with exiting technique, the invention has the advantages of continual heat transfer, fast gasification rate, full burning, processing domestic garbage without auxiliary fuel etc.

Owner:福建省丰泉环保控股有限公司

Novel phase-change material composition

ActiveCN104726069AImprove thermal performanceGood dispersionHeat-exchange elementsParticulatesCarbon nanotube

The invention discloses a novel phase-change material composition. The novel phase-change material composition mainly comprises carbon nanotubes, graphene, fumed silica, metal or metal oxide particles and a phase-change material. The carbon nanotubes, graphene and metal or metal oxide particles can further accelerate heat transmission. The phase-change material is used for improving a hot end initial temperature absorption rate. The fumed silica has effects of precipitation prevention and thickening and can prevent graphene and particle aggregation settlement after heat absorption liquefaction of the phase-change material. The carbon nanotubes, graphene and metal or metal oxides can finally form a full 3D network comprising particles (metal or metal oxides), wires (carbon nanotubes) and planes (graphene) in the fluid (of phase-change material subjected to heat absorption melting). The novel phase-change material composition has high heat conductivity and low thermal resistance value, has high specific heat capacity, greatly improves phase-change material heat absorption, heat storage and heat radiation efficiency and has a high practical value.

Owner:HUZHOU MINGSHUO OPTOELECTRONICS TECH CO LTD

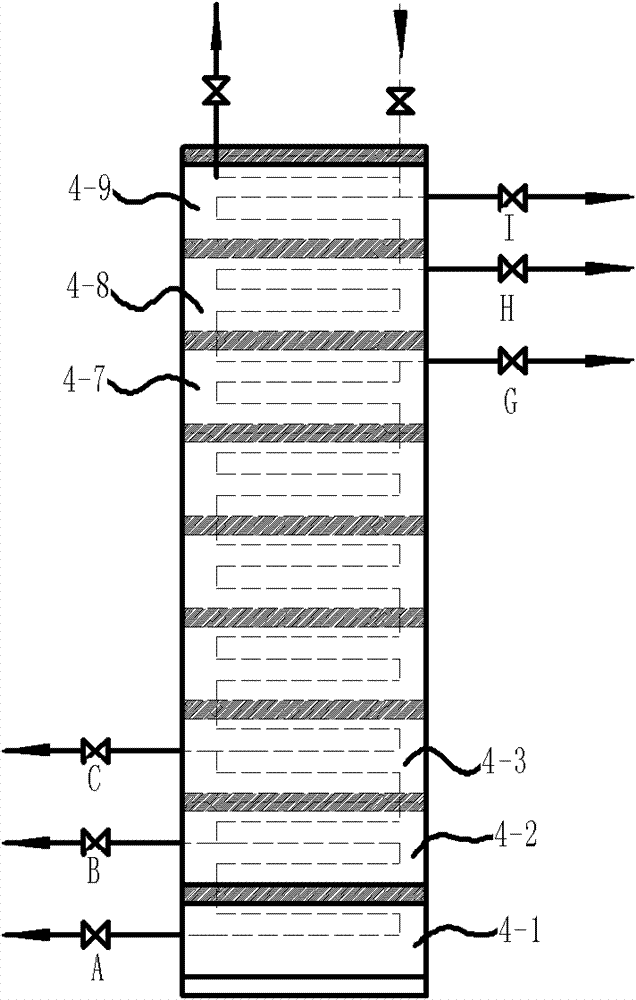

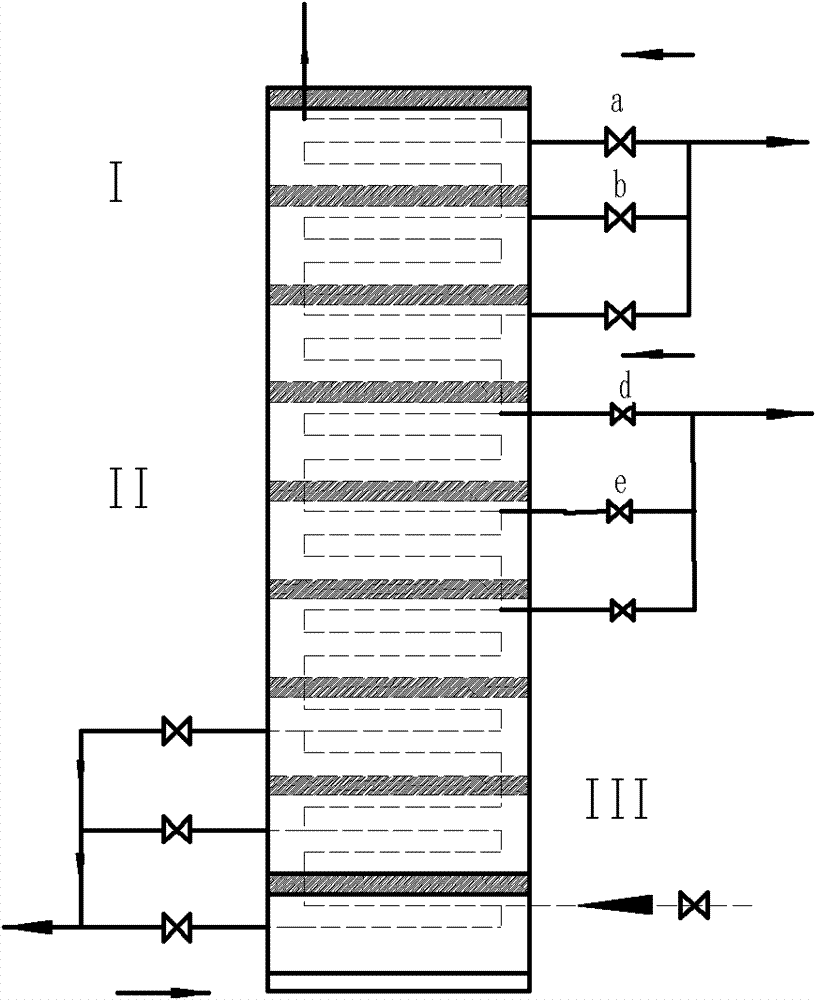

Solid heat storage device

InactiveCN102818468AGuaranteed uptimeImprove thermal conductivitySolar heating energyThermal insulationInsulation layerControl system

The invention provides a solid heat storage device which is formed by combining at least one heat storage unit in series and / or parallel. The heat storage unit comprises a casing, a solid heat storage medium arranged in the casing and a heat insulation layer arranged outside the casing. The outer surface of the solid heat storage medium is a heat exchange interface. Heat insulation layers are regularly arranged in the heat storage unit, an inclined temperature layer is arranged in the axial direction, and a layering control system is arranged in the heat storage unit to ensure high grade storage and output of heat. The heat storage unit of an array can be vertically arranged and can also be horizontally arranged with a certain inclined angle. The solid heat storage medium utilizes solid sensible heat to store heat, and is safe in running, simple to process and low in cost. The surface of the solid heat storage medium has good heat exchange efficiency and good heat storage performance and can be widely applied to various heat storage applications, especially a solar photo-thermal utilization system.

Owner:BEIJING TERASOLAR PHOTOTHERMAL TECH CO LTD

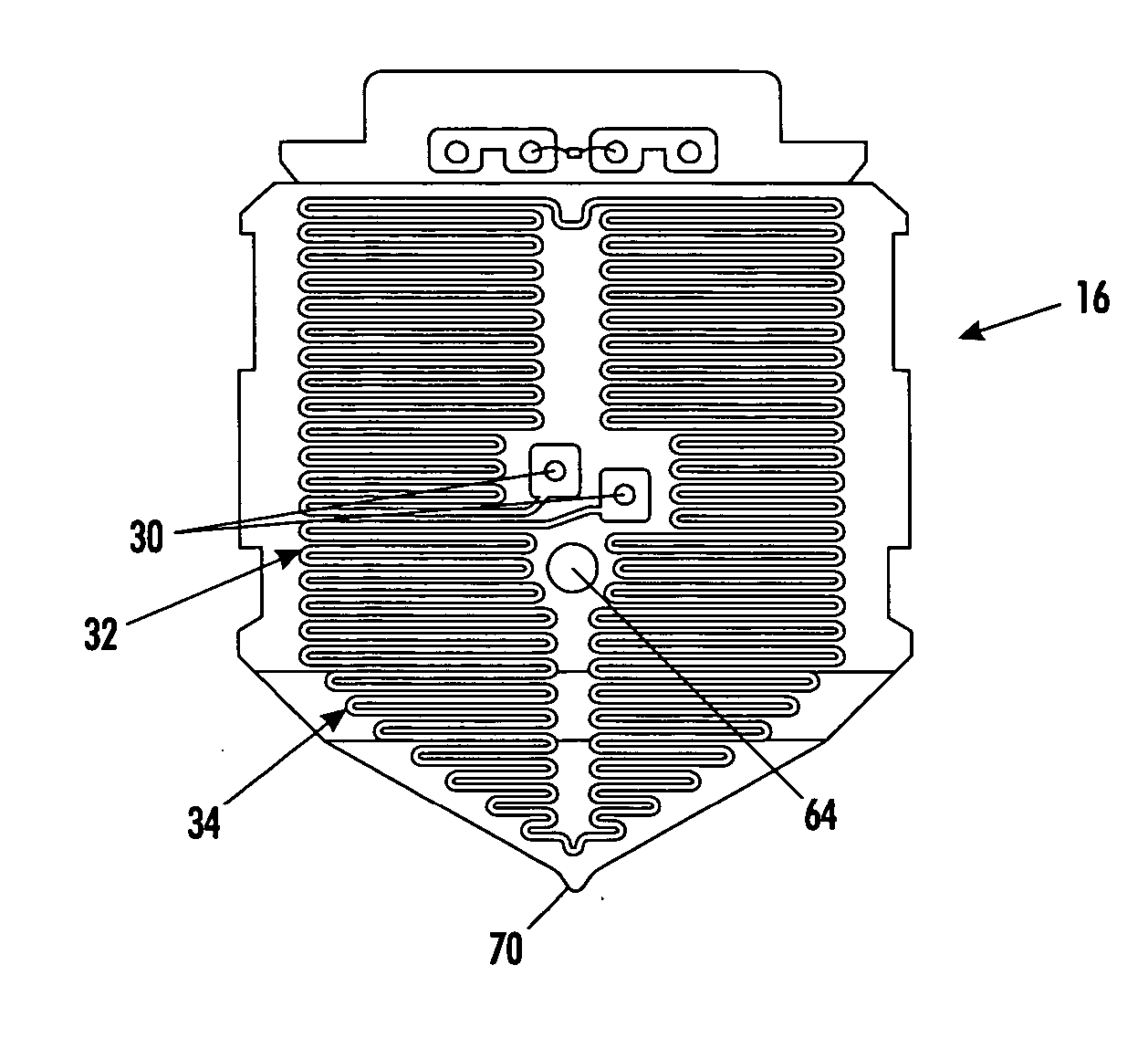

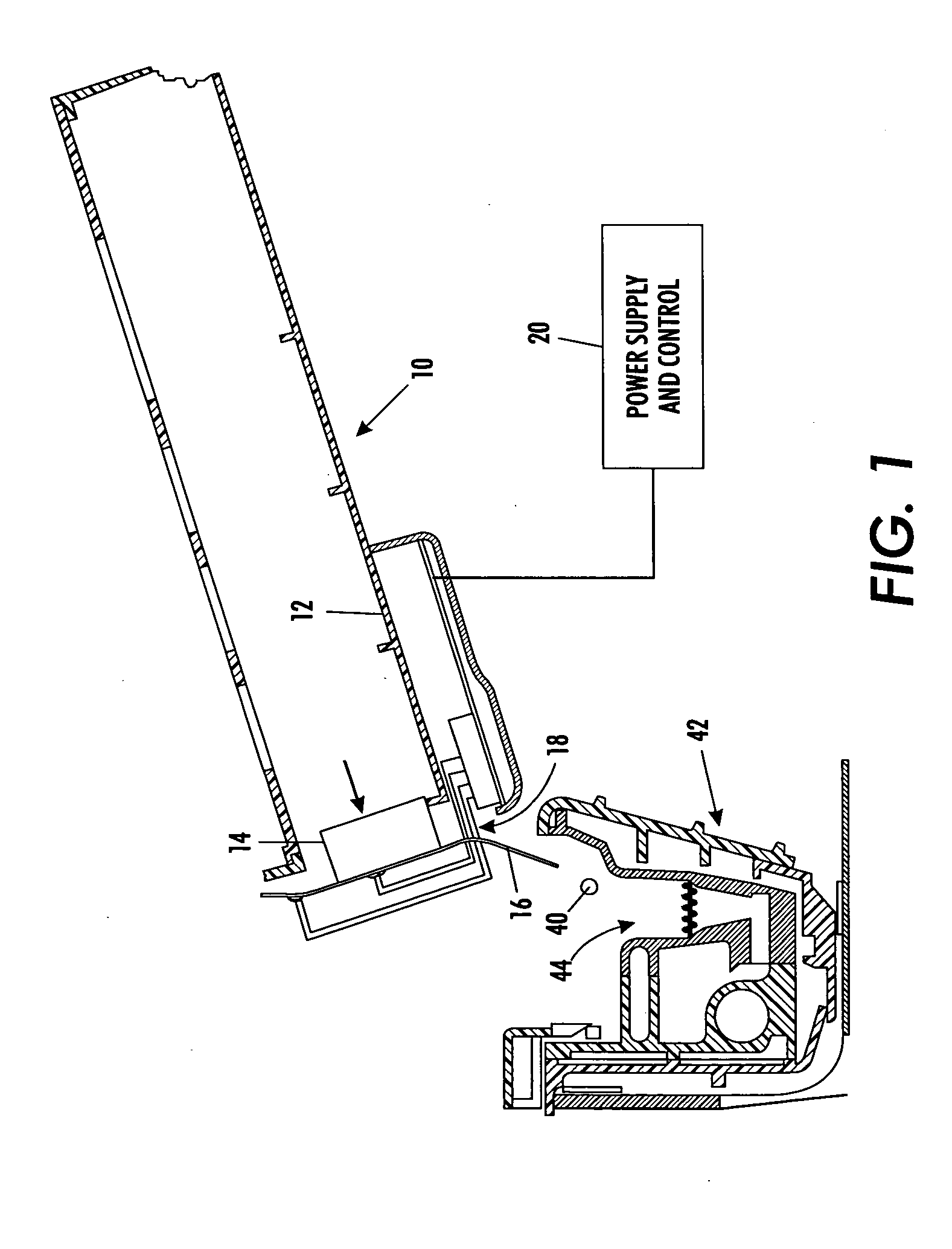

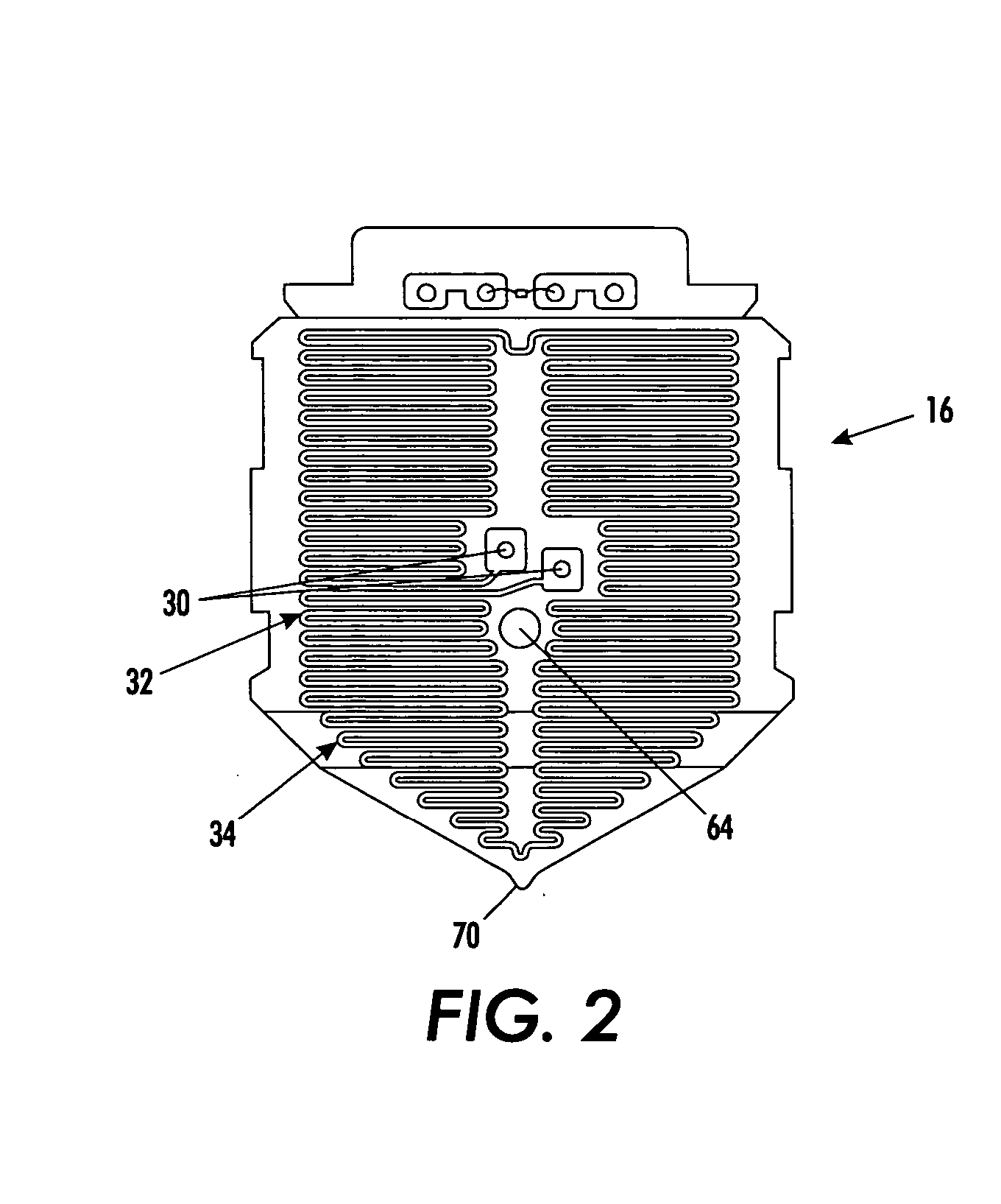

Low thermal mass, variable watt density formable heaters for printer applications

InactiveUS20050146584A1Low thermal massFast heat transferMeasurement apparatus componentsPrintingEngineeringVolumetric Mass Density

An ink melt heater is disposed in a phasing printing system for heating a solid ink stick for melting the ink stick from a solid to a liquid phase. The heater includes a trace assembly having a plurality of powerzones having different wattage densities respectively. The heat transfer plate is adhered to the trace assembly for mating engagement against the solid ink stick. The heater has a low thermal mass for enhanced and rapid heat transfer from the trace assembly through the transfer to the ink stick.

Owner:XEROX CORP

Method for producing aluminum plate-fin heat exchanger

InactiveCN1943973AHigh strengthLow strength, good cleaning qualityDetection of fluid at leakage pointMaterial strength using tensile/compressive forcesShielding gasNitrogen

The process of producing aluminum plate-fin heat exchanger includes the steps of blanking, washing, mounting, brazing, argon arc welding and pressure test. The present invention adopts numerically controlled lathe with high machining precision for blanking; ultrasonic washing for high washing efficiency and high washing quality; continuous high purity nitrogen protected brazing for high brazing quality; and argon arc welding with welding robot for high welding quality and high production efficiency.

Owner:管保清 +1

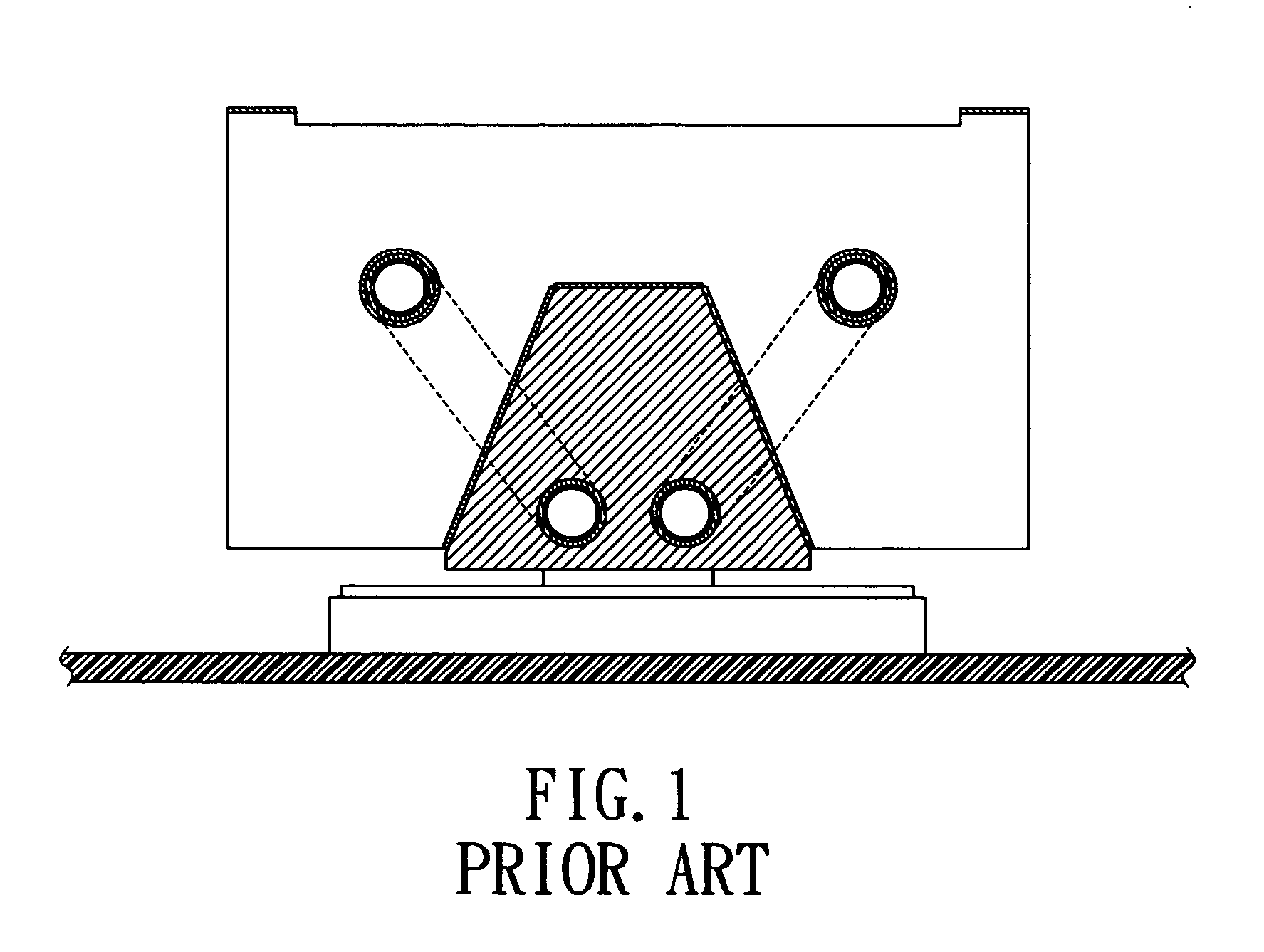

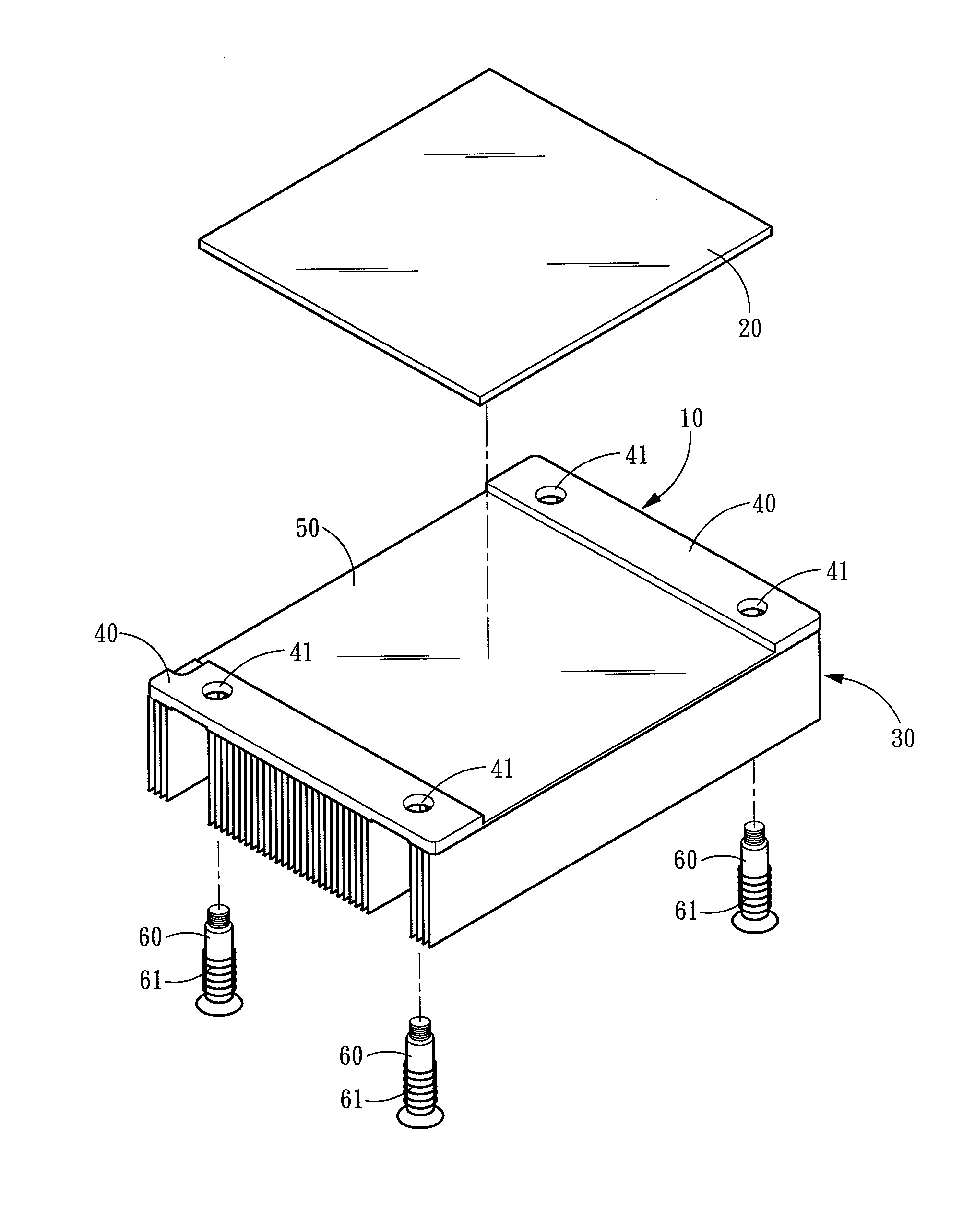

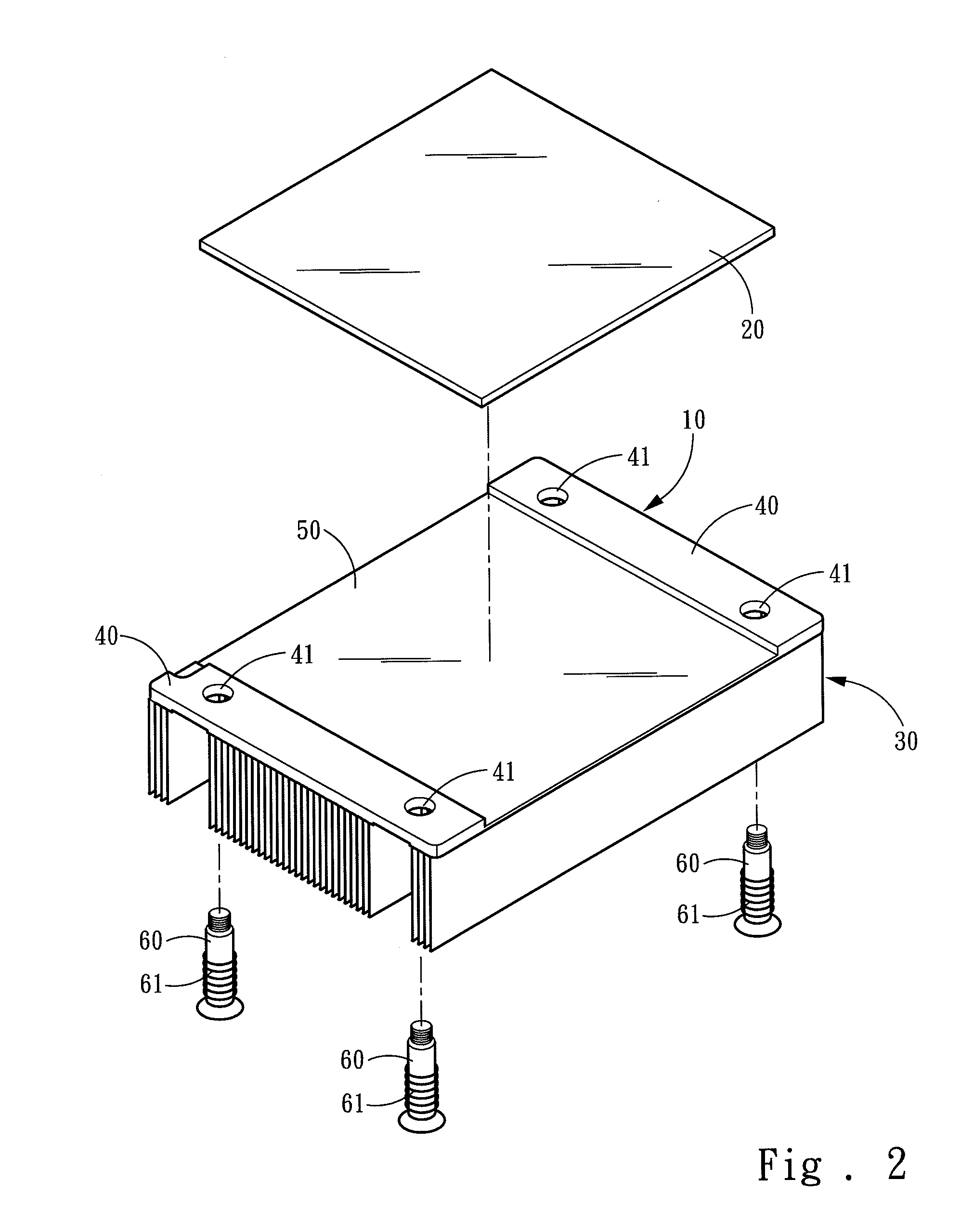

Heat sink equipped with a vapor chamber

InactiveUS20120211211A1Quickly and effectively transfer heatSmoothly contact heat generation elementSemiconductor/solid-state device detailsSolid-state devicesEngineeringUltimate tensile strength

A heat sink equipped with a vapor chamber includes a heat conduction plate and a vapor chamber. The heat conduction plate has one side formed integrally a plurality of radiation fins and another side with two lateral edges formed respectively and integrally a fastening portion. The two fastening portions are interposed by a recess to bond the vapor chamber. Each fastening portion is fastened to a printed circuit board through at least one screw to allow the vapor chamber to contact a heat generation element. The fastening portion is integrally formed at a desired thickness, thus has sufficient strength to withstand the fastening force of the screw to prevent tight sealing between the vapor chamber and heat generation element affected by deformation of the heat conduction plate. Thereby the vapor chamber can smoothly contact the heat generation element to rapidly transfer heat outside.

Owner:CHIA CHERNE IND CO LTD

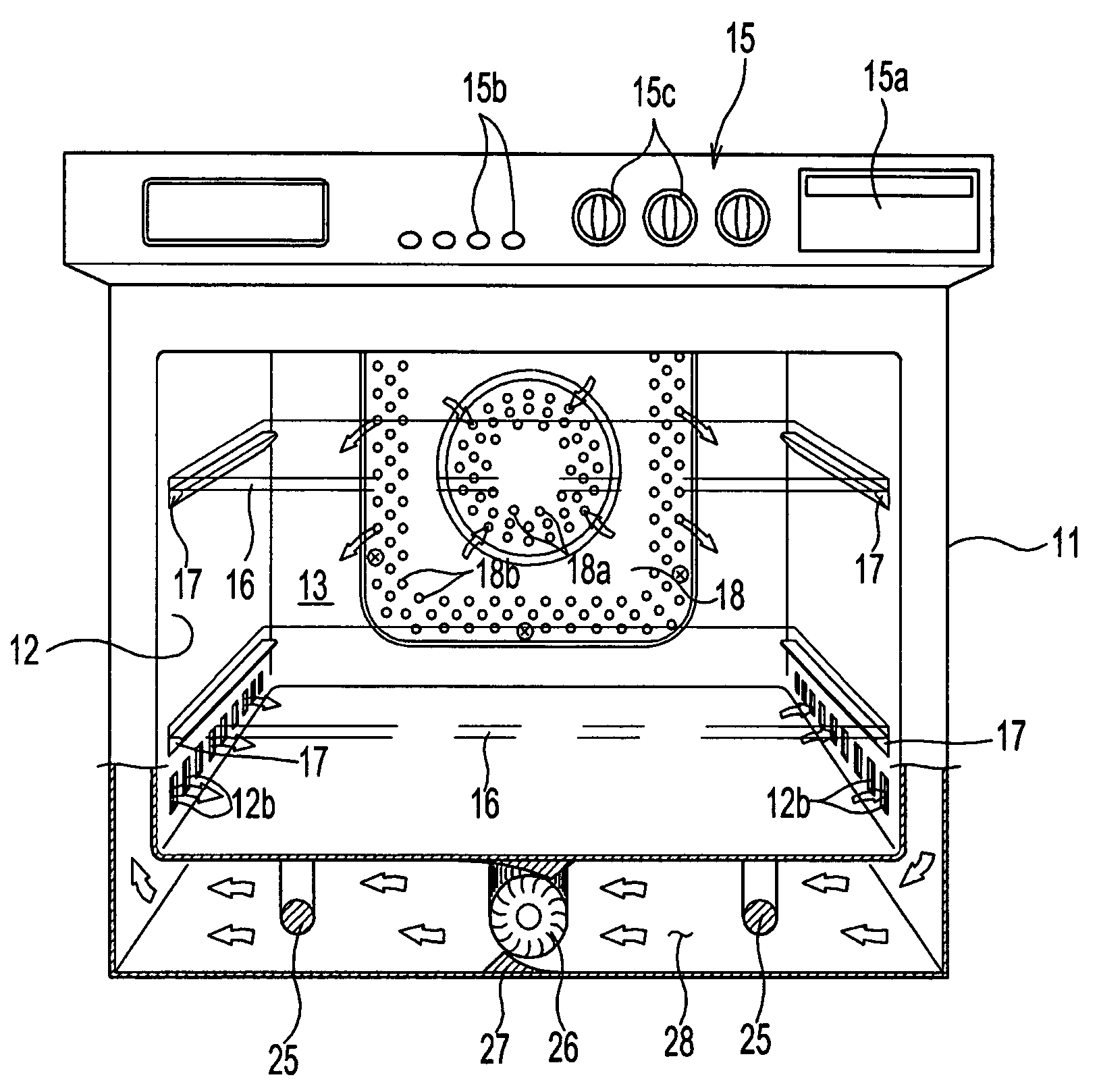

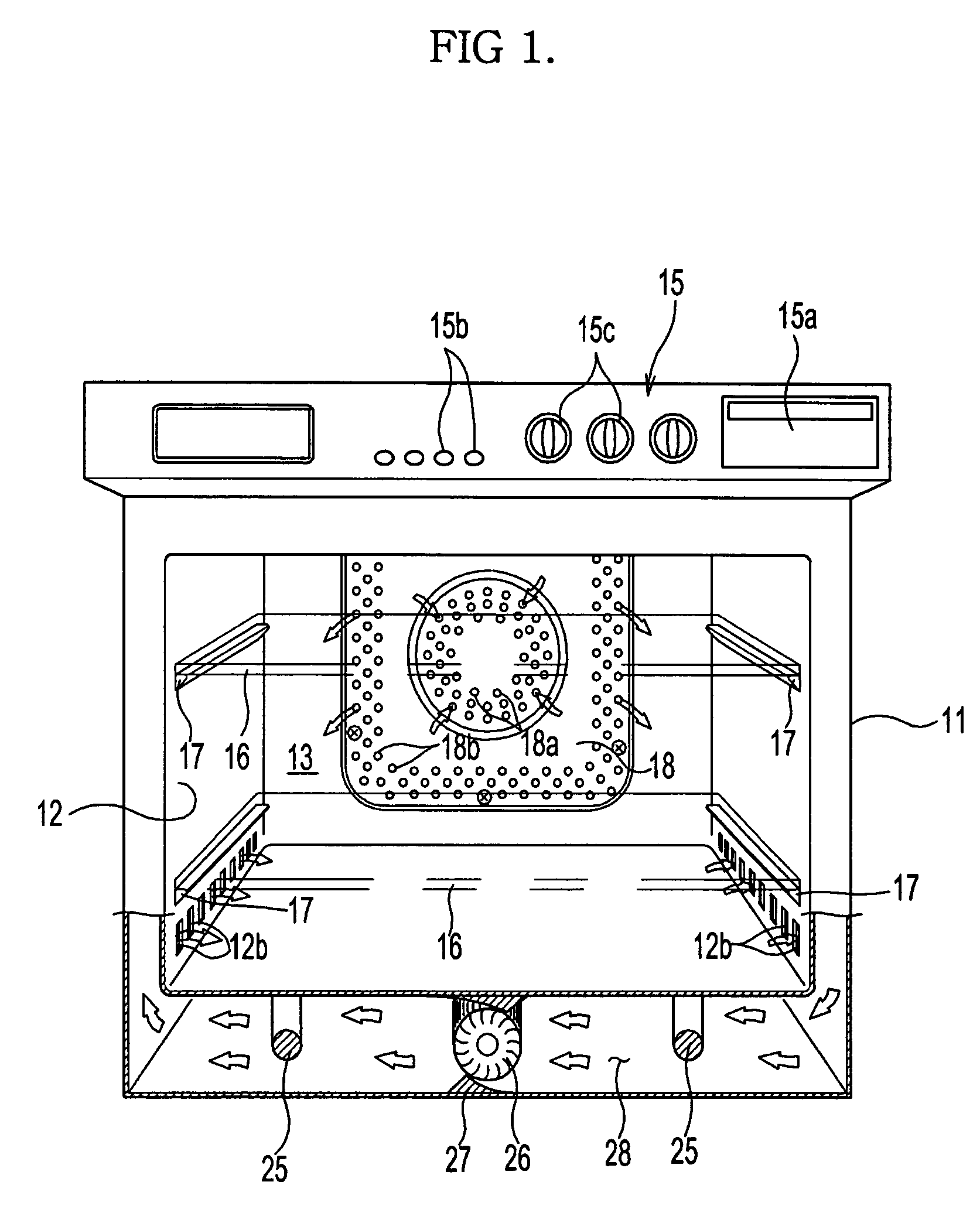

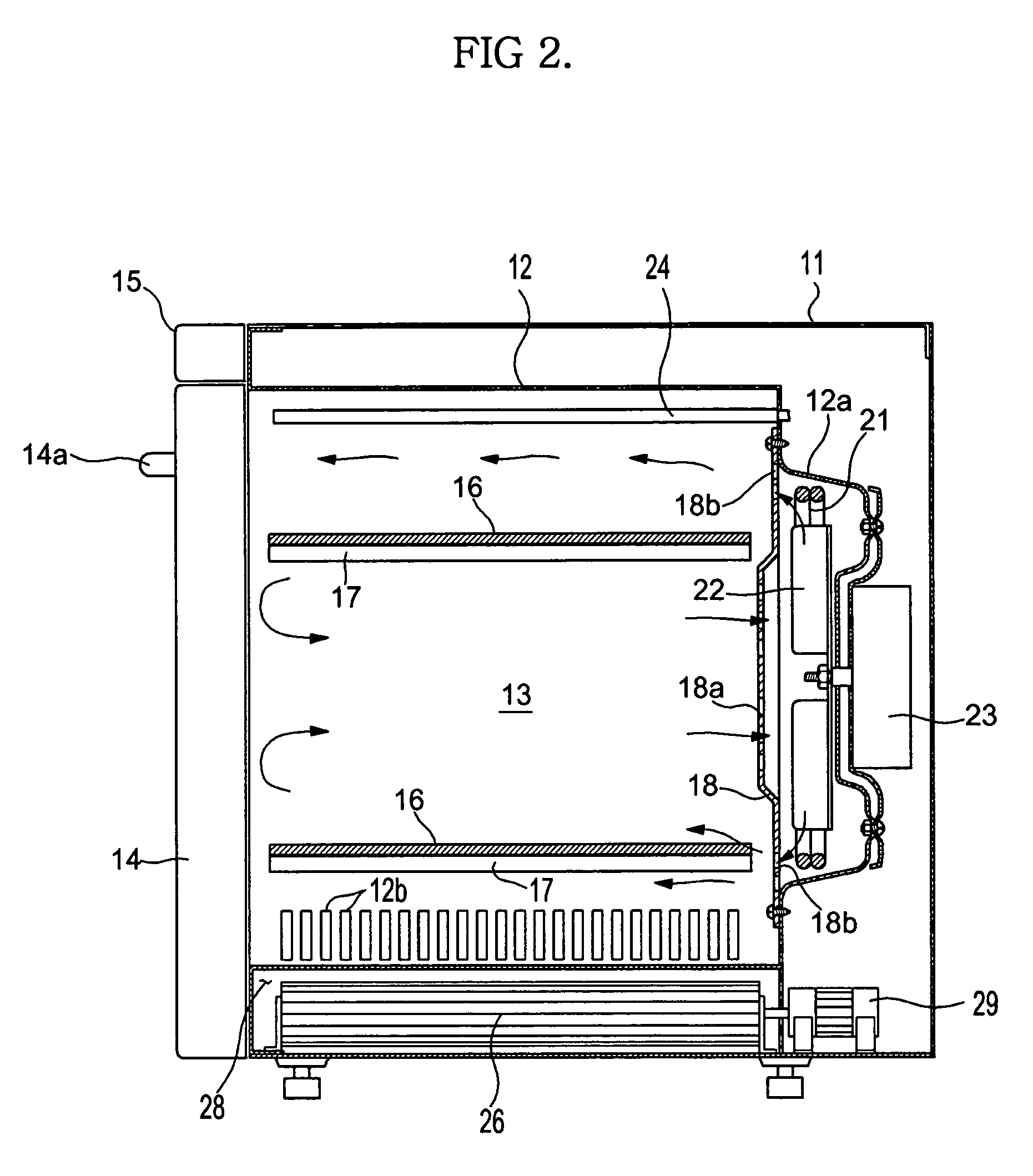

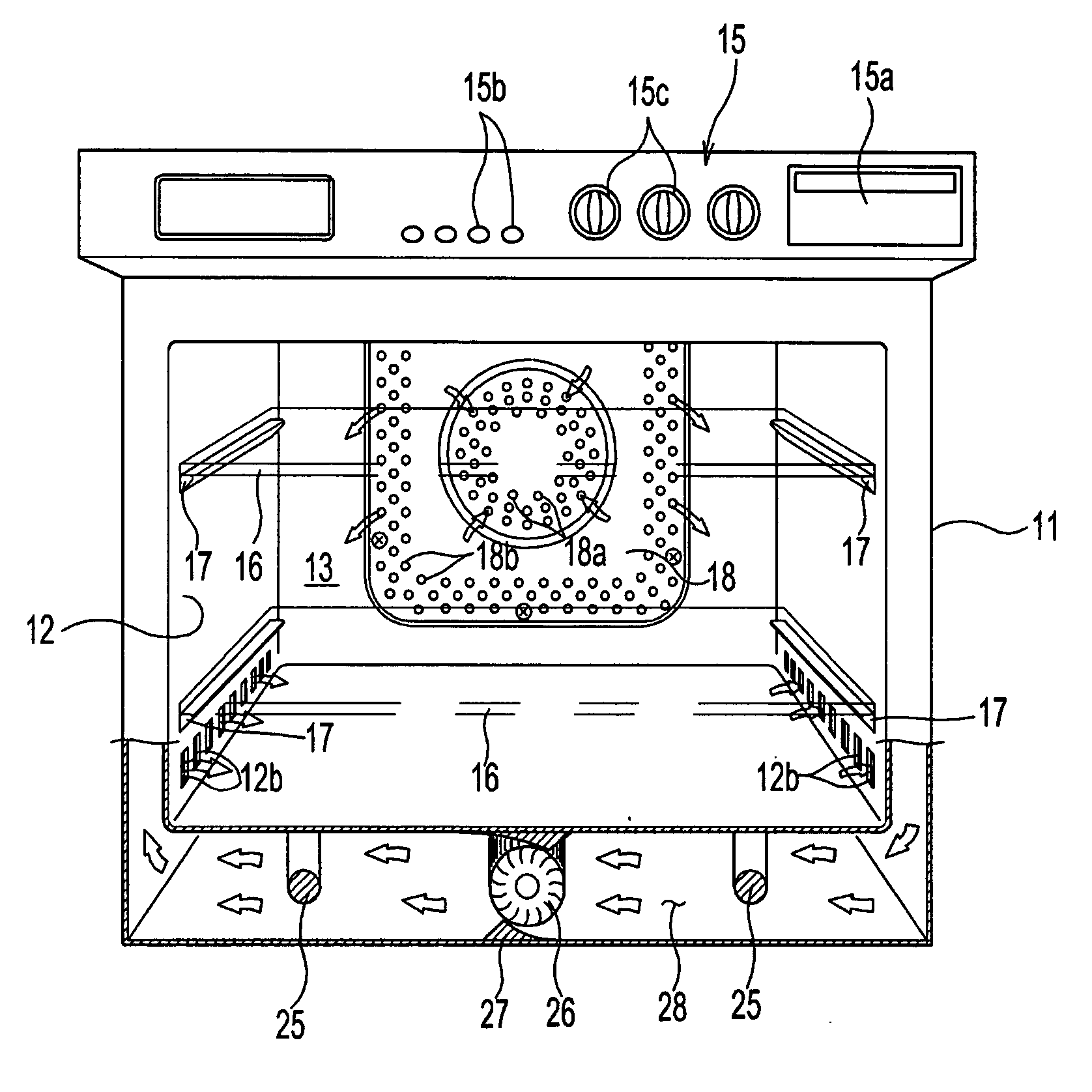

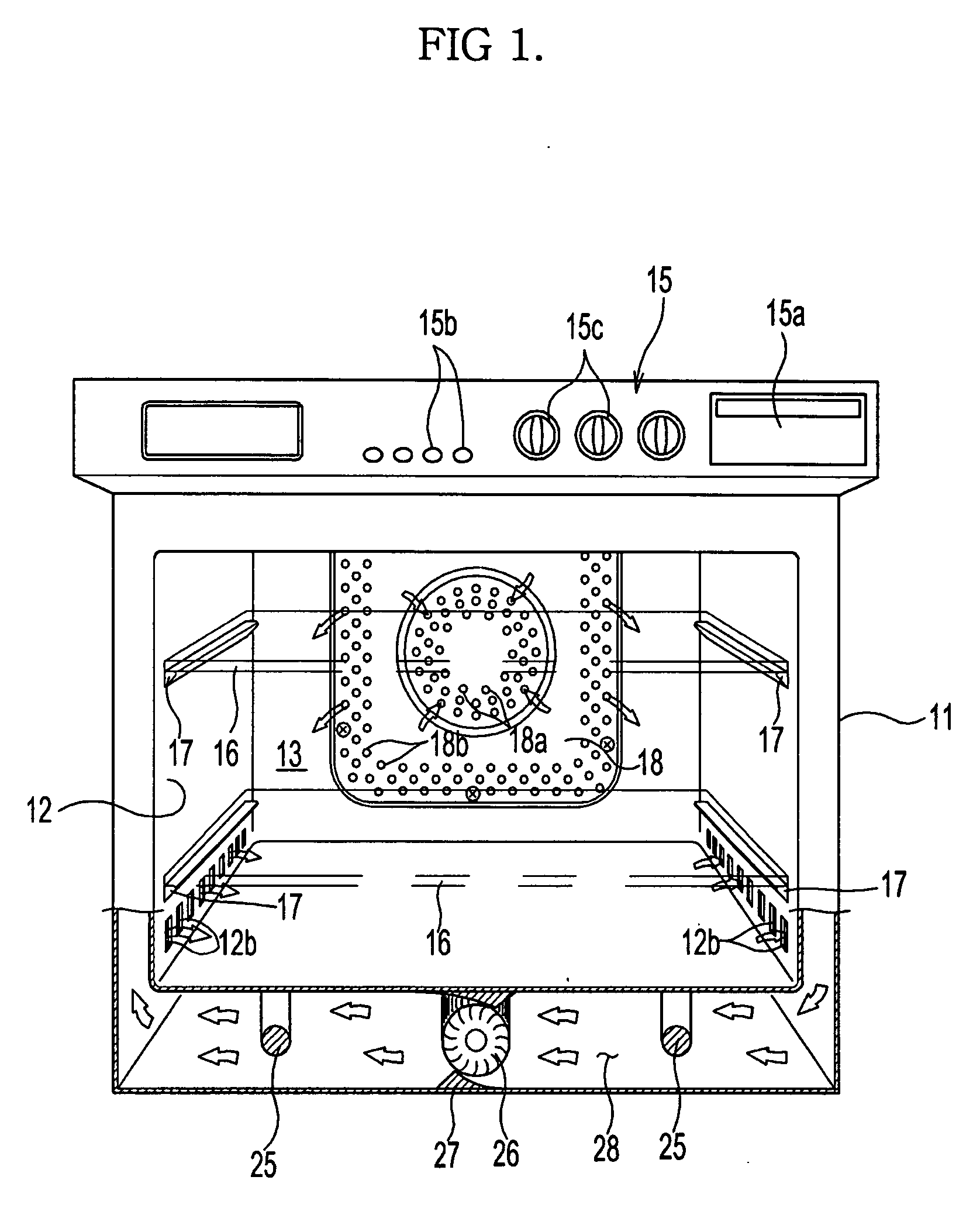

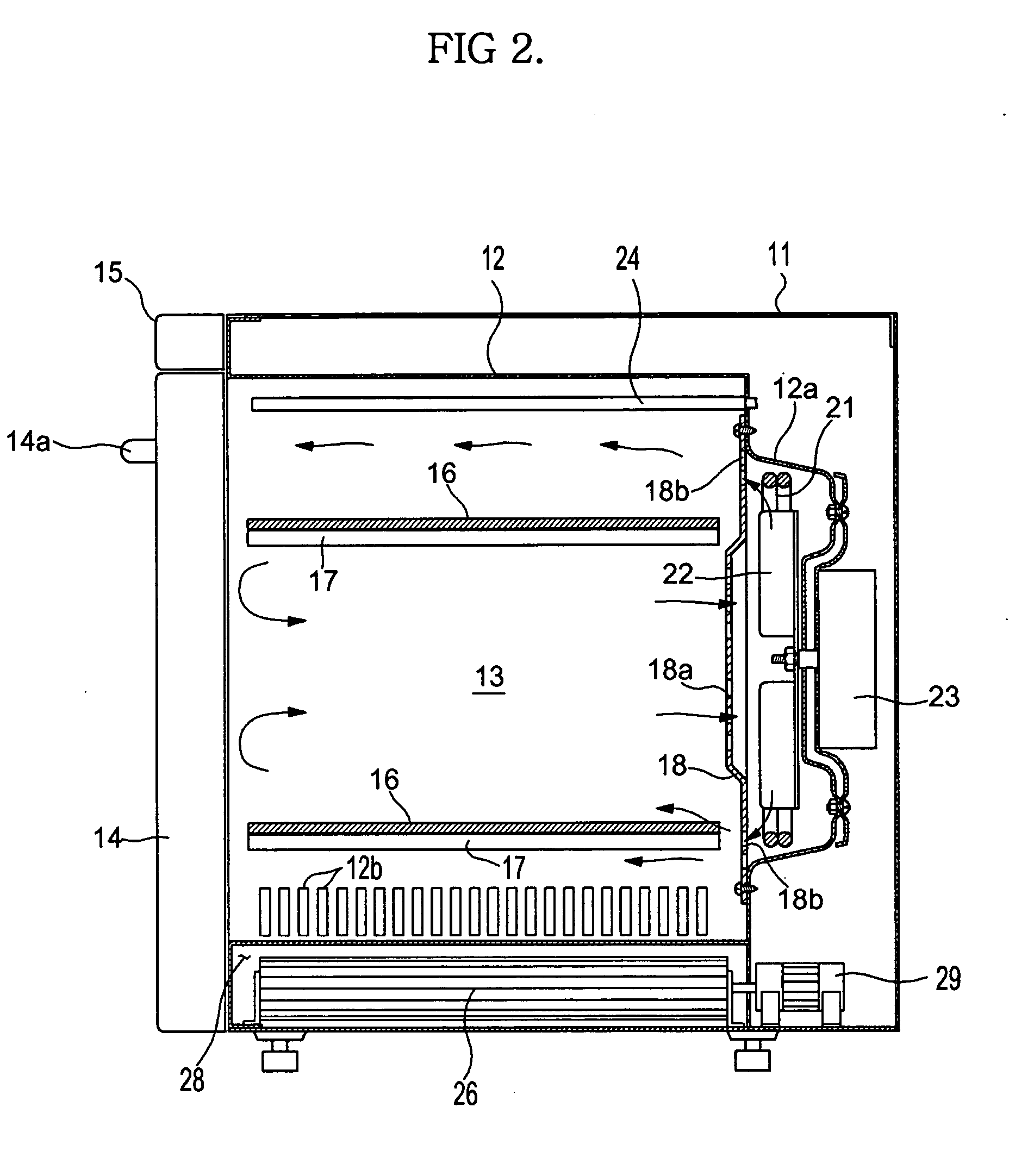

Electric oven

InactiveUS7102105B2Improve heating efficiencyImprove heat transfer efficiencyAir-treating devicesDomestic stoves or rangesEngineeringHeat transfer

An electric oven including lower heaters arranged under a cooking chamber thereof. The electric oven includes an outer case defining the appearance of the electric oven, an inner case inwardly spaced apart from the outer case by a predetermined distance, and lower heaters arranged between bottom walls of the outer and inner cases. The inner case internally defines a cooking chamber, and a blowing fan is installed near the lower heaters to circulate air existing in the cooking chamber toward the lower heaters. With the electric oven configured as stated above, heat generated by the lower heaters is transferred to the cooking chamber in the form of conductive heat and convective heat, resulting in fast and efficient heat transfer and even cooking of food.

Owner:SAMSUNG ELECTRONICS CO LTD

Electric oven

InactiveUS20060131298A1Improve heat transfer efficiencyImprove heating efficiencyAir-treating devicesDomestic stoves or rangesEngineeringIngested food

An electric oven including lower heaters arranged under a cooking chamber thereof. The electric oven includes an outer case defining the appearance of the electric oven, an inner case inwardly spaced apart from the outer case by a predetermined distance, and lower heaters arranged between bottom walls of the outer and inner cases. The inner case internally defines a cooking chamber, and a blowing fan is installed near the lower heaters to circulate air existing in the cooking chamber toward the lower heaters. With the electric oven configured as stated above, heat generated by the lower heaters is transferred to the cooking chamber in the form of conductive heat and convective heat, resulting in fast and efficient heat transfer and even cooking of food.

Owner:SAMSUNG ELECTRONICS CO LTD

Continuous flow thermal device

ActiveUS7709250B2Improve heat transfer efficiencyAvoid vaporizationBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringThermal contact

The present invention provides a thermal cycling device including: a heat exchanger body (3) having a longitudinal axis and longitudinally divided to provide at least two segments which are able to be heated to different temperatures so that said body has peripheral surfaces of different temperatures; a conduit (2) extending about said body so as to be in thermal contact with said peripheral surfaces; a first delivery device to deliver a first fluid to said conduit to cause said fluid to pass therealong and therefore change in temperature as the fluid passes said segments; and a second delivery device to deliver a second fluid to said conduit so as to flow with said first liquid and therefore also change in temperature. The fluid then leaves the device by conduit (4). The invention also is directed to an injector means for use in the thermal cycling device of this invention, comprising: a septum (26); a needle (20) which is able to pierce the septum; a reservoir (27) in fluid contact with septum (26) having an inlet (28) and an outlet (30); wherein when in use, the needle is urged through the fluid in said reservoir and then through the septum while continually purging the reservoir with said purge fluid. The present invention also includes a scanning detector (5) fitted to the outside of the heat exchange body (3) which monitors the course of reaction inside the conduit (2).

Owner:QIAGEN GMBH

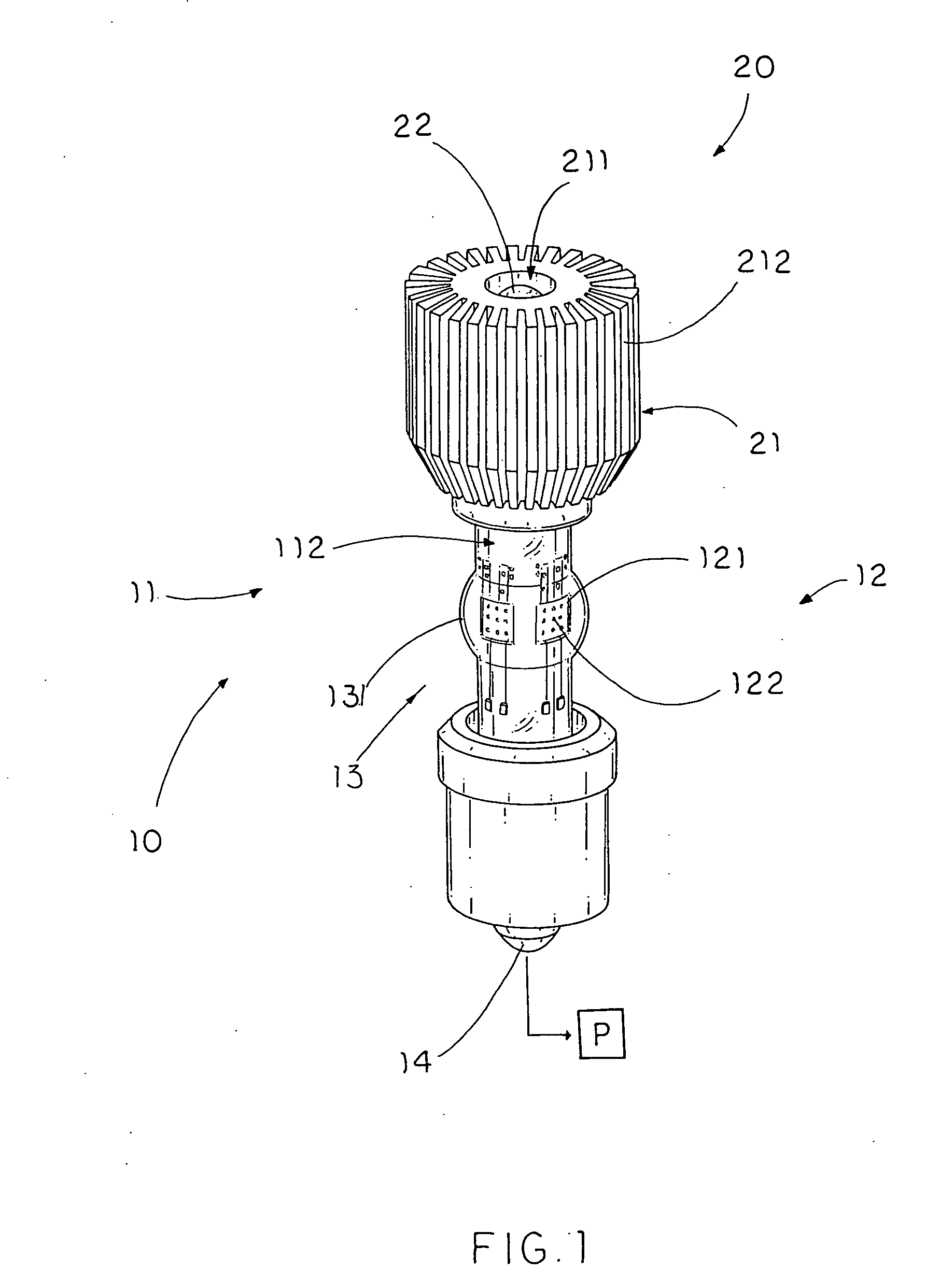

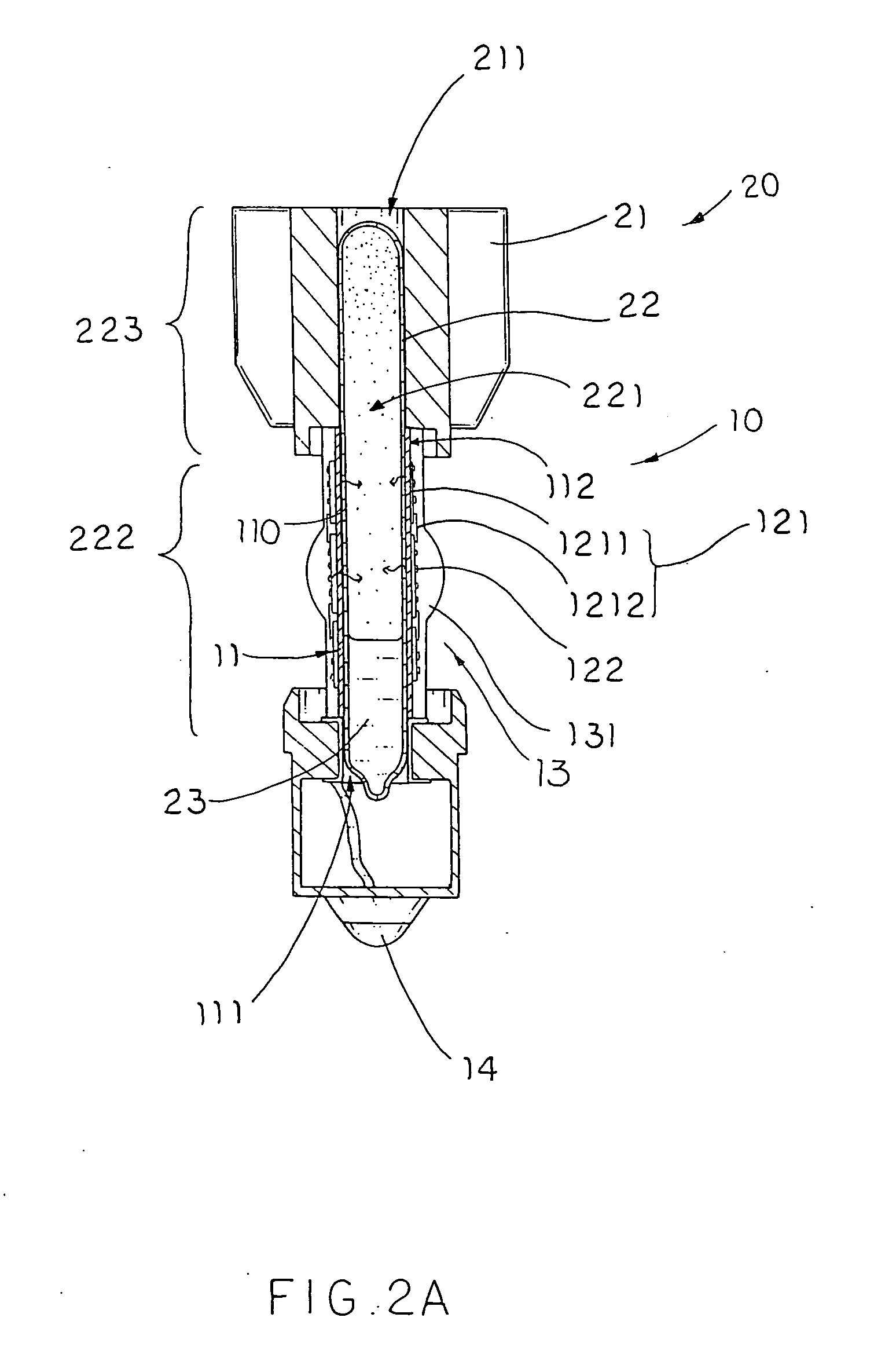

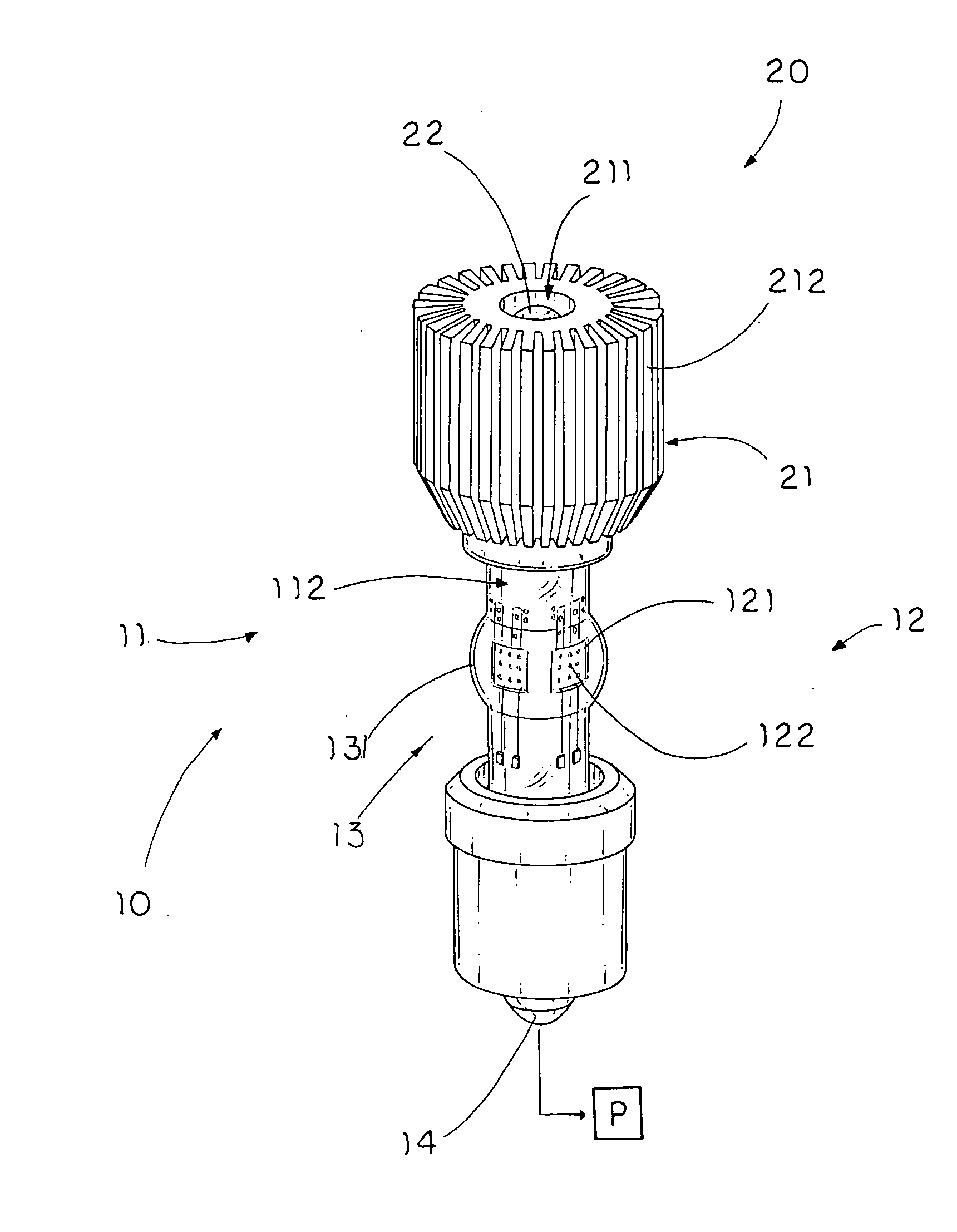

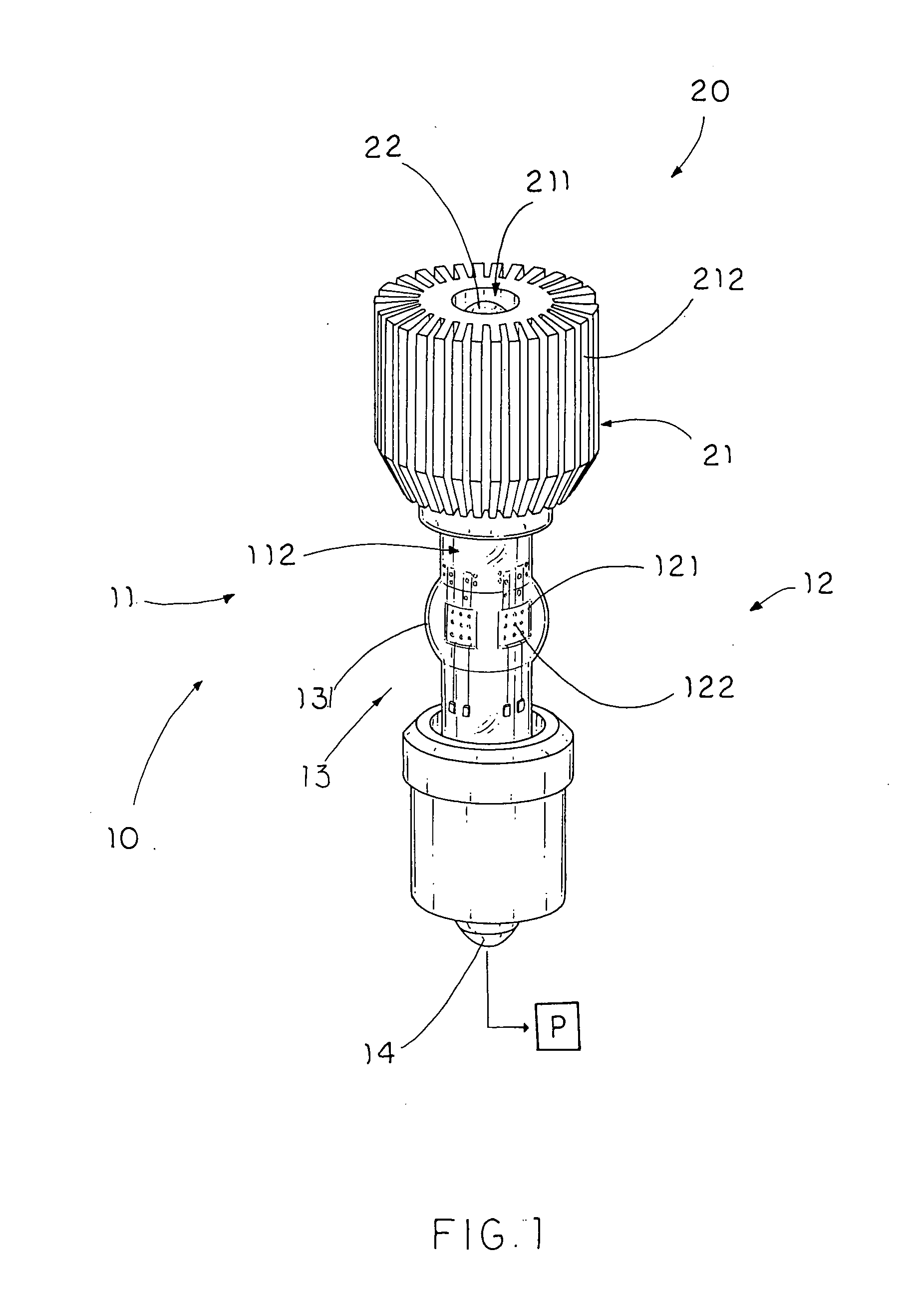

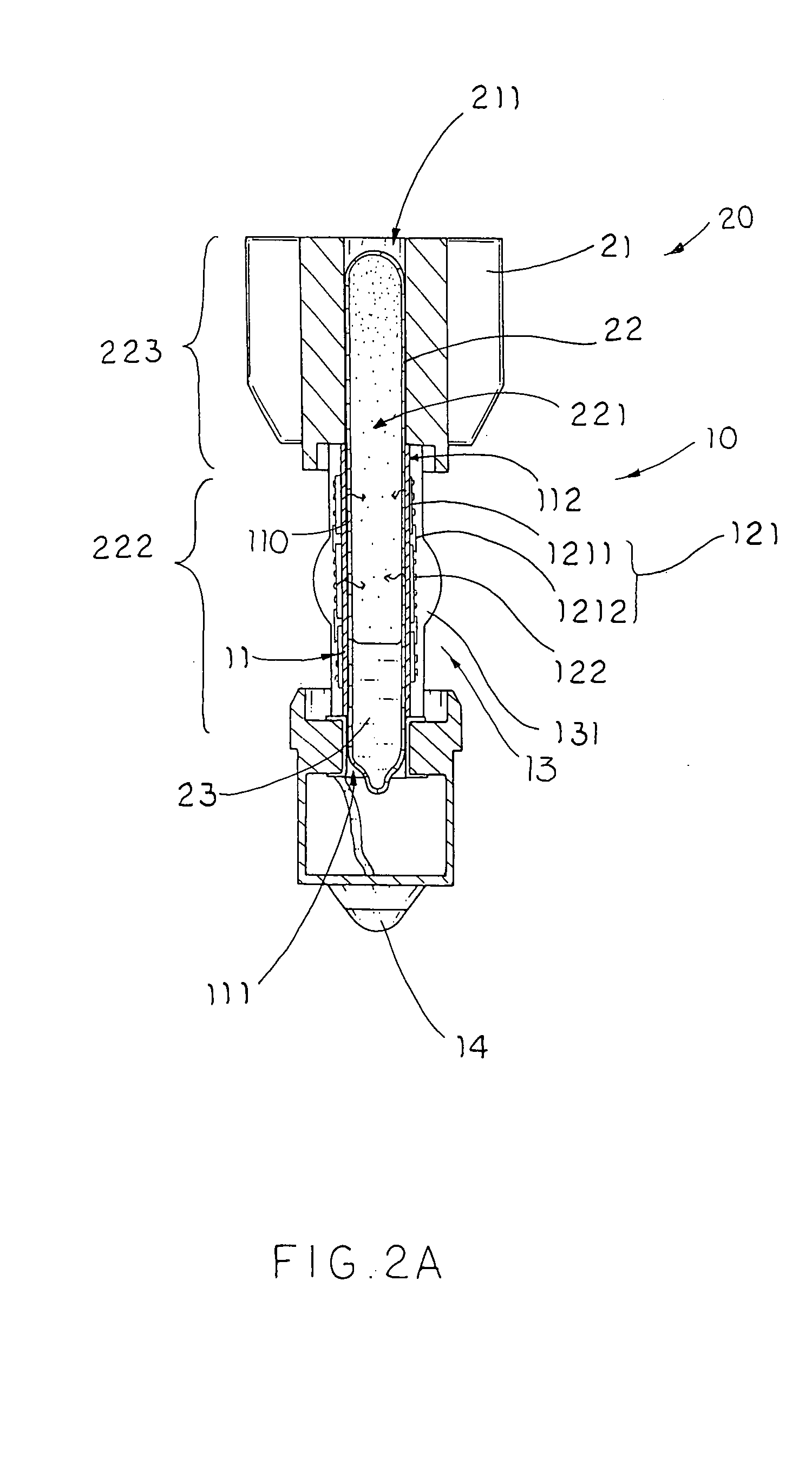

Light source with heat transfer arrangement

InactiveUS20050041428A1Improve conductivityFast heat transferPoint-like light sourceLighting heating/cooling arrangementsInterior spaceElectrical conductor

Owner:A L LIGHTECH

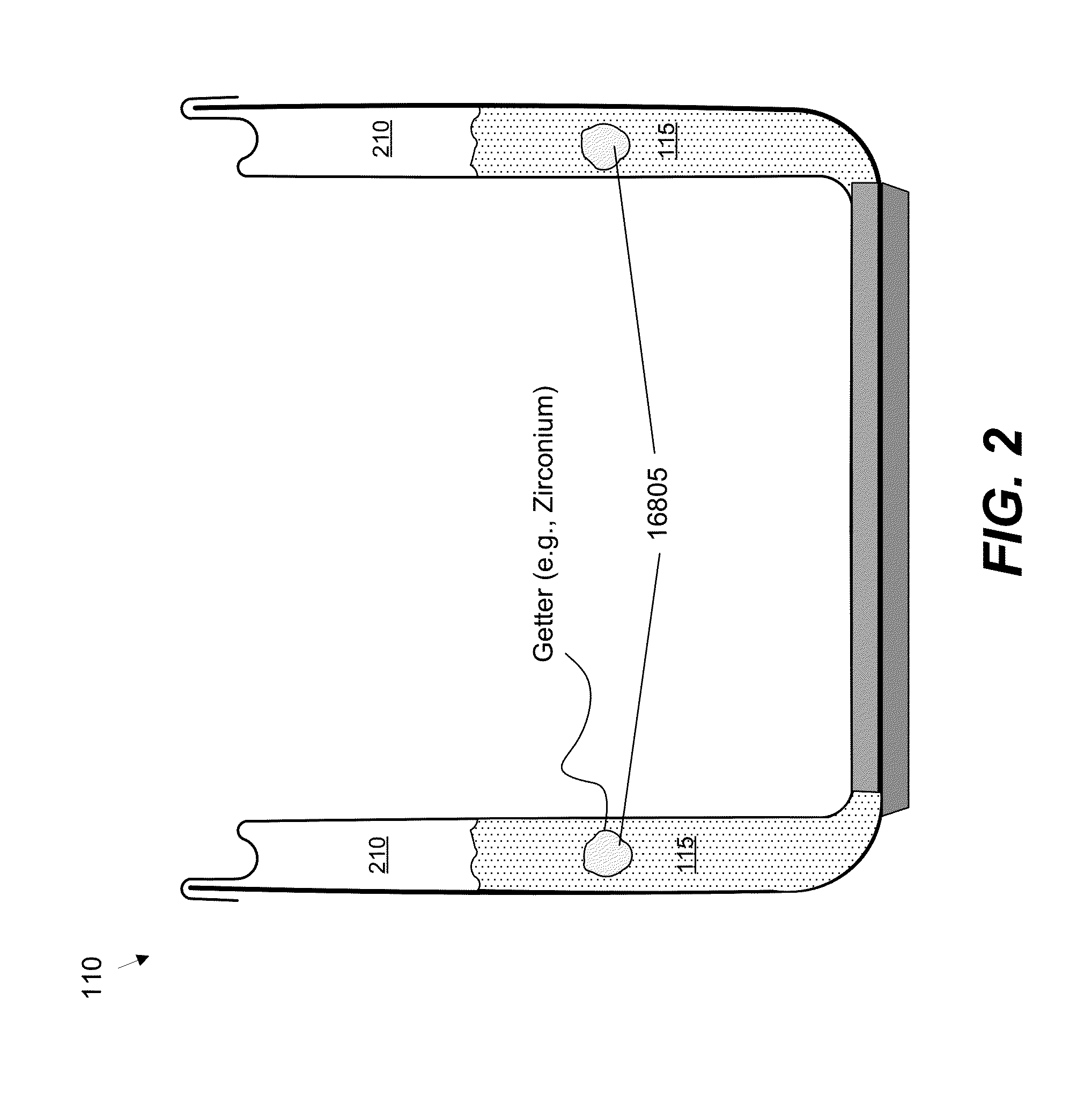

Electrostatic chuck

InactiveUS6141203AFast heat transferMinimize risk of damageSleeve/socket jointsSemiconductor/solid-state device manufacturingPotential differenceDielectric surface

An electrostatic chuck is provided having a plurality of small electrostatic structures for holding an electrically conductive workpiece forming a plate of a capacitor. Each electrostatic structure includes a first thermally conductive single-crystal dielectric sheet, and a first electrode in sheet form sandwiched between the first dielectric sheet and a second dielectric surface. The workpiece, typically a conductive or semiconductive wafer, is juxtaposed to the first dielectric sheet of each electrostatic structure and forms a second electrode. The second dielectric sheet, if thick, is used as a thermally conducting base plate which can be attached to a low pressure reactor. If the second dielectric is a thin sheet, then it is mounted to a thermally conductive metal base plate through which heat can be controllably conducted. The resultant electrostatic structure may be brazed to the metal base plate if the thermal expansion characteristics of the two elements are sufficiently matched. The first thermally conductive dielectric sheet is preferably formed of sapphire (Al2O3), which is sufficiently thermally conductive to allow for rapid heat transfer between the base plate and the workpiece. The first electrodes of different electrostatic structures are held at different electrical potentials (typically of several thousand volts difference) and a charge is maintained by this potential difference between selected electrostatic structures.

Owner:SHERMAN ARTHUR

Frozen dessert product

InactiveUS20060134274A1Simple structureStructure is undesirableMilk preservationWort preparationFood flavorLiquid nitrogen

The present invention is directed to formulations of the premix utilized in the production of a pellet structured frozen dessert type product. The pelletized frozen dessert product is manufactured by introducing the liquid premix into a body of a cryogen such as liquid nitrogen such that the small volume of liquid premix is frozen rapidly. The invention elevates the melting temperature as well as the fusing temperature of the finished pellets such that the storage and serving temperatures of the pellets are similar to the bulk products. The invention utilizes the basic formulas and names and flavors associated with bulk type frozen desserts such as Ice Cream, Sorbet, Water ice, Ice Milk, Frozen Yogurt and similar type products. The pellet produced utilizing the pre-mix is structurally stable at normal retail and home freezer situations. The formulation and manufacture of the pelletized dessert product is substantially different from bulk frozen desserts: it is in itself a unique type product. The result of this invention is a product that maintains the desired individuality of the pellets while maintaining structure, such that fusing is inhibited at the storage and serving temperature.

Owner:FROZEN NORTH TRADING

Apparatus and Process for the Pyrolysis of Agricultural Biomass

InactiveUS20080197012A1Prevent escapeFast heat transferFluidized bed combustionCombustible gas coke oven heatingCombustion chamberFluidized bed

An integrated combustion chamber and fluidized bed pyrolysis reactor. In one embodiment, the combustion chamber is cylindrical and the pyrolysis reactor is provided annularly about the combustion chamber with an annular wall that provides a common surface for heat transfer. A lift tube in fluid communication with the pyrolysis reactor is provided within the combustion chamber for circulating biomass and an inert fluidizable media upwardly through the lift tube; this advantageously increases heat transfer and leads to more rapid pyrolysis. The media and biomass exit the lift tube into either a freeboard area of the pyrolysis reactor or into a low density region of the fluidized bed. A condensable gaseous product is produced during pyrolysis that has economic value. The apparatus and process are especially well suited to the pyrolysis of low density agricultural biomass. The apparatus is compact and particularly well suited to mobile operation.

Owner:AGRI THERM

Light source with heat transfer arrangement

ActiveUS20050024875A1High heat conductivityQuickly and effectively transferPoint-like light sourceLighting heating/cooling arrangementsInterior spaceElectrical conductor

A light source includes a light head and a heat transfer arrangement. The light head includes a tubular supporting frame, which has an interior space, and a luminary unit provided on the supporting frame. The heat transfer arrangement, for dissipating heat generated from the light head, includes a heat sink and a heat conductor having a sealed chamber, which has a first portion in the supporting frame and a second portion extended to the heat sink, and a cooling agent contained in the sealed chamber of the heat conductor, wherein the cooling agent is capable of being vaporized by the heat of the luminary unit and condensed by said heat sink so as to substantially enable the heat to flow from the luminary unit towards the heat sink.

Owner:CHEN AMY YUN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com