Aqueous coating with high heat-dissipation performance and preparation method thereof

A water-based coating, high heat dissipation technology, applied in anti-corrosion coatings, conductive coatings, epoxy resin coatings, etc., can solve the problems of large pollution, unsatisfactory heat dissipation effect of heat dissipation coatings, etc., to achieve good heat dissipation effect, green environmental protection price, enhanced cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

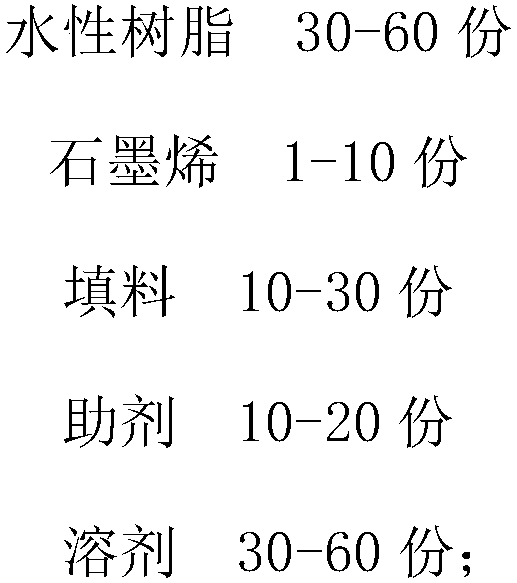

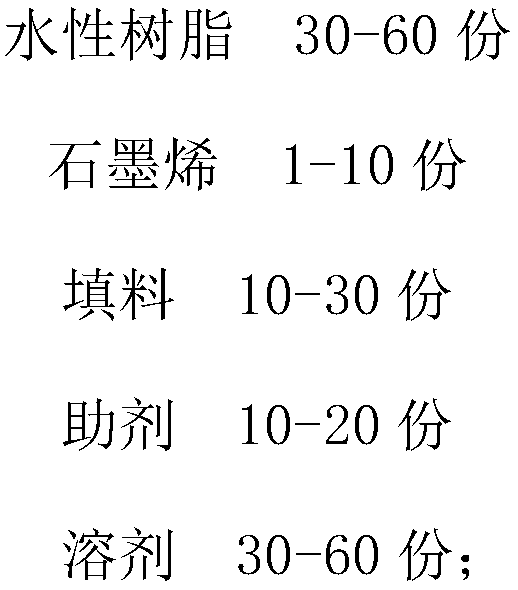

Method used

Image

Examples

Embodiment 1

[0023] Mix 30 parts of acrylic resin, 10 parts of graphene, and 60 parts of water into the blender, control the speed at 2000 rpm, and stir for 2 hours; add 15 parts of aluminum nitride, 10 parts of silicon carbide, 5 parts of carbon nanotubes, carboxymethyl 4 parts of sodium cellulose, 4 parts of polydimethylsiloxane, 4 parts of ethylenediamine, 4 parts of polyether modified polydimethylsiloxane, 4 parts of aminopropyl trimethoxysilane, control The rotation speed is 2000rpm, and the stirring time is 3h; the above mixture is put into a sand mill to grind and disperse for 1h, and the graphene heat dissipation coating is obtained.

Embodiment 2

[0031] Mix 30 parts of acrylic resin, 1 part of graphene, and 30 parts of water into the mixer, control the rotation speed at 1000 rpm, and stir for 1 hour; add 15 parts of aluminum oxide, 5 parts of carbon black, and 2 parts of sodium carboxymethyl cellulose to the mixer in sequence. 2 parts, 2 parts of polydimethylsiloxane, 2 parts of ethylenediamine, 2 parts of polyether modified polydimethylsiloxane, 2 parts of aminopropyl trimethoxysilane, control the speed of 1000rpm, stirring time 1h; add the above mixture into a sand mill to grind and disperse for 1h to obtain a graphene heat dissipation coating.

[0032] Comparative example 1, this comparative example is basically the same as Example 1, but heat dissipation coating is prepared without adding graphene. Mix 30 parts of acrylic resin and 30 parts of water into the blender, control the speed at 1000 rpm, and stir for 1 hour; add 15 parts of aluminum oxide, 5 parts of carbon black, 2 parts of sodium carboxymethyl cellulose...

Embodiment 3

[0039] Mix 40 parts of acrylic resin, 5 parts of graphene, and 35 parts of water into the mixer, control the rotation speed at 1500 rpm, and stir for 1.5 hours; add 10 parts of aluminum nitride, 5 parts of magnesium oxide, 5 parts of carbon nanotubes, and carboxylate to the mixer in sequence. 3 parts of sodium methylcellulose, 3 parts of polydimethylsiloxane, 3 parts of ethylenediamine, 3 parts of polyether modified polydimethylsiloxane, 3 parts of aminopropyl trimethoxysilane, The rotation speed is controlled at 1500rpm, and the stirring time is 2h; the above mixture is put into a sand mill to grind and disperse for 1h, and the graphene heat dissipation coating is obtained.

[0040]Comparative example 1, this comparative example is basically the same as Example 1, but heat dissipation coating is prepared without adding graphene. Mix 40 parts of acrylic resin and 35 parts of water into the mixer, control the speed at 1500 rpm, and stir for 1.5 hours; add 10 parts of aluminum n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com