Method for comprehensively recovering valuable metals from waste lithium-ion battery material

A technology for lithium-ion batteries and valuable metals, which is applied in the field of recycling and electronic waste recycling, can solve the problems of complex purification and separation procedures and difficulties in lithium recovery, and achieve the effects of low reagent cost, high recovery rate, and high-efficiency recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

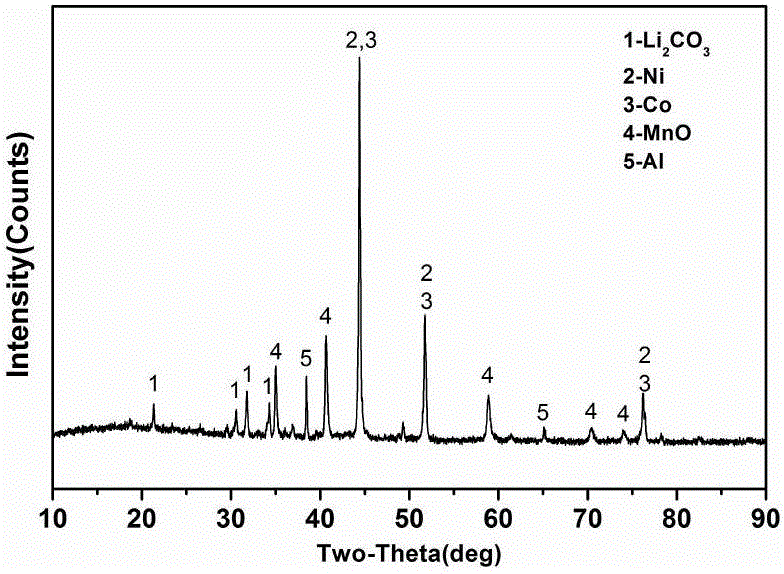

[0024] 10g of nickel-cobalt-manganese ternary lithium-ion battery waste was crushed and ground, then mixed evenly with 6g of lignite with a carbon content of 45%, and placed in a muffle furnace for reduction roasting. The reduction roasting temperature was controlled at 500°C and the roasting time was 5 hours. The roasted product is placed in water at a solid-to-liquid ratio of 1:20 for water immersion while passing CO 2 , the incoming CO 2 The molar amount is 0.65 times of the lithium molar amount in the solution, the water immersion temperature is 5°C, the time is 0.5 hour, the pH is controlled to 8.13, and the lithium-containing aqueous solution is obtained by filtration after water immersion, which can be used to prepare lithium carbonate products. The filter residue was added to a 1.5mol / L sulfuric acid solution at a solid-to-liquid ratio of 1:20, while air was blown in, stirred at a constant temperature of 50°C for 5 hours, and filtered to obtain a sulfate solution conta...

Embodiment 2

[0026] Simply crush and finely grind the scrapped lithium cobalt oxide battery soft pack, and measure the carbon content in it to be 1.8%, then mix 10g of battery waste powder with 1g of anthracite with a carbon content of 91%, and place it in a muffle furnace for reduction For roasting, control the reduction roasting temperature to be 500° C., and the roasting time is 3 hours. Weigh the product after reduction and roasting, place it in water for water immersion according to the solid-to-liquid ratio of 1:15, and introduce CO 2 , the incoming CO 2 The molar amount is 4.6 times the lithium molar amount in the solution, the water immersion temperature is 25°C, the time is 2 hours, the pH is controlled to 8.56, and the lithium-containing aqueous solution is obtained by filtration after water immersion, which can be used to prepare lithium carbonate products. The filter residue was added to a 3mol / L sulfuric acid solution at a solid-to-liquid ratio of 1:10, while oxygen was blown...

Embodiment 3

[0028] 10g of lithium manganate battery waste was crushed and ground, then mixed evenly with 5g of bituminous coal with a carbon content of 75%, and placed in a muffle furnace for reduction roasting. The reduction roasting temperature was controlled at 750°C and the roasting time was 1 hour. Weigh the product after reduction and roasting, put it in water for water immersion according to the solid-liquid ratio of 1:10, and introduce CO 2 , the incoming CO 2 The molar amount is 3.8 times of the lithium molar amount in the solution, the water immersion temperature is 30°C, the time is 3 hours, the pH is controlled at 9.00, and the lithium-containing aqueous solution is obtained by filtration after water immersion, which can be used to prepare lithium carbonate products. The filter residue was added to a 4mol / L nitric acid solution at a solid-to-liquid ratio of 1:3, and hydrogen peroxide was added at the same time, stirred at a constant temperature of 20°C for 10 hours, and then f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com