Artificial graphite lithium ion battery anode material and preparation method thereof

A lithium-ion battery, artificial graphite technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low capacity and poor compaction performance of lithium-ion battery carbon anode materials, and achieve the first discharge capacity improvement, comprehensive Excellent performance and good safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

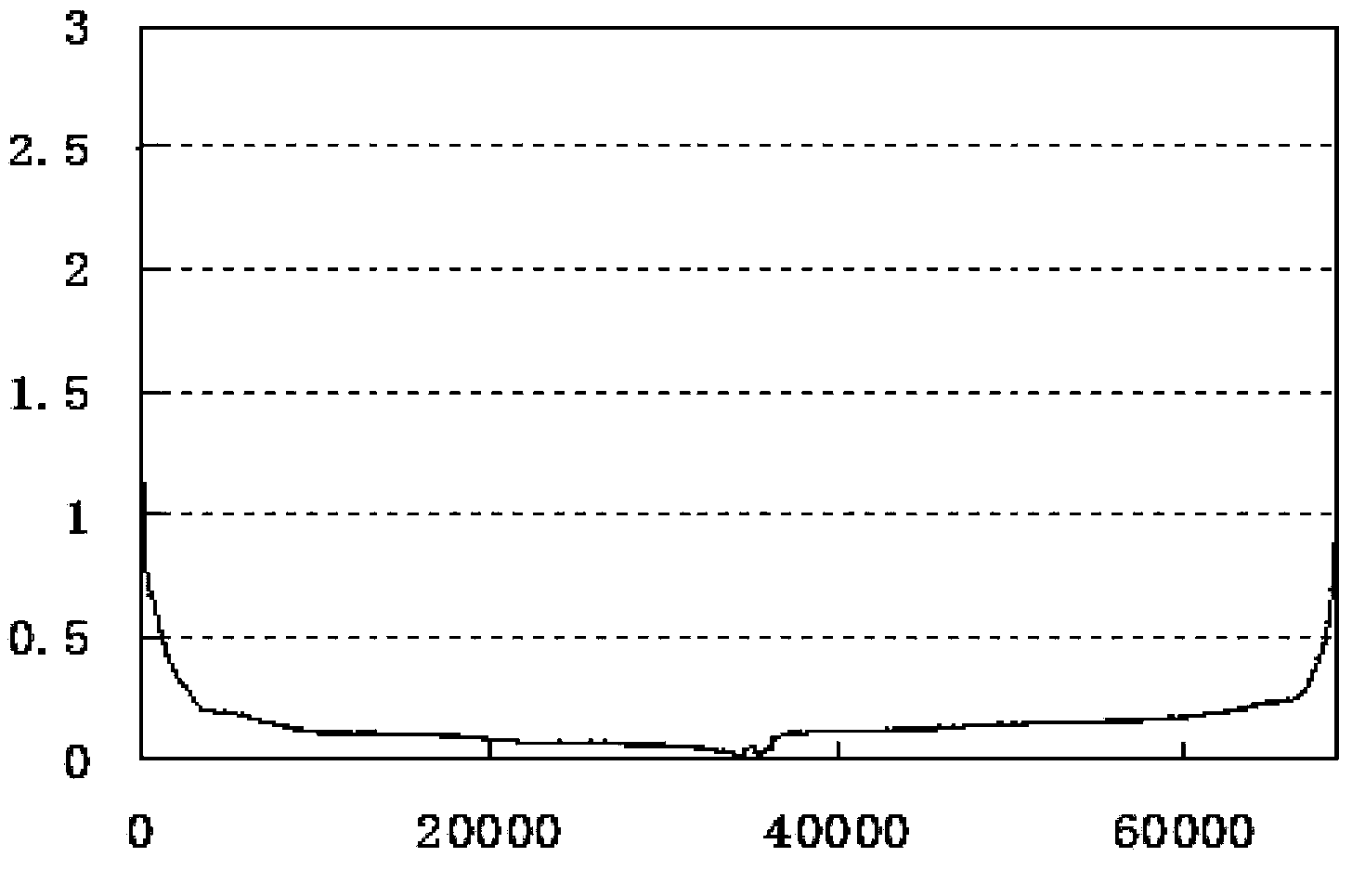

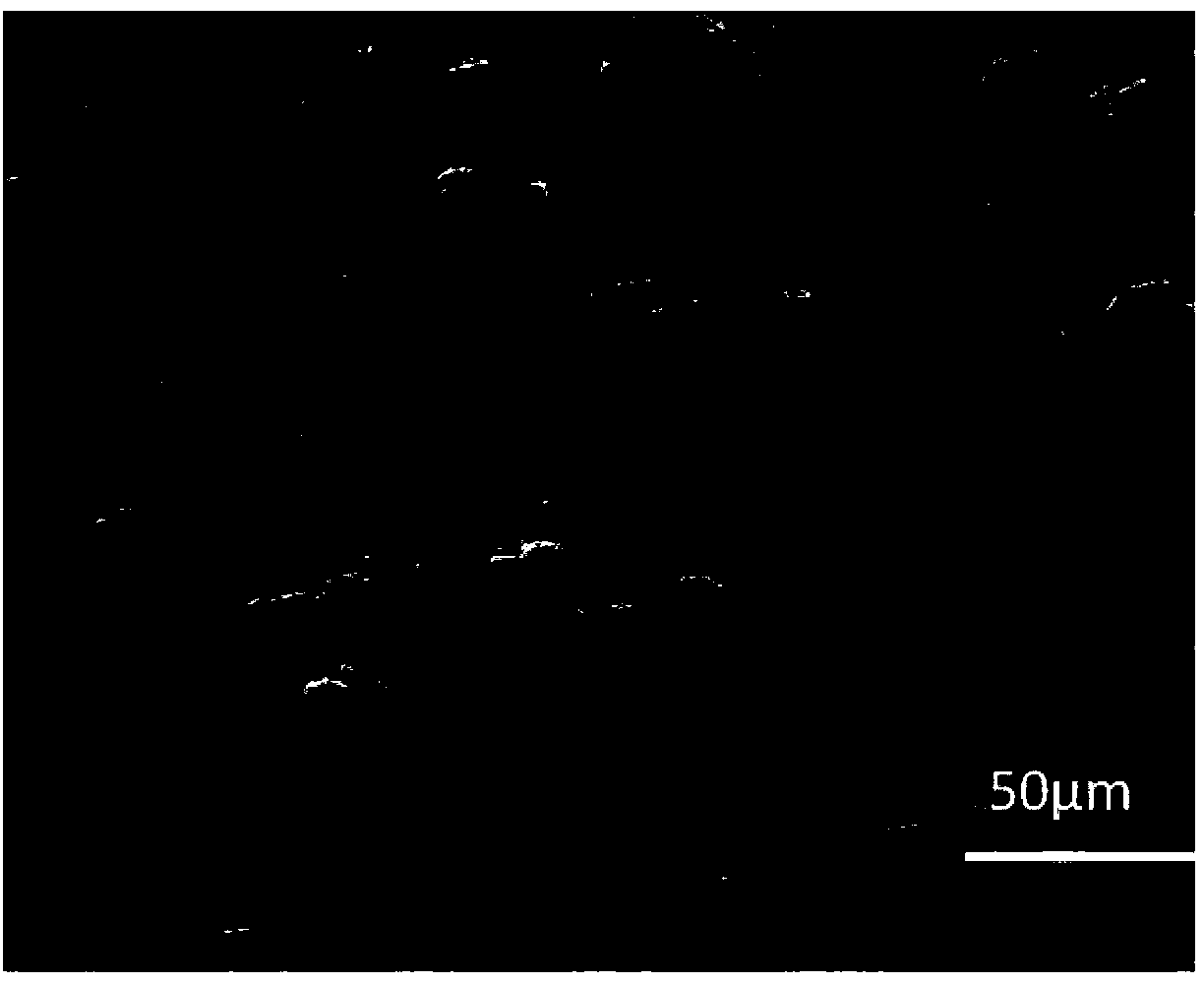

[0034] A method for preparing an artificial graphite lithium-ion battery negative electrode material, comprising the following steps: ① kneading coal tar soft pitch and nano silicon powder in a pitch kneader at 80° C. for 2 hours at a weight ratio of 5:1 until the mixture is uniform Afterwards, carry out thermal polymerization reaction at 420°C for 3 hours; ②The product after the reaction is subjected to decompression treatment, the temperature of decompression treatment is 350°C, the vacuum degree of decompression treatment is -0.08MPa, and the decompression treatment time is 1 hour ; ③Carry out carbonization treatment at 1150°C for 5 hours under the protection of an inert gas to obtain block materials, which are crushed and classified by a crushing and classifying machine to obtain particles with a D50 particle size of 20.2 μm; ④at 3000°C The graphitization treatment was carried out for 5 hours to obtain the artificial graphite lithium ion battery negative electrode material ...

Embodiment 2

[0036] The preparation method of artificial graphite lithium-ion battery negative electrode material, it comprises the following steps: ① knead coal tar soft pitch and nano-silicon dioxide at 80 ℃ in a pitch kneader for 2 hours at a weight ratio of 10:1, until mixed After uniformity, thermal polymerization reaction was carried out at 400°C for 4 hours; ②The product after the reaction was subjected to decompression treatment, the temperature of decompression treatment was 370°C, the vacuum degree of decompression treatment was -0.09MPa, and the decompression treatment time was 1.5 3 hours; ③Carry out carbonization treatment at 800°C for 6 hours under the protection of inert gas to obtain block materials, which are crushed and classified by a crushing and classifying machine to obtain particles with a D50 particle size of 18.0 μm; ④at 3000°C Graphitization treatment was carried out for 4 hours to obtain an artificial graphite lithium-ion battery negative electrode material with a...

Embodiment 3

[0038] The preparation method of artificial graphite lithium-ion battery negative electrode material, it comprises the following steps: ① knead coal tar soft pitch and nano-silicon carbide at 80 ℃ in a pitch kneader for 2 hours at a weight ratio of 20:1 until the mixture is uniform Afterwards, carry out thermal polymerization reaction at 430°C for 2 hours; ②The product after the reaction is subjected to decompression treatment, the temperature of decompression treatment is 390°C, the vacuum degree of decompression treatment is -0.08MPa, and the decompression treatment time is 1 hour ; ③Carry out carbonization treatment at 1200°C for 4 hours under the protection of an inert gas to obtain block materials, which are crushed and classified by a crushing and classifying machine to obtain particles with a D50 particle size of 22.0 μm; ④at 3000°C The graphitization treatment was carried out for 8 hours to obtain the artificial graphite lithium ion battery negative electrode material w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com