Electrode material and lithium ion battery with same

A technology of electrode materials and electrode active materials, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, battery electrodes, etc., can solve problems affecting battery performance, high cost, serious gas inflation, etc., to improve safety performance and quality assurance , high discharge capacity for the first time, and the effect of solving the problem of inflation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

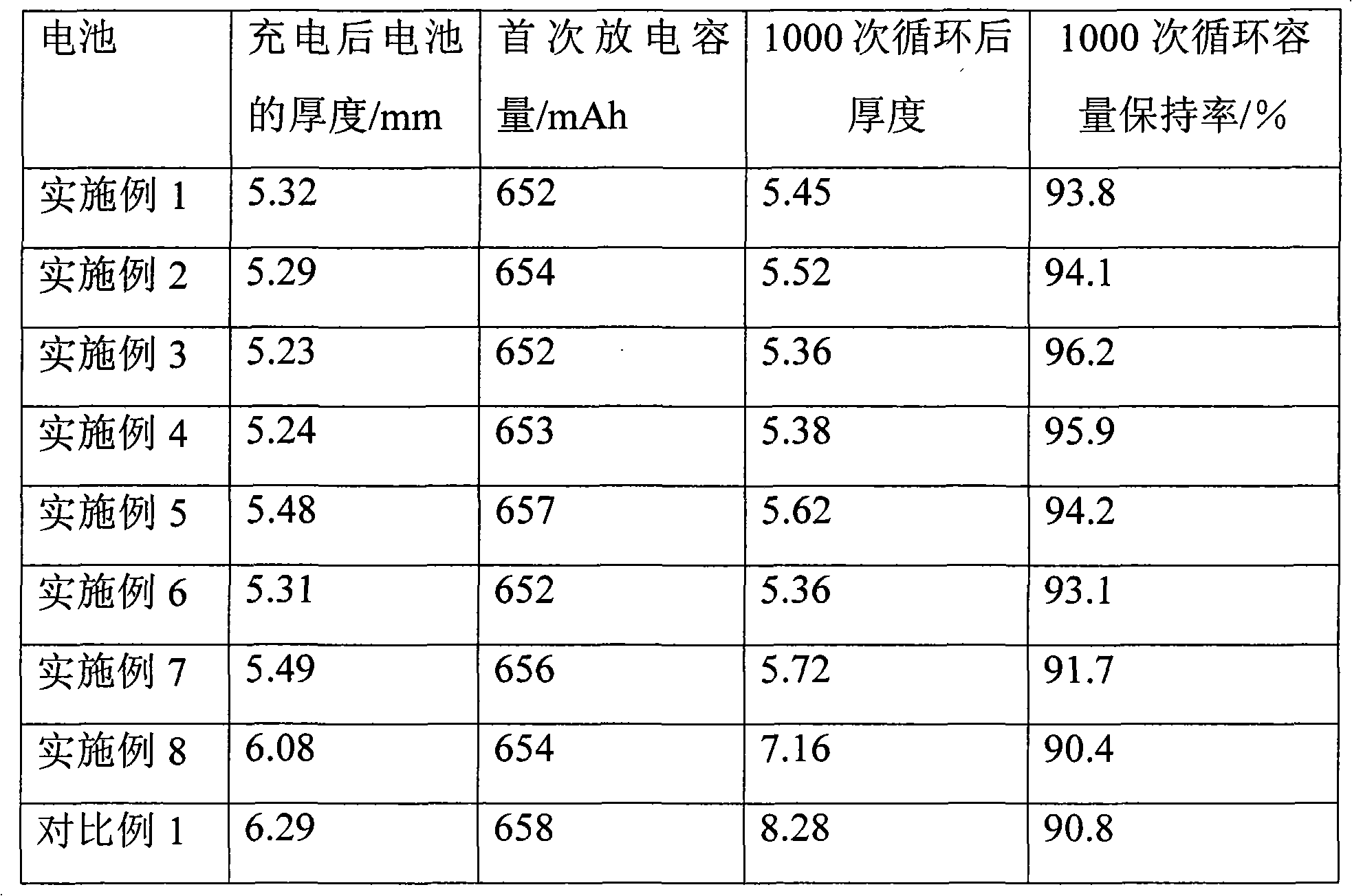

Examples

Embodiment 1

[0016] (1) Ingredients of electrode materials

[0017] LiFePO 4 , acetylene black, PVDF, and PVP are dosed according to a weight ratio of 100:5:6:0.5 to obtain a positive electrode slurry; lithium titanate (LiTi 5 o 12 ), acetylene black, PVDF, PVP, NaNi 5 According to the weight ratio of 100:1:7:0.5:3, the negative electrode slurry is obtained.

[0018] (2) Preparation of pole piece

[0019] Use a pulper to pull one side first, dry it at 100 degrees simultaneously, and then pull the other side, and dry it at 100 degrees simultaneously. The dressing area of the positive electrode is 470*43mm, and the dressing area of the negative electrode is 490*44mm. The capacity ratio of positive and negative electrodes is 1:1.1. Then press the tablet so that the thickness of the positive side is 118 microns, the dressing amount is 5.28g, and the bulk density is 2.2g / cm 3 . The thickness of the negative electrode side is 91 microns, the dressing amount is 2.16g, and the bulk den...

Embodiment 2

[0023] Electrode materials, pole pieces and batteries are prepared in the same manner as in Example 1, except that the negative electrode slurry is made of lithium titanate (LiTi 5 o 12 ), acetylene black, PVDF, PVP, V-Ti according to the 100:1:7:0.5:3 ingredients prepared.

Embodiment 3

[0025] Electrode materials, pole pieces and batteries are prepared in the same manner as in Example 1, except that the negative electrode slurry is made of lithium titanate (LiTi 5 o 12 ), acetylene black, PVDF, PVP, ZrCr 2 Prepared according to the ingredients of 100:1:7:0.5:3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com