Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

79results about How to "No demulsification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing amphiphilic nano silica powder and method for preparing Pickering emulsion using same

InactiveCN101704529AEasy hard reunionHard reunion noNanostructure manufactureSilicaNano sio2Room temperature

The invention discloses a method for preparing amphiphilic nano silica powder and is used for preparing nano silica powder with about 90 degrees of a tri-phase contact angle. The method uses ultrasonic preparation, thus having short preparation process; the invention adopts liquid phase modification, thus avoiding processing means such as grinding, calcining and the like which are easy to cause the powder to generate hard particle agglomeration; the invention can prepare better amphiphilic surface (about 90 degrees of tri-phase contact angle) nano silica powder. The invention also discloses a method for preparing Pickering emulsion by using the amphiphilic nano silica powder under the action of ultrasound or cutting, the nano silica powder stably exists in oil-water interface, thus preventing diffused oil (water) droplets to re-agglomerate into big droplets to split phase and stabilizing emulsion. The prepared emulsion can be stored at room temperature without occurrence of demulsification in three months.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

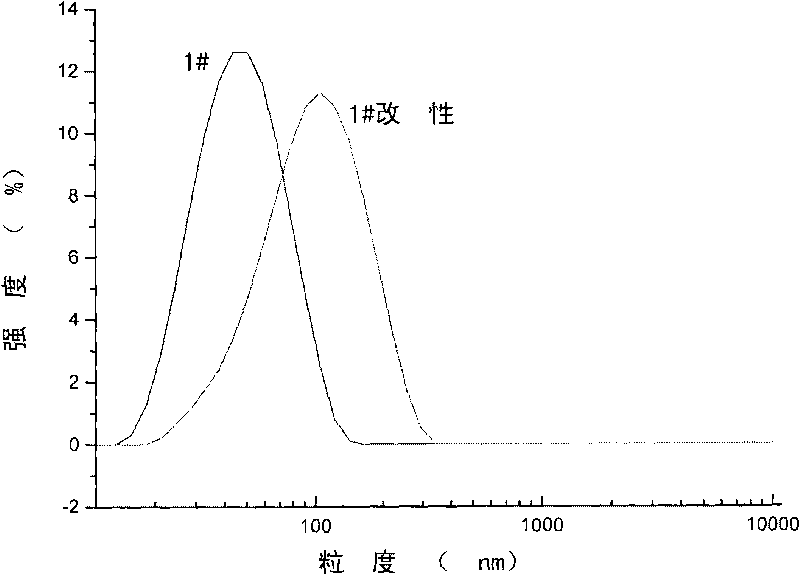

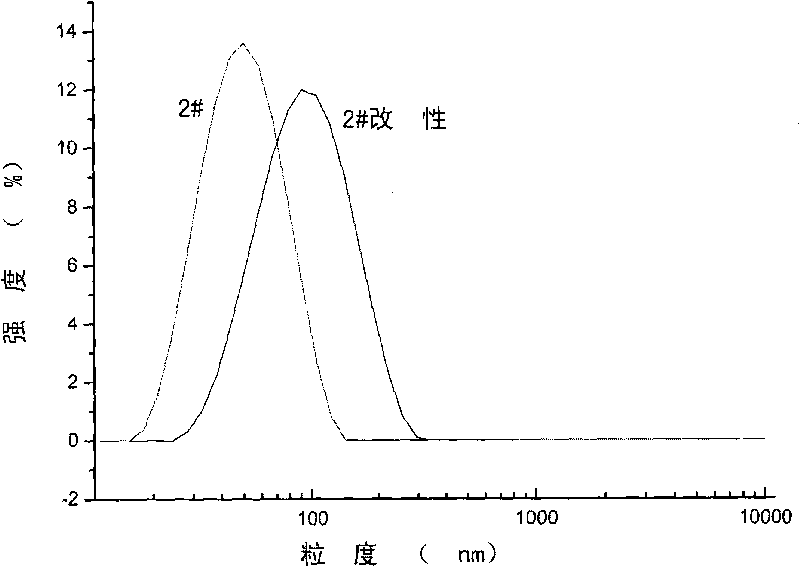

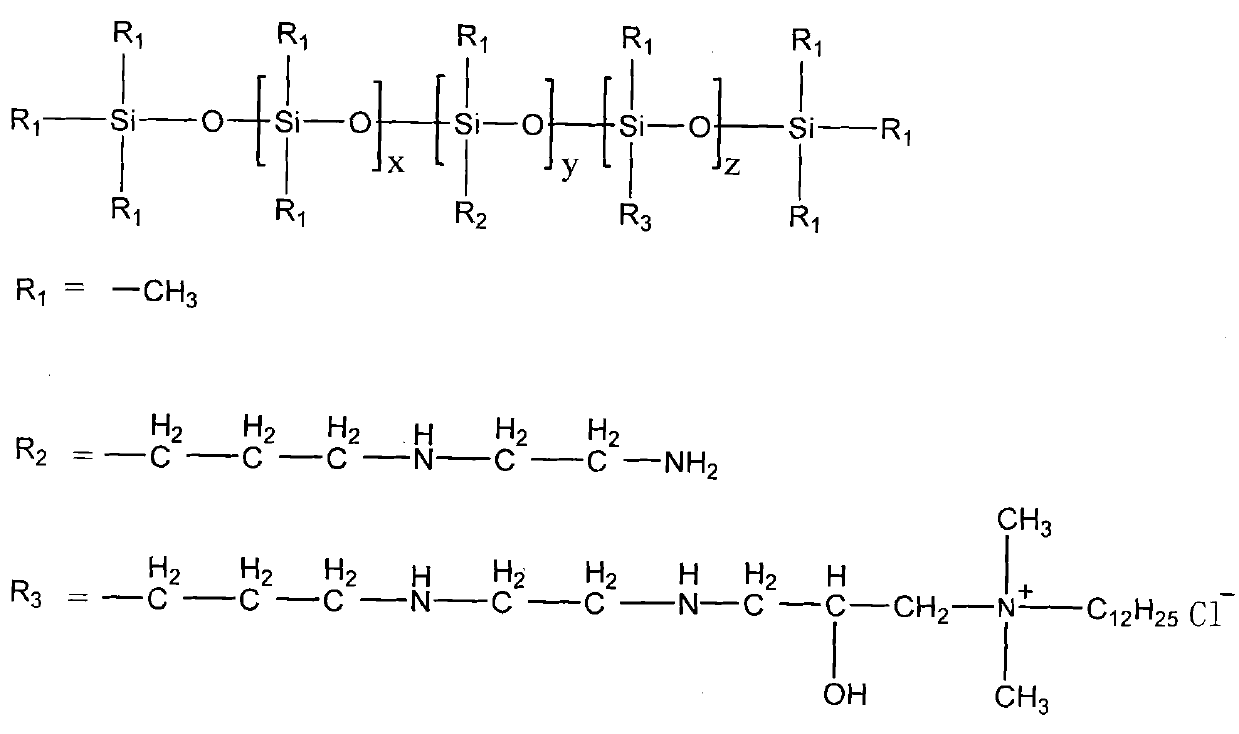

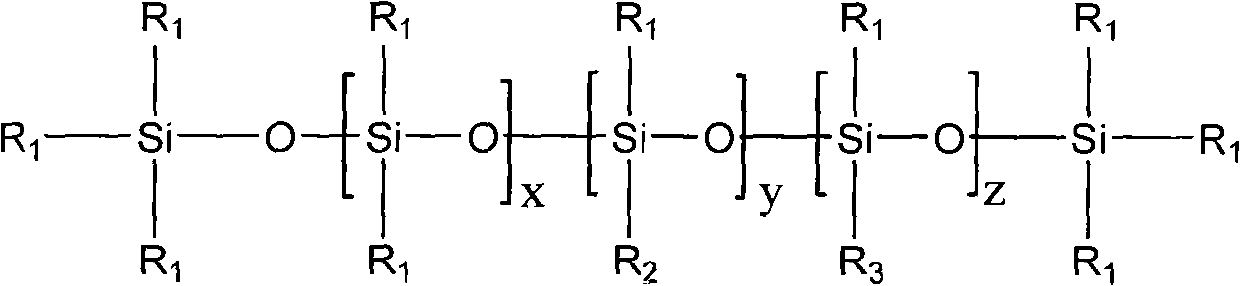

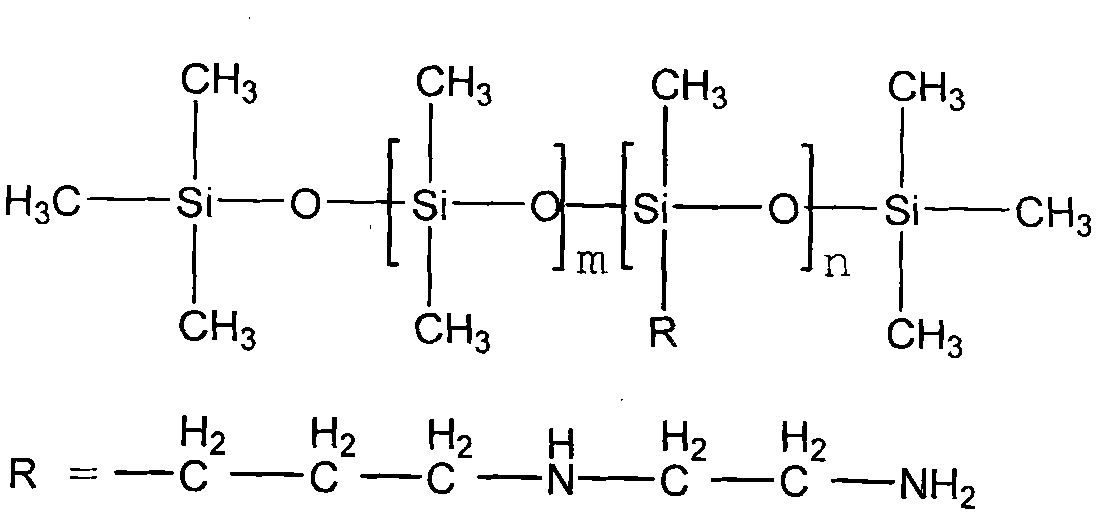

Quaternized modified amino silicone oil softener and preparation and application thereof

InactiveCN101914206AAvoid yellowingImprove hydrophilicityVegetal fibresTetramethylammonium hydroxideDisiloxane

The invention relates to a quaternized modified amino silicone oil softener and preparation and application thereof. The softener comprises the following general formula in the specification. The preparation comprises the following steps of: (1) adding octamethylcy-clotetrasiloxane into a container, adding a coupling agent N-beta-(aminoethyl)-gamma-aminopropyl methyl dimethoxysilane into the container dropwise, adding a tetramethyl ammonium hydroxide catalyst and subsequently a capping agent hexamethyl disiloxane into the container, and then performing reduced pressure distillation to obtain amino silicon oil; (2) dissolving the amino silicon oil into a solvent, adding the mixture into epichlorohydrin, stirring and heating to react under the protection of nitrogen, and removing the solvent by steaming to obtain an intermediate product; and (3) uniformly mixing N,N-dimethyl-decanamide and the solvent to obtain a mixture, stirring with heating, adding the intermediate product dropwise into the mixture under the protection of nitrogen, performing a thermostatic reaction, and removing the solvent by steaming to obtain the product. The softener of the invention has high hydrophilicity and high stability; fabric processed by the softener has excellent soft handfeel, high hydrophilicity, low yellowing, antibacterial property and the like; and the softener is simple to prepare and is suitable for industrial production.

Owner:DONGHUA UNIV

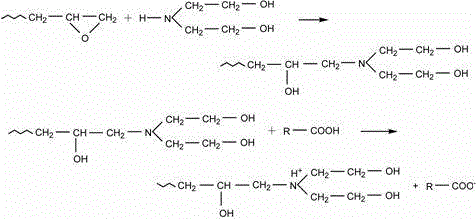

Carbon fiber water-soluble epoxy resin sizing agent

The invention discloses a carbon fiber water-soluble epoxy resin sizing agent and a preparation method thereof. The sizing agent comprises main slurry and deionized water as main components, wherein the mass ratio of the main slurry to the deionized water is (50-80):(20-50); and the main slurry consists of modified phenol-formaldehyde epoxy resin and allyl polyoxylethylene ether (AEPH), and the mass ratio of the modified phenol-formaldehyde epoxy resin to AEPH is (60-90):(10-40). The preparation method of the sizing agent comprises the following steps: firstly reacting phenol-formaldehyde epoxy resin with diethanolamine to obtain water-soluble phenol-formaldehyde epoxy resin; and then mixing the water-soluble resin with AEPH in proportion, and performing dilution to reach a certain concentration by using the deionized water to obtain the sizing agent. The sizing agent disclosed by the invention is good in stability and low in cost, cannot cause environmental pollution, and is simple in preparation method; good post-processing performance of carbon fibers can be provided by adding flexible molecular AEPH; experiments show that after the carbon fibers are coated with a proper amount of the sizing agent, the post-processing performance can be significantly improved; and the performance of a carbon fiber epoxy resin composite material can be improved.

Owner:UNIV OF JINAN

Water-based paint for quick-drying alcohol-resistance plastics and preparation method thereof

The invention discloses a water-based paint for quick-drying alcohol-resistance plastics, comprising the following components by weight parts: 20-80 parts of modified polyacrylic ester water dispersoid, 1-25 parts of coloring pigment paste, 0-10 parts of filler pump, 5-25 parts of film formation assistant, 0.5-10 parts of assistant for water-based paint, and 10-50 parts of water. The invention further discloses a preparation method of the water-based paint, comprising the following steps: the water, the film formation assistant, polymer water dispersoid resin and the assistant for partial water-based paint are added in a make-up tank and are stirred uniformly, and then the coloring pigment paste and the assistant for the remaining partial water-based paint are sequentially added in and are stirred uniformly, the viscosity and pH value are regulated, filtering and discharging are carried out to obtain the water-based plastic paint finished products. The water-based paint is used for coating surface of the plastics, so as to achieve good decoration effect; in addition, the performance of the water-based paint is equivalent to that of solvent plastic paint, the water-based paint has good alcohol resistance and can be dried at 50 DEG C for 10 minutes, so as to meet the process requirements of manufacturers who use the solvent plastic paint at present.

Owner:GUANGZHOU KINTE IND

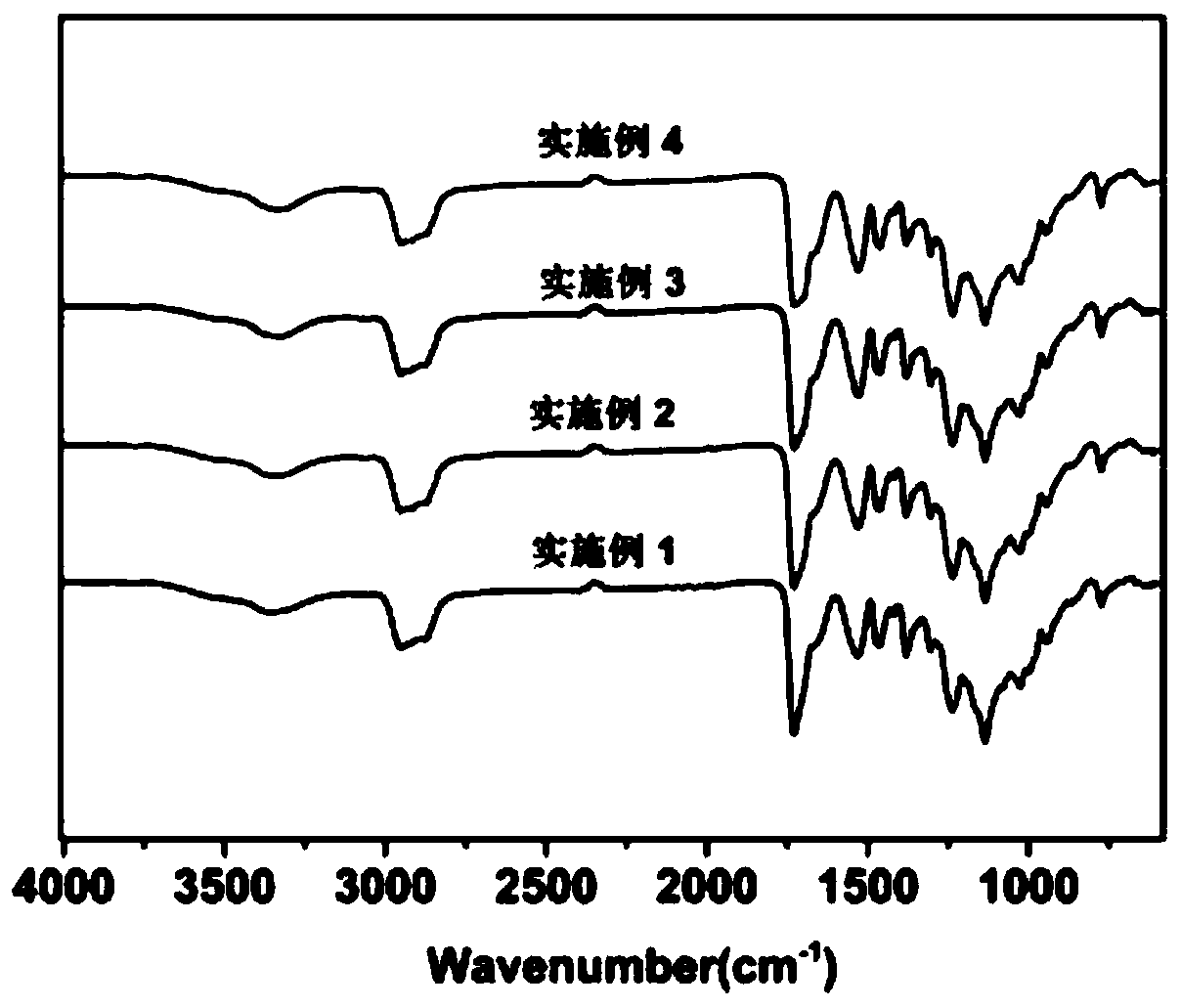

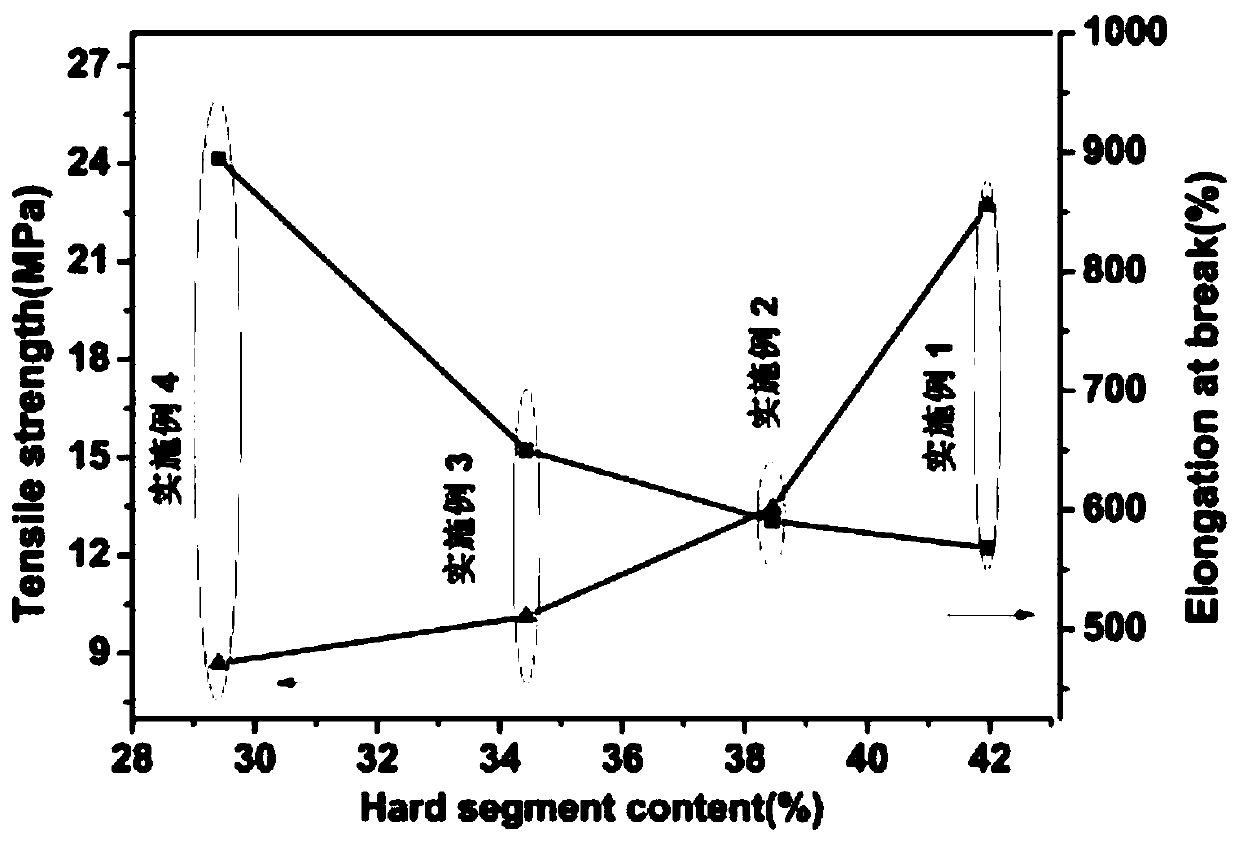

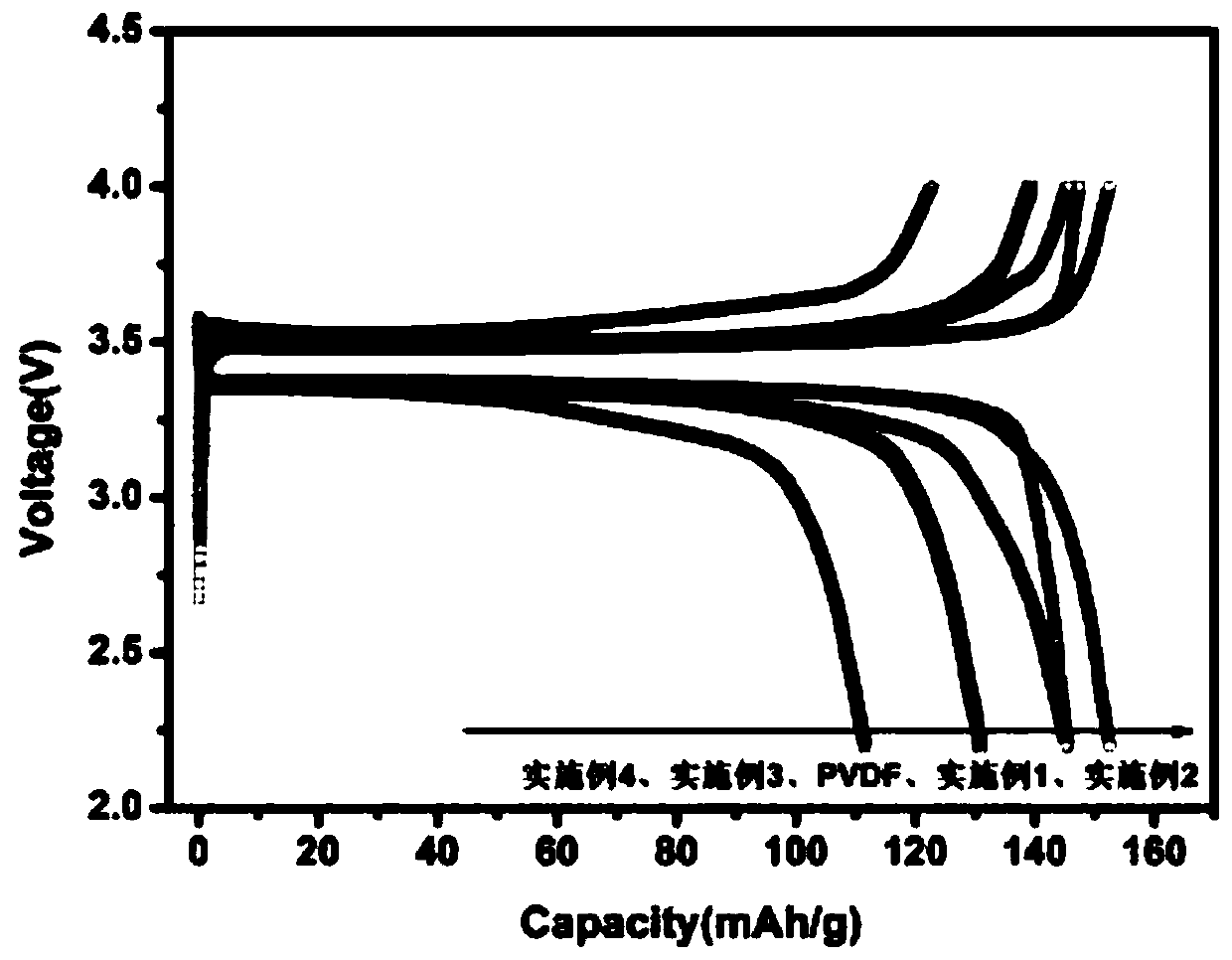

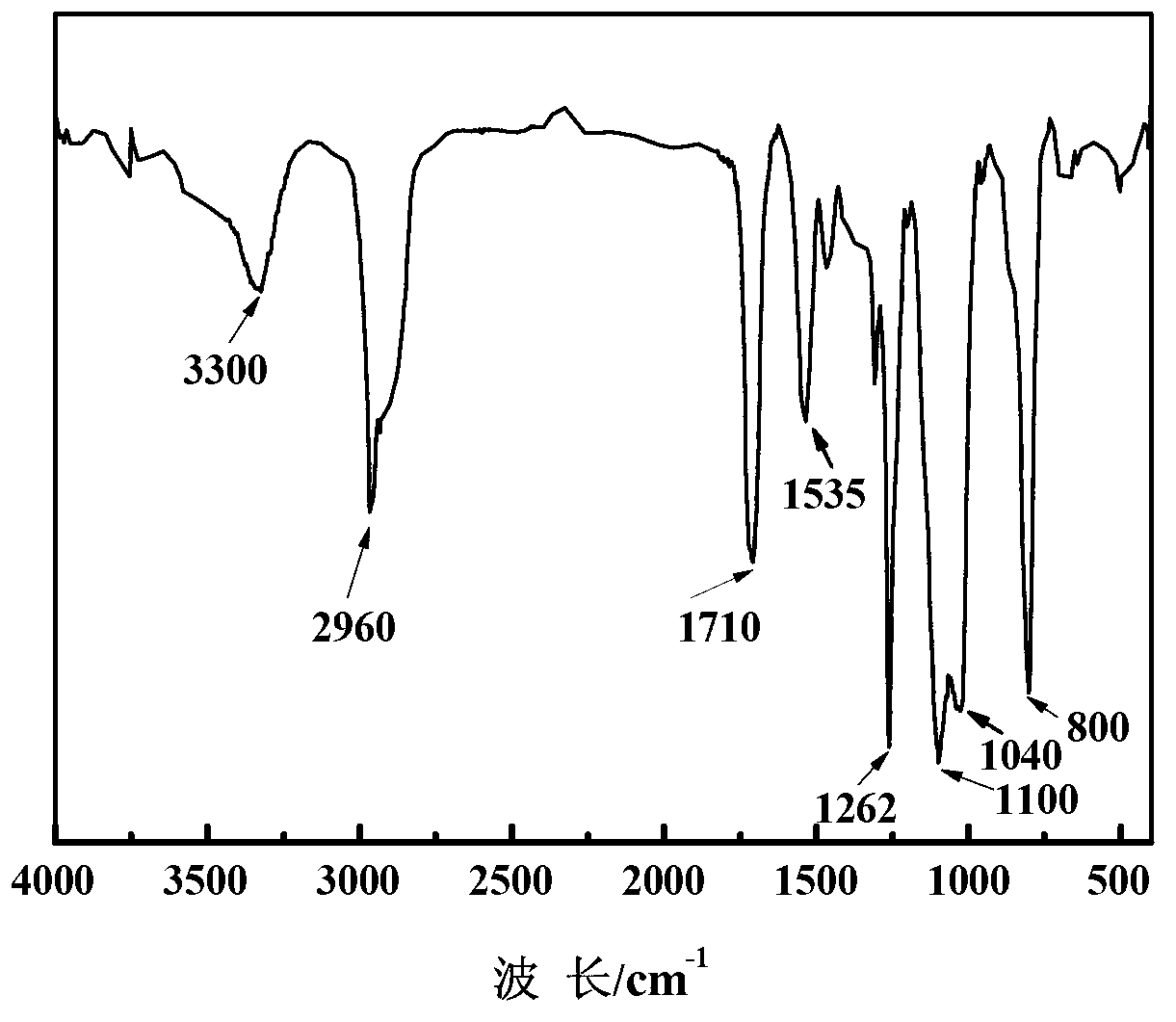

Preparation method for waterborne polyurethane binder and lithium-ion battery anode slurry containing waterborne polyurethane binder

InactiveCN110144033AImprove flexibilityNo demulsificationCell electrodesSecondary cellsHydrophilic monomerDistillation

The invention discloses a preparation method for a waterborne polyurethane binder and a lithium-ion battery anode slurry containing the waterborne polyurethane binder, and relates to the technical field of lithium ions. The preparation method for the waterborne polyurethane binder comprises the following steps: subjecting macromolecular dihydric alcohol to dehydration treatment, mixing dehydratedmacromolecular dihydric alcohol with diisocyanate, carrying out a reaction under heating, then carrying out cooling, adding a side-chain type nonionic hydrophilic monomer, carrying out a reaction under heating, then carrying out cooling, adding a micromolecular chain extender, a catalyst and a solvent, carrying out a reaction under heating, and carrying out cooling and discharging so as to obtaina prepolymer emulsion; and adding water into the prepolymer emulsion, carrying out emulsification under high-speed dispersion, then adding a diamine chain extender, and carrying out pressure-reduced distillation to remove the solvent so as to obtain a waterborne polyurethane emulsion with a side-chain structure. The polyurethane binder prepared by using the preparation method provided by the invention has good flexibility and excellent bonding performance, and is used in an anode slurry; and a button type lithium-ion battery assembled by using the anode slurry has large first discharge capacity and good cycle performance.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

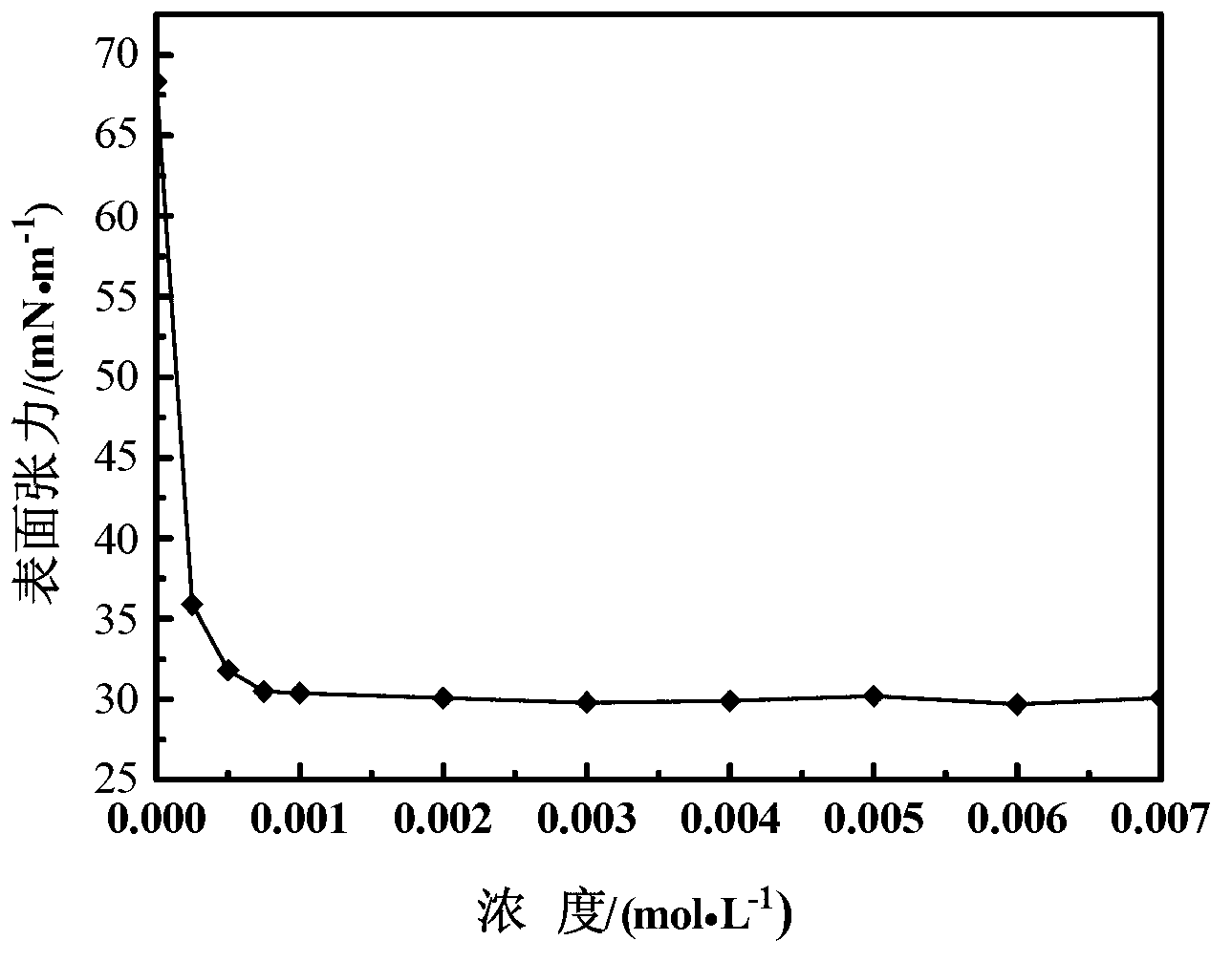

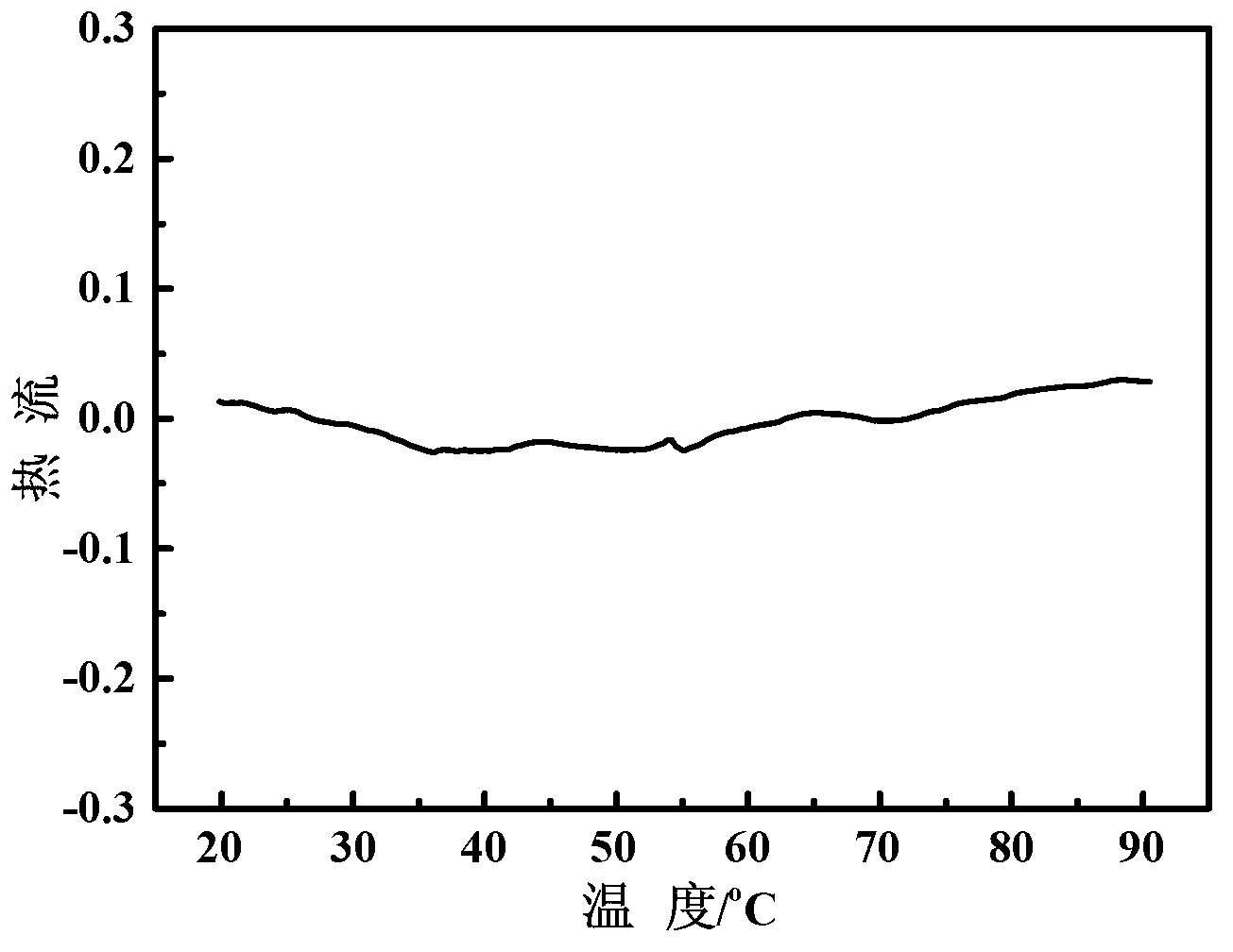

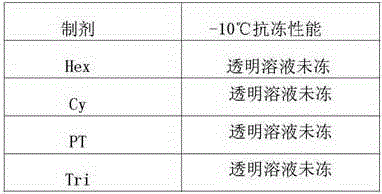

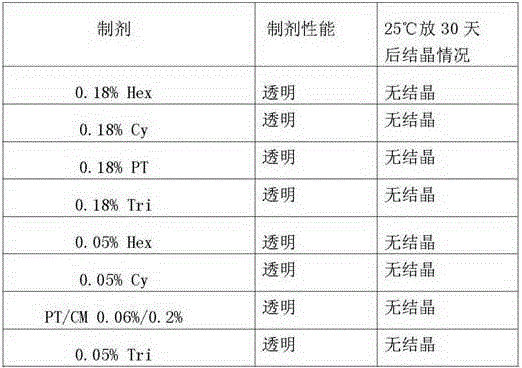

Silicon-containing polyurethane surfactant and preparation method thereof

The invention discloses a preparation method of a silicon-containing polyurethane surfactant. The method is characterized by comprising the following steps of: heating hydrophobic silicon oil and a hydrophilic dihydric alcohol monomer while stirring in the molar ratio of 10:1-1:10 in a solvent in an inert atmosphere to 50-60 DEG C, adding a catalyst, and slowly adding isocyanate at the temperature of 70-80 DEG C for reacting for 2-3 hours; and cooling to 60 DEG C, adding a neutralizing agent, evaporating a solvent out at the temperature of 50-55 DEG C 30-60 minutes later, precipitating in methanol of 20-25 DEG C, and drying at the temperature of 50-60 DEG C to constant weight to obtain a product. A silicon oil chain segment with low surface tension is introduced into polyurethane molecules, so that the surface tension of polyurethane is reduced; and a hydrophilic part of the product consists of an ionic monomer and a nonionic monomer, so that the defect of the sensitivity of a single nonionic emulsifier to temperature is overcome, and a product aqueous solution is prevented from undergoing phase splitting emulsion breaking at the temperature of 20-90 DEG C, and can be applied in the industries of spinning, papermaking, oilfields and the like.

Owner:佛山市方普防护技术有限公司

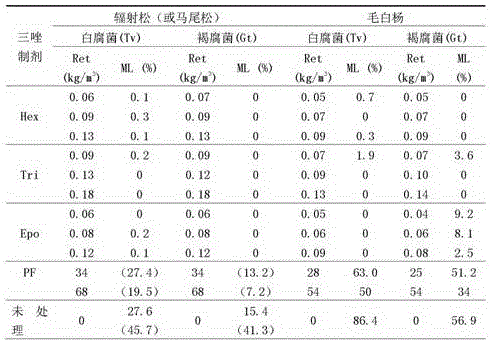

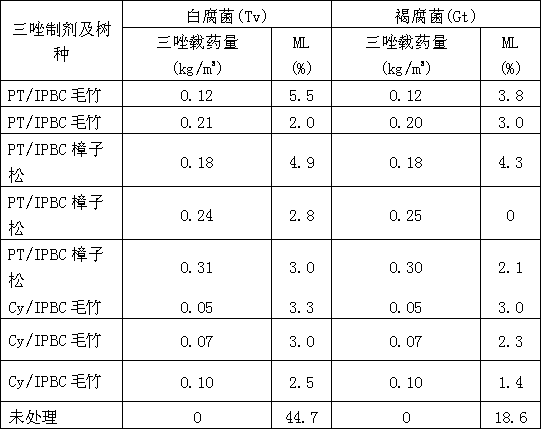

Wood bamboo material corrosion and discoloration prevention triazole composition and preparation method thereof

ActiveCN106003312AImprove anti-corrosion performanceImprove mildew resistanceWood treatment detailsReed/straw treatmentFatty alcoholHexaconazole

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Preparation method of self-healing agent for oil well cement, well cementation self-healing cement slurry and application

ActiveCN104418965ATo achieve the effect of oil expansionEasy construction pumpingDrilling compositionSelf-healingPolyethylene glycol

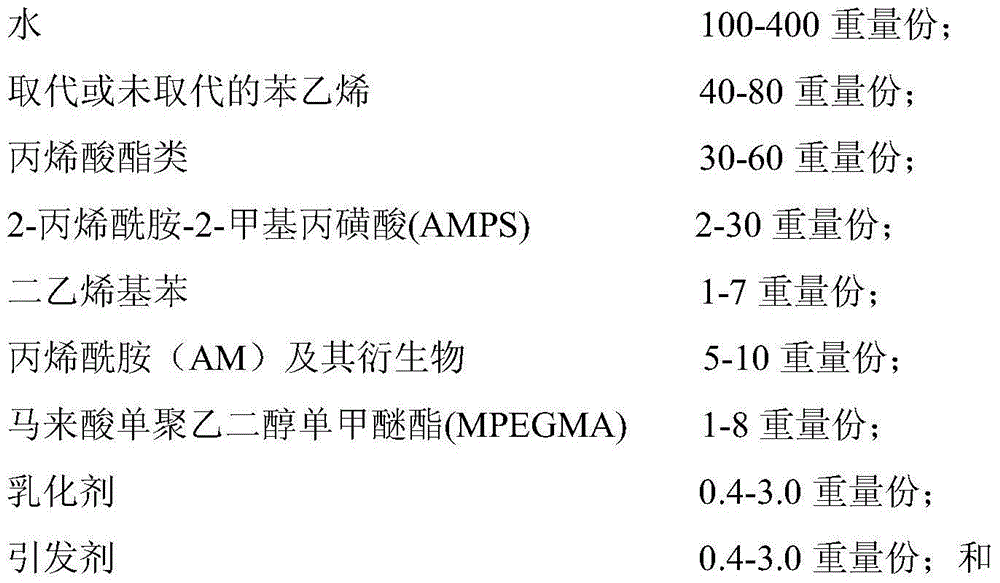

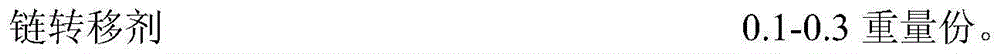

The invention discloses a preparation method of a self-healing agent for oil well cement. The preparation method comprises the following steps: i) mixing substituted or unsubstituted styrene, acrylates, 2-acrylamide-2-methyl propane sulfonic acid, divinyl benzene, acrylamide and derivatives thereof, mono polyethylene glycol maleate, an emulsifier and a chain transfer agent with water and pre-emulsifying to obtain a pre-emulsion A; ii) preparing an initiator solution B by water and an initiator; iii) heating a part amount of the pre-emulsion A to 70-90 DEG C and then adding a part amount of the initiator solution B; then, further adding the residual amount of the pre-emulsion A and the initiator solution B; and iv) after reaction, adjusting the pH value to 7-9 to obtain the self-healing agent for oil well cement. The invention further relates to well cementation self-healing cement slurry which contains the self-healing agent prepared by the method as well as an application of the self-healing agent or the well cementation self-healing cement slurry in oil gas well cementing operation.

Owner:CHINA PETROLEUM & CHEM CORP +2

Waterborne polyurethane adhesive for synthetic leather and preparation method thereof

ActiveCN103450837ADelayed thermal oxidationExtended service lifePolyureas/polyurethane adhesivesIsophoroneEnvironmental resistance

The invention provides an environment-friendly and safe waterborne polyurethane adhesive for synthetic leather and a preparation method thereof. The polyurethane adhesive is prepared mainly from the raw materials such as polytetrahydrofuran glycol, dicyclohexylmethylmethane diisocyanate, phosphoric acid, dimethylolpropionic acid, trimethylolpropane polyoxypropylene polyoxyethylene ether, isophorone diamine and deionized water. In a using process of the waterborne polyurethane adhesive for synthetic leather, the volatilized gas is water vapor which is harmless to environment, thereby greatly reducing the cost for controlling environmental pollution. The waterborne polyurethane adhesive for synthetic leather is insensitive to the environmental factors such as acid, alkali and electrolyte, and avoids the phenomenon of emulsion breaking caused by adding various auxiliaries; meanwhile, by adding a proper amount of carboxylic chain extender into the formula, the obtained waterborne polyurethane adhesive for synthetic leather has excellent performance such as high strength, high wear resistance, yellowing resistance, aging resistance, low-temperature resistance, folding resistance and good permeability.

Owner:SHANDONG TIANQING TECH DEV

Emulsified paraffin wax damp-proof agent for mineral wool sound absorption board and its preparation method

The present invention relates to emulsion of polymer. The emulsified paraffin damp-proof agent consists of paraffin, modified resin, non-ionic surfactant composite, emulsifying assistant and water. It has high stability and damp resisting performance, and may be used to optimize the production process of mineral wool sound absorbing board, reduce the consumption of damp-proof agent and lower the cost.

Owner:山东环绿康新材料科技有限公司

Wood and bamboo material corrosion and mold prevention modified combination agent and wood and bamboo material treating method

ActiveCN109015981AAnti-corrosionMildew proofWood treatment detailsReed/straw treatmentWater solubleFire retardant

The invention belongs to a wood and bamboo material corrosion and mold prevention modified combination agent and a wood and bamboo material treating method. The wood and bamboo material corrosion andmold prevention modified combination agent comprises, by weight, 0.04-0.10 part of triazole, 0.05-0.12 part of 3-iodo-2-propynyl butylcarbamate, 1-6 parts of water soluble dyes, 1-6 parts of dyeing assistants, 1-6 parts of fire retardants and 1-10 parts of polymerization inhibitors. A wood and bamboo material treated through the modified combination agent can simultaneously have the functions of corrosion prevention, mold prevention, dyeing, inflaming retarding and pharmaceutical composition loss resistance, and has the advantages of easy operation, easy implementation, low preparation and using cost, good durability and long service life.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Preparation method of water-based polyurethane drier

The invention relates to a method for preparing a water polyurethane drier, which comprises the following steps: weighing material, oil main drier, oil auxiliary drier, emulsifier, emulsion reaction drier, chelant and deionized water according to 1:1.5-1.5:0.005-0.1:0.0001-0.005:0.001-0.02:1-5; adding deionized water in the emulsifier with high shearing force( the rotary speed is 13000-15000 rotation / minute, the linear speed isn't less than 25m / s); adding oil main drier, oil auxiliary drier, chelant, dilaurate ortho-butyl tin and emulsifier sequentially; starting the recalculated water in the emulsifier when the material temperature in the reactor is 40Deg. C; keeping the temperature of liquid less than 40Deg. C; acquiring the water polyurethane drier by mixing 25-30minutes. The water polyurethane drier can dissolve with water, which can dissolve with water polyurethane according to any proportion, and has the long saving time and the low cost.

Owner:闫里选

Caviar shower gel capable of blooming and whitening skin

InactiveCN107582498APromote absorptionStrong split frequencyCosmetic preparationsToilet preparationsIrritationShower gel

The invention provides a caviar shower gel capable of blooming and whitening skin. Raw materials for preparation of the shower gel comprise a skin conditioning agent, wherein the skin conditioning agent comprises sturgeon caviar extract, and the weight percentage of the sturgeon caviar extract in the raw materials for preparation of the shower gel is 0.03 to 0.3%. The caviar shower gel provided bythe invention adopts the skin conditioning agent containing micromolecular proteins, and the micromolecular proteins can more easily enter the body, supplements collagen to skin, and allows skin to be more elastic, smooth, moist and tender; the caviar shower gel utilizes oil-controlling components with natural and powerful adsorption effect, so deep cleaning of stains in pores can be realized, and the body is allowed to better absorb the skin conditioning agent; the caviar shower gel also employs an anti-sensitizer capable of alleviating irritation of active substances to skin; and a humectant and arbutin capable of rapidly infiltrating into skin are used, so deep cleaning of the skin is realized, whitening and deep moistening effects are obtained, and skin is allowed to be skin and elastic.

Owner:曾万祥

Emulsion adhesive

InactiveCN103805103AExcellent performanceHigh bond strengthMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesEmulsionRosin

The invention provides a nontoxic and tasteless emulsion adhesive for food packaging, which consists of the following raw materials in percentage by weight: 45-62% of acrylic acid mixed emulsion, 8-10% of rosin emulsion and 30-45% of liquid resin emulsion. The emulsion adhesive has the advantages of high adhesive strength and long opening time, and is suitable for the manual and flow line production of food packaging boxes; moreover, the emulsion adhesive is remarkably convenient to apply and easy to clean.

Owner:SHAANXI TECHN INST OF DEFENSE IND

Water-in-oil emulsion, preparation method thereof and oil-based drilling fluid

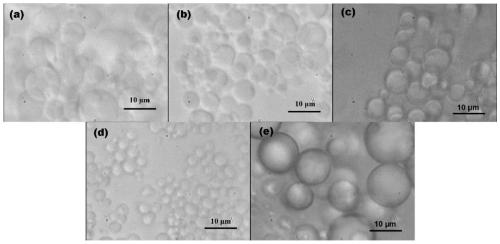

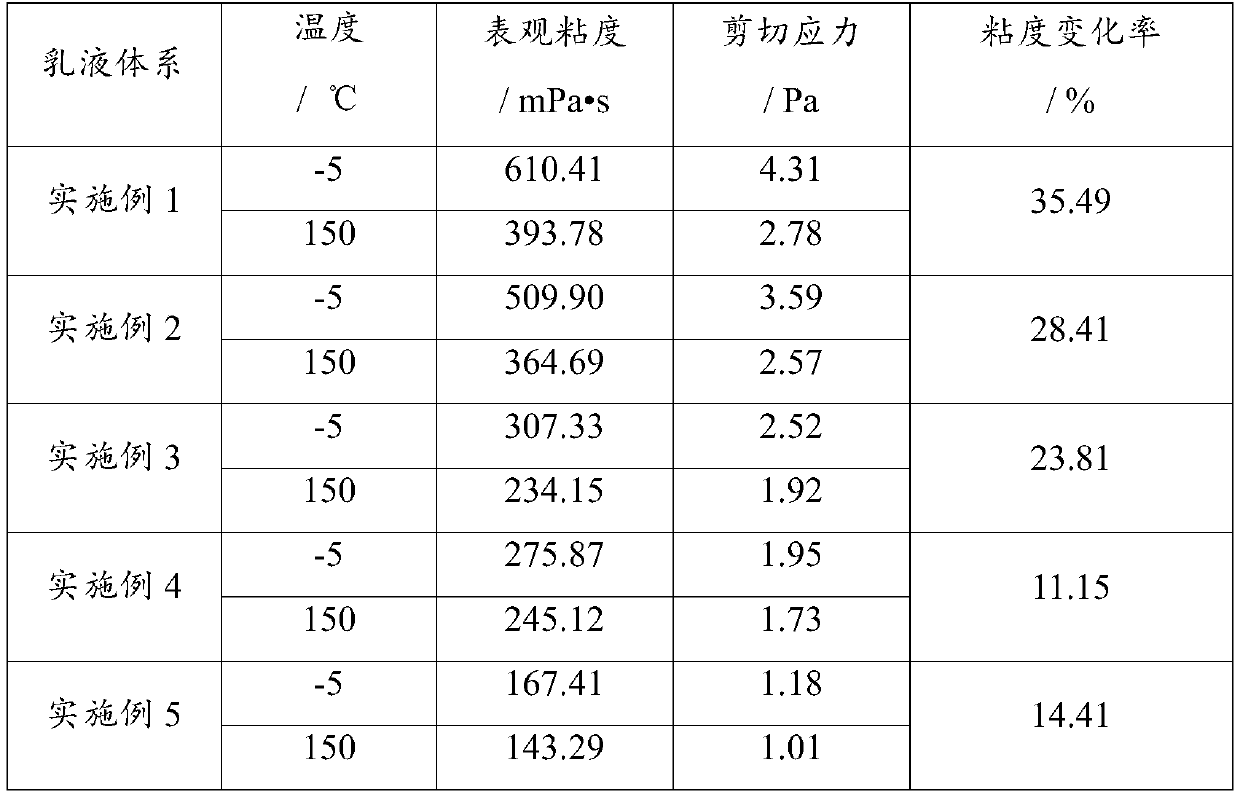

InactiveCN110003865AImprove stabilityLow rate of viscosity changeDrilling compositionUltrasonic emulsificationGas phase

Provided are a water-in-oil emulsion, a preparation method thereof and an oil-based drilling fluid. The water-in-oil emulsion comprises an oil phase, an aqueous phase and hydrophobically modified gas-phase silica, wherein the content of the oil phase is 60-90 parts by weight, the content of the aqueous phase is 10-40 parts by weight, and the content of the hydrophobically modified gas-phase silicais 0.5-1.5 parts by weight, based on 100 parts by weight of the total content of the oil phase and the aqueous phase. The method comprises the following steps: dispersing the hydrophobically modifiedgas-phase silica in the oil phase and executing stirring to obtain a hydrophobically modified gas-phase silica-oil dispersion system; adding the aqueous phase to the hydrophobically modified gas-phase silica-oil dispersion system, carrying out ultrasonic emulsification after stirring to obtain the water-in-oil emulsion. The water-in-oil emulsion has excellent stability and wide-temperature-rangeconstant rheological property, and can be used for simulating or constructing soilless phase oil-based drilling fluids suitable for drilling engineering of deep water and frozen soil zone low-temperature formations.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Aqueous woodenware statin topcoat and preparation method thereof

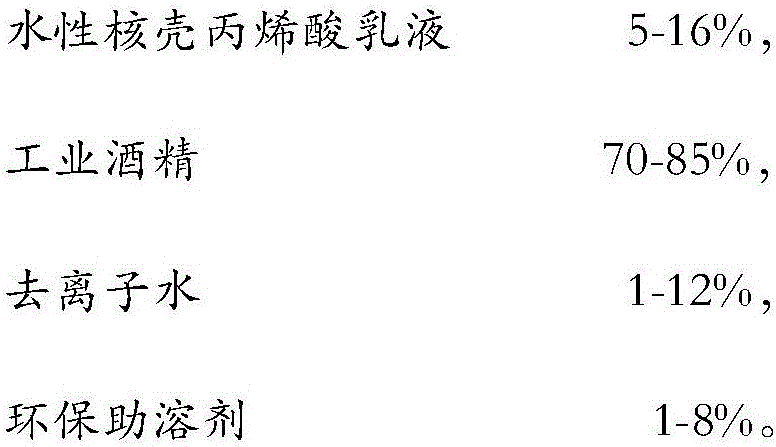

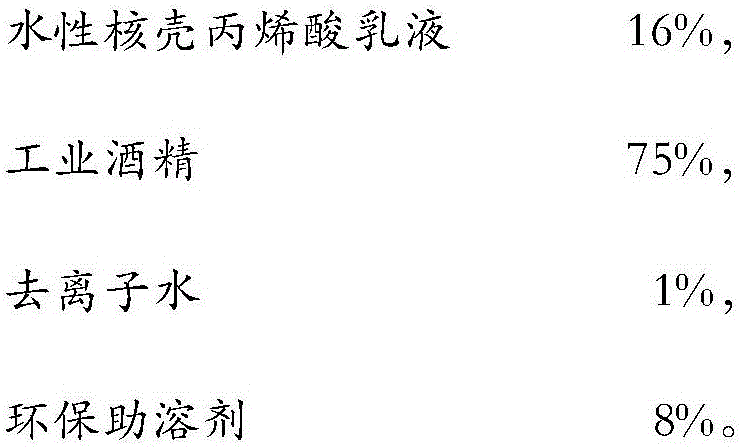

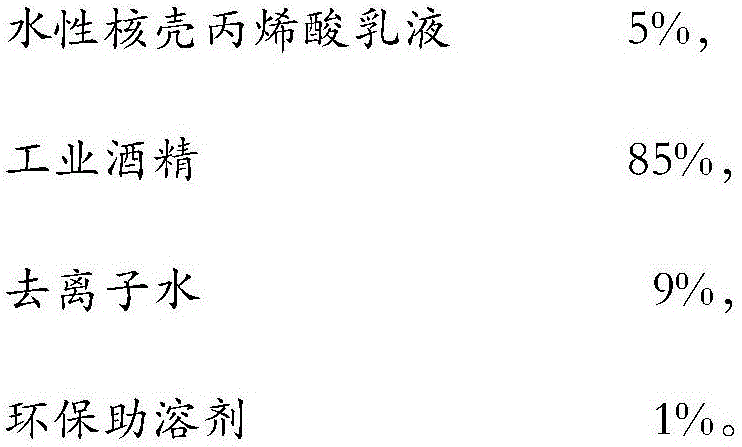

The invention discloses an aqueous woodenware statin topcoat and a preparation method thereof. The aqueous woodenware statin topcoat comprises, by mass, 85-97% of an aqueous color remanding base material and 3-15% of a high-concentration aqueous color concentrate. The aqueous color remanding base material comprises, by weight, 5-16% of an aqueous core-shell acrylic emulsion, 70-85% of industrial alcohol, 1-12% of deionized water and 1-8% of an environmentally-friendly cosolvent. The paint has the advantages of fast drying speed, good stability, uniform color remanding effect, uniform color, and convenience in construction.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

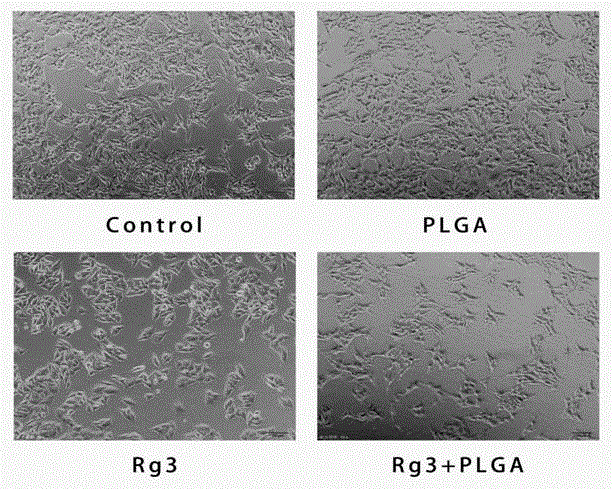

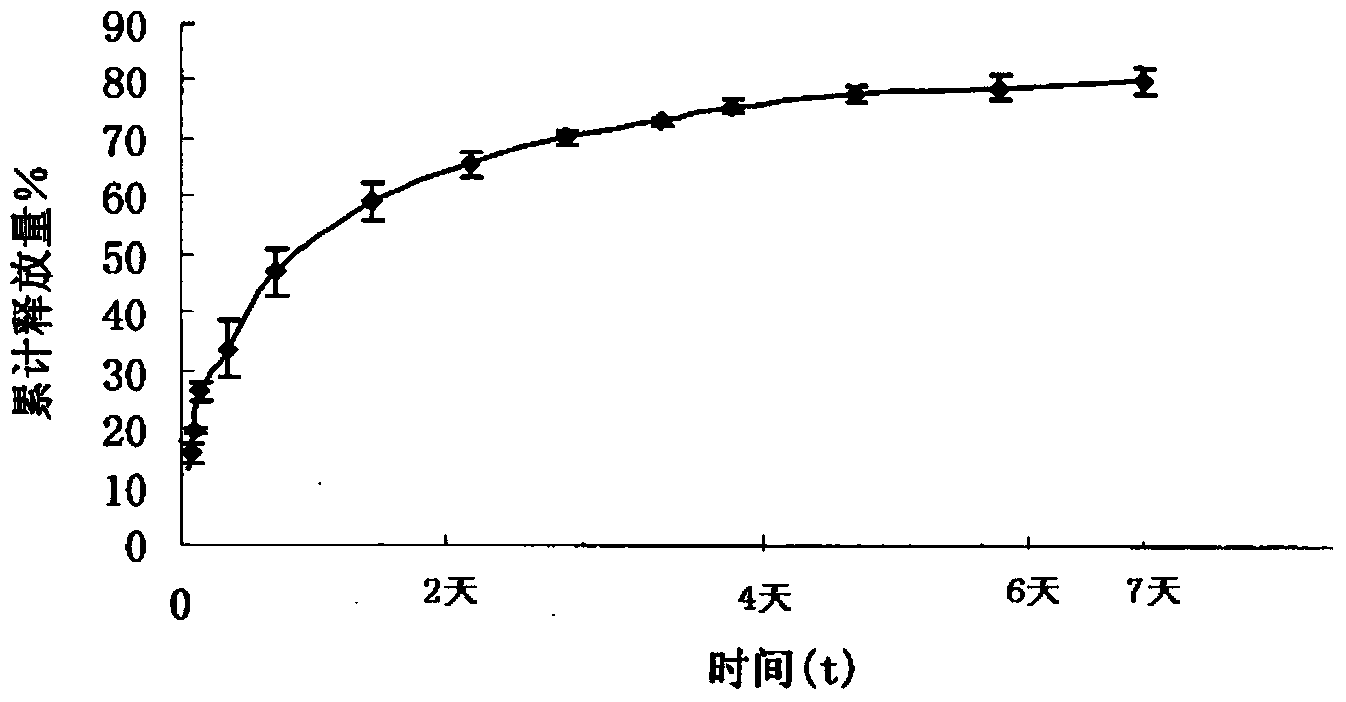

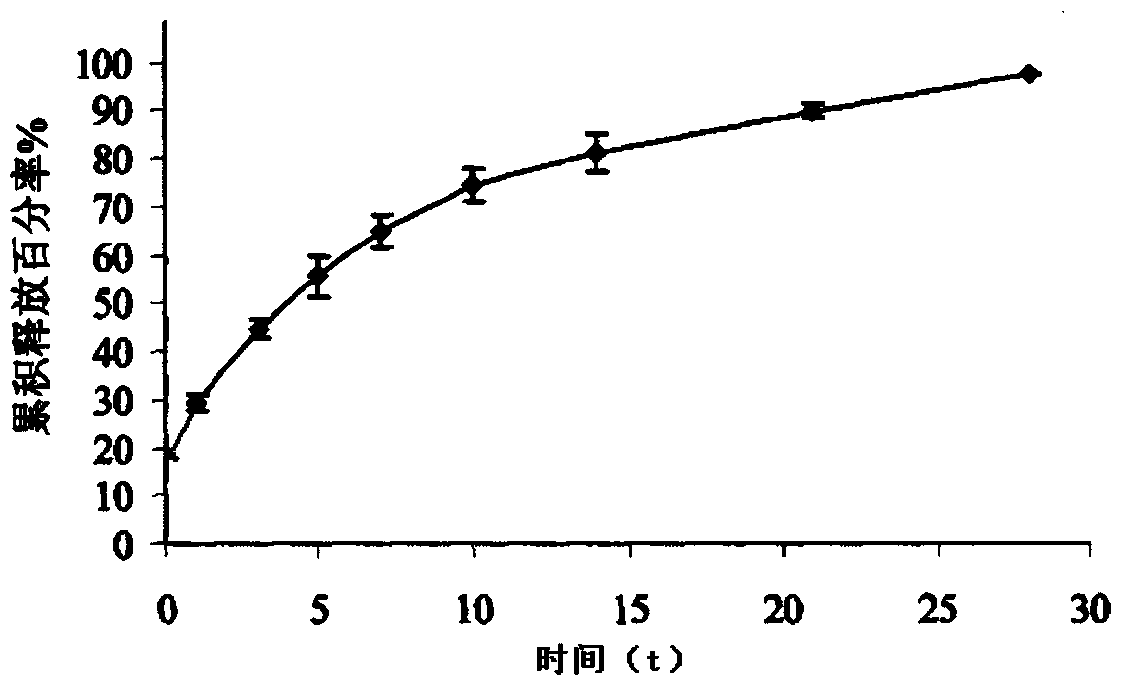

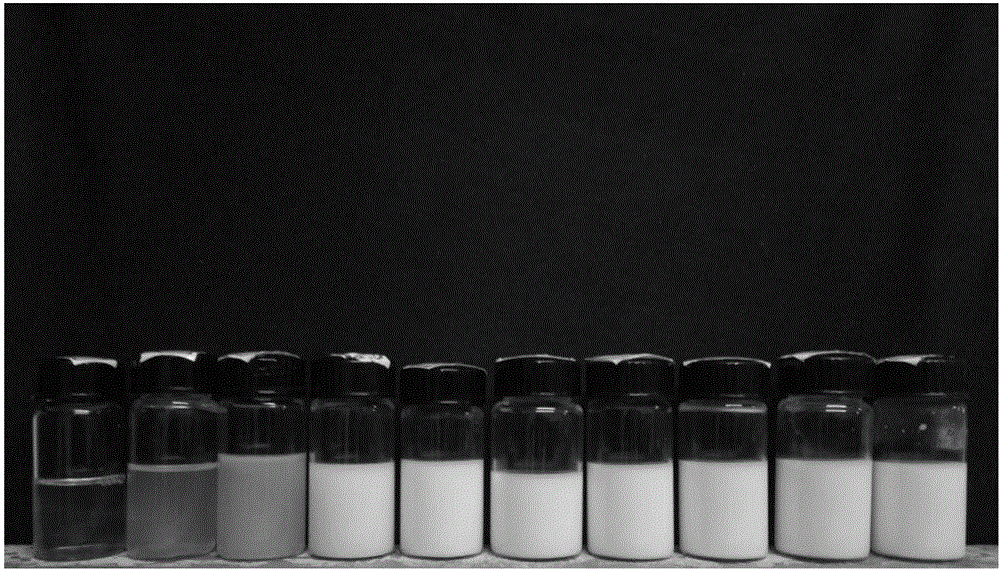

20(R)-ginsenoside Rg3 slow release nanometer microsphere composition, and preparation method thereof

ActiveCN106361724AGood passive targetingSmall particle sizeOrganic active ingredientsAntineoplastic agentsMicrospherePolyvinyl alcohol

The invention discloses a ginsenoside Rg3 slow release nanometer microsphere composition, and a preparation method and a use thereof. The method is characterized in that a medicine coating matrix is a polylactic acid-glycolic acid copolymer (PLGA), polyvinyl alcohol (PVA) is adopted as an emulsifier, and Rg3-PLGA nanoparticles with good re-dispersibility are prepared through purifying and drying by adopting a solvent volatility technology; and the Rg3-PLGA nanoparticles are dried to form white powder which can be preserved for a long term. The particles have the advantages of smooth and round surfaces, no adhesion among the particles, good dispersiveness and uniform size, and the average particle size of the particles is 97.5 nm. The composition has high endophilicity to the PLGA material, has a high entrapment rate (of 94.3%), and has a good slow release performance, and the slow release period is 4 d or more. The nanoparticles can be used in antitumor therapy in an intravenous injection and local administration mode, and has wide application prospect.

Owner:富力

Alkenyl succinic anhydride sizing agent as well as preparation method and application thereof

InactiveCN111749047ANo pollution in the processReduce manufacturing costWater-repelling agents additionNon-macromolecular organic additionPolymer scienceEmulsion

The invention belongs to the technical field of papermaking, and particularly relates to an alkenyl succinic anhydride sizing agent as well as a preparation method and application thereof. The preparation method comprises the following steps: mixing alkenyl succinic anhydride and a cellulose nanocrystalline dispersion liquid, and carrying out first emulsification to obtain ASA-1 emulsion; and carrying out ultrasonic treatment on the ASA-1 emulsion, mixing the obtained emulsion with nano cellulose fibers, and carrying out second emulsification to obtain the alkenyl succinic anhydride sizing agent. Results of the embodiment show that the ASA sizing agent emulsion does not generate particle aggregation and precipitation after being placed for 30 days, does not have any phase body precipitation and demulsification phenomenon, and is good in stability; the paper sheet sizing degree of the sized paper is 224-332 seconds, and the sizing performance of the ASA sizing agent emulsion is good; after the ASA sizing agent emulsion is placed for 72 hours, the sizing degree of sized paper is 210-325 seconds, and the hydrolysis resistance of the emulsion is good.

Owner:QILU UNIV OF TECH

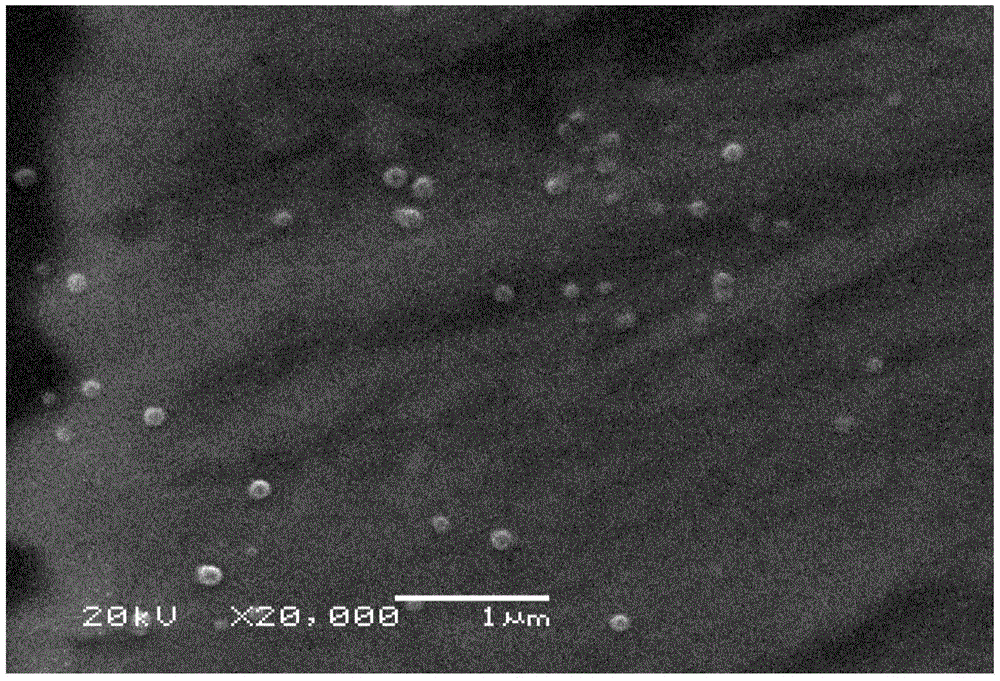

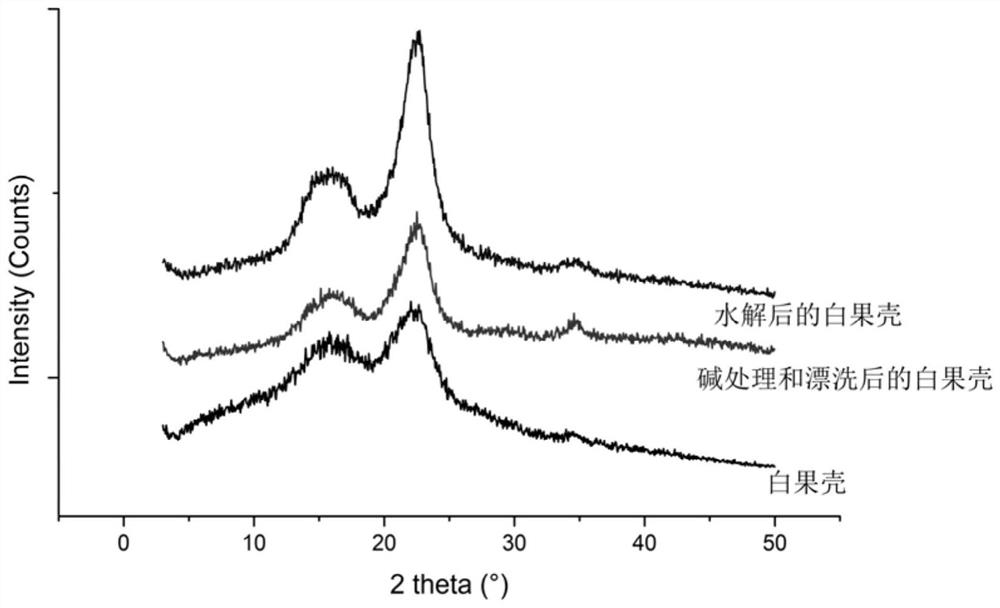

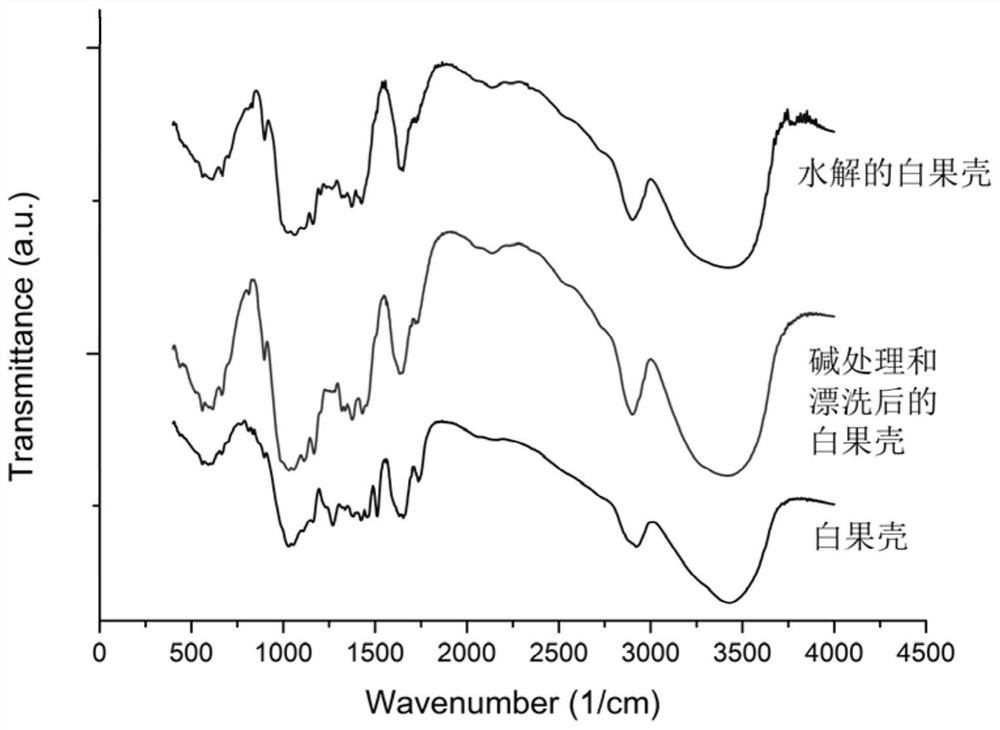

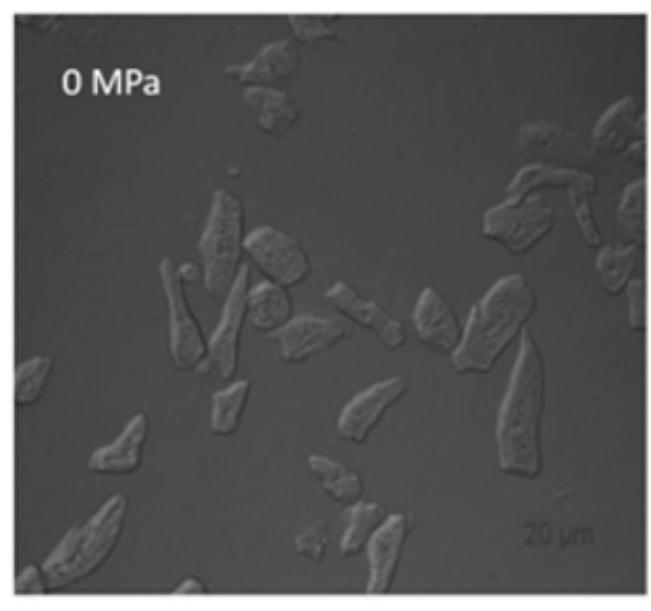

A kind of pickering emulsion that utilizes ginkgo husk cellulose to stabilize and preparation method thereof

ActiveCN110591117BHigh purityPromote crystallizationPretreatment with water/steamEdible oils/fats ingredientsSodium chloratePickering emulsion

The invention discloses a Pickering emulsion stabilized by ginkgo husk cellulose and a preparation method thereof, belonging to the fields of biomass material preparation methods and food chemical industry. The ginkgo shell is treated with hot alkali and bleached with sodium chlorite to remove lignin and hemicellulose to obtain high-purity cellulose. After drying with hot air, it is hydrolyzed with sulfuric acid, washed with deionized water and dialyzed to obtain a suspension of cellulose nanocrystals. The above suspension is mixed with the oil phase, and a stable Pickering emulsion is obtained through high-speed shearing and homogeneous emulsification. The emulsion prepared by the invention has the characteristics of less cellulose consumption, wide range of oil phase, good storage stability and ability to resist environmental changes.

Owner:JIANGNAN UNIV

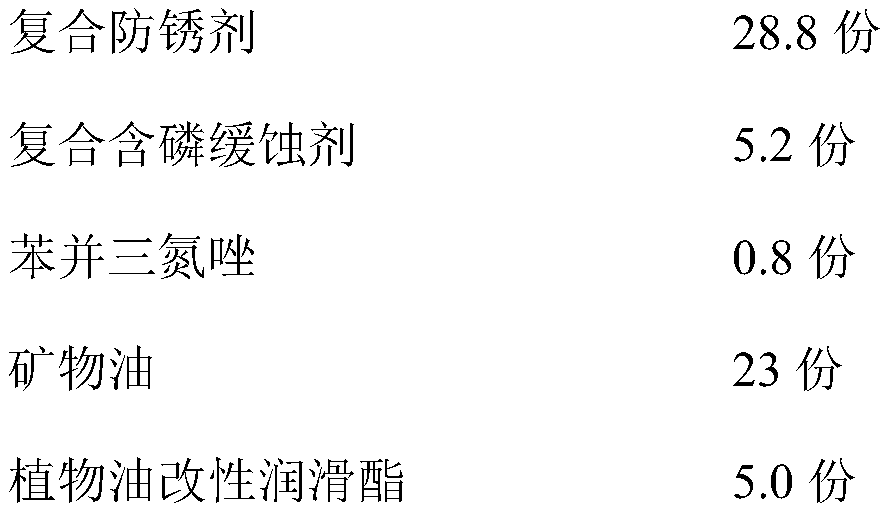

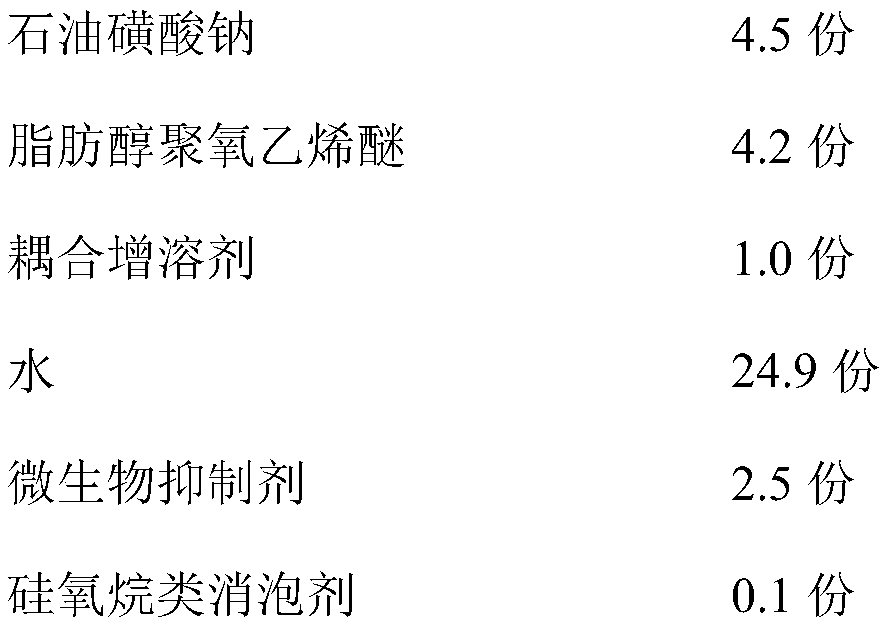

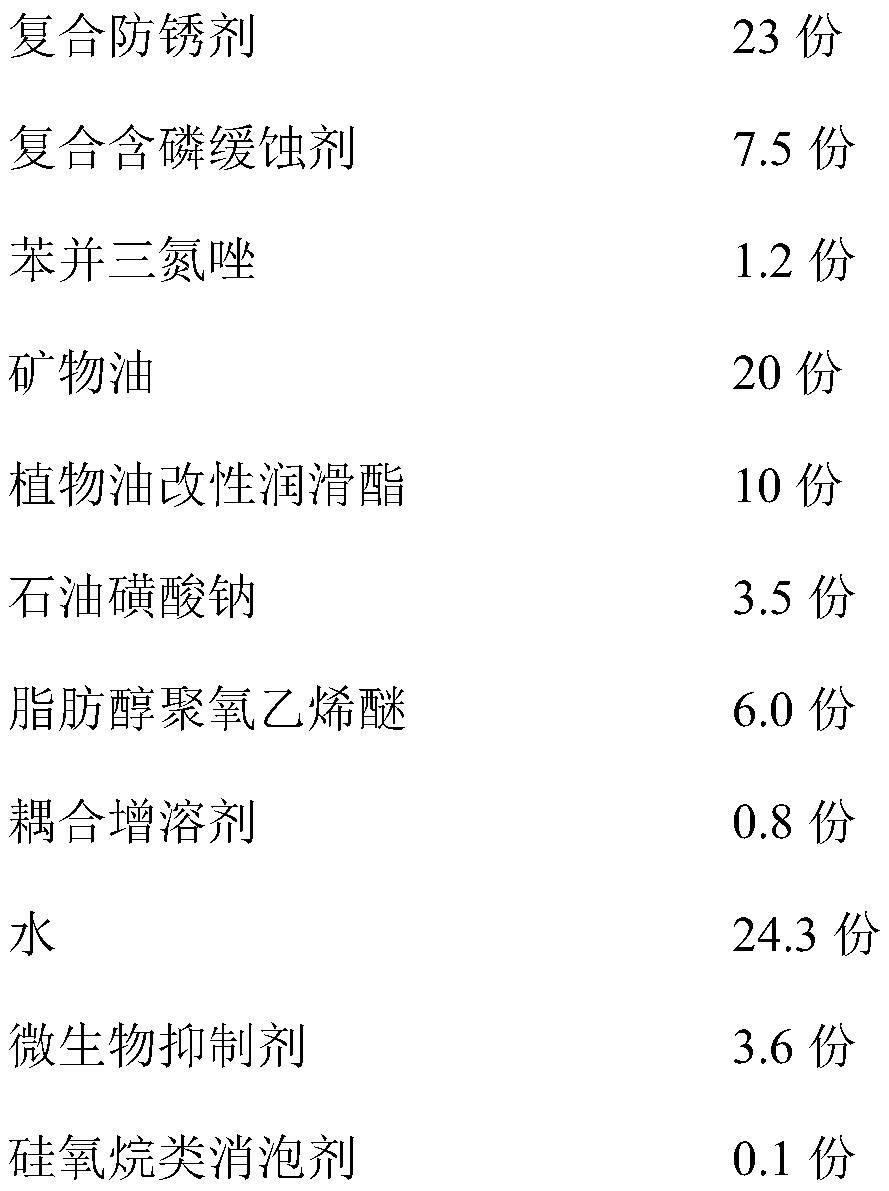

Magnesium alloy cutting fluid resistant to bimetallic contact corrosion and preparation method thereof

InactiveCN110387285AExcellent contact corrosion performancePrevent rustAdditivesVegetable oilSolvent

The invention discloses a magnesium alloy cutting fluid resistant to bimetallic contact corrosion. The magnesium alloy cutting fluid comprises the following raw materials by weight: 23-30 parts of a composite rust inhibitor, 5-8 parts of a composite phosphorus-containing corrosion inhibitor, 0.6-1.5 parts of benzotriazol, 20-40 parts of mineral oil, 5-12 parts of vegetable oil-modified lubricatingester, 3-5 parts of petroleum sulfonate, 4-7 parts of fatty alcohol polyoxyethylene ether, 0.6-1.2 parts of a coupled solubiliser, 20-35 parts of water, 2-4 parts of a microbial inhibitor and 0.05-0.2 part of a siloxane antifoaming agent. The invention also discloses a preparation method for the magnesium alloy cutting fluid resistant to bimetallic contact corrosion. The cutting fluid of the invention can meet the requirements of magnesium alloy for anti-corrosion performance and solve the problem of bimetal contact corrosion occurring in the processing of the magnesium alloy by metal processing enterprises, thereby improving the yield and the production efficiency of magnesium alloy processing.

Owner:俄美达(武汉)有限公司

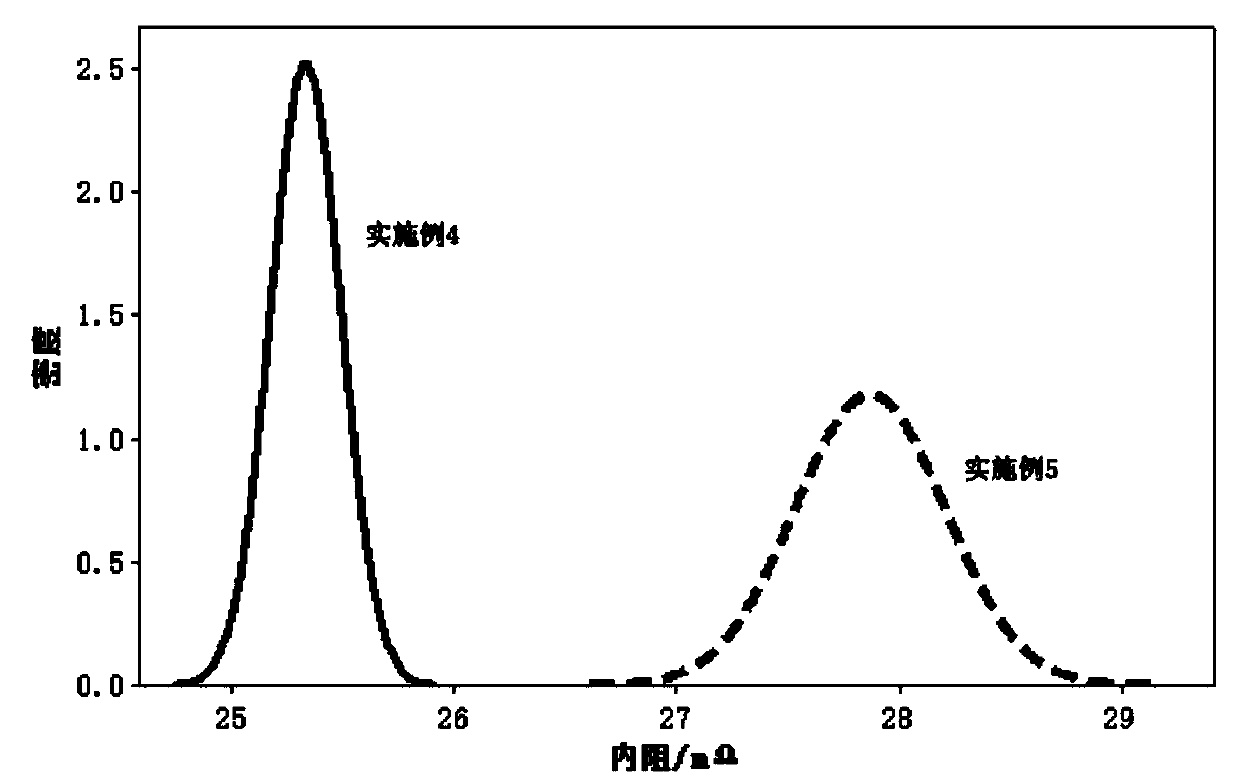

Lithium ion battery anode, preparation method of lithium ion battery anode and lithium ion battery

ActiveCN107732150ANegative electrode has good conductivityImprove conductivityCell electrodesSecondary cellsInternal resistancePhysical chemistry

The invention provides a lithium ion battery anode, a preparation method of the lithium ion battery anode, and a lithium ion battery. The lithium ion battery anode comprises an anode current collectorand an anode material, wherein the anode material is adhered to the surface of the anode current collector; the anode material comprises an anode active material, a conductive agent, an adhesive anda dispersing agent; the dispersing agent accounts for 0.6-1.0% of the total mass of the anode material; by 100% of the mass of the dispersing agent, the dispersing agent comprises the following components: 45-55% of sodium carboxymethylcellulose and 45-50% of lauryl sodium sulfate; and the feeding ratio of the sodium carboxymethylcellulose to the lauryl sodium sulfate is greater than or equal to 0.9 and less than or equal to 1.2. A paste prepared from the anode material is stable in property and not liable to sink; when a current collector is coated by the anode material to form a anode, the phenomenon of peeling is avoided; and after the lithium ion battery is assembled, the internal resistance of the battery is reduced, and the service life of the battery is prolonged.

Owner:DONGGUAN CHUANGMING BATTERY TECH

Ziconotide injection hypodermic implant and preparation method thereof

InactiveCN103705910ASimple preparation processFully encapsulatedPowder deliveryNervous disorderSubcutaneous implantationSterile water

The invention belongs to the technical field of medicine preparation, and discloses a preparation method of a ziconotide injection hypodermic implant as well as the ziconotide injection hypodermic implant prepared by the method. The implant prepared by the method is dissolved by sterile water for injection before use and is then injected to human subcutaneous tissues. The implant prepared by the method is a novel sustained-release preparation which can be subcutaneously injected in form of a liquid. Under the effect of body temperature, the liquor becomes a gel which is slowly released in vivo, so that a long-acting effect of treating and relieving pains is realized.

Owner:HYBIO PHARMA

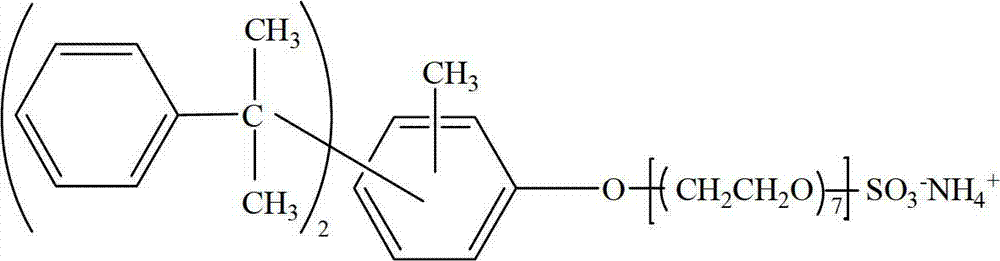

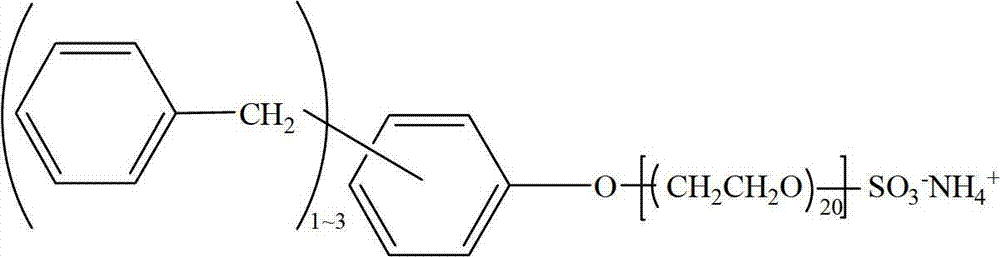

High-efficiency composite emulsifying agent and preparation method of O/W nanometer emulsion by high-efficiency composite emulsifying agent

ActiveCN107519815AEasy to synthesizeLow costTransportation and packagingMixing methodsRoom temperatureOil phase

The invention relates to a high-efficiency composite emulsifying agent and a preparation method of an O / W nanometer emulsion by the high-efficiency composite emulsifying agent. The high-efficiency composite emulsifying agent is prepared by compounding an anionic surfactant and an amphiphilic supermolecular compound. The preparation method of the O / W nanometer emulsion by the high-efficiency composite emulsifying agent comprises the following steps of mixing an oil phase and the amphiphilic supermolecular compound, heating, and uniformly stirring, so as to form an oil mixed solution; uniformly mixing water and the anionic surfactant, and heating, so as to form a surfactant water solution; adding the surfactant water solution into the oil mixed solution, stirring, and emulsifying; or, mixing the components together, heating, stirring and emulsifying. The O / W nanometer emulsion with the stable composite emulsifying agent has excellent stability, and the demulsifying cannot occur after the O / W nanometer emulsion is placed at room temperature for half a year. When the nanometer emulsion with same average particle size is prepared, the usage amount of the composite emulsifying agent is only equal to 30% to 60% of the usage amount of other common emulsifying agent; the smaller the particle size of the prepared emulsion is, more efficient the composite emulsifying agent is; the preparation cost of the O / W nanometer emulsion is greatly reduced.

Owner:SHANDONG UNIV

Emulsion type sizing agent for carbon fiber as well as preparation method and application of emulsion type sizing agent

The invention discloses an emulsion type sizing agent for a carbon fiber as well as a preparation method and application of the emulsion type sizing agent. The sizing agent contains 2-40 percent of epoxy resin, 0-97 percent of water, 0.5-14 percent of surfactant, 0.3-12.5 percent of cardanol, 0.1-1.5 percent of formaldehyde and 0.1-2.0 percent of inorganic ammonium salts. The emulsion type sizing agent contains the cardanol and the formaldehyde as toughening and modifying agents, so that when the carbon fiber sized by using the emulsion type sizing agent for the carbon fiber is compounded with an epoxide resin matrix taking polyamine as a curing agent to form a composite material, the interlaminar shear strength is improved by over 30 percent and the carbon fiber composite material is enabled to have higher integral performance. The emulsion type sizing agent contains the inorganic ammonium salts, so that the storage stability of the sizing agent is greatly improved and the phenomena of demixing and non-uniformity of concentration are avoided. According to the emulsion type sizing agent disclosed by the invention, the phenomena of demixing and emulsion breaking in the use process of the sizing agent are avoided. After the carbon fiber sized by the sizing agent disclosed by the invention is stored at normal temperature for five years, the mass percentage of the sizing agent on the surface of the carbon fiber is unchanged.

Owner:KINGFA SCI & TECH CO LTD +1

Method for preparing multiple emulsions from layered active particles

ActiveCN102728252AGood sustained release effectReduce dosageMixing methodsDrilling compositionWater in oil emulsionActive particles

A method for preparing multiple emulsions from layered active particles comprises steps of: preparing a surfactant oily solution, a water-in-oil emulsion and a layered active particle water dispersion system and further preparing a water-in-oil-in-water multiple emulsion. The preparation technology comprises the following steps of: (A) preparing the surfactant oily solution with the mass concentration of 1.0-4.0%; (B) gradually adding clear water into the surfactant oily solution at the stirring rate of 800-1200 r / s to obtain the water-in-oil emulsion; (C) preparing the layered active particle water dispersion system with the mass concentration of 0.5-1.5%; and (D) gradually adding the water-in-oil emulsion into the layered active particle water dispersion system at the high stirring rate of 3000-5000 r / s to obtain the oil-in-water water-covering multiple emulsions. The method provided by the invention has characteristics of long stabilization time, small amount of the surfactant, low cost, safety, environmental protection, no toxic and side effect and the like, and is widely applied in petroleum exploitation technologies.

Owner:CHINA PETROLEUM & CHEM CORP +1

Compound emulsion for animals and preparation method thereof

InactiveCN102058612AReduce poisonReduce toxicity and reduce environmental pollutionAntibacterial agentsOrganic active ingredientsAzithromycinOrganic solvent

The invention belongs to the technical field of veterinary medicaments, and particularly relates to a compound emulsion for animals and a preparation method thereof. The compound emulsion for animals comprises tylosin tartrate, azithromycin, emulsifier, poloxamer, propylene glycol, soybean oil for injection and water for injection. The compound emulsion for animals has high safety; and because the emulsion contains no organic solvent, the toxicity of the organic solvent is reduced, and the emulsion has good environmental friendliness.

Owner:河南亚卫动物药业有限公司

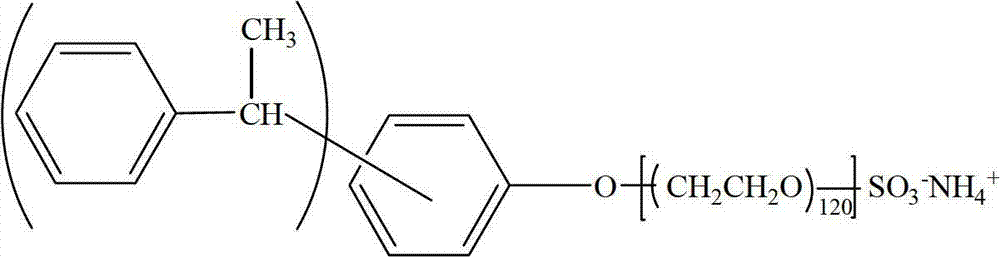

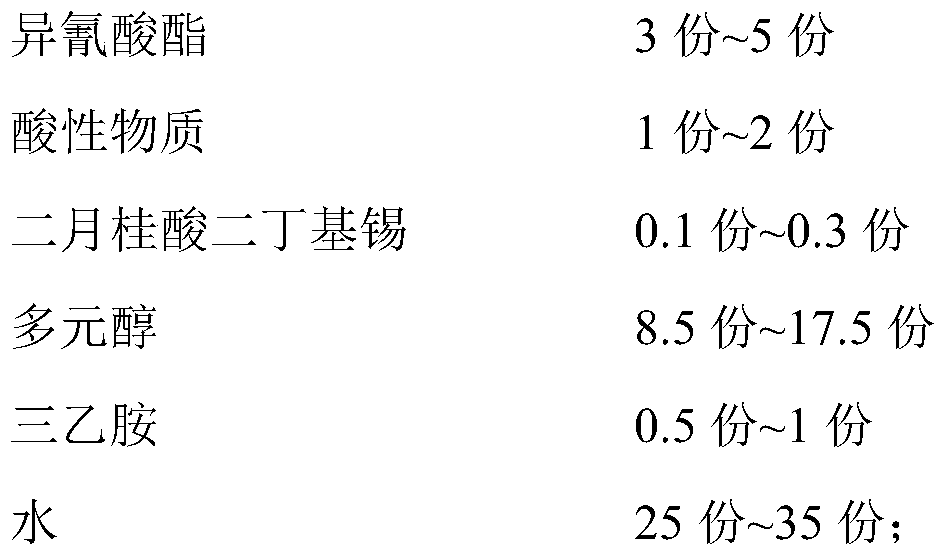

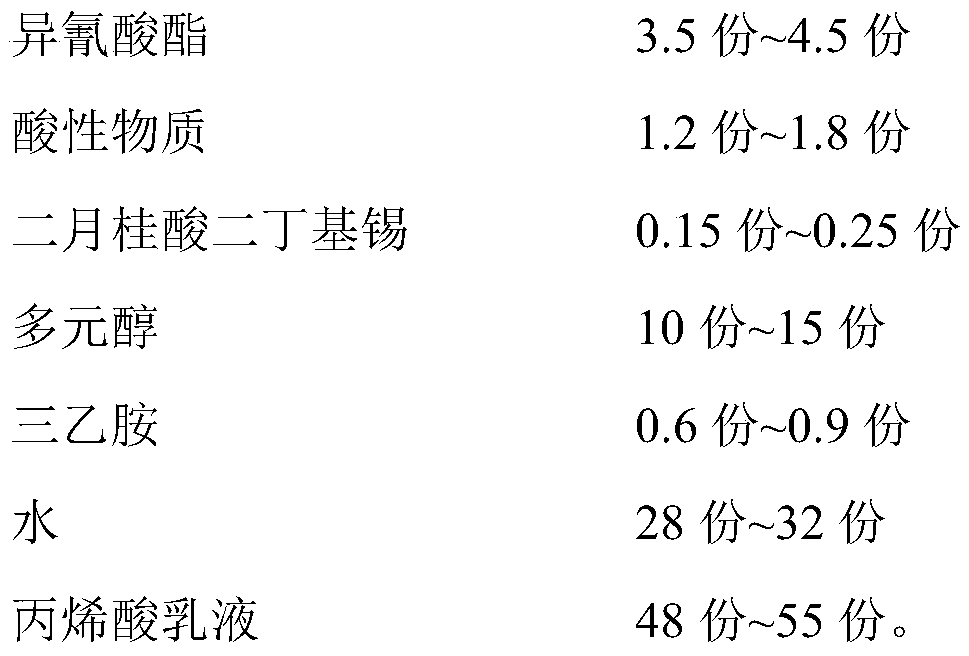

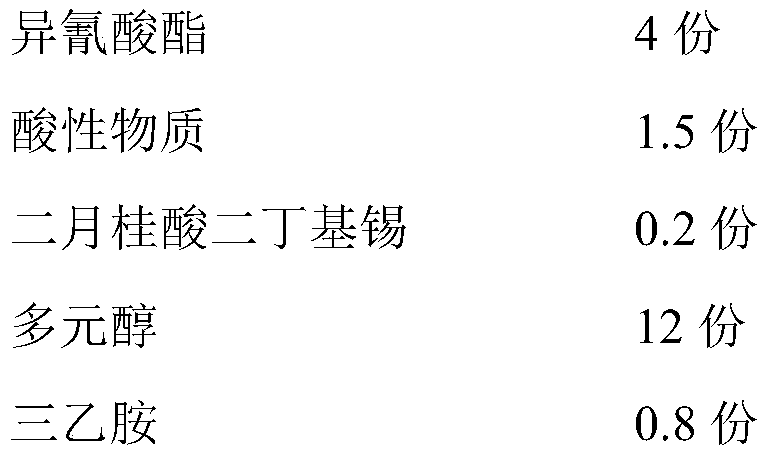

Self-matting emulsion and preparation method thereof

ActiveCN110564091AHigh extinction efficiencyDoes not affect transparencyPolyurea/polyurethane coatingsPolymer scienceCoating system

The invention relates to the technical field of resin synthesis, in particular to a self-matting emulsion and a preparation method thereof. The self-matting emulsion comprises a micron-sized particlesize polyurethane emulsion and a nano-sized particle size acrylic emulsion, wherein the polyurethane emulsion comprises an isocyanate, an acidic substance, dibutyltin dilaurate, a polyol, triethylamine and water. The micron-sized particle size polyurethane emulsion is innovatively used as a matting agent, compared with a matting powder of the prior art, the polyurethane emulsion has good storage stability, the demulsification phenomenon cannot occur, and transparency of a paint film cannot be affected after being introduced into a coating system. Compared with an organosilicone-modified acrylic emulsion and a fluorine-modified acrylic emulsion in the prior art, the polyurethane emulsion has the advantage of low production cost. In addition, the self-matting emulsion has higher matting efficiency compared with the prior art. The preparation method of the self-matting emulsion has the characteristics that the process is simple, the production cost is low, and the method can be suitable for large-scale production.

Owner:东莞大宝化工制品有限公司

Preparation method of alkyl ketene dimer papermaking sizing agent and product

ActiveCN112878097AStrong hydrolysis resistanceGood emulsion stabilityWater-repelling agents additionPaper recyclingDodecylsulfonic acidMixed solution

The invention provides a preparation method of an alkyl ketene dimer papermaking sizing agent. The preparation method comprises the following steps: mixing a hectorite aqueous dispersion with acetone, ammonia monohydrate and hexadecyl trimethyl siloxane, and carrying out ultrasonic dispersion to obtain a mixed solution I; adding tridecafluorooctyltriethoxysilane into the mixed solution I, and carrying out ultrasonic dispersion to obtain a mixed solution II; drying the mixed solution II to obtain modified hectorite powder; mixing the modified hectorite powder with perfluorohexane, carrying out ultrasonic dispersion, adding molten AKD, conducting mixing and heating, and carrying out ultrasonic emulsification to obtain an AKD-A emulsion; and mixing the AKD-A emulsion with a sodium dodecyl sulfate aqueous solution, and carrying out ultrasonic emulsification to obtain the alkyl ketene dimer papermaking sizing agent. The sizing performance of the AKD emulsion prepared by the method disclosed by the invention is remarkably improved, and meanwhile, the hydrolysis resistance and emulsion stability of the AKD can be greatly improved; and the AKD sizing agent emulsion disclosed by the invention is simple in preparation process, low in emulsifying cost and good in sizing effect, and the dosage of an emulsifying agent is small.

Owner:山东济清科技服务有限公司

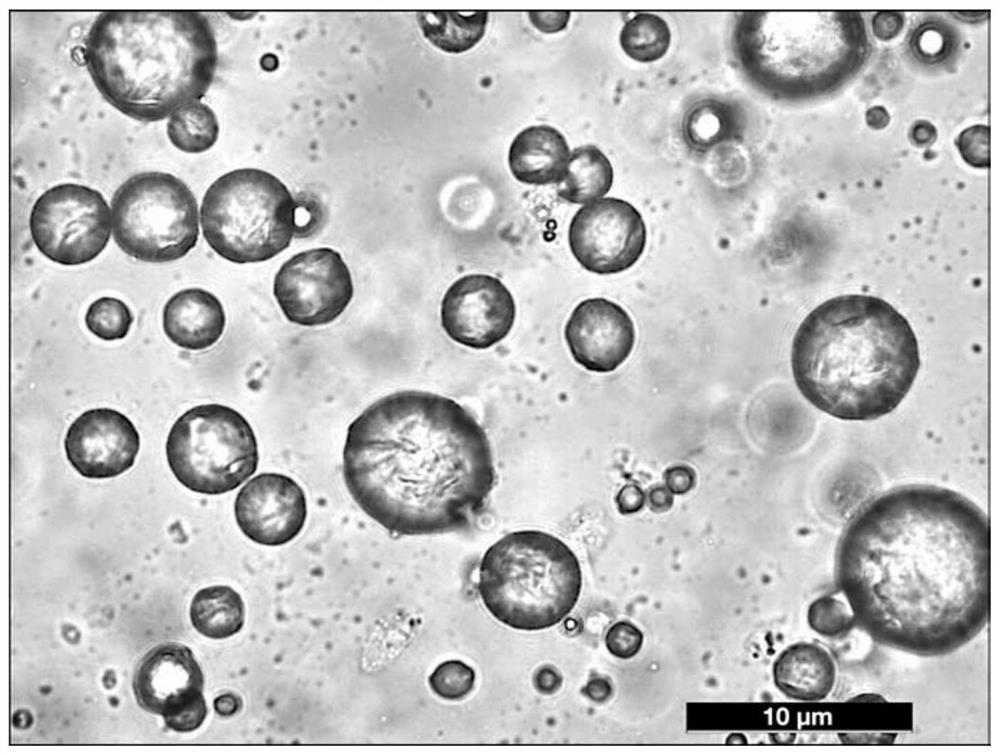

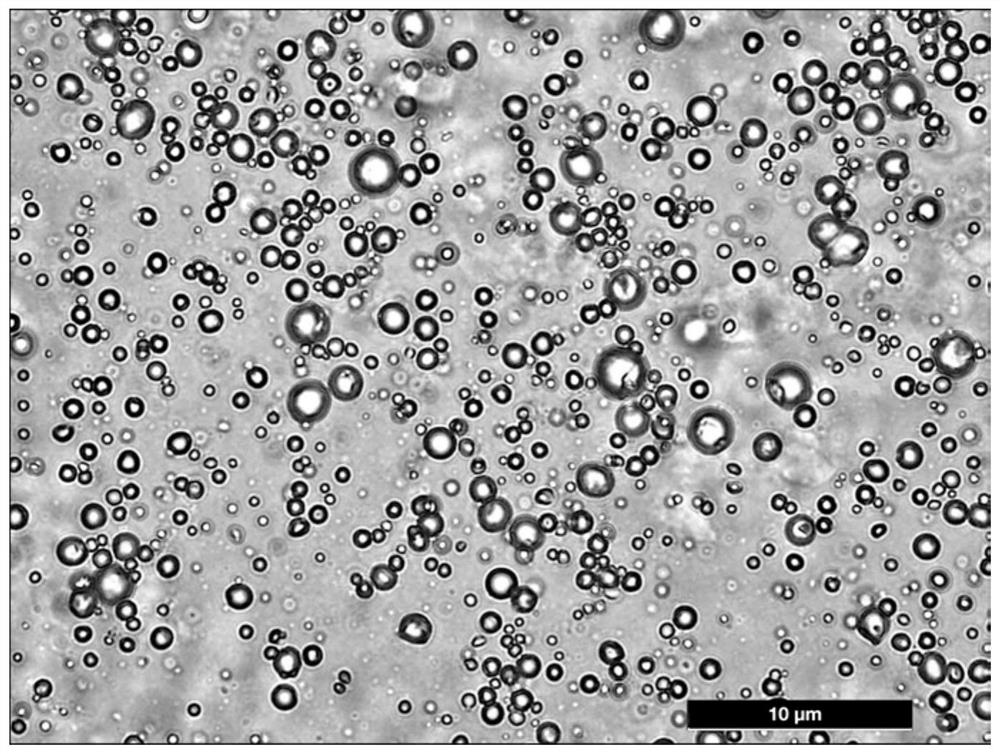

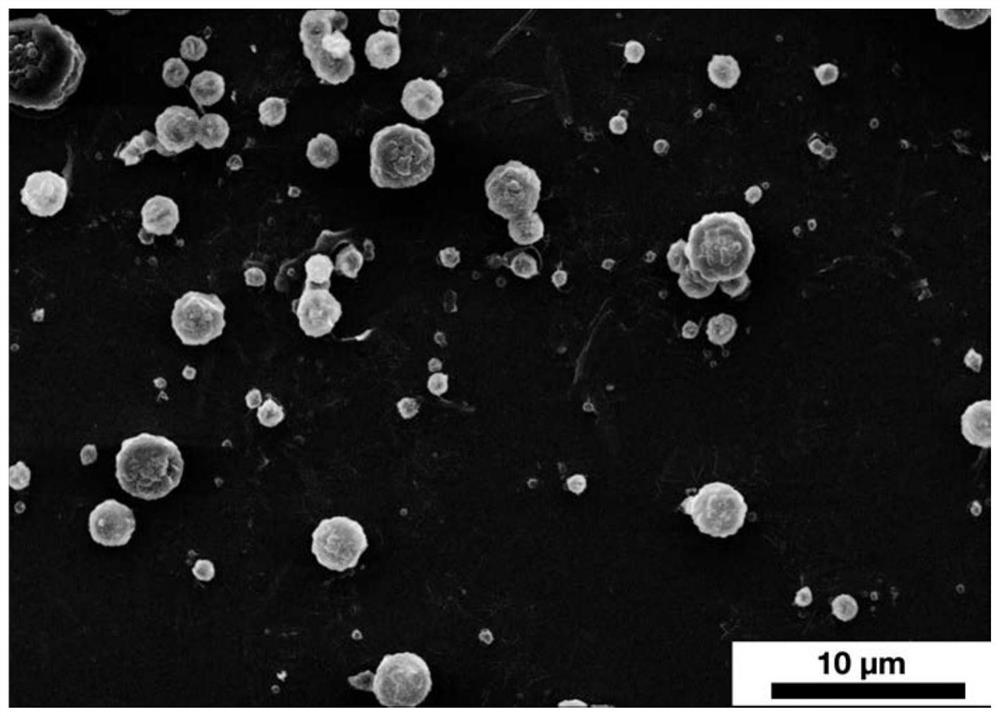

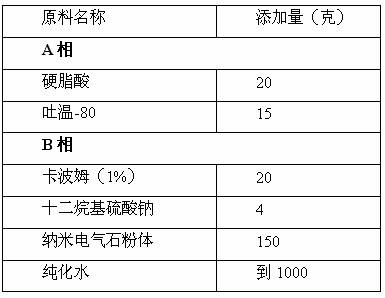

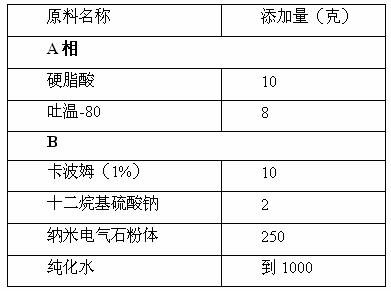

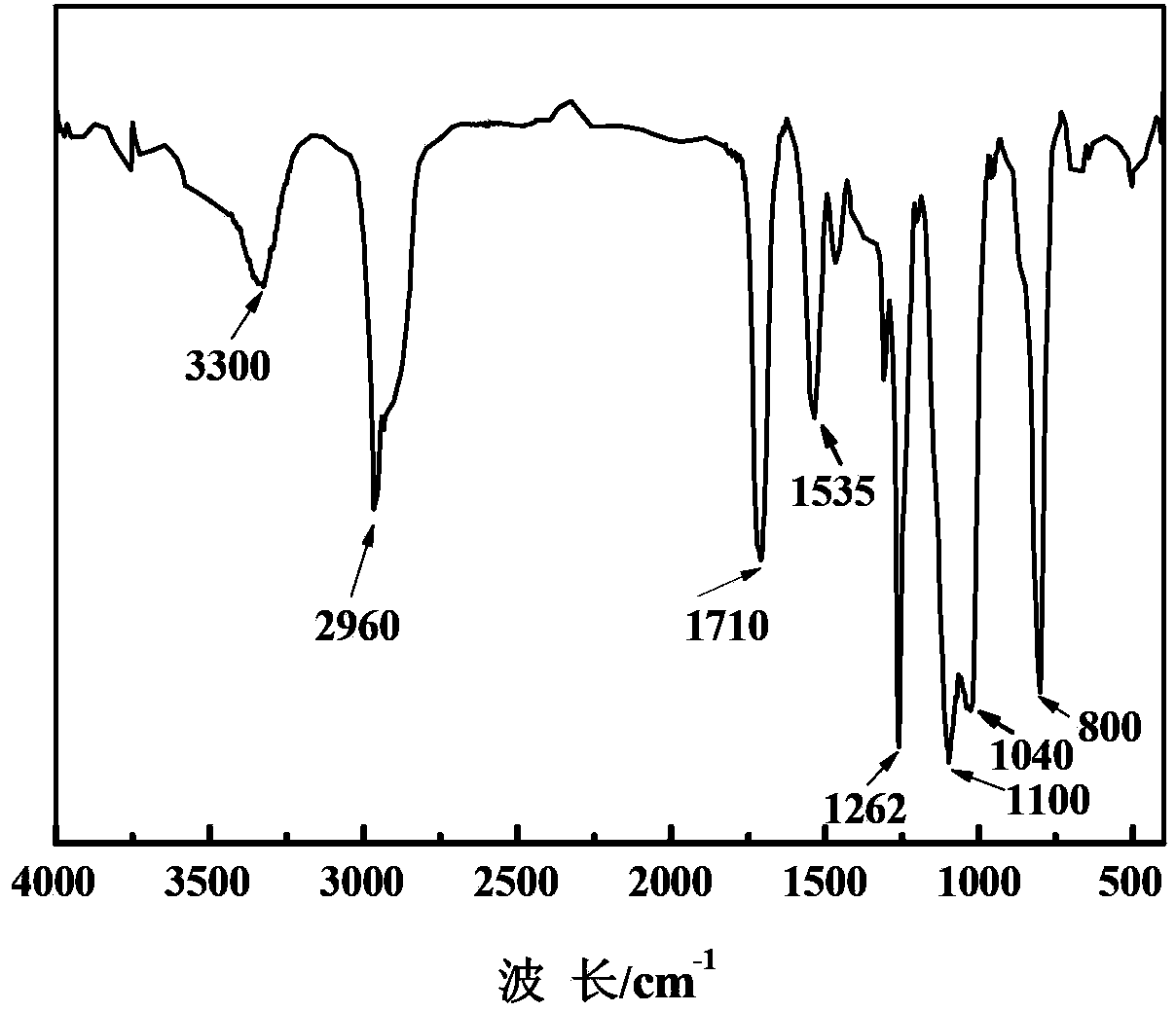

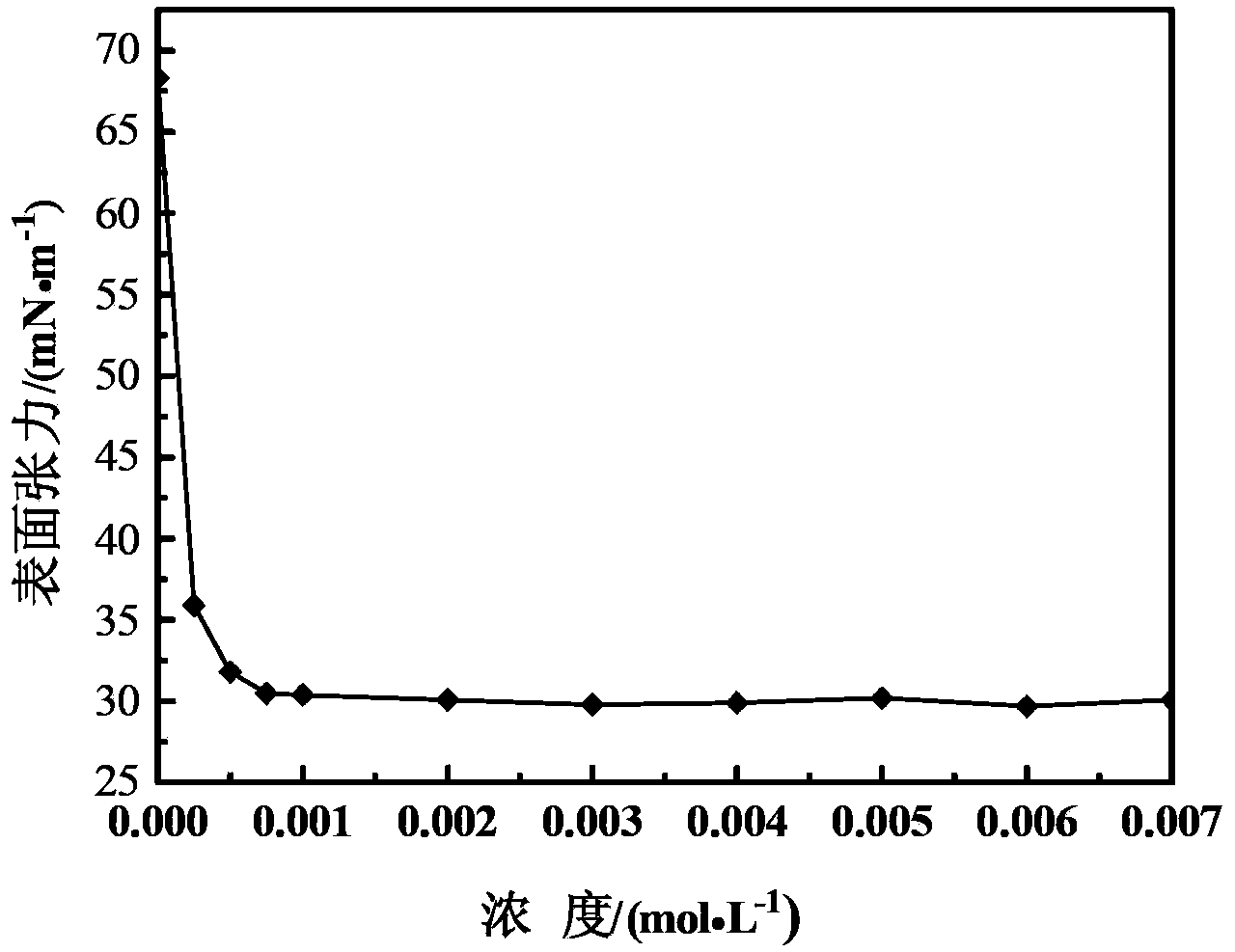

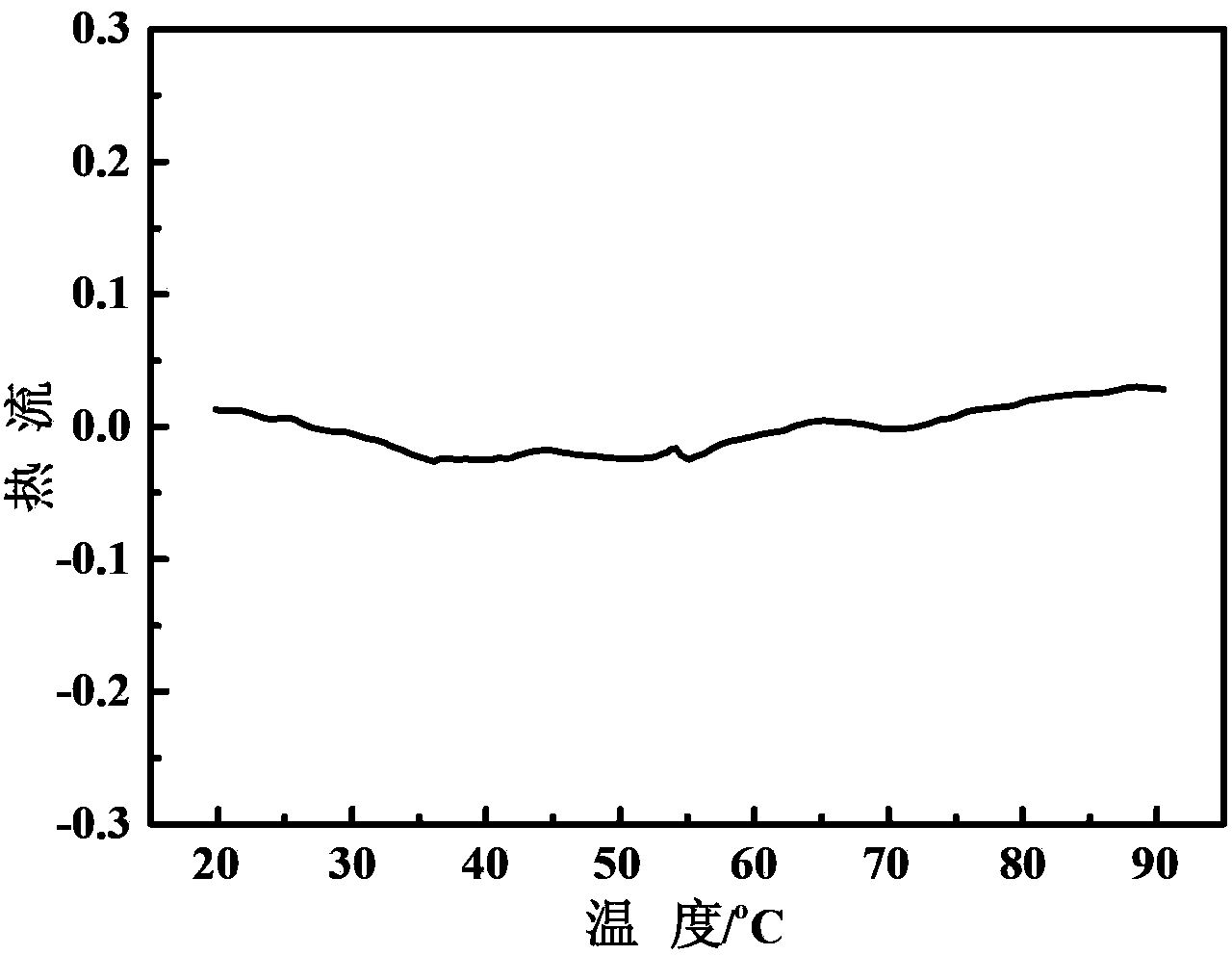

Nano tourmaline dispersion liquid and preparation method thereof

PendingCN112044295AUniform and stable dispersionStable composite systemBiocideCosmetic preparationsActive agentPhysical chemistry

The invention discloses nano tourmaline dispersion liquid and a preparation method thereof. The preparation method comprises the following steps: mixing an oil phase component and an emulsifier in anoil phase system according to a certain addition ratio; adding a dispersion stabilizer, a surfactant and nano tourmaline powder into water according to a certain addition ratio in the water dispersionsystem, and performing mixing; respectively uniformly mixing the two phases, performing heating to a certain temperature, carrying out homogeneous mixing on the two phases under rapid stirring, and performing cooling to room temperature to form a stable emulsion dispersion system; according to the nano tourmaline composite dispersion liquid prepared by the method, the difference between the tourmaline particle size and the particle size of a nano tourmaline powder raw material is within 20%; in the dispersion liquid, the nano tourmaline particles are suspended in the solution in a monodisperse form; and after the nano tourmaline composite dispersion liquid is placed for more than 60 days, the phenomena of layering, demulsification or caking of the nano tourmaline composite dispersion liquid are avoided. Moreover, the preparation method is simple and convenient to operate, wide in parameter adjustable range, low in energy consumption, short in period and suitable for pilot scale-up andindustrial large-scale production.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Silicon-containing polyurethane surfactant and preparation method thereof

The invention discloses a preparation method of a silicon-containing polyurethane surfactant. The method is characterized by comprising the following steps of: heating hydrophobic silicon oil and a hydrophilic dihydric alcohol monomer while stirring in the molar ratio of 10:1-1:10 in a solvent in an inert atmosphere to 50-60 DEG C, adding a catalyst, and slowly adding isocyanate at the temperature of 70-80 DEG C for reacting for 2-3 hours; and cooling to 60 DEG C, adding a neutralizing agent, evaporating a solvent out at the temperature of 50-55 DEG C 30-60 minutes later, precipitating in methanol of 20-25 DEG C, and drying at the temperature of 50-60 DEG C to constant weight to obtain a product. A silicon oil chain segment with low surface tension is introduced into polyurethane molecules, so that the surface tension of polyurethane is reduced; and a hydrophilic part of the product consists of an ionic monomer and a nonionic monomer, so that the defect of the sensitivity of a single nonionic emulsifier to temperature is overcome, and a product aqueous solution is prevented from undergoing phase splitting emulsion breaking at the temperature of 20-90 DEG C, and can be applied in the industries of spinning, papermaking, oilfields and the like.

Owner:佛山市方普防护技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com