Lithium ion battery anode, preparation method of lithium ion battery anode and lithium ion battery

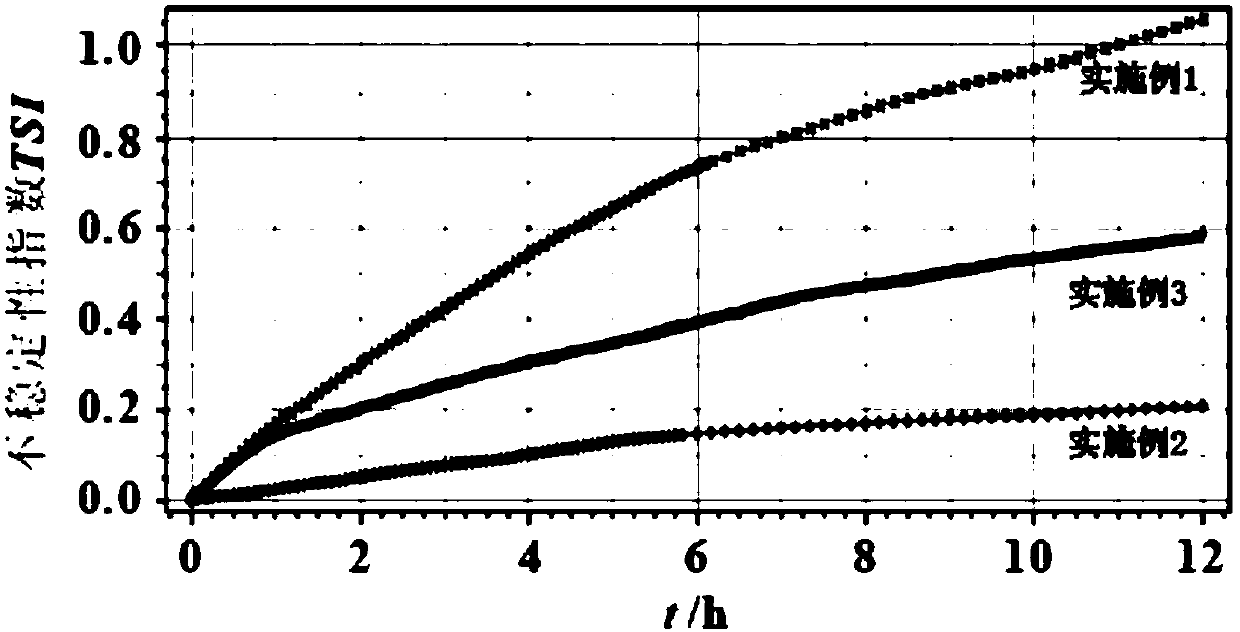

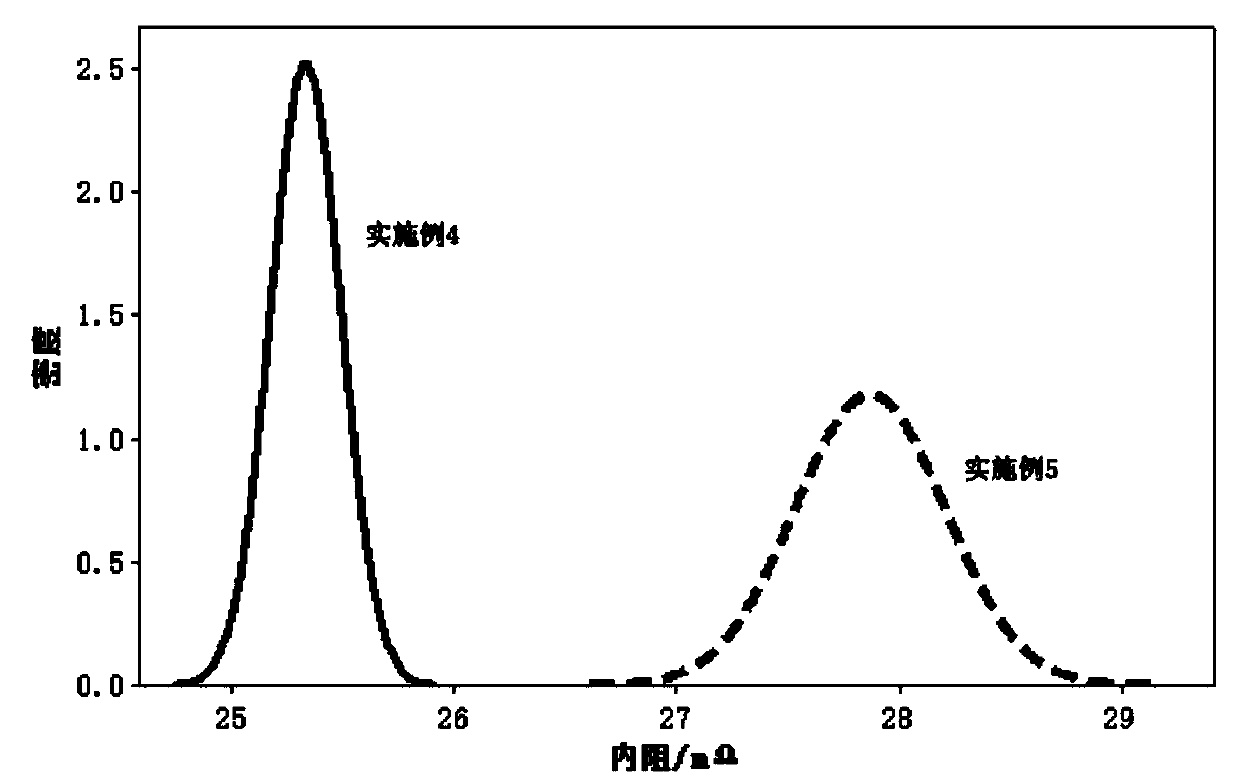

A lithium-ion battery, negative electrode technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of shortening battery life, reducing negative electrode conductivity, and increasing battery internal resistance, achieving good conductivity and internal resistance. The effect of lowering and high stability of slurry viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] Wherein, the preparation method of the negative electrode slurry at least includes the following steps:

[0054] Step S01, dry-blending the negative electrode active material, conductive agent, binder, and dispersant to obtain a first mixed material;

[0055] Step S02, adding 30-35 wt% of the solvent into the first mixed material for wet mixing treatment, and at the same time performing the first ultrasonic dispersion treatment;

[0056] Step S03, adding 35-45 wt% of the solvent, continuing the wet mixing process under vacuum conditions, and simultaneously performing the second ultrasonic dispersion process;

[0057] Step S04, adding the rest of the solvent, continuing the wet mixing process under vacuum conditions, and at the same time performing the third ultrasonic dispersion process.

[0058] In a specific manufacturing process, the above-mentioned negative electrode slurry is prepared in a stirring tank.

[0059] In step S01, when the negative electrode active ma...

Embodiment 1

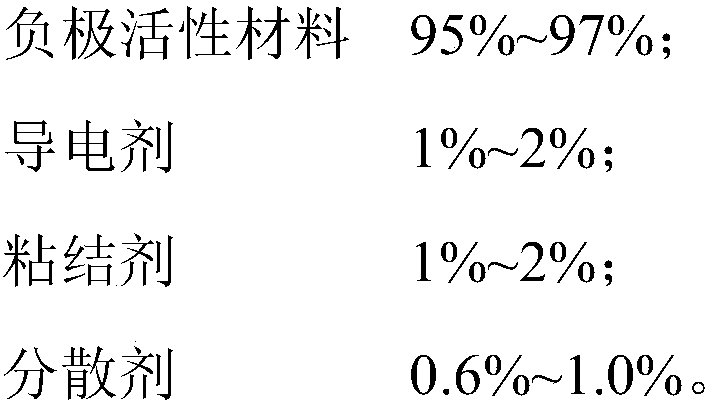

[0081] A lithium-ion battery negative electrode, comprising a copper foil current collector and a negative electrode material attached to the copper foil current collector, in terms of 100% by mass, the negative electrode material includes the following components:

[0082]

[0083] Wherein, in terms of 100% of the mass of the dispersant, the dispersant includes the following components:

[0084] Sodium Carboxymethyl Cellulose 50%;

[0085] Sodium Lauryl Sulfate 50%.

[0086] In the preparation method process of the negative electrode of the lithium ion battery, it is necessary to add deionized water accounting for 50% of the total mass of the negative electrode slurry. The specific preparation method is as follows:

[0087] Step S01, when dry-mixing the graphite, acetylene black, PTFE and dispersant in a stirred tank, control the stirring speed of the stirred tank to be 8 revolutions per minute, and stir for 10 minutes. During the whole dry-mixing process, control the tem...

Embodiment 2

[0097] A lithium-ion battery negative electrode, comprising a copper foil current collector and a negative electrode material attached to the copper foil current collector, in terms of 100% by mass, the negative electrode material includes the following components:

[0098]

[0099] Wherein, in terms of 100% of the mass of the dispersant, the dispersant includes the following components:

[0100] Sodium Carboxymethyl Cellulose 50%;

[0101] Sodium Lauryl Sulfate 50%.

[0102] The preparation method of the negative electrode of the lithium ion battery is the same as that of Example 1, so it will not be described in detail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com