Lithium-intercalated metal oxide and preparation method and application thereof

A lithium metal oxide and alkali metal compound technology, which is applied in the field of lithium intercalation metal oxide and its preparation, can solve the problems of low initial discharge capacity and capacity retention rate of lithium-ion batteries, difficulty in uniform distribution of lithium elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

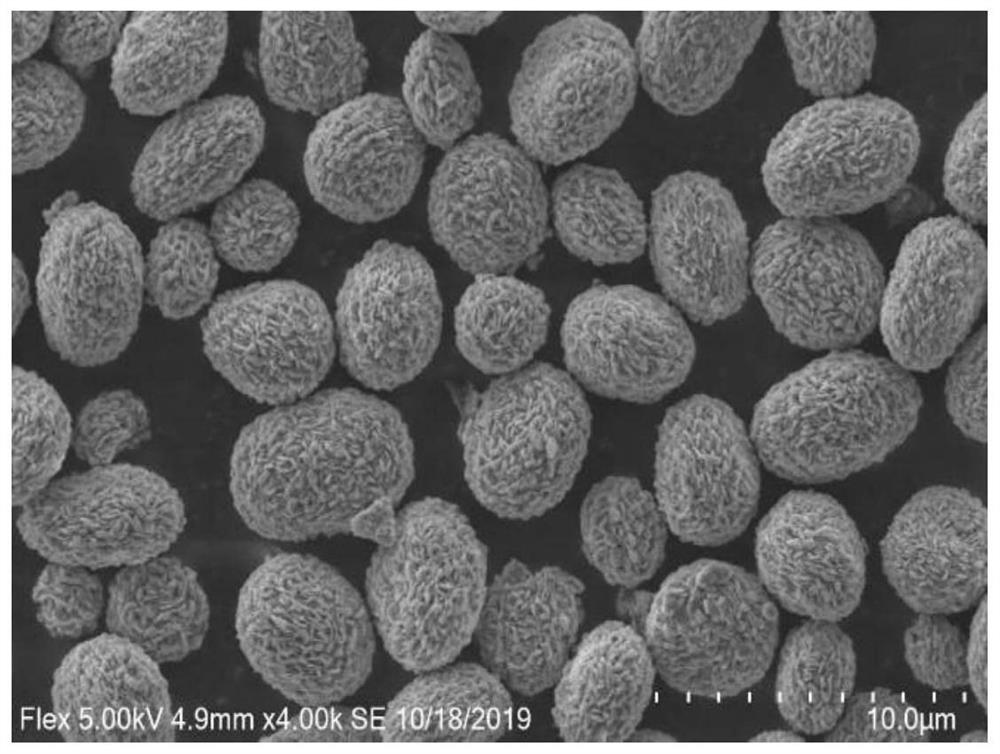

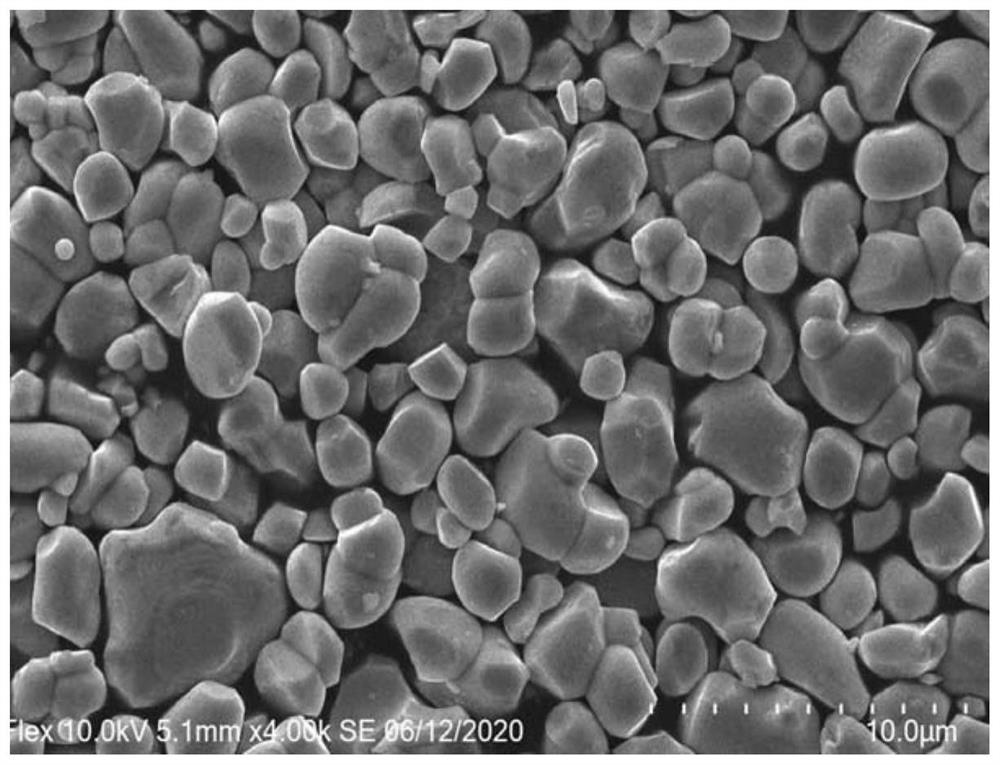

Image

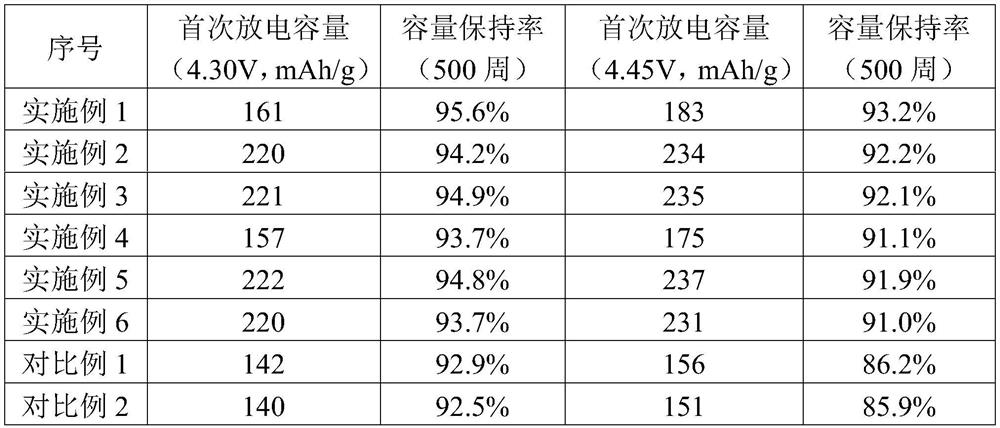

Examples

Embodiment 1

[0037] S1. Combine the metal mixture (Ni, Co, Mn, Zr and W five metals at a molar ratio of 1:1:1:0.04:0.07), nitric acid, high purity water, and sodium sulfate in a molar ratio of 10:2:2:1. At the same time, add 13g / L ammonium sulfate to the reactor for chemical corrosion crystallization reaction, and under normal pressure, control the ORP value of oxidation-reduction potential at -2000mv, the conductivity at 300uS / cm, and the input power of stirring Control at 0.8kw / m 3 ·H, the metal ion concentration is controlled at 6g / L, the pH value is controlled at 7-8, the reaction temperature is controlled at 50°C, the residence time of the material in the reactor is controlled at 30h, the crystallization process continuously consumes water and does not produce excess waste water After full reaction, magnetic particles and slurry are obtained by magnetic separation at a magnetic separation intensity of 200Gas. The slurry is solid-liquid separated to obtain solid particles and filtrate. T...

Embodiment 2

[0041] S1, the metal mixture (NiO, MgO, ZrO and WO 3 The four metal oxides are mixed at a molar ratio of 1:0.008:0.005:0.008), nitric acid, high-purity water, and sodium chloride are simultaneously added to the reactor for chemical corrosion crystallization reaction in parallel flow according to the molar ratio of 10:2:1:2. Add 30g / L of ethylenediaminetetraacetic acid, under normal pressure, control the ORP value of oxidation-reduction potential at -600mv, the conductivity at 500uS / cm, and the stirring input power at 0.9kw / m 3 ·H, the metal ion concentration is controlled at 9g / L, the pH value is controlled at 8-10, the reaction temperature is controlled at 60℃, the residence time of the material in the reactor is controlled at 15h, the crystallization process continuously consumes water and does not produce excess waste water After full reaction, magnetic particles and slurry are obtained by magnetic separation at a magnetic separation intensity of 5000 Gas. The slurry is solid-...

Embodiment 3

[0045] S1. Combine the metal mixture (Ni, Co, Al, Zr and Ti five metals at a molar ratio of 1:0.12:0.15:0.01:0.012), nitric acid, high purity water, and sodium sulfate in a molar ratio of 10:2:1:2. At the same time, add 30g / L ammonium chloride to the reactor for chemical corrosion crystallization reaction. Under normal pressure, control the ORP value of the oxidation-reduction potential at 100mv, the electrical conductivity at 5000uS / cm, and stir the input power Control at 0.7kw / m 3 ·H, the metal ion concentration is controlled at 15g / L, the pH value is controlled at 6-8, the reaction temperature is controlled at 50°C, the residence time of the material in the reactor is controlled at 15h, the crystallization process continuously consumes water and does not produce excess waste water After full reaction, magnetic particles and slurry are obtained by magnetic separation at a magnetic separation intensity of 3000Gas. The slurry is solid-liquid separated to obtain solid particles a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com