Denitrification filler, denitrification filler ball and application thereof

A packing ball and denitrification technology, which is applied in the control of water treatment parameters, water/sludge/sewage treatment, water pollutants, etc., can solve the problems of low cost and poor biocompatibility of nitrogen carriers, so as to improve efficiency and promote hanging Effects of membranes, good biocompatibility and degradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

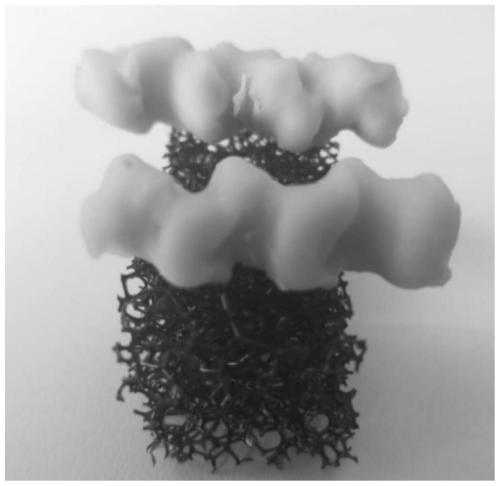

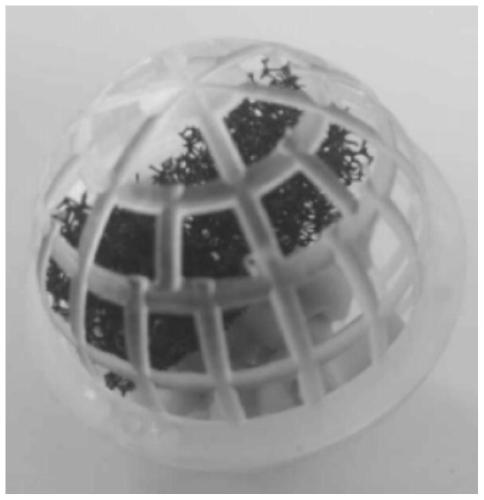

Embodiment 1

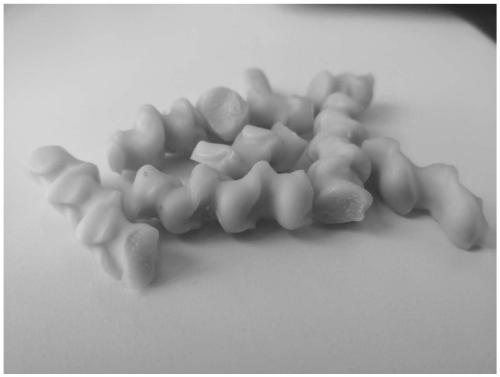

[0042] The sewage denitrification filler ball includes a shell and a denitrification filler. The shell is a hollow sphere, and the denitrification filler is arranged inside the hollow sphere. The denitrification filler is prepared from the following raw materials in weight percentage: polyhydroxybutyrate valeric acid co- 50% polyester, 10% nitrifying bacteria, 5% denitrifying bacteria and 35% iron powder; the particle size of iron powder is 300nm; the shell material is recycled polyethylene, and the shell diameter is 30mm; the denitrification filler is filled to the shell In the body, it occupies 35% of the shell volume.

[0043] The preparation method of the denitrification filler is as follows: add polyhydroxybutyrate valeric acid copolyester into the solvent, dissolve it completely, then add nitrifying bacteria, denitrifying bacteria and iron powder, mix evenly, press molding, and dry to obtain spiral rod-shaped Nitrogen removal packing.

Embodiment 2

[0045] The sewage denitrification filler ball includes a shell and a denitrification filler. The shell is a hollow sphere, and the denitrification filler is arranged inside the hollow sphere. The denitrification filler is prepared from the following raw materials in weight percentage: polyhydroxybutyrate valeric acid co- 60% polyester, 10% nitrifying bacteria, 15% denitrifying bacteria and 25% iron powder; the particle size of iron powder is 500nm; the shell material is recycled polyethylene, and the shell diameter is 60mm; the denitrification filler is filled to the shell In the body, it occupies 75% of the shell volume.

[0046] The preparation method of the denitrification filler is as follows: add polyhydroxybutyrate valeric acid copolyester into the solvent, dissolve it completely, then add nitrifying bacteria, denitrifying bacteria and iron powder, mix evenly, press molding, and dry to obtain spiral rod-shaped Nitrogen removal packing.

Embodiment 3

[0048] The sewage denitrification filler ball includes a shell and a denitrification filler. The shell is a hollow sphere, and the denitrification filler is arranged inside the hollow sphere. The denitrification filler is prepared from the following raw materials in weight percentage: polyhydroxybutyrate valeric acid co- 55% polyester, 10% nitrifying bacteria, 5% denitrifying bacteria and 30% iron powder; the particle size of iron powder is 325nm; the shell material is recycled polyethylene, and the shell diameter is 40mm; the denitrification filler is filled to the shell In the body, it occupies 50% of the volume of the shell.

[0049] The preparation method of the denitrification filler is as follows: add polyhydroxybutyrate valeric acid copolyester into the solvent, dissolve it completely, then add nitrifying bacteria, denitrifying bacteria and iron powder, mix evenly, press molding, and dry to obtain spiral rod-shaped Nitrogen removal packing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com