Method for removing sulfur oxides and nitrogen oxides in catalytic cracking regeneration flue gas

A technology for regenerating flue gas and catalytic cracking, which is applied in chemical instruments and methods, separation methods, and air quality improvement. The effect of pollutant treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

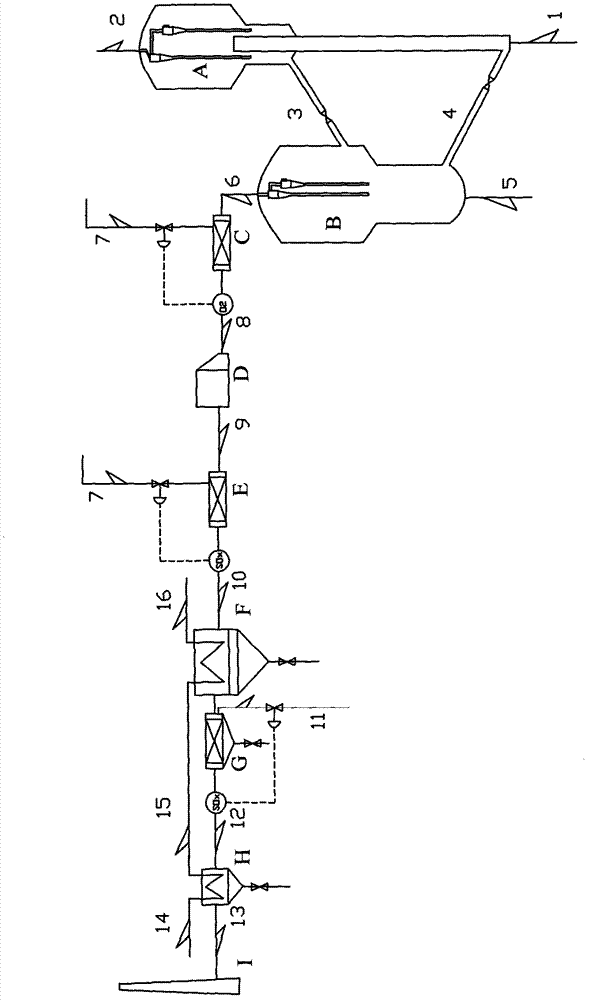

Method used

Image

Examples

preparation example Construction

[0049] Catalyst preparation method:

[0050] Will Al 2 o 3 ·H 2 O(pseudoboehmite), Ce(NO 3 ) 3 , ZrO(NO 3 ) 2 , put it in a beaker according to the ratio of m(Al):m(Ce):m(Zr)=85:5:10, add deionized water to make a slurry, stir and age for 2 hours, then add appropriate amount of scallop powder to form The semi-solid is further extruded into Φ1mm cylindrical strips, dried at 110°C, and then baked at 700°C for 4 hours, and cut into Φ1×2mm columnar particles as carriers for later use.

[0051] H 2 PtCL 6 ·6H 2 The aqueous solution of O impregnated the carrier twice, and each time was dried at 110°C and calcined at 650°C for 4 hours to obtain catalyst A. Based on the total weight of the catalyst, the weight percentage of PtO in the catalyst A is 0.40wt%. Before the catalyst was used, it was heated under H at the reaction temperature 2 Pre-reduction in the atmosphere for half an hour.

[0052] La(NO 3 ) 3 .6H 2 The aqueous solution of O impregnated the carrier twice,...

Embodiment

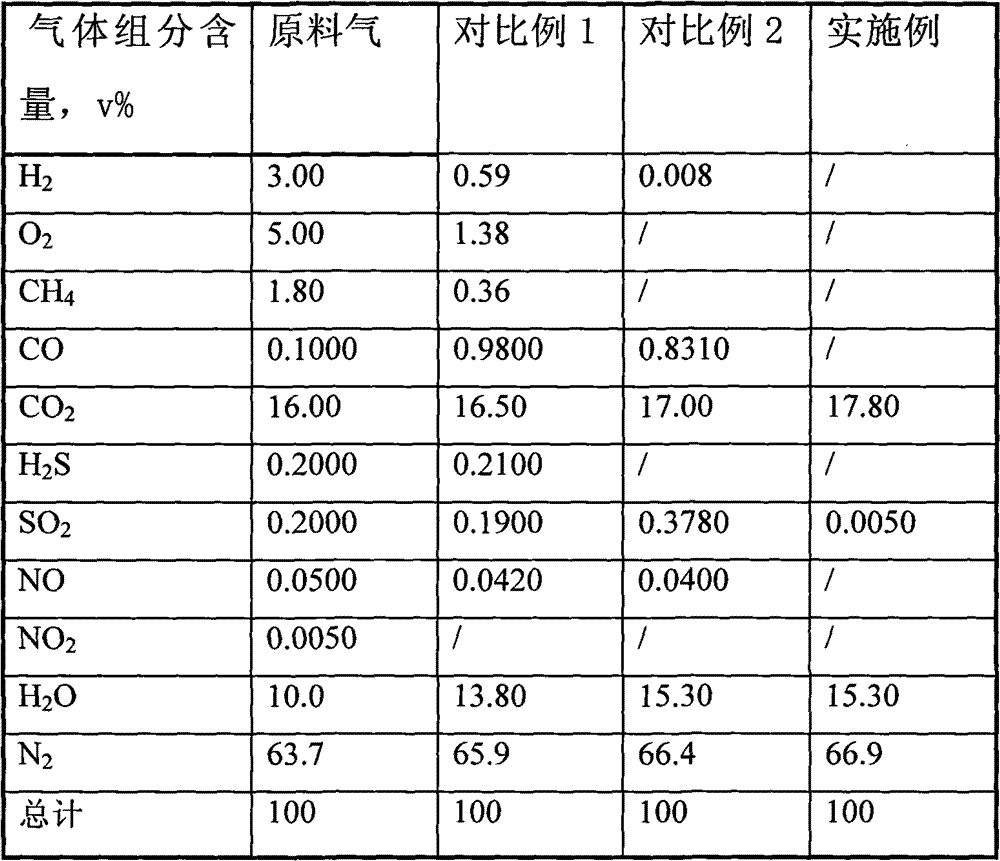

[0060] Two fixed-bed reactors (Φ20×600mm) are connected in series. The former reactor I is filled with catalyst A, with a loading capacity of 5.0g. The reaction is carried out under the conditions of normal pressure and reaction temperature of 650°C, and the weight hourly space velocity is 48h. -1 . The latter reactor II is loaded with catalyst B, the catalyst loading amount is 5.0 g, and the reaction is carried out under the conditions of normal pressure and reaction temperature of 500°C. The tail gas composition when the reaction reaches equilibrium is shown in Table 1.

[0061] Table 1

[0062]

[0063] It can be seen from Table 1 that the reactor in Comparative Example 1 was not filled with catalyst, and after the two streams of flue gas and reducing gas contacted at 650°C, the oxygen in the feed gas was consumed and the carbon monoxide content in the tail gas increased. In comparative example 2, due to the H in the feed gas 2 S is oxidized during the reaction, so SO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com