Ammonia process type double-cycle desulfurization and denitrification dust removal system

A technology for desulfurization, denitrification, and dust removal systems, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of inability to meet environmental protection standards, tailing of flue gas, and high density of absorption liquid, and improve the utilization rate of ammonia in the system. , Improve the stripping efficiency, reduce the effect of ammonia release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

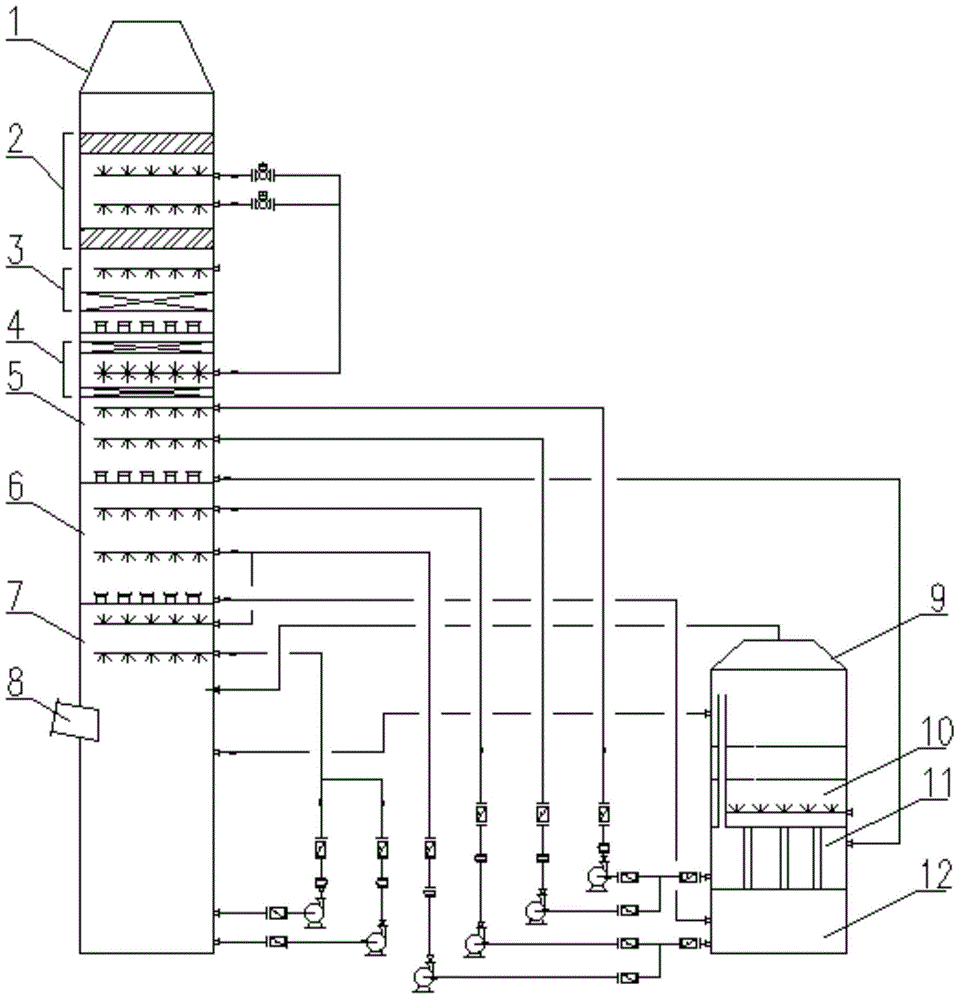

[0040] Such as figure 1 As shown, an ammonia double-cycle desulfurization, denitrification and dust removal system includes a washing absorption tower 1 and an oxidation circulation tank 9; the washing absorption tower 1 is sequentially composed of a high-efficiency water mist removal section 2, an enhanced ammonia mist removal section 3, and an absorption liquid demisting section Section 4, secondary absorption section 5, primary absorption section 6, washing and cooling section 7; oxidation circulation tank 9 is composed of oxidation section 10, secondary absorption liquid circulation section 11 and primary absorption liquid circulation section 12 in turn;

[0041] The oxidation section 10 communicates with the washing and cooling section 7 through pipelines; the secondary absorption liquid circulation section 11 communicates with the secondary absorption section 5 through pipelines; the primary absorption liquid circulation section 12 communicates with the primary absorption...

Embodiment 2

[0051] The method for desulfurization, denitrification and dust removal of the above-mentioned system includes the following steps:

[0052] SO 2 Concentration≥4000mg / Nm 3 The hot flue gas with a temperature of 120°C to 180°C enters the washing and cooling section 7 from the flue gas inlet pipe 8, and is washed in countercurrent contact with the ammonium sulfate solution containing ammonium nitrate, and then enters the main SO removal 2 The primary absorption section 6) is absorbed by the countercurrent spraying of the absorption liquid, and then enters into the auxiliary SO removal 2 The second-level absorption section 5 uses the absorption liquid to continue spraying and absorbing to purify the flue gas; then enters the absorption liquid demist section 4 for demisting, then enters the enhanced ammonia mist removal section 3, and then enters the high-efficiency water mist removal section 2.

[0053] When the flue gas enters the primary absorption section 6, the ammonium sul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com