Method for preparing fibers in linear structure through pickering emulsion electrospinning

A linear structure, emulsion technology, applied in the chemical characteristics of fibers, rayon manufacturing, textiles and papermaking, etc., can solve the problems of difficult to popularize, harsh conditions, rare raw materials, etc., and achieve easy mass production, mild conditions, and easy raw materials. the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

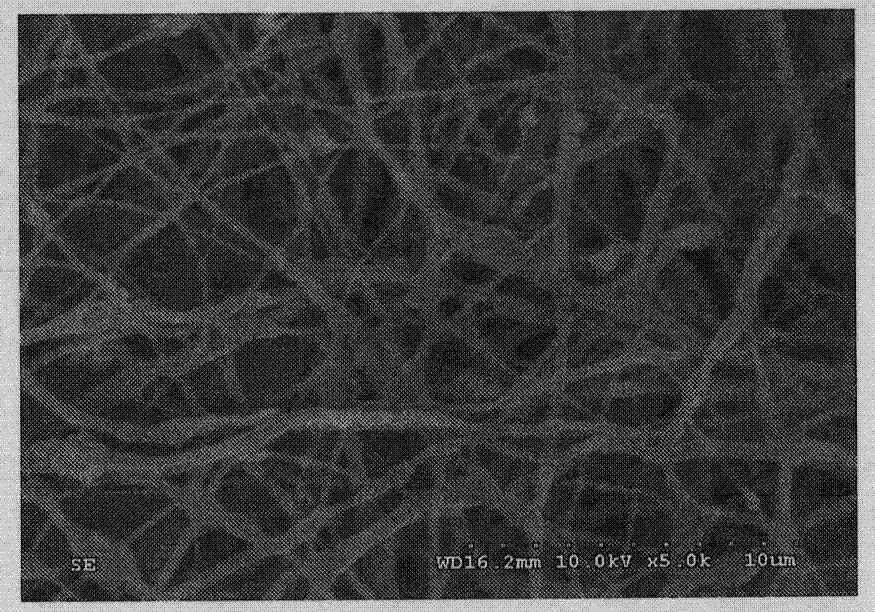

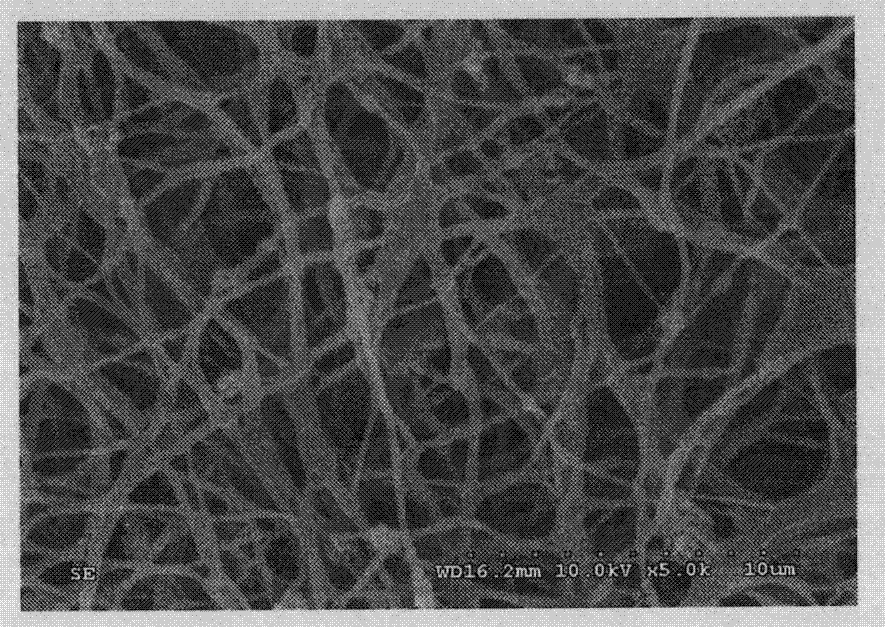

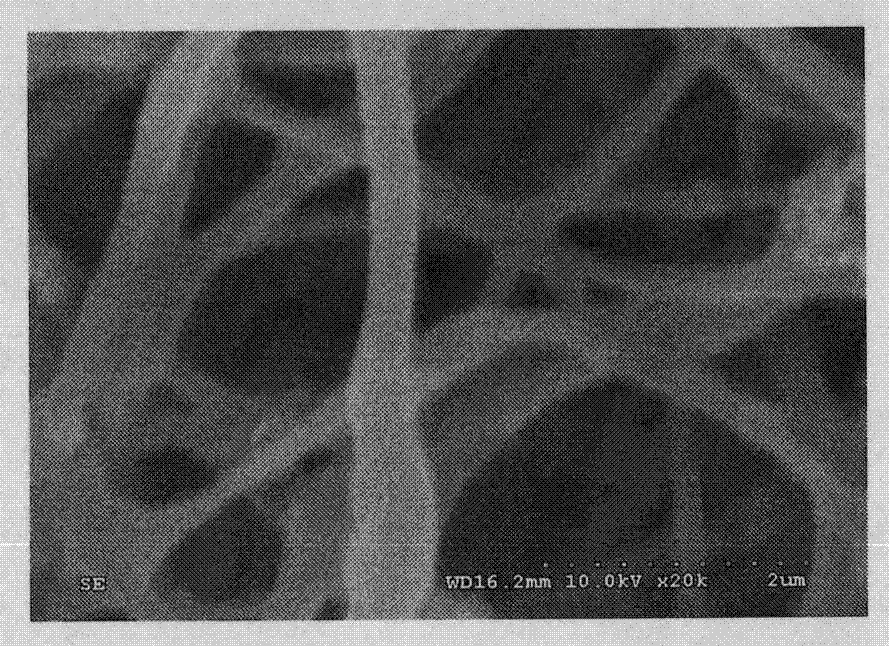

Image

Examples

Embodiment 1

[0042] (1) Preparation of Sodium Alginate Derivatives

[0043] Put 5g of sodium alginate and 230ml of ultrapure water in a 500mL round bottom flask, heat to 35°C and stir until completely dissolved, then weigh 1.213g of EDC·HCL (1-ethyl-(3-dimethylaminopropyl) Carbodiimide hydrochloride) was dissolved in 5mL HCl, and it was quickly added to the dissolved sodium alginate, after stirring evenly, the pH value of the solution was adjusted to 3.41 with 0.5mol / L HCl. After reacting for 10 minutes, octylamine was added according to a certain molar ratio, and reacted at 35° C. for 24 hours while stirring at a constant temperature. The obtained product was precipitated with absolute ethanol and centrifuged, washed twice, and the precipitate was put into a constant temperature blast drying oven, and dried at 60° C. to constant weight. Dissolve the obtained solid product in ultrapure water, dialyze for three days to remove small molecular impurities, add ethanol again to precipitate, ce...

Embodiment 2

[0054] (1) Preparation of Sodium Alginate Derivatives

[0055] Put 5g of sodium alginate and 230ml of ultrapure water in a 500mL round bottom flask, heat to 35°C and stir until completely dissolved, then weigh 1.213g of EDC·HCL (1-ethyl-(3-dimethylaminopropyl) Carbodiimide hydrochloride) was dissolved in 5mL HCl, and it was quickly added to the dissolved sodium alginate, after stirring evenly, the pH value of the solution was adjusted to 3.41 with 0.5mol / L HCl. After reacting for 10 minutes, octylamine was added according to a certain molar ratio, and reacted at 35° C. for 24 hours while stirring at a constant temperature. The obtained product was precipitated with absolute ethanol and centrifuged, washed twice, and the precipitate was put into a constant temperature blast drying oven, and dried at 60° C. to constant weight. Dissolve the obtained solid product in ultrapure water, dialyze for three days to remove small molecular impurities, add ethanol again to precipitate, ce...

Embodiment 3

[0066] (1) Preparation of Sodium Alginate Derivatives

[0067] Put 5g of sodium alginate and 230ml of ultrapure water in a 500mL round bottom flask, heat to 35°C and stir until completely dissolved, then weigh 1.213g of EDC·HCL (1-ethyl-(3-dimethylaminopropyl) Carbodiimide hydrochloride) was dissolved in 5mL HCl, and it was quickly added to the dissolved sodium alginate, after stirring evenly, the pH value of the solution was adjusted to 3.41 with 0.5mol / L HCl. After reacting for 10 minutes, octylamine was added according to a certain molar ratio, and reacted at 35° C. for 24 hours while stirring at a constant temperature. The obtained product was precipitated with absolute ethanol and centrifuged, washed twice, and the precipitate was put into a constant temperature blast drying oven, and dried at 60° C. to constant weight. Dissolve the obtained solid product in ultrapure water, dialyze for three days to remove small molecular impurities, add ethanol again to precipitate, ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com