Preparation method of waterborne polyurethane

A technology for water-based polyurethane and polyester diol, applied in the field of chemical synthesis, can solve the problems of difficult control of the preparation process of water-based polyurethane and the use of sulfonic acid type chain extenders, etc., and achieves easy large-scale production, high solid content, Good dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

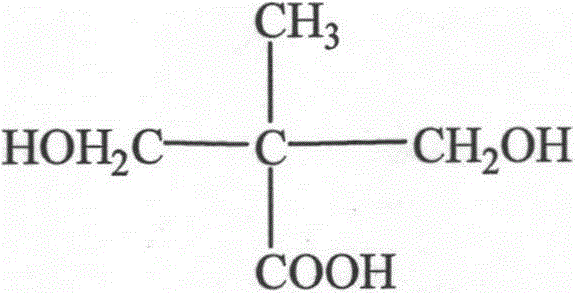

Method used

Image

Examples

Embodiment 1

[0043] A kind of preparation method of aqueous polyurethane, concrete steps are:

[0044] In the reaction equipment equipped with stirrer, thermometer and reflux condenser, add PCL (number average molecular weight 3000) 1Kg, then add HDI 0.2Kg and LDMPA 0.1Kg (hydroxyl value 550KOH mg / g, acid value 355KOHmg / g), After stirring evenly, the temperature was raised slowly, and the reaction was stirred at 80° C. for 2 h. Then lower the temperature to 35°C, add 20gTEA, neutralize at 30°C, add acetone to adjust the viscosity, stir for 0.5h to obtain a prepolymer; then slowly add 1.3Kg of distilled water into the system, and vigorously stir to emulsify and disperse. Then add the aqueous solution of 11g EDHPS, continue to stir and react for 1h, finally, the low-boiling-point solvent acetone is removed by vacuum distillation, and the water-based polyurethane with a solid content of 50% is obtained.

[0045] Mechanical properties of water-based polyurethane film: tensile strength at brea...

Embodiment 2

[0047] In the reaction equipment equipped with stirrer, thermometer and reflux condenser, add PTMEG (number average molecular weight 2000) 1.1Kg, then add IPDI 0.2Kg and LDMPA 0.1Kg (hydroxyl value 550KOH mg / g, acid value 355KOHmg / g) After stirring evenly, the temperature was raised slowly, and the reaction was stirred at 80° C. for 2 h. Then lower the temperature to 35°C, add 20gTEA, neutralize at 30°C, add acetone to adjust the viscosity, stir for 0.5h to obtain a prepolymer; then slowly add 1.3Kg of distilled water into the system, and vigorously stir to emulsify and disperse. Then add 11 g of AAS-Na aqueous solution, continue to stir and react for 1 h, and finally, distill under reduced pressure to remove acetone, a low-boiling solvent, to obtain water-based polyurethane with a solid content of 50%.

[0048] The mechanical properties of the waterborne polyurethane film: the tensile breaking strength is 55Mpa, and the breaking elongation is 530%.

Embodiment 3

[0050] In the reaction equipment equipped with stirrer, thermometer and reflux condenser, add PTMEG (number average molecular weight 2000) 1.1Kg, then add IPDI0.2Kg and LDMBA0.1Kg (hydroxyl value 500KOH mg / g, acid value 345KOHmg / g) After stirring evenly, the temperature was raised slowly, and the reaction was stirred at 80° C. for 2 h. Then lower the temperature to 35°C, add 20gTEA, neutralize at 30°C, add acetone to adjust the viscosity, stir for 0.5h to obtain a prepolymer; then slowly add 1.3Kg of distilled water into the system, and vigorously stir to emulsify and disperse. Then add 11 g of DHPA aqueous solution, continue to stir and react for 1 h, and finally, distill under reduced pressure to remove acetone, a low-boiling solvent, to obtain water-based polyurethane with a solid content of 50%.

[0051] The mechanical properties of the waterborne polyurethane film: the tensile breaking strength is 55Mpa, and the breaking elongation is 530%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength at break | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com