Preparation method of waterborne polyurethane capable of selfreparing

A water-based polyurethane, self-repairing technology, applied in the field of water-based polyurethane synthesis, to achieve good repairing effect, environmental friendliness, mild self-repairing conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

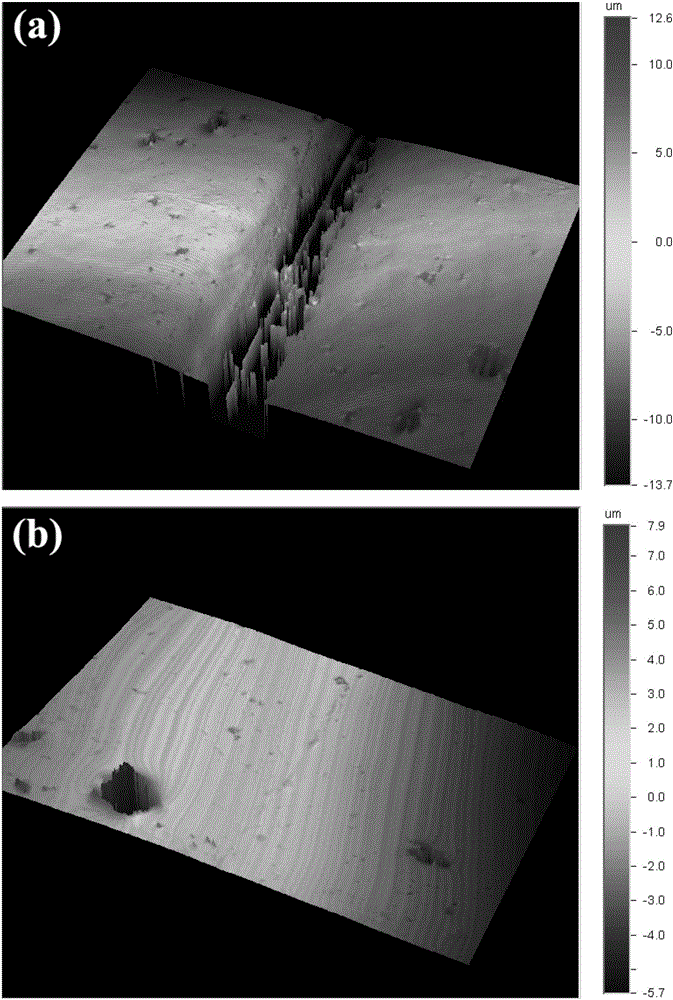

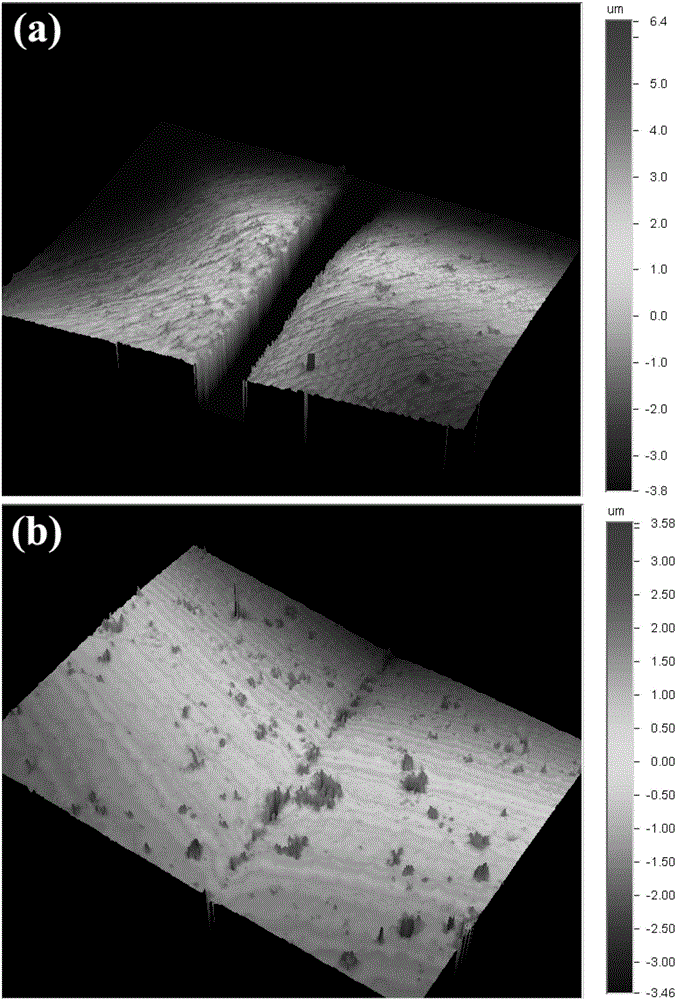

Image

Examples

Embodiment 1

[0029]Add 20g of polycaprolactone diol (molecular weight 1000), 1.788g of dimethylolpropionic acid dissolved in methylpyrrolidone into a three-necked flask, heat up to 120°C, vacuumize and keep the vacuum of the reaction system at Above 0.08MPa, after dehydration for 2 hours, the temperature drops to 80°C, add 9.78g of isophorone diisocyanate, stir and react for 1.5 hours under the protection of nitrogen, then the temperature drops to 50°C, and add methyl ethyl ketone to adjust the viscosity, add 1.028g Two (2-hydroxyethyl) disulfides and 0.03g dibutyltin dilaurate continued to react for 1 hour, then the temperature was lowered to 35°C, and 1.349g triethylamine was added for neutralization for 0.5 hour, then the temperature was lowered to room temperature. Add 80g of deionized water to emulsify and disperse under the condition that the speed of the agitator is 1500r / min, then add 0.240g of ethylenediamine, continue to stir and react for 1 hour, and finally, remove the low boili...

Embodiment 2

[0033] Add 20g of polycaprolactone diol (molecular weight 1000), 1.610g of dimethylolpropionic acid dissolved in methylpyrrolidone into a three-necked flask, heat up to 120°C, vacuumize and keep the vacuum of the reaction system at Above 0.08MPa, after dehydration for 2 hours, the temperature drops to 80°C, add 9.78g of isophorone diisocyanate, stir and react for 1.5 hours under the protection of nitrogen, then the temperature drops to 50°C, and add butanone to adjust the viscosity, add 1.234g Two (2-hydroxyethyl) disulfide and 0.03g dibutyltin dilaurate continued to react for 1 hour, then the temperature dropped to 35°C, and 1.2143g triethylamine was added for neutralization for 0.5 hour, then the temperature was dropped to room temperature, Add 79.5g of deionized water under the condition of 1500r / min rotating speed of the agitator to stir and emulsify and disperse, then add 0.2404g of ethylenediamine, continue to stir and react for 1 hour, and finally, remove the low boiling...

Embodiment 3

[0036] Add 20g of polycaprolactone diol (molecular weight 1000), 1.341g of dimethylolpropionic acid dissolved in methylpyrrolidone into a three-necked flask, heat up to 120°C, vacuumize and keep the vacuum of the reaction system at Above 0.08MPa, after dehydration for 2 hours, the temperature drops to 80°C, add 9.78g of isophorone diisocyanate, stir and react for 1.5 hours under the protection of nitrogen, then the temperature drops to 50°C, and add butanone to adjust the viscosity, add 1.543g Two (2-hydroxyethyl) disulfides and 0.03g dibutyltin dilaurate continued to react for 1 hour, then the temperature was lowered to 35°C, and 1.012g triethylamine was added for neutralization for 0.5 hour, then the temperature was lowered to room temperature. Add 79g of deionized water to stir emulsification and disperse at the speed of the agitator at 1500r / min, then add 0.2404g of ethylenediamine, continue to stir and react for 1 hour, and finally, remove the low boiling point solvent but...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile breaking strength | aaaaa | aaaaa |

| Tensile breaking strength | aaaaa | aaaaa |

| Tensile breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com