Heat exchange core for ventilation

A technology of heat exchange core and fresh air, which is applied to indirect heat exchangers, heat exchanger types, and household heating. The effect of water and heat transfer, reducing the thermal resistance of fouling, and good heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

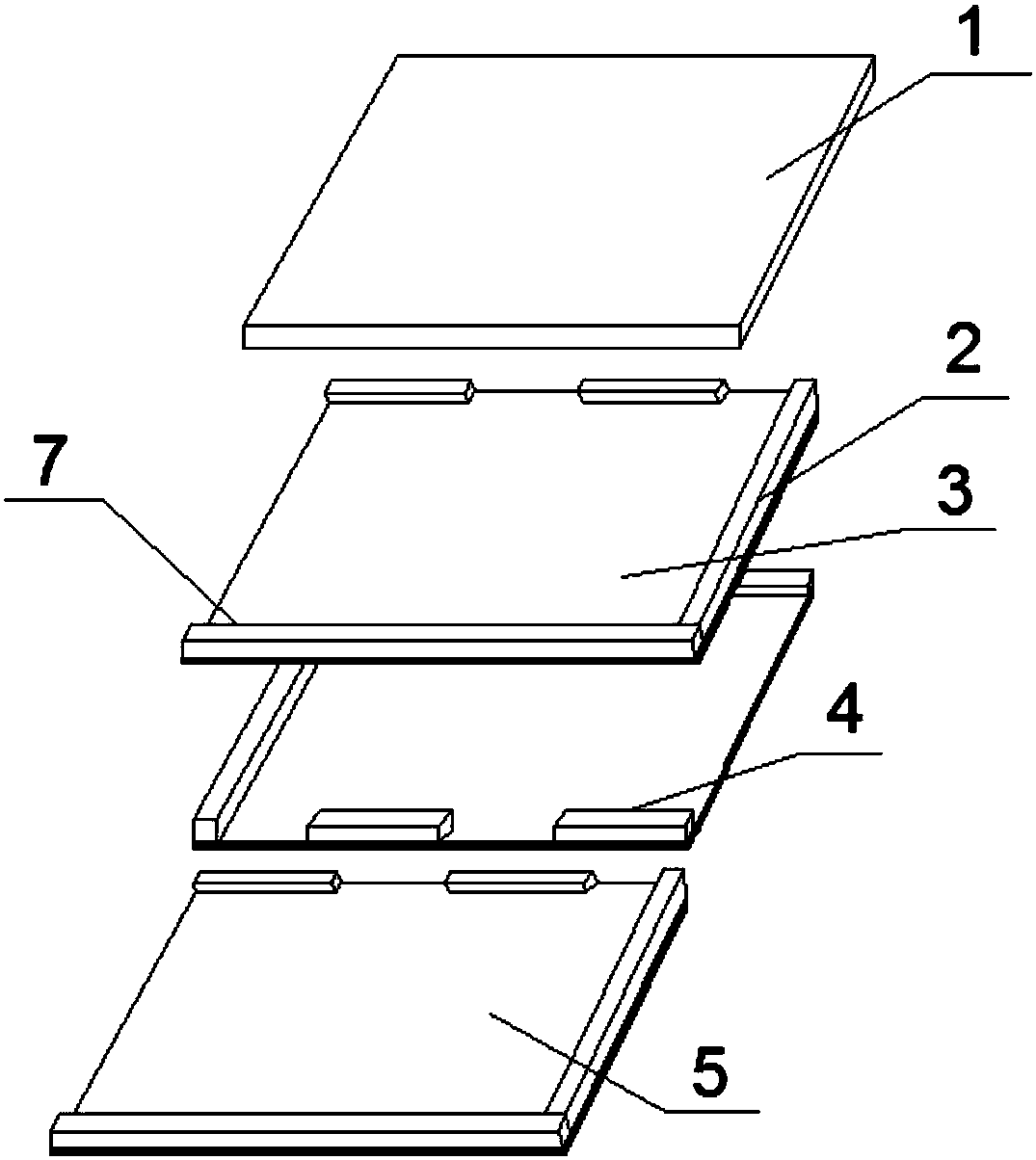

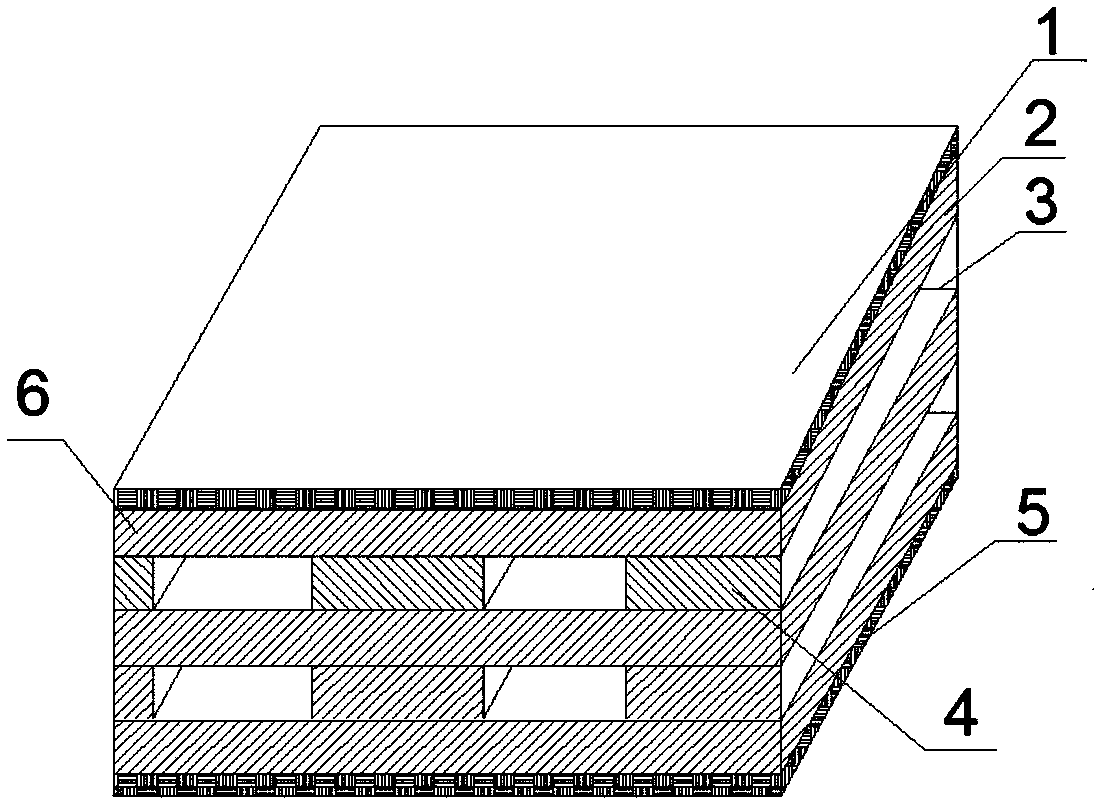

[0038] image 3 A schematic diagram of the air flow in the fresh air heat exchange core is shown.

[0039] Such as image 3 As shown, the heat exchange core is placed in the fresh air ventilator shell 12, and baffles 11 are arranged on both sides of the fresh air inlet 7 and the exhaust air inlet 9 and the heat exchange core to completely separate the fresh air and the exhaust air. The exhaust air inlet 7 and the fresh air inlet 9 are equipped with a fresh fan and an exhaust fan. The outdoor fresh air enters the uniform heat exchange core through the fresh air inlet 7, and the indoor exhaust air enters the heat exchange core evenly through the exhaust air inlet 9. , heat exchange is realized in the heat exchange core, and the exchanged gas is sent into the room and exhausted from the outside by the fresh air outlet 8 and the exhaust outlet 10 respectively, realizing the exchange of indoor air and energy recovery, making it possible to ventilate and take a breath at the same t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com