Lead-free halogen-free tin paste and production process thereof

A production process and solder paste technology, applied in the field of lead-free and halogen-free solder paste and its production process, can solve the problems of easy cracking, corrosion, welding failure, etc., and achieve lower welding temperature, longer service life, and improved solderability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

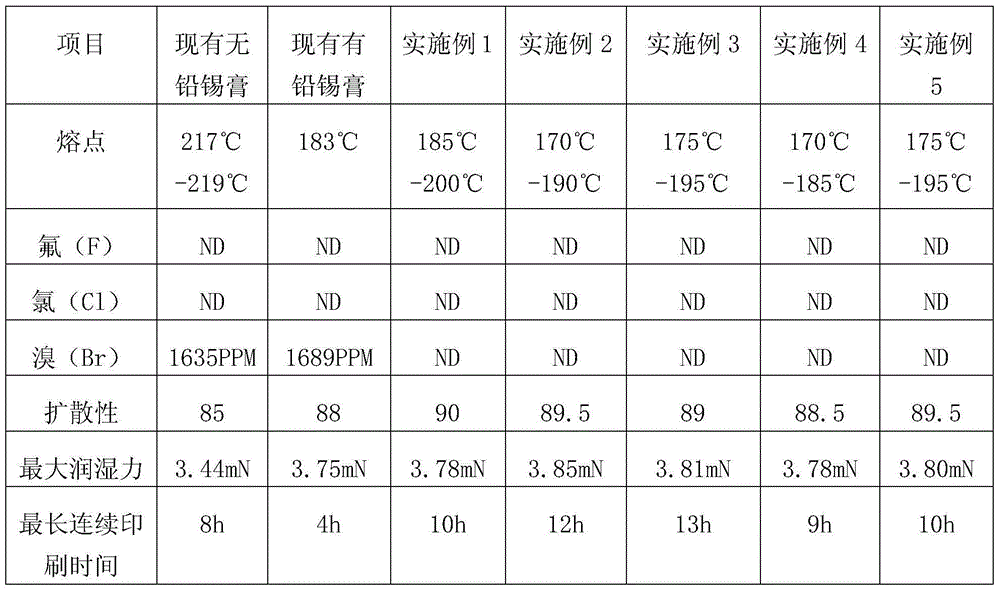

Examples

Embodiment 1

[0023] A lead-free and halogen-free solder paste comprises the following materials in weight percentage: 88% of tin powder and 12% of solder paste. Wherein, the tin powder is Sn94.5%Ag0.2%Cu0.3%Bi5% alloy. Described flux paste is mainly made up of following weight percentage material:

[0024] Rosin: 50%

[0025] Solvent: 40%

[0026] Thixotropic agent: 3%

[0027] Corrosion inhibitor: benzotriazole 1%, diethylimidazole 1%

[0028] Active Agents: Dodecanoic Acid 1.0%, Malonic Acid 0.5%, Salicylic Acid 2%, Diethanolamine 0.5%

[0029] Thickener: 1%

[0030] The above-mentioned materials are made into solder paste at a temperature of 50-100°C according to the process of emulsification, dispersion and high-speed shearing, and then cooled to room temperature for use.

[0031] The production process of the above-mentioned lead-free and halogen-free solder paste comprises the following steps:

[0032] 1) Take the following materials by weight percentage: tin powder 88%, solde...

Embodiment 2

[0036] A lead-free and halogen-free solder paste comprises the following materials in weight percentage: 90% of tin powder and 10% of solder paste. Wherein, the tin powder is Sn88.5%Ag1.0%Cu0.5%Bi 10% alloy. Described flux paste is mainly made up of following weight percentage material:

[0037] Rosin: 35%

[0038] Solvent: 50%

[0039] Thixotropic agent: 4.5%

[0040] Corrosion inhibitor: methyl benzotriazole 1%

[0041] Active agents: Dipropionic acid 0.5%, Methylsuccinic acid 0.5%, Salicylic acid 3%, Triethanolamine 0.5%

[0042] Thickener: 5%

[0043] The above-mentioned materials are made into solder paste at a temperature of 50-100°C according to the process of emulsification, dispersion and high-speed shearing, and then cooled to room temperature for use.

[0044] The production process of the above-mentioned lead-free and halogen-free solder paste comprises the following steps:

[0045] 1) Take the following materials by weight percentage: tin powder 90%, solder...

Embodiment 3

[0049] A lead-free and halogen-free solder paste comprises the following materials in weight percentage: 89% of tin powder and 11% of solder paste. Wherein, the tin powder is Sn91.5%Ag1.2%Cu0.8%Bi6.5% alloy. Described flux paste is mainly made up of following weight percentage material:

[0050] Rosin: 45%

[0051] Solvent: 30%

[0052] Thixotropic agent: 6%

[0053] Corrosion inhibitor: benzotriazole 1%, diethylimidazole 3%

[0054] Active Agents: Glutaric Acid 1.2%, Methylsuccinic Acid 0.5%, Salicylic Acid 2.5%, Monoethanolamine 0.8%

[0055] Thickener: 10%

[0056] The above-mentioned materials are made into solder paste at a temperature of 50-100°C according to the process of emulsification, dispersion and high-speed shearing, and then cooled to room temperature for use.

[0057] The production process of the above-mentioned lead-free and halogen-free solder paste comprises the following steps:

[0058] 1) Take the following materials by weight percentage: tin powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com