Water-based ultraviolet curing coating and preparation method thereof

A technology for curing coatings and ultraviolet light, applied in the field of coatings, can solve the problems of reducing the durability of buildings, yellowing of paint films, exposed corrosion of building surfaces, etc., and achieves the effect of easy industrial production and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

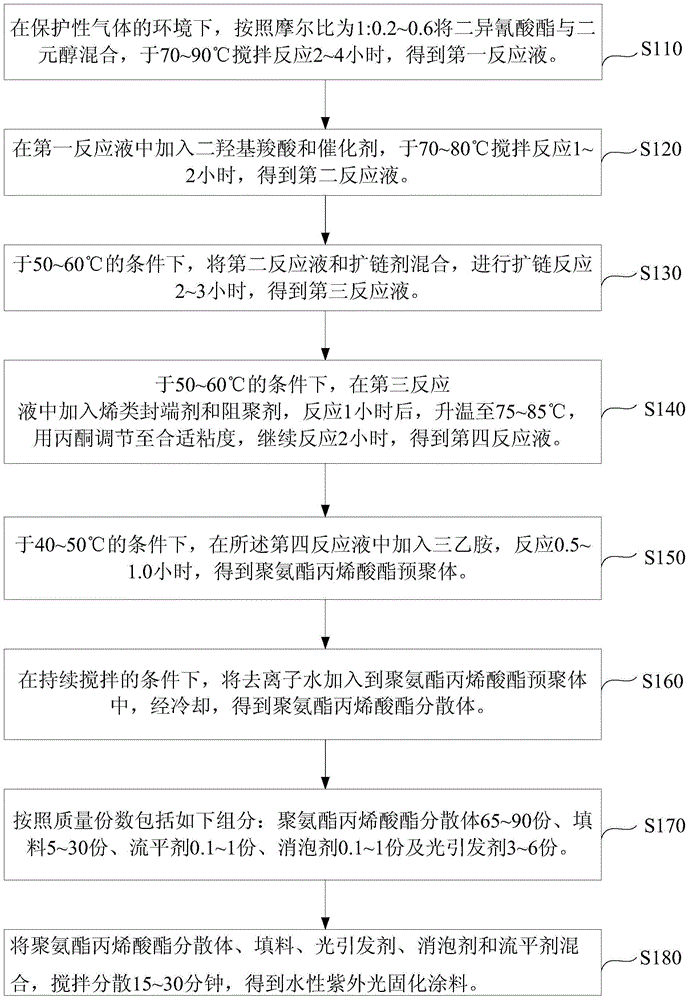

[0028] Such as figure 1 Shown, the preparation method of the waterborne ultraviolet light curing coating of one embodiment, comprises the steps:

[0029] Step S110: Under the environment of protective gas, diisocyanate and diol are mixed according to the molar ratio of 1:0.2-0.6, and stirred and reacted at 70-90° C. for 1-3 hours to obtain a first reaction liquid.

[0030] Wherein, the protective gas can be nitrogen or inert gas.

[0031] Wherein, the diisocyanate is selected from at least one of xylene diisocyanate, dicyclohexylmethane diisocyanate, diphenylmethane diisocyanate, terexylylene diisocyanate, hexamethylene diisocyanate and isophorone diisocyanate.

[0032] Wherein, the diol is selected from at least one of polyether diol, polycaprolactone diol and polycarbonate diol. And the molecular weight of dihydric alcohol is 500g / mol, 600g / mol or 1000g / mol.

[0033] Step S120: adding dihydroxycarboxylic acid and a catalyst to the first reaction liquid, stirring and react...

Embodiment 1

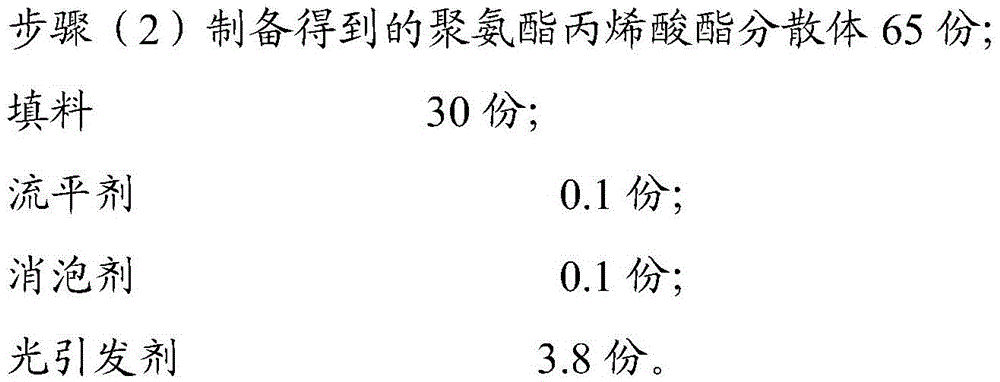

[0063] The preparation process of the water-based UV-curable coating of the present embodiment is as follows:

[0064] (1) Preparation of chain extender: Pentaerythritol triacrylate and methoxyphenol (MEHQ) are transferred to a three-necked flask equipped with a thermometer, condenser tube and stirrer with 10 g of acetone, wherein the mass of methoxyphenol The mass ratio to pentaerythritol triacrylate is 0.5:100; then it is placed in a constant temperature water bath at 45°C, and isophorone diisocyanate is added dropwise into a three-necked flask using a constant pressure funnel, and dibutyltin dilaurate is added at the same time (DBTAL) for catalysis, and then rise to 55 ° C for 2 hours, until the content of isocyanate ions in the system is 8%. Drop trimethylolpropane into the reaction system at a constant pressure, add an appropriate amount of acetone, raise the temperature to 65°C for 3 hours, wait for the isocyanate ions in the reaction system to disappear, and discharge t...

Embodiment 2

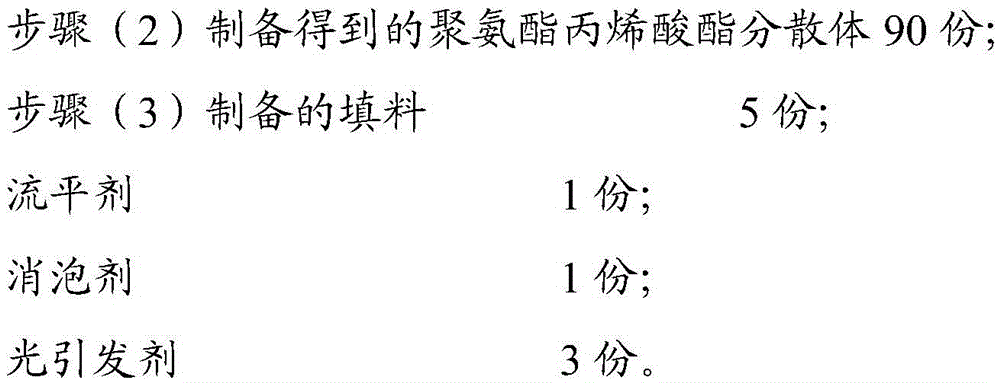

[0079] The preparation process of the water-based UV-curable coating of the present embodiment is as follows:

[0080] (1) Preparation of chain extender: Pentaerythritol triacrylate and methoxyphenol (MEHQ) are transferred to a three-necked flask equipped with a thermometer, condenser tube and stirrer with 10 g of acetone, wherein the mass of methoxyphenol The mass ratio to pentaerythritol triacrylate is 0.5:100; then it is placed in a constant temperature water bath at 45°C, and isophorone diisocyanate is added dropwise into a three-necked flask using a constant pressure funnel, and dibutyltin dilaurate is added at the same time (DBTAL) for catalysis, then rise to 55°C and react for 2 hours until the content of isocyanate ions in the system is 8%, drop trimethylolpropane into the reaction system at constant pressure, add acetone in an appropriate amount, and heat up to 65°C After reacting for 3 hours, the isocyanate ion in the reaction system isocyanate ion disappears, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com