Preparation method of waterborne polyurethane dispersoid

A water-based polyurethane and dispersion technology, applied in the chemical field, can solve the problems of short shelf life, unsuitable for digital inkjet printing, and easy to produce gel, etc., achieve high water resistance and chemical stability, excellent resistance to dry and wet rubbing, The effect of excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

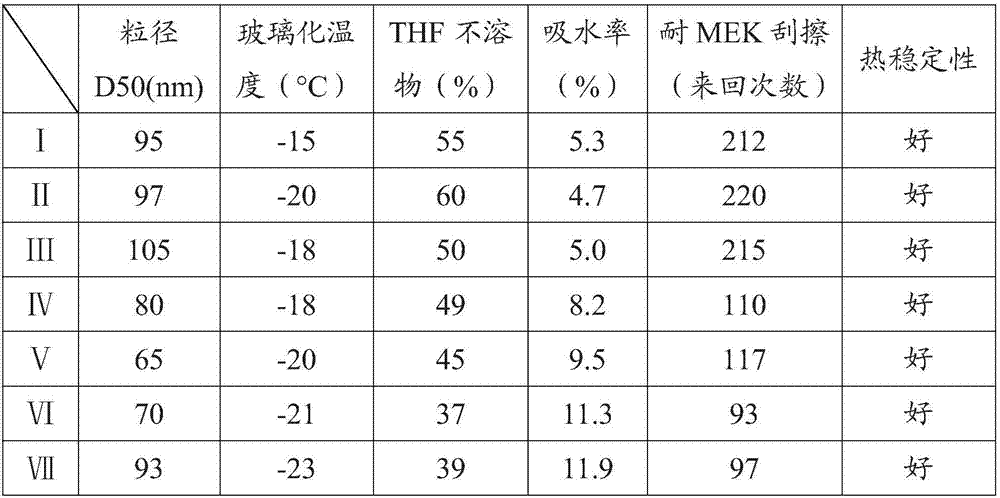

Examples

preparation example Construction

[0029] The invention provides a kind of preparation method of aqueous polyurethane dispersion, comprises the following steps:

[0030] Under the action of acetone and a catalyst, a prepolymer is obtained by using polyglycol, diisocyanate monomer and the first small molecule polyol and / or isocyanate multimer to perform crosslinking;

[0031] Add a hydrophilic chain extender to the prepolymer to form a hydrophilic prepolymer;

[0032] After adding the neutralizing agent into the hydrophilic prepolymer for neutralization, adding deionized water for emulsification and dispersion, adding a second small molecule polyol for secondary crosslinking, and removing acetone to obtain an aqueous polyurethane dispersion.

[0033] In the preparation method provided by the invention, at first, acetone can be used as a solvent to dilute the viscosity of the mixture of polyglycol, diisocyanate monomer and the first small molecule polyol and / or isocyanate multimer, under the action of catalyst, ...

Embodiment 1

[0061] a. Dehydrate the polycarbonate diol (PCDL-2000) under reduced pressure at 120°C for 1.5 hours for later use.

[0062] b. Under nitrogen protection, add 300g of polycarbonate diol (PCDL-2000) , 200g of acetone and 0.04g of DBTDL were heated to 40°C and mixed thoroughly; 66.7g of IPDI and 43.8g of DesmodurN3390 were added to the reaction vessel at 40°C for 60 minutes using a dropping device, and 10.0g of acetone was added to the The residue in the dropping device is washed into the reaction vessel, and the temperature of the reaction vessel can be raised to 50°C and kept for about 30 minutes, so that under the action of acetone and DBTDL, polycarbonate diol (PCDL-2000), IPDI and DesmodurN3390 are cross-linked once to obtain a prepolymer with a cross-linked structure;

[0063] C, utilize the DMPA of 13.4g to add in the reaction container by dripping device, form hydrophilic prepolymer;

[0064] d. Add 10.1g of triethylamine to the reaction vessel using the dropping devic...

Embodiment 2

[0067] a. After mixing polycarbonate diol (PCDL-1000) and polytetrahydrofuran diol (PTMEG-1000) at a ratio of 1:1, dehydrate under vacuum at 120°C for 1.5h for later use.

[0068]b. Under nitrogen protection, add 200g of polycarbonate diol (PCDL-1000) The mixture mixed with polytetrahydrofuran glycol (PTMEG-1000) at a ratio of 1:1, 10g of TMP, 300g of acetone and 0.03g of DBTDL was heated to 40°C and mixed thoroughly; using a dropping device at 40°C for 60 minutes Add 120g of HDI to the reaction vessel, rinse the residue in the dropping device into the reaction vessel with 10.0g of acetone, and raise the temperature of the reaction vessel to 50°C and keep it for about 30 minutes, so that the mixture of acetone and DBTDL Under the action of polycarbonate diol (PCDL-1000), polytetrahydrofuran diol (PTMEG-1000), HDI and TMP are cross-linked once to obtain a prepolymer with a cross-linked structure;

[0069] C, utilize the DMPA of 22.3g to add in the reaction container by drippin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com