Preparation method of micron-sized polymethylmethacrylate microsphere

A polymethyl methacrylate, micron-scale technology, applied in the field of biomedical materials, to achieve the effect of mild implementation conditions and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] A preparation method of micron polymethyl methacrylate microspheres, comprising the following steps:

[0018] (1) Polymethyl methacrylate (PMMA) is dissolved in organic solvent, and the mass fraction range of polymethyl methacrylate solution is 0.5~5.0%; Organic solvent can be dichloromethane, dichloroethane, chloroform , tetrahydrofuran, toluene, acetone or both; the preferred range of the mass fraction of the polymethyl methacrylate solution is 0.7-3.0%, and the more preferred range is 0.9-1.5%.

[0019] (2) Polyvinyl alcohol is dissolved in deionized water to prepare a polyvinyl alcohol solution with a mass percentage (weight) concentration of 0.5 to 2.5%; polymethyl methacrylate solution (PMMA solution) is added dropwise under magnetic stirring Add polyvinyl alcohol solution, the volume ratio of water phase to organic phase is 1-10:1; wherein the water phase is polyvinyl alcohol solution, and the organic phase is polymethyl methacrylate solution; after adding polyme...

Embodiment 1

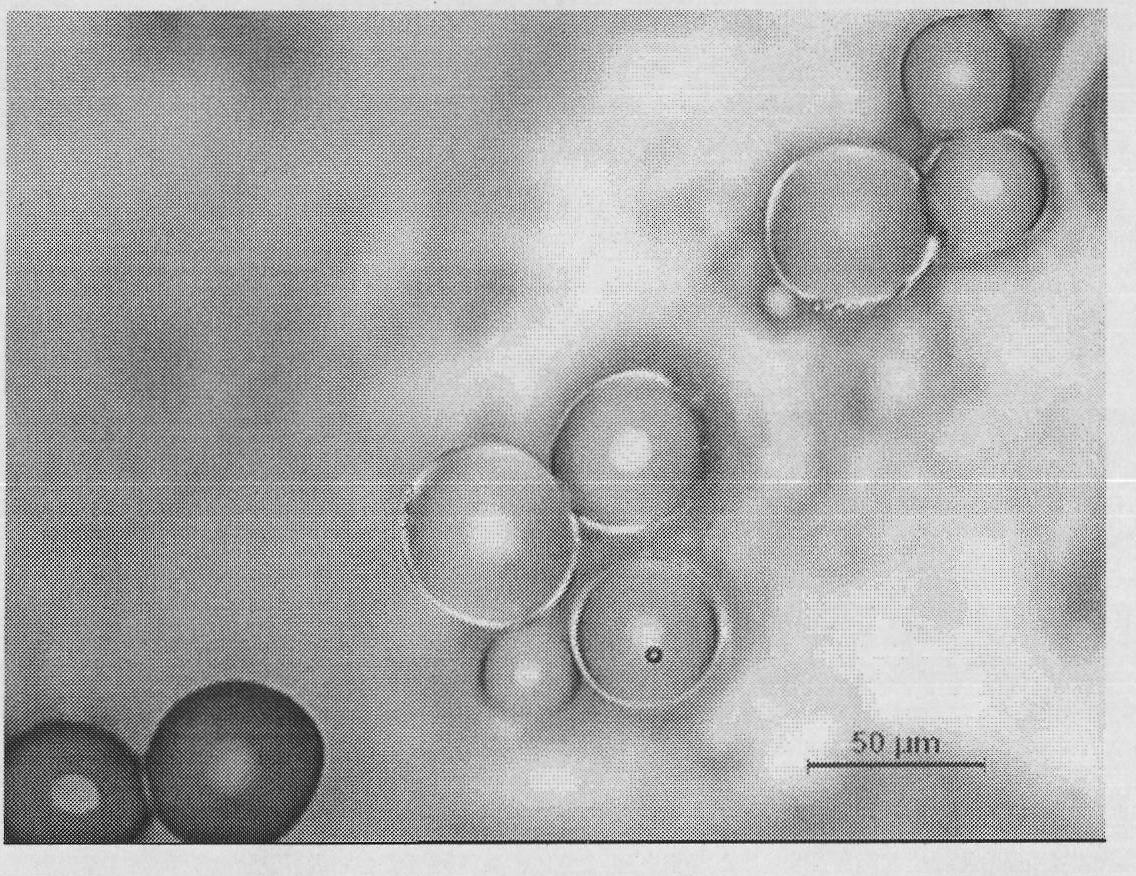

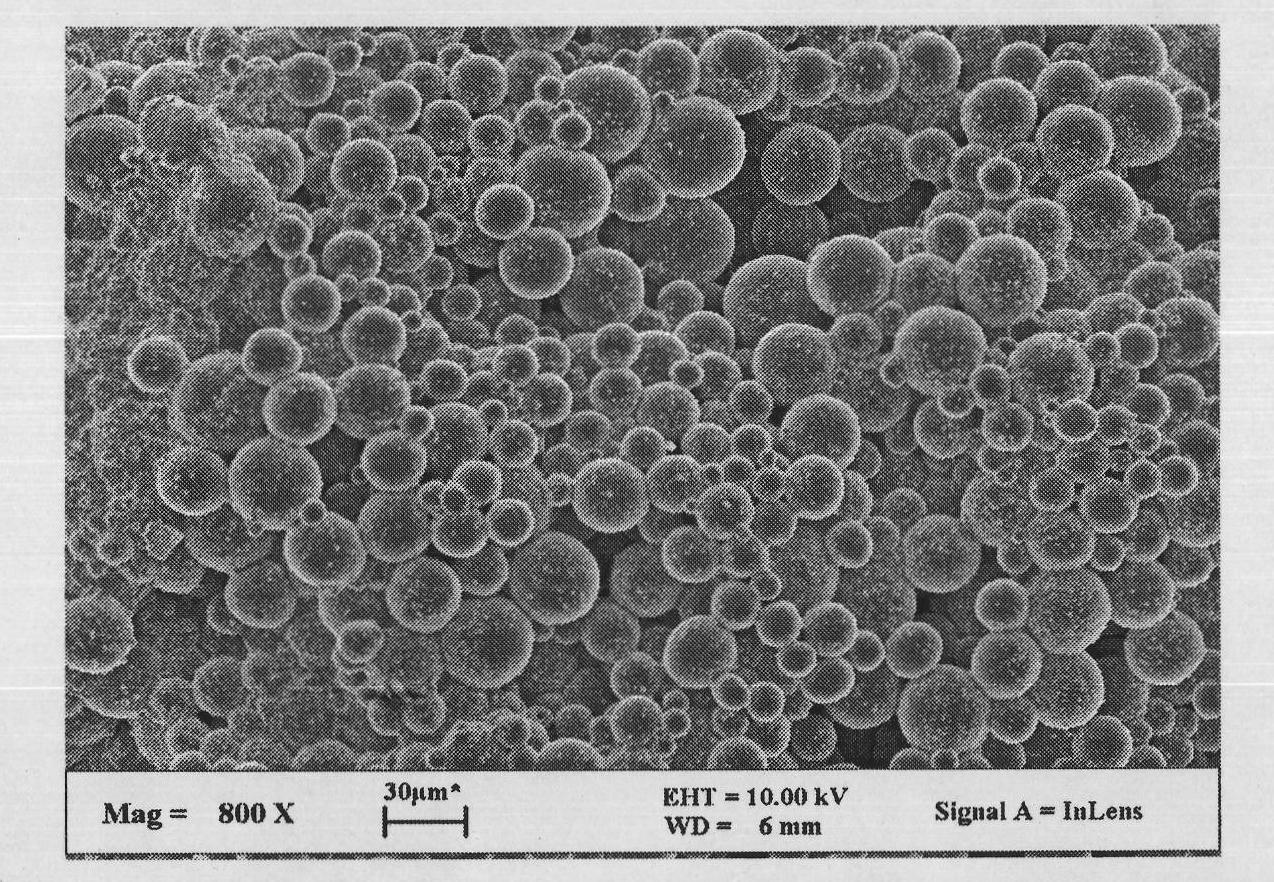

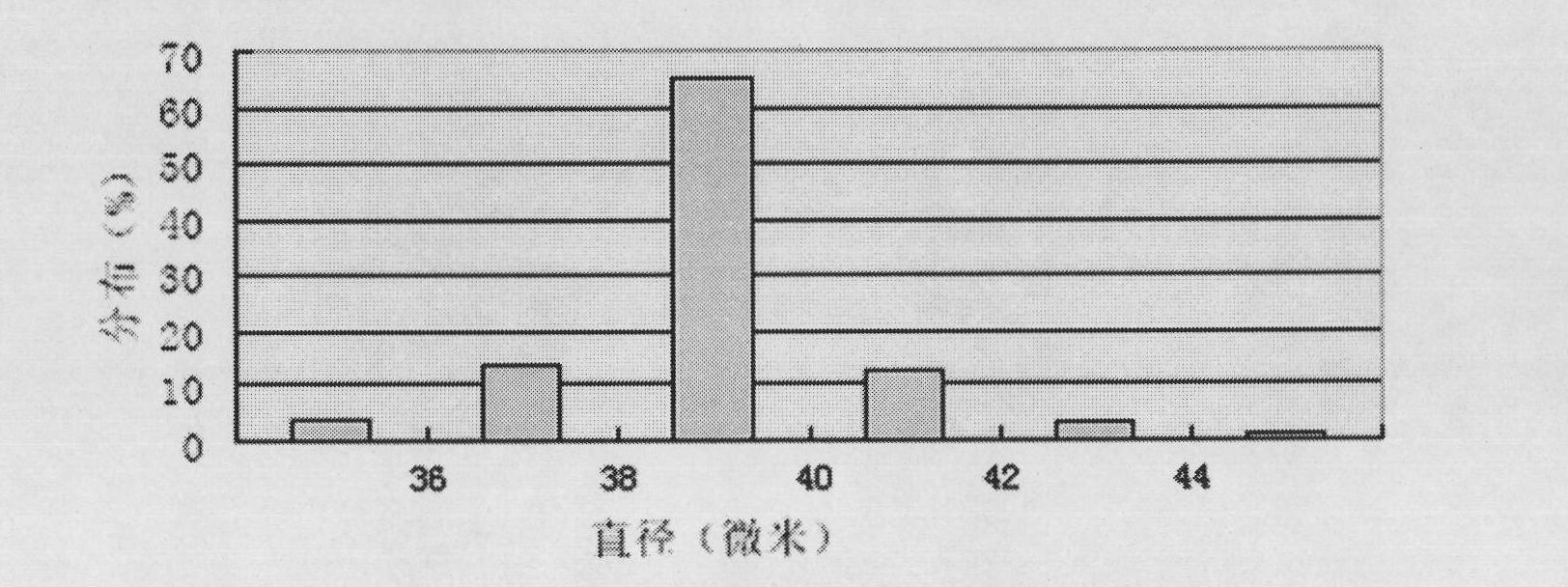

[0023] Weigh 1 g of polymethyl methacrylate (PMMA) with a relative molecular mass of 410,000, dissolve it in 100 mL of chloroform, and dissolve it completely. Measure 20 mL of 1% polyvinyl alcohol (PVA) aqueous solution, put it into a 500 mL Erlenmeyer flask, and stir with a magnetic stirrer at a stirring speed of 1400 r / min. Add 10 mL of the completely dissolved PMMA solution dropwise into the PVA aqueous dispersion medium. Cover the mixture after the addition, and keep stirring evenly at room temperature for about 120 minutes. The evenly distributed and stable emulsion was ultrasonically treated for 10 minutes (ultrasonic power 150W), then the lid was opened, and stirring was continued for 6-8 hours at 40-50°C. After the solvent evaporated, filter with a glass sand funnel to collect the microspheres. At room temperature, the PMMA microspheres were dispersed in distilled water, and then centrifuged with a high-speed refrigerated centrifuge, and the operation was repeated th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com