Method for preparing nano porous silver based on Ag-based amorphous alloy

A nanoporous silver and amorphous alloy technology, applied in the field of design and preparation of nanoporous metal materials, can solve the problems of low purity of nanoporous materials, unenvironmental protection of corrosive liquid, and uneven pore size, and achieve uniform pore size distribution and composition The effect of wide range and mild corrosion process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) with Ag 60 Mg 15 Ca 25 As the nominal composition of the initial alloy, the pure elements (Ag> 99.99 wt%, Mg>99.99 wt%, Ca> 99.0 wt%) required by the initial alloy were converted into mass (5g) according to the atomic percentage of the alloy, and immediately Place the corundum crucible and seal the tube, and vacuum the tube to 10 -4 below pa, and filled with high-purity argon (>99.9 wt%).

[0035] (2) Use induction heating equipment to seal the Ag after sealing 60 Mg 15 Ca 25 The initial alloying components are smelted.

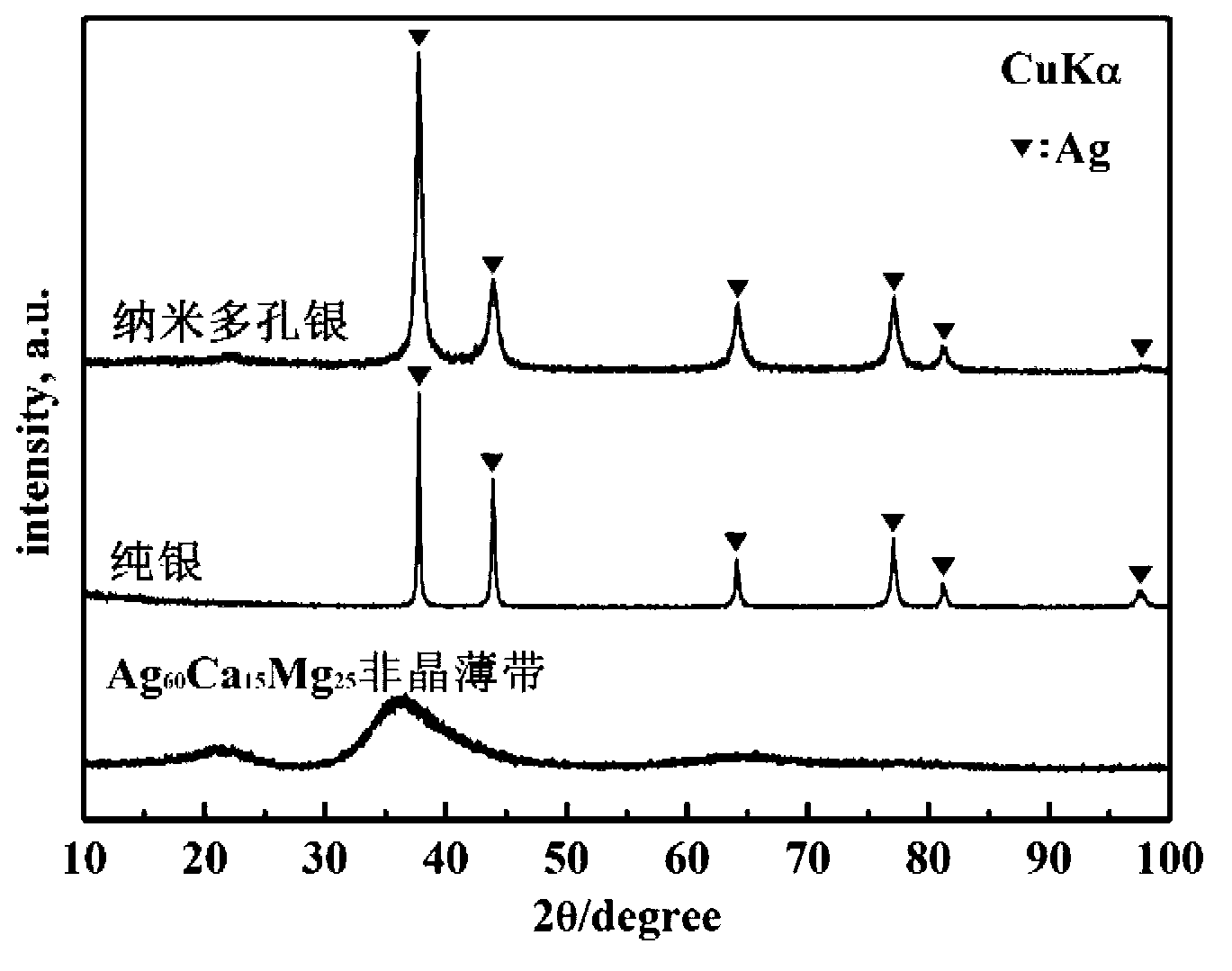

[0036] (3) Ag that will remove the surface oxide scale 60 Mg 15 Ca 25 The initial alloy ingot was remelted by induction heating in a quartz tube, and was continuously and rapidly sprayed onto a water-cooled rotating copper roll under the action of high-purity argon with a pressure of about 0.2 MPa to form Ag 60 Mg 15 Ca 25 Rapid quenching strip, Ag 60 Mg 15 Ca 25 The amorphous structural features of the thin ribbon samples were conf...

Embodiment 2

[0042] (1) Ag prepared in Example 1 60 Mg 15 Ca 25 Amorphous ribbons are used as precursors.

[0043] (2) An ice-salt bath (1 mol / L NaCl in ice water solution) was used to control the temperature of the corrosion environment at about 0 °C, and electrochemical corrosion was carried out at 0 °C.

[0044] (3) Under the temperature conditions of step (2), with Ag 60 Mg 15 Ca 25 Amorphous ribbon as anode, pure silver as cathode, using 0.2 mol / L MgCl 2 The solution was used as an electrolytic etching solution, and was etched for 30 min under the action of 1.5 V for dealloying treatment.

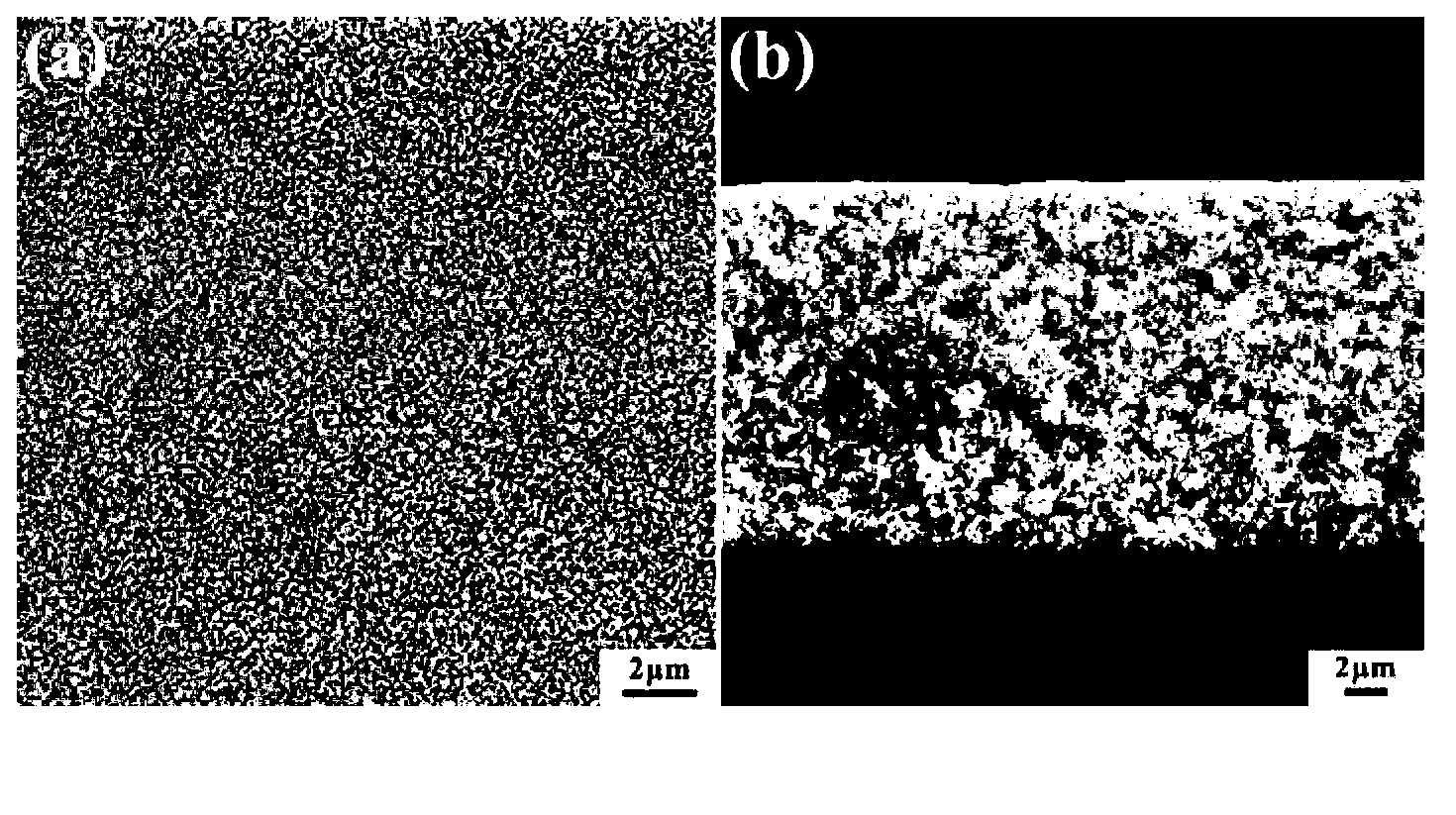

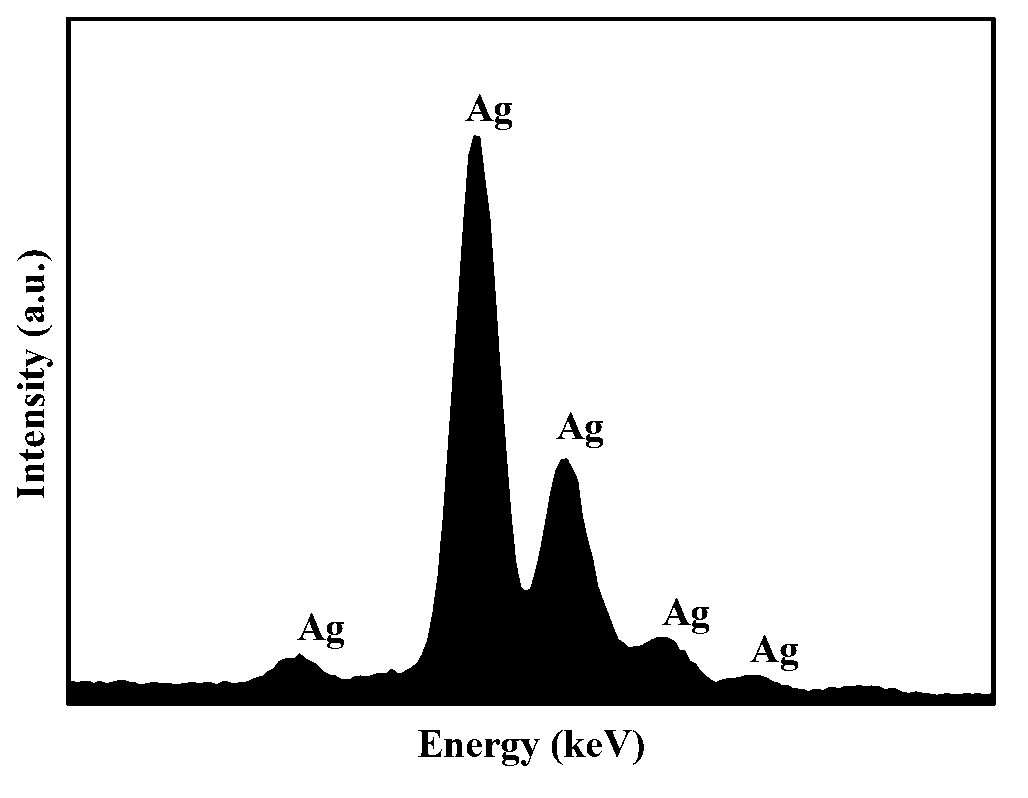

[0045] (4) After the corrosion is over, repeatedly wash with anhydrous alcohol until MgCl 2 The electrolytic etching solution is completely washed, and then dried and stored at room temperature. The obtained nanoporous silver still has a three-dimensional continuous through-hole structure, the pore size and distribution are more uniform, the ligament size is about 50 nm, and the pore size is...

Embodiment 3

[0049] (1) with Ag x Mg 80-x Ca 20 (x=40, 45, 50, 55, 60, x is the atomic percentage) as the initial alloy, the pure elements required for the initial alloy (Ag>99.99 wt%, Mg>99.99 wt%, Ca>99.0 wt%), Weigh it according to the atomic percentage of the alloy converted into mass (5g), and immediately place it in a corundum crucible and seal the tube, and vacuum the tube to 10 -4 below pa, and filled with high-purity argon (>99.9 wt%).

[0050] (2) Use induction heating equipment to seal the Ag after the tube respectively x Mg 80-x Ca 20 The initial alloying components are smelted.

[0051] (3) Ag that will remove the surface oxide scale x Mg 80-x Ca 20 The initial alloy ingot was remelted by induction heating in a quartz tube, and was continuously and rapidly sprayed onto a water-cooled rotating copper roll under the action of high-purity argon with a pressure of about 0.2 MPa to form Ag x Mg 80-x Ca 20 Amorphous fast quenching ribbon.

[0052] (4) Under normal temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com