Waterborne polyurethane wood primer resin and preparation method thereof

A water-based polyurethane and woodware technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of high synthesis difficulty, water resistance and adhesion defects, and achieve good wettability, anti-oil leakage and anti-pigmentation bleeding Excellent performance and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

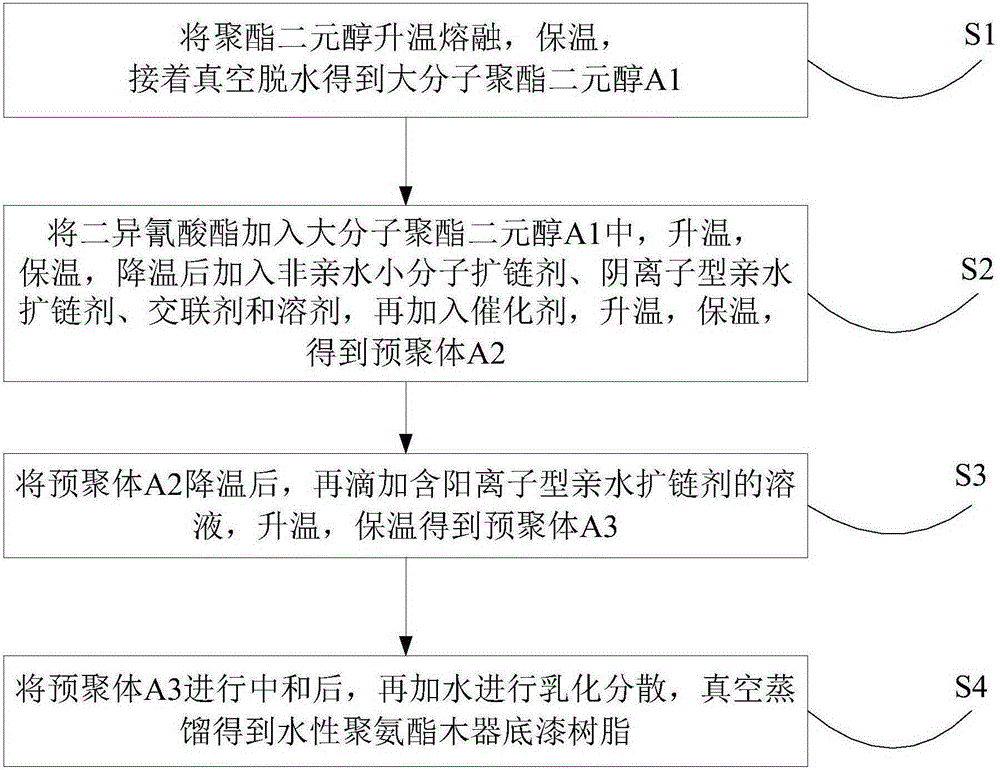

[0041] refer to figure 1 , the preparation method of a kind of aqueous polyurethane wood primer resin that the present invention proposes, comprises the following steps:

[0042] S1, heating and melting the polyester diol, followed by vacuum dehydration to obtain macromolecular polyester diol A1;

[0043] S2. Add diisocyanate to macromolecular polyester diol A1, heat up, keep warm, add non-hydrophilic small molecule chain extender, anionic hydrophilic chain extender, cross-linking agent and solvent after cooling down, and then add catalyst, Heating up and keeping warm to obtain prepolymer A2;

[0044] S3. After cooling the prepolymer A2, dropwise add a solution containing a cationic hydrophilic chain extender, heat up, and keep warm to obtain the prepolymer A3;

[0045]S4. After neutralizing the prepolymer A3, add water for emulsification and dispersion, and vacuum distillation to obtain a waterborne polyurethane wood primer resin.

Embodiment 1

[0048] A kind of preparation method of waterborne polyurethane woodware primer resin that the present invention proposes, comprises the following steps:

[0049] S1. After mixing 20 parts by weight of terephthalic anhydride polyester diol with a number average molecular weight of 2500 and 26 parts of polycarbonate diol with a number average molecular weight of 1000, heat up to 130°C to melt, and the holding time For 1h, then vacuum dehydration to obtain macromolecular polyester diol A1;

[0050] S2. Add 52 parts of isophorone diisocyanate to macromolecular polyester diol A1, raise the temperature to 65°C, keep it warm for 4 hours, cool down to 40°C, add 11 parts of 1,4-butanediol, 0.1 part of dihydroxy Add methacrylic acid, 3 parts of trimethylolpropane and solvent, then add 0.05 part of stannous octoate, raise the temperature to 80°C, and keep it warm for 1 hour to obtain prepolymer A2;

[0051] S3. After cooling the prepolymer A2 to 40°C, add dropwise a solution containing ...

Embodiment 2

[0054] A kind of preparation method of waterborne polyurethane woodware primer resin that the present invention proposes, comprises the following steps:

[0055] S1. Heat up 50 parts by weight of terephthalic anhydride polyester diol with a number average molecular weight of 3200 to 80° C. to melt, hold the temperature for 4 hours, and then vacuum dehydrate to obtain macromolecular polyester diol A1;

[0056] S2. Add 33 parts of 4,4-dicyclohexylmethane diisocyanate into macromolecular polyester diol A1, raise the temperature to 100°C, keep it warm for 2 hours, cool down to 50°C, add 6 parts of diethylene glycol, 0.5 1 part of dimethylolbutyric acid, 2 parts of trimethylolpropane and solvent, then add 0.3 part of dibutyltin dilaurate, raise the temperature to 75°C, and keep it warm for 4 hours to obtain prepolymer A2;

[0057] S3. After the prepolymer A2 is cooled to 30°C, a solution containing 5 parts of N-methyldiethanolamine and 2 parts of dimethylethanolamine is added dropw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com