Porous spherical silica chromatography filler and preparing method thereof

A technology of porous spherical and silica gel chromatography, which is applied in chemical instruments and methods, and other chemical processes, can solve the problems of affecting the output of microspheres with target particle size and increasing production costs, and achieves high yield, easy control of conditions, and excellent preparation process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of porous spherical silica gel chromatographic filler, comprises the steps:

[0035] (1) Add absolute ethanol and tetraethyl orthosilicate (TEOS, 104 g) into a three-necked flask at a molar ratio of 1, stir and mix at 500 rpm to obtain a mixed solution;

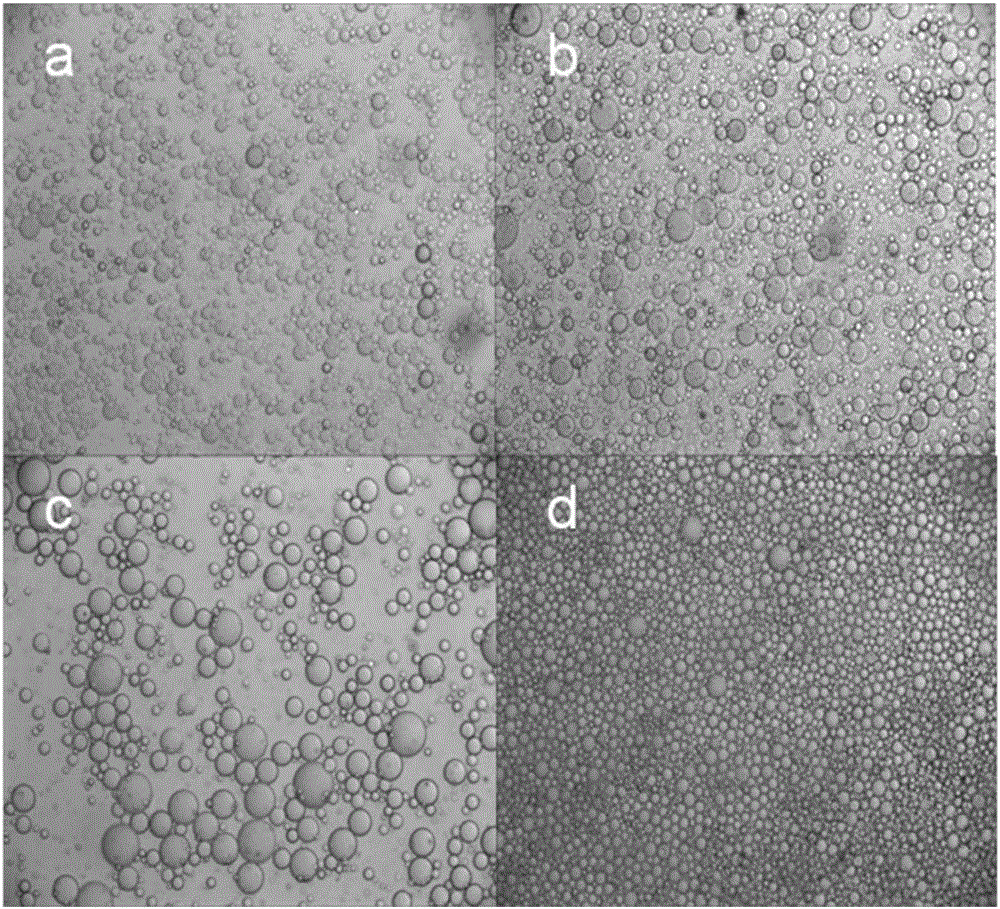

[0036] (2) Add 0.1M hydrochloric acid aqueous solution to the mixed solution, stir at 30°C for 0.5h, and distill off the solvent under reduced pressure to obtain a polysiloxane prepolymer; The molar ratios are 0.5, 1.0, 1.5, 2.0 respectively;

[0037](3) The viscosity modifier solution is a continuous phase; the dispersion phase polysiloxane prepolymer is dispersed into the continuous phase at a ratio of 0.2 by volume, and stirred evenly to obtain an emulsion dispersion system;

[0038] Viscosity modifier solution is the solution of the polyethylene glycol 10000 aqueous solution that mass ratio is 0.5% surfactant triton X-100 and mass concentration,

[0039] (4) Add concentrated ammonia water i...

Embodiment 2

[0046] The preparation method of porous spherical silica gel chromatographic filler, comprises the steps:

[0047] (1) Add absolute ethanol and ethyl silicate-40 (TES-40, 48g) into a three-necked flask at a molar ratio of 4, stir and mix at 500 rpm to obtain a mixed solution;

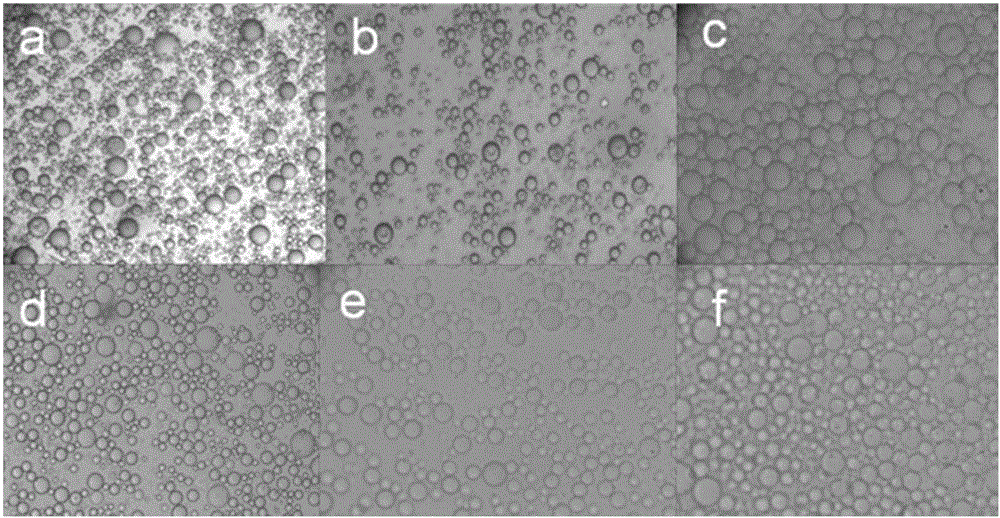

[0048] (2) Add 0.1M hydrochloric acid aqueous solution to the mixed solution, stir at 30°C for 1h, and distill off the solvent under reduced pressure to obtain a polysiloxane prepolymer; the water in the hydrochloric acid aqueous solution and ethyl silicate-40 The molar ratio is 1.2;

[0049] (3) Mix absolute ethanol and viscosity modifier solution uniformly by volume ratio 0.5 to make continuous phase; disperse phase polysiloxane prepolymer into said continuous phase by volume ratio 0.2, stir evenly to obtain emulsion dispersion system;

[0050] The viscosity regulator solutions are respectively polyethylene glycol 200 aqueous solution, polyethylene glycol 2000 aqueous solution, polyethylene glycol 4...

Embodiment 3

[0056] The preparation method of porous spherical silica gel chromatographic filler, comprises the steps:

[0057] (1) Add absolute ethanol and ethyl silicate-40 (TES-40, 48g) into a three-necked flask at a molar ratio of 4, stir and mix at 500 rpm to obtain a mixed solution;

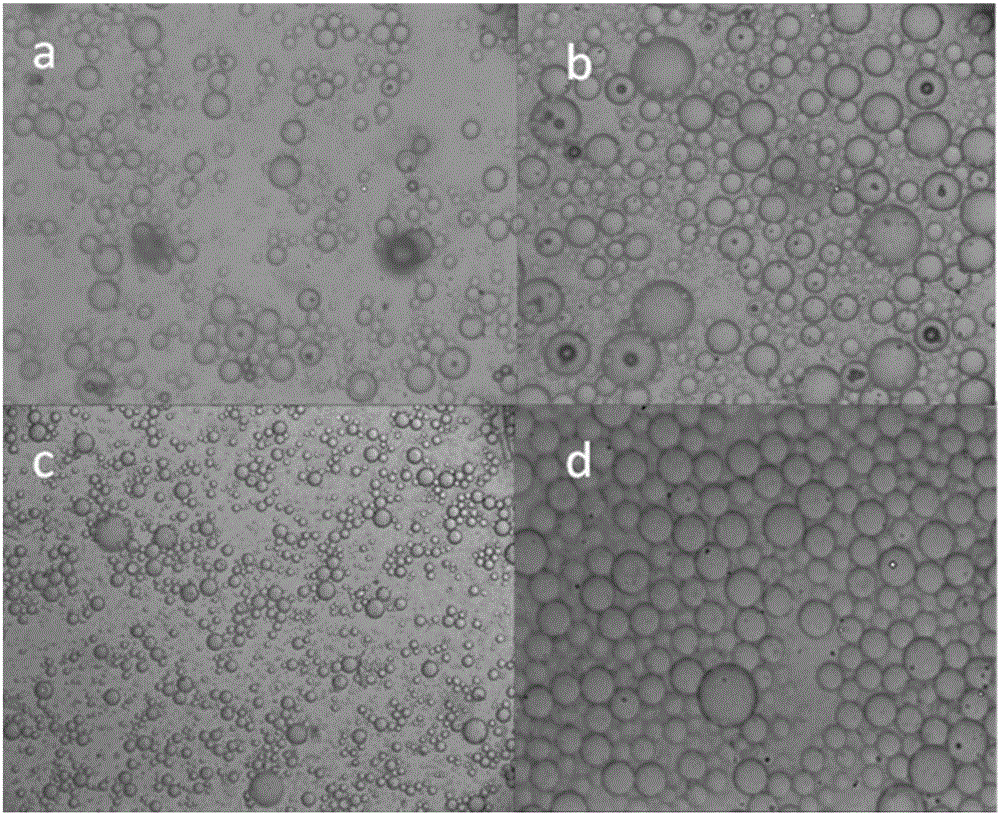

[0058] (2) Add 0.1M hydrochloric acid aqueous solution to the mixed solution, stir at 30°C for 1h, and distill off the solvent under reduced pressure to obtain a polysiloxane prepolymer; the water in the hydrochloric acid aqueous solution and ethyl silicate-40 The molar ratio is 1.2;

[0059] (3) Mix absolute ethanol and viscosity modifier solution uniformly by volume ratio 0.5 to make continuous phase; disperse phase polysiloxane prepolymer into said continuous phase by volume ratio 0.2, stir evenly to obtain emulsion dispersion system;

[0060] Described viscosity modifier solution is the solution of the polyethylene glycol 10000 aqueous solution that mass ratio is 5% surfactant and mass concentrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com