Thick oil activating agent and preparation method thereof

A technology of initiator and functional monomer, which is applied in the field of heavy oil activator and its preparation, can solve the problems of difficult to achieve the overall viscosity reduction of formation heavy oil and improve the overall benefit of the oil field, achieve good profile control ability and improve recovery rate, the effect of increasing liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

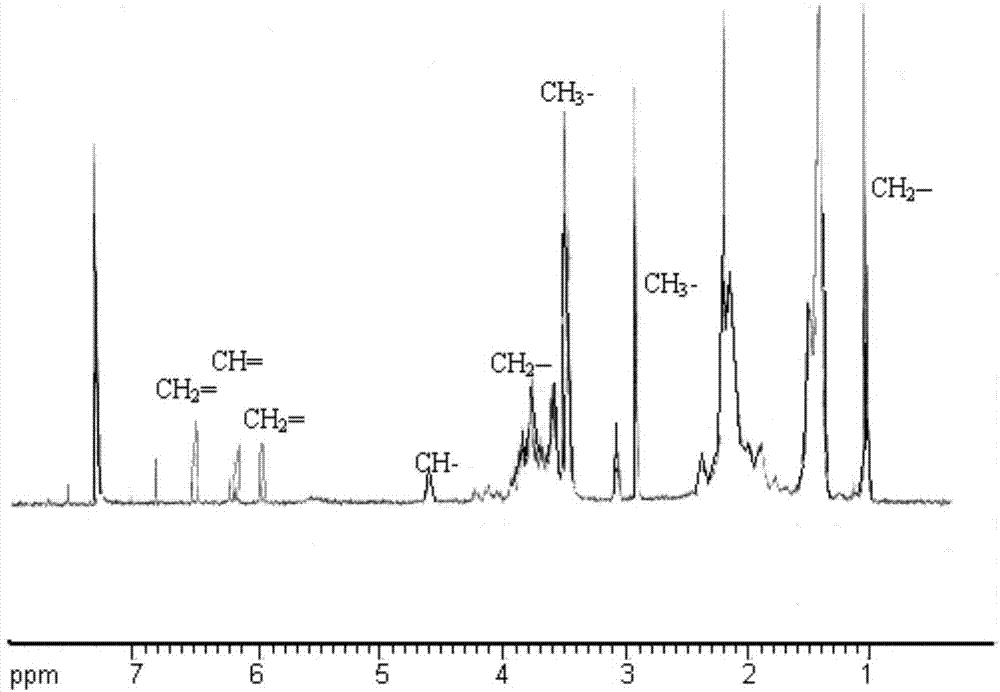

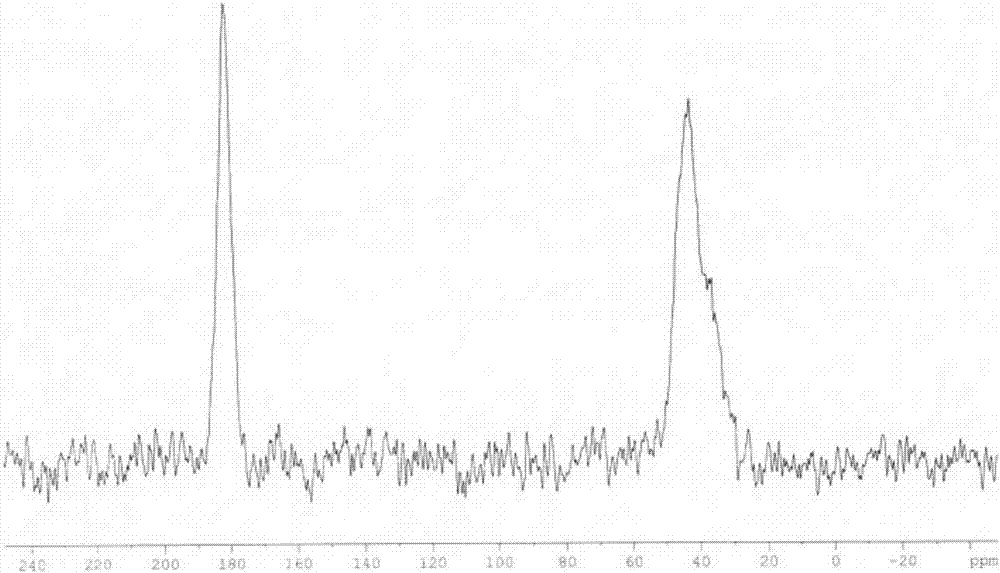

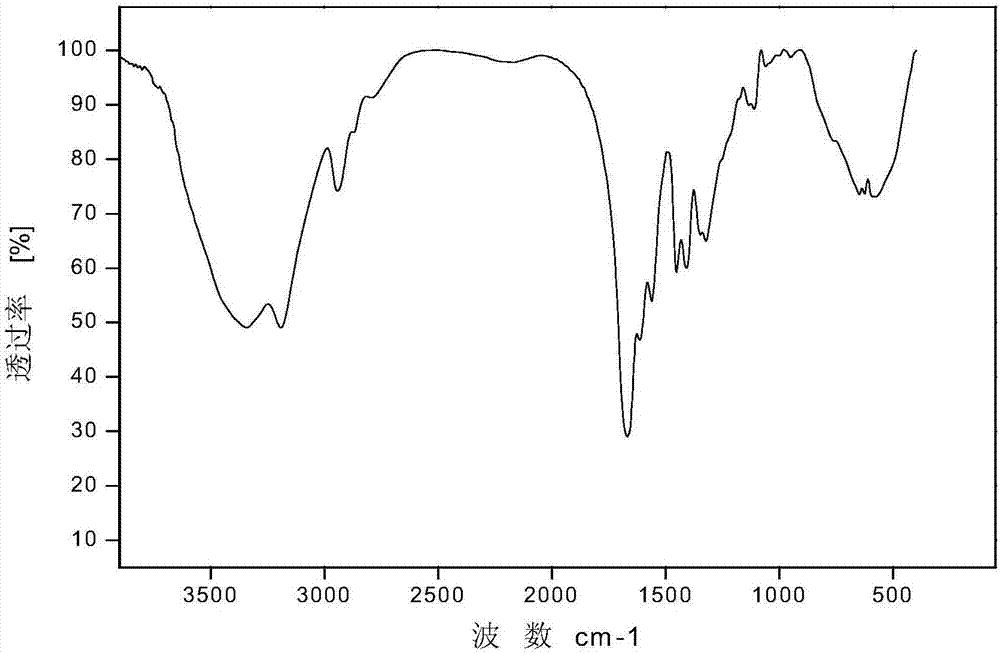

[0056] 1. Preparation of activated polymer

[0057] The activated polymer shown in formula (1) is specifically prepared by the following method:

[0058] First prepare the functional monomer I through the following steps:

[0059] 14.6g (0.1mol) 1,3-bis(N,N-dimethyl)-2-propanol and 42.5g (0.22mol) bromooctane ethanol solution are packed into a 250ml three-necked flask, magnetically stirred, and heated at 65 It was refluxed and condensed at ~70°C, and reacted for 24 hours. The solvent was removed by vacuum rotary evaporation at 50°C, an appropriate amount of acetone was added to heat to dissolve, and after cooling, a white solid was precipitated with diethyl ether to obtain product I. Acetone-diethyl ether was recrystallized three times to obtain a white solid with a yield of over 95%. Put 26.6g (0.05mol) of anhydrous chloroform solution of product I into a 250ml three-necked flask, add dropwise 6.06g (0.06mol) of triethylamine in chloroform, and add a small amount of hydroq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com