Viscoelastic Surfactant System and Its Application in Waterflooding Heavy Oil Reservoir Production

A surfactant and viscoelastic technology, which is applied in the field of oil exploitation to achieve the effects of improving oil recovery, reducing mobility ratio and reducing viscous force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] (2) Preparation of dimer quaternary ammonium salt surfactant: get intermediate 1.6g (6.0mmol), 1-bromododecane 6.0g (24.0mmol) (the number of carbon atoms n of the alkyl chain R of compound A is For other values, when X is other options, select the corresponding raw material to replace 1-bromododecane) Dissolve in methanol / acetone mixed solvent, react at 40°C for 72h. The solvent was removed by rotary evaporation, and the crude product was recrystallized in methanol / ethyl acetate to obtain a powdery product, Compound A.

[0031] Specifically, the preparation method of compound B (the carbon number n of the alkyl chain R is 12, and X is Br) is as follows:

[0032] (1) Synthesis of intermediate tripolyamide: 10.6 g (120.0 mmol) of N,N-dimethylethylenediamine was added to 2.3 g (10.0 mmol) of trimethyl citrate, and refluxed at 106° C. for 3 h. After the reaction, use a rotary evaporator to remove excess N,N-dimethylethylenediamine to obtain the intermediate;

[0033] (2)...

Embodiment

[0035] Example Preparation of viscoelastic surfactant system

[0036] Under normal temperature (15-30°C) and mechanical stirring at a speed of 200-400rpm, add the oligomeric cationic quaternary ammonium salt surfactant and small molecule additives to the water whose water volume is 1 / 3-2 / 3 of the total amount, Stir for 30-100 minutes until fully dissolved; then add anionic non-ionic surfactant and the rest of water, stir for 1-5 hours at room temperature and 1000-4000 rpm until completely mixed, and prepare a viscoelastic surfactant system. The water in the preparation process is all selected mineralized water, and the degree of salinity is 20000mg / L.

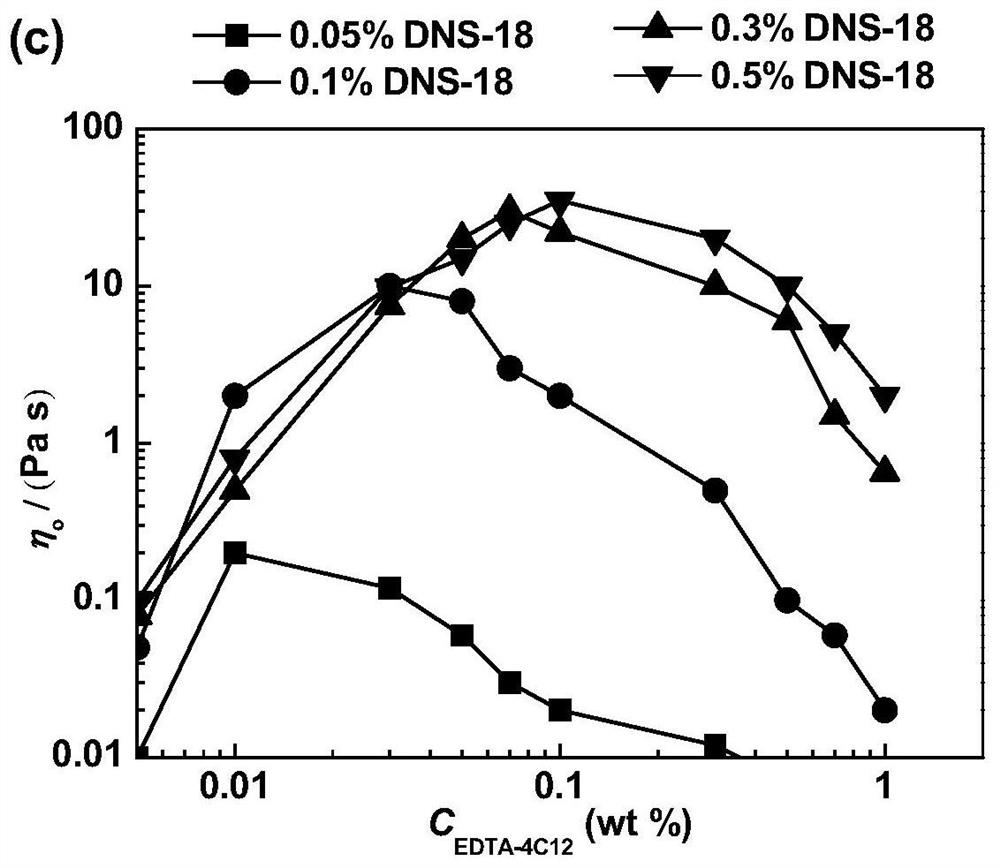

[0037] According to the above method, select three kinds of oligomeric cationic surfactant Malic-2C respectively 12 、Citric-3C 12 and EDTA-4C 12 Anion nonionic surfactant is selected alkyl alcohol polyoxyethylene ether ammonium sulfate (DNS-18); with ethanol-diethanolamine mixed solvent (the two each account for 0.5% of the ...

Embodiment 4

[0061] Embodiment 4 prepares viscoelastic surfactant system

[0062] The components are composed of: 0.05% of compound A (the carbon number n of the alkyl chain R is 4, and X is Cl), 0.1% of alkyl alcohol polyoxyethylene ether ammonium sulfate (DNS-18), 1% of methanol, and the balance is water.

[0063] Preparation method: Add oligomeric cationic quaternary ammonium salt surfactant and small molecule additives into appropriate amount of water under normal temperature and mechanical stirring at 200-400rpm, and stir until fully dissolved; then add anionic nonionic surfactant and other Amount of water, stirred until completely mixed, to prepare a viscoelastic surfactant system. The water in the preparation process is mineralized water, with a salinity of 20000mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com