High-temperature physical carbonization method of carbide furnace and wood

A carbonization furnace and wood technology, applied in the direction of burning charcoal/combustion, can solve the problems of loss of chemical components, deformation, cracking, etc., and achieve the effects of convenient and reliable use, simple carbonization process, and expansion of the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

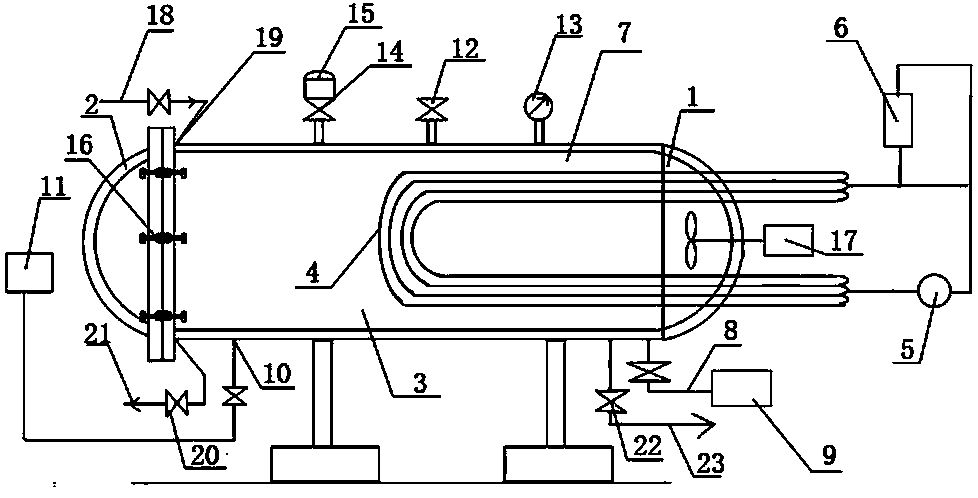

[0023] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, the carbonization furnace of the present invention includes a horizontal carbonization tank body 3 with a head 1 at one end and a tank cover 2 at the other end. The heat-conducting pipe 4 communicates with the heat-conducting oil supply device formed by the heat-conducting oil pump 5 and the heat-conducting oil heater 6 provided outside; the middle of the carbonization tank body 3 is a space 7 for placing carbonized wood; 8. The vacuum machine 9 connected to the carbonization tank body 3 is placed outside the carbonization tank body 3; the carbonization tank body 3 is connected to the external steam generation and supply device 11 through a steam connecting pipe 10; Also be provided with safety valve 12, pressure gauge 13 on, have parts such as the wood distillation gas release pipe 15 of on-off valve 14.

[0024] The tank cover 2 is hinged on one end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com