Wood preservation carbonizing method

A technology of wood preservation and wood, which is applied in the direction of charcoal burning/combustion, can opening and impregnation, etc. It can solve the problems of lack of anti-corrosion performance of carbonized wood and unsatisfactory mechanical properties of carbonized wood, so as to achieve good carbonization effect, sufficient carbonization, and enhanced anti-corrosion performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

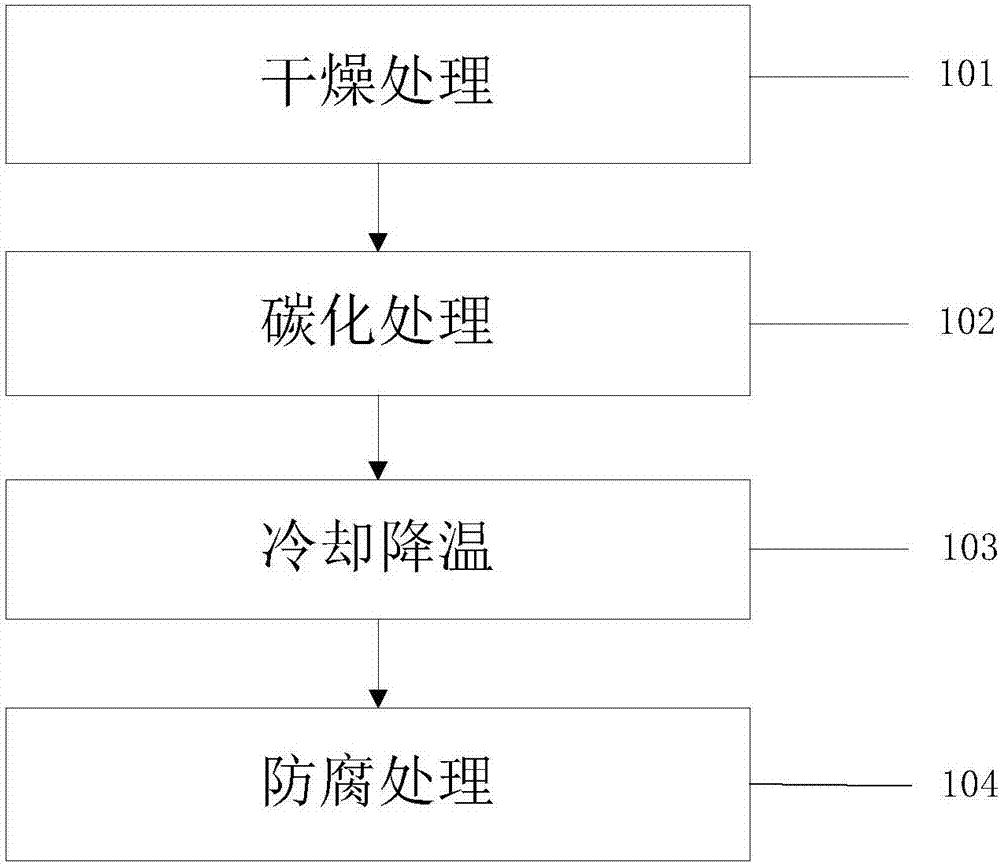

[0039] The present invention provides a wood anticorrosive carbonization method, which includes: drying treatment, drying the cut wood step by step; carbonization treatment, heating and preheating the wood after the drying treatment, and then carbonizing; cooling and cooling, Water vapor is passed into the carbonization kiln for cooling treatment; anticorrosion treatment, the wood after the cooling treatment is soaked in an antiseptic solution; wherein, the stepwise drying includes first-stage drying, second-stage drying and third-stage drying Drying; the first-stage drying temperature is 90°C and the time is 13h; the second-stage drying temperature is 125°C and the time is 9h; the third-stage drying temperature is 150°C and the time is 9h; The preheating is to increase the temperature to 175°C at a rate of 5°C per hour; the carbonization includes first-stage carbonization, second-stage carbonization, and third-stage carbonization. The conditions of the first-stage carbonization...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com