Novel environment-friendly coating with superhigh marine environment corrosion resistance and preparation method and application thereof

An environmentally friendly coating and marine environment technology, applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., to achieve the effects of excellent salt spray resistance, excellent anti-corrosion performance, and low VOC content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

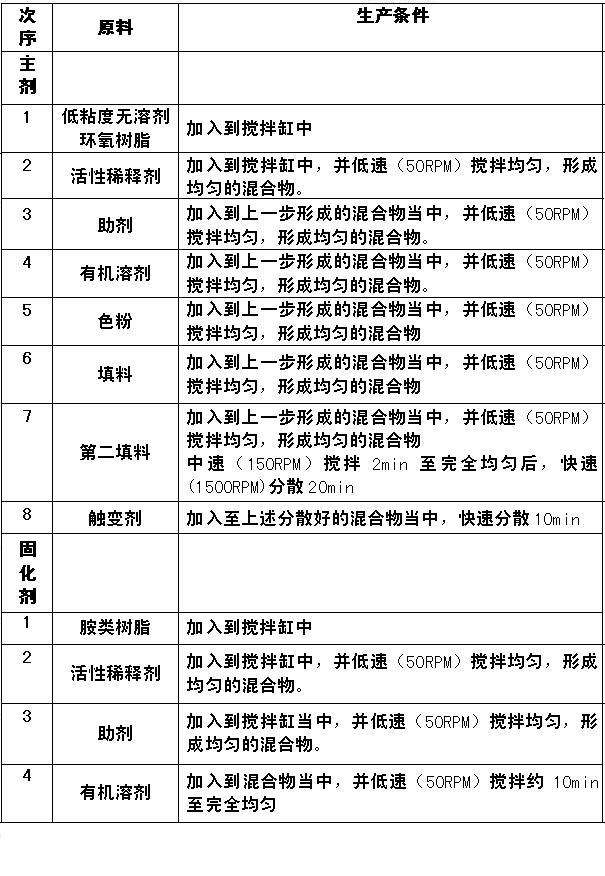

Method used

Image

Examples

Embodiment 1

[0096] The following components are calculated in parts by weight: 29 parts of low-viscosity solvent-free bisphenol A epoxy resin E-51, 10 parts of reactive diluent hydrocarbon petroleum resin, 0.5 parts of organic silicon defoamer as auxiliary agent, 7 parts of organic solvent, Among them, 5 parts of S-100, 2 parts of anhydrous alcohol, 5.5 parts of toner namely phthalein white powder, 14 parts of the first filler, including 7 parts of talcum powder, 7 parts of kaolin, 32 parts of the second filler, including 6 parts of glass fiber powder, 26 parts of hollow microspheres and 2 parts of organic bentonite as a thixotropic agent are added into the tank and stirred evenly to form a coating base material.

[0097] The following components are calculated by weight: 72 parts of aromatic polyamine resin, 21 parts of reactive diluent hydrocarbon petroleum resin, 5.0 parts of auxiliary agent tertiary amine drier K-54, 2 parts of organic solvent S-100 are added to the tank Stir in mediu...

Embodiment 2

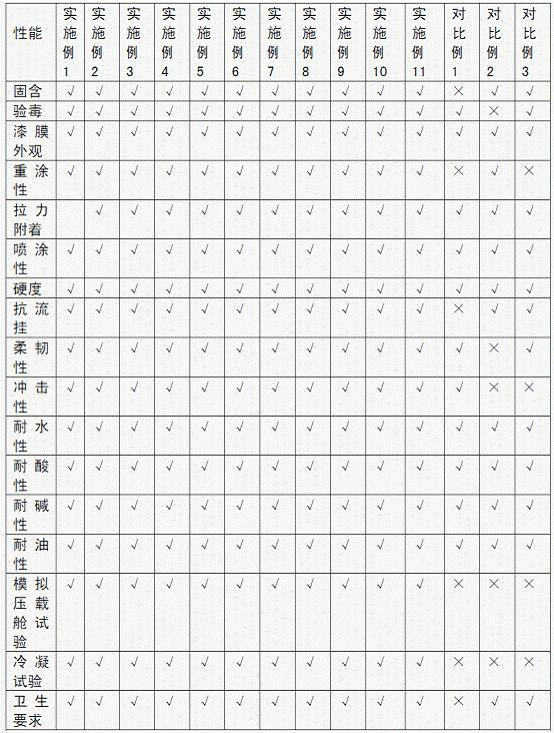

[0119] According to the specified components corresponding to Example 2 in Table 3, repeat the corresponding operation of Example 1 to obtain a cured paint film. And test its technical performance as described in embodiment 1. The test indicators are shown in Table 1. The test results show that the technical performance is good, as shown in Table 4.

Embodiment 3

[0121] According to the specified components corresponding to Example 3 in Table 3, repeat the corresponding operation of Example 1 to obtain a cured paint film. And test its technical performance as described in embodiment 1. The test indicators are shown in Table 1. The test results show that the technical performance is good, as shown in Table 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com