Water-based high-corrosion-resistance coating with excellent stamping performance and preparing method and application of water-based high-corrosion-resistance coating

A punching and corrosion-resistant technology, applied in the field of water-based high corrosion-resistant coatings and their preparation, can solve the problems of unreported salt spray properties of coatings, unfavorable industrial application of coatings, affecting coating forming and punching, etc. Avoid creating weak points, good punchability, and improve the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1. Preparation of water-based high corrosion-resistant coatings with excellent flushability

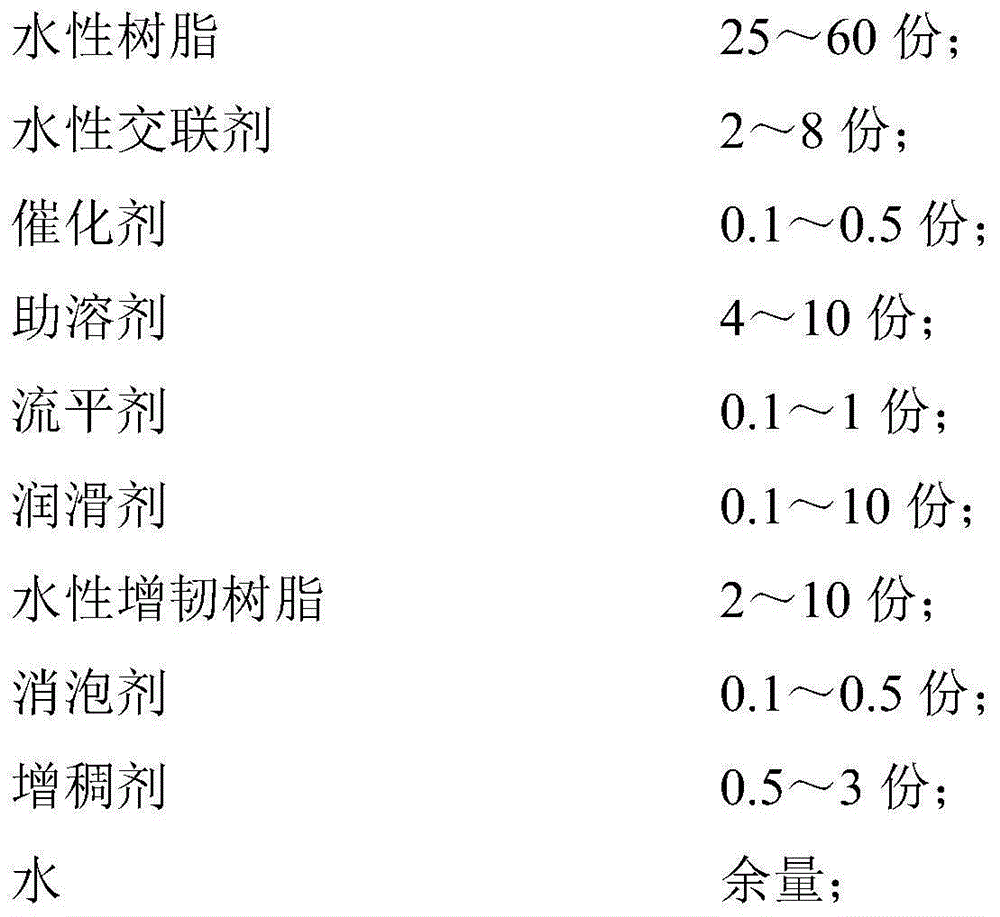

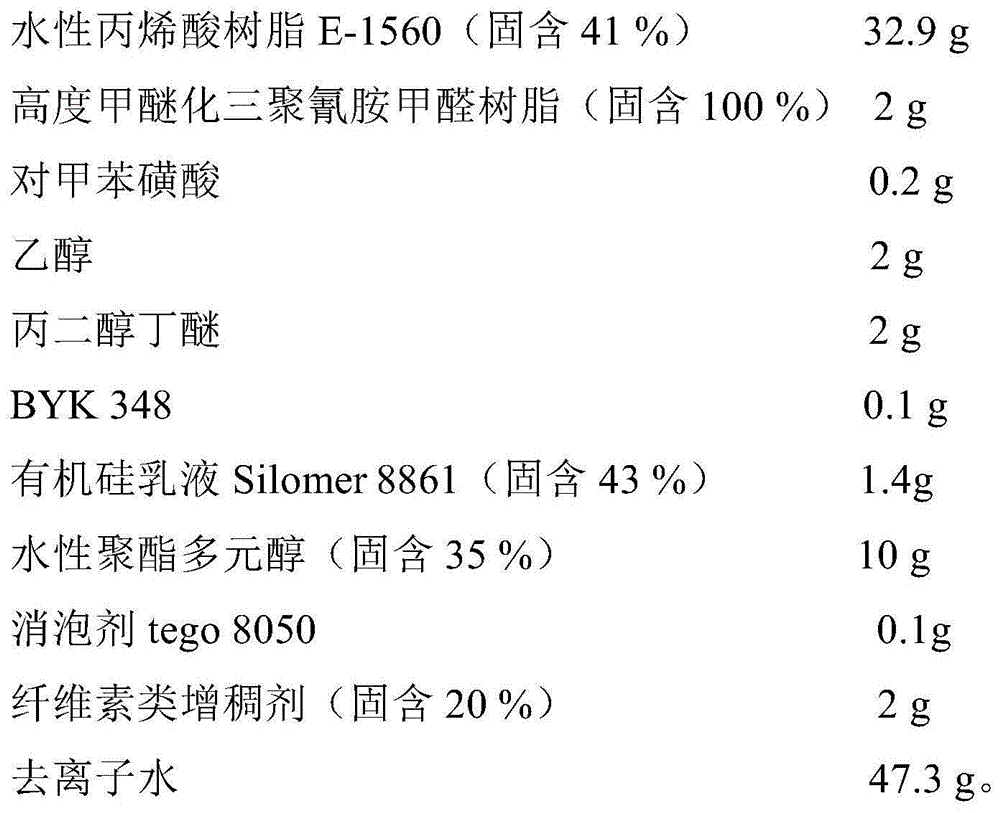

[0043] (1) Weigh the raw materials of the following components in proportion

[0044]

[0045] (2) Mix the above-mentioned raw materials and disperse them evenly to prepare a water-based super corrosion-resistant coating with a solid content of 20%. The viscosity of the coating is 22 ± 2s when coated with 4 cups.

[0046] 2. Coating the prepared water-based super corrosion-resistant coating on the aluminum foil to form a corrosion-resistant coating. First, the aluminum foil was degreased and dried, and then the above-mentioned coating was applied to the aluminum foil, and baked in an oven at 200°C for 60s to obtain a coating with a dry film thickness of 5 μm.

[0047] The corrosion-resistant coating prepared above has excellent alkali resistance, cooking resistance, and salt spray resistance after testing, and the salt spray resistance of the coating after stamping and bend...

Embodiment 2

[0049] 1. Preparation of water-based high corrosion-resistant coatings with excellent flushability

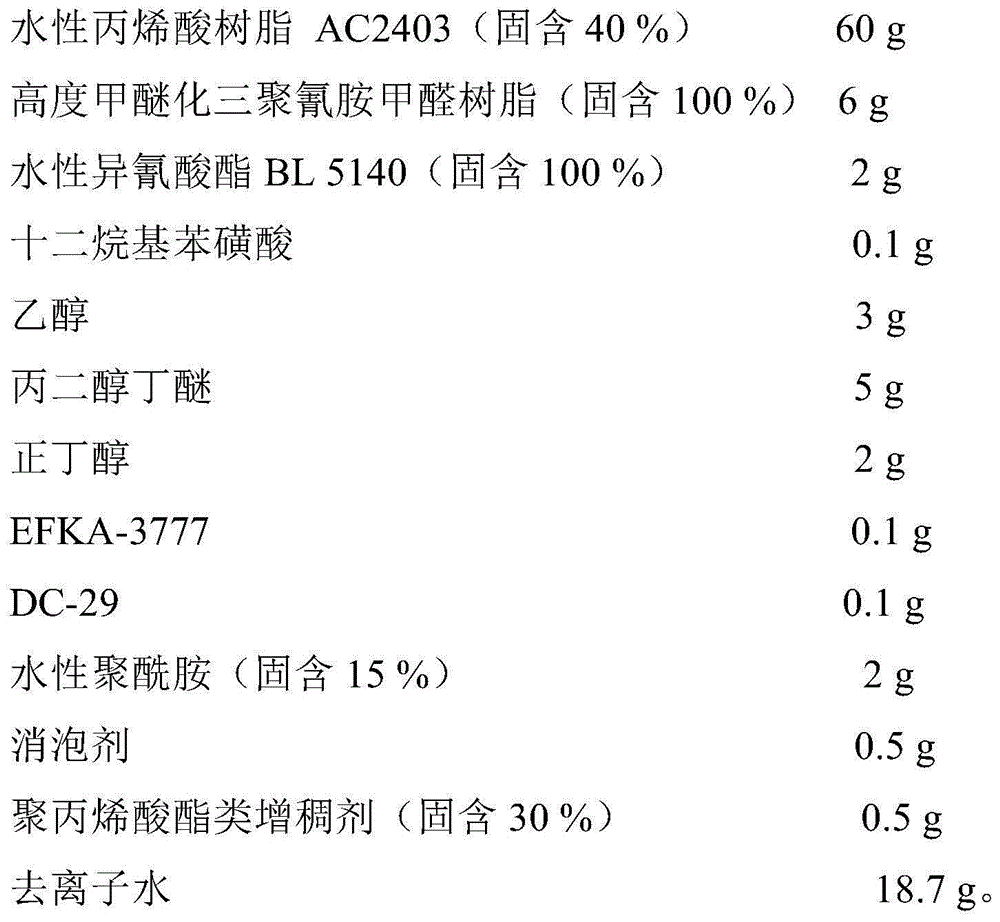

[0050] (1) Weigh the raw materials of the following components in proportion

[0051]

[0052] (2) Mix the above raw materials and disperse them evenly to prepare a water-based super corrosion-resistant coating with a solid content of 36.5%. The viscosity of the coating is 53 ± 5s when coated with 4 cups.

[0053] 2. Coating the prepared single-coated water-based super corrosion-resistant coating on the aluminum foil to form a corrosion-resistant coating. First, the aluminum foil was degreased and dried, and then the paint was applied to the aluminum foil, and baked in a 300°C oven for 25s to obtain a coating with a dry film thickness of 3 μm.

[0054] The corrosion-resistant coating prepared above has excellent alkali resistance, cooking resistance, and salt spray resistance after testing, and the salt spray resistance of the coating after stamping and bending is still con...

Embodiment 3

[0056] 1. Preparation of water-based high corrosion-resistant coatings with excellent flushability

[0057] (1) Weigh the raw materials of the following components in proportion

[0058]

[0059] (2) Mix the above raw materials and disperse them evenly to prepare a water-based super corrosion-resistant coating with a solid content of 40%. The viscosity of the coating measured by coating -4 cups is 110 ± 10s.

[0060] 2. Coating the prepared single-coated water-based super corrosion-resistant coating on the aluminum foil to form a corrosion-resistant coating. Firstly, the aluminum foil was degreased and dried, then the coating was applied to the aluminum foil, and baked in an oven at 300°C for 50s to obtain a coating with a dry film thickness of 5 μm.

[0061] The corrosion-resistant coating prepared above has excellent alkali resistance, cooking resistance, and salt spray resistance after testing, and the salt spray resistance of the coating after stamping and bending is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com