Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

198 results about "Marine corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Marine corrosion refers to the breakdown or degradation of metallic materials due to an electrochemical reaction when the surrounding environment (e.g., ocean, lake, sea) contains a naturally high salt moisture content.

Novel environment-friendly coating with superhigh marine environment corrosion resistance and preparation method and application thereof

ActiveCN102352171AImprove anti-corrosion performanceGood resistance to salt sprayAnti-corrosive paintsEpoxy resin coatingsEpoxyEnvironmental resistance

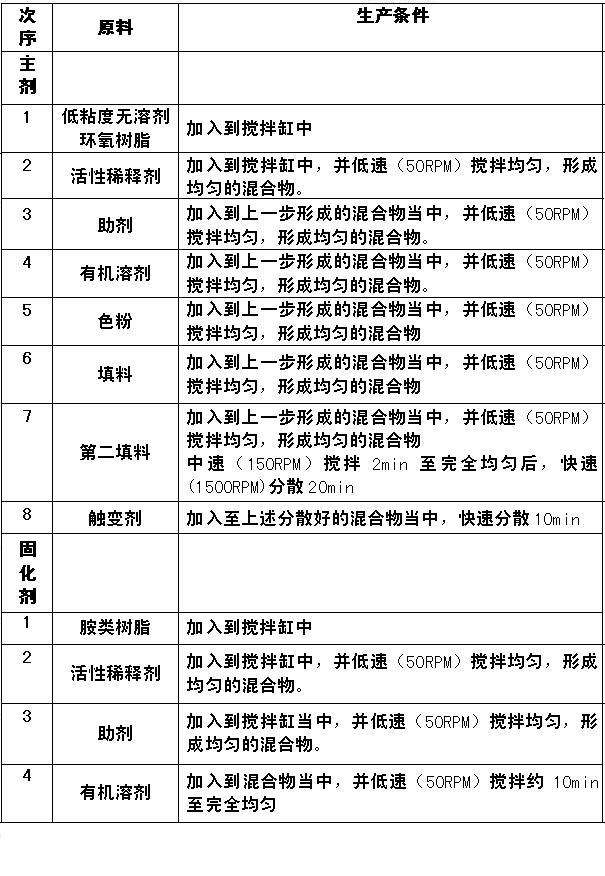

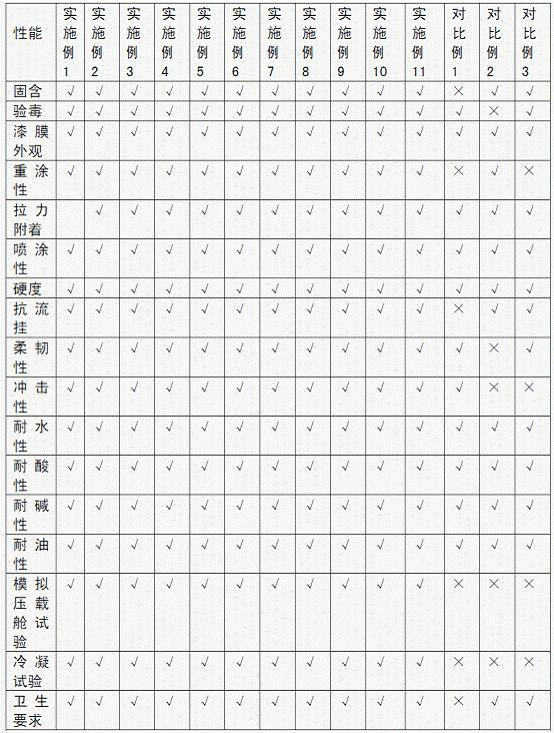

The invention discloses a novel environment-friendly coating with superhigh marine environment corrosion resistance and a preparation method and application thereof. The environment-friendly coating with superhigh marine corrosion resistance consists of the following components in part by weight: a main agent comprising 22 to 35 parts of low-viscosity solvent-free epoxy resin, 9 to 15 parts of activated thinner, 0.2 to 5 parts of aid, 5 to 8 parts of organic solvent, 0.5 to 15 parts of toner, 10 to 25 parts of first filler, 20 to 45 parts of second filler and 0.5 to 5 parts of thixotropic agent, and a curing agent comprising 60 to 90 parts of amine resin, 10 to 30 parts of activated thinner, 2 to 8 parts of aid and 2 to 10 parts of organic solvent. During use, the main agent and the curing agent are uniformly mixed, and the mixture is applied to the surface of a substrate. A film formed by the coating is high in corrosion resistance and low in content of volatile organic compounds (VOC), does not contain any toxic or harmful substance, can be universally used in a drinking water tank, and also can be used for a ship ballast tank, a ship bottom, a deck and each position of a marine platform.

Owner:CHINA PAINT MFG CO SHENZHEN

Production method of anti-corrosion and high strength ultra-thick steel plates

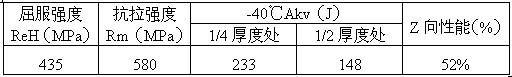

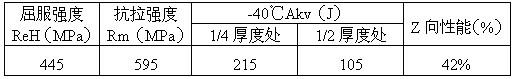

A production method of anti-corrosion and high strength ultra-thick steel plates comprises the process flows of (1) raw material preparing, (2) smelting in a converter, (3) LF refining, (4) vacuum degassing in a VD furnace, (5) continuous casting, (6) plate blank heating, (7) rough rolling, (8) finish rolling, (9) controlled rolling and cooling by ACC, (10) online normalizing, (11) finishing and (12) finished product warehousing. The method is characterized in that the steel comprises the following components by weight: 0.05-0.13% of C, 0.10-0.50% of Si, 0.6-1.60% of Mn, not more than 0.015% of P, not more than 0.005% of S, not more than 0.05% of Nb, not more than 0.02% of Ti, 0.02-0.06% of Al, not more than 0.60% of Ni, not more than 0.70% of Cu, not more than 0.1% of V, not more than 0.008% of N and the balance Fe and inevitable impurities. The steel plates produced by the method have high strength, high tenacity and anti-marine corrosion property.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

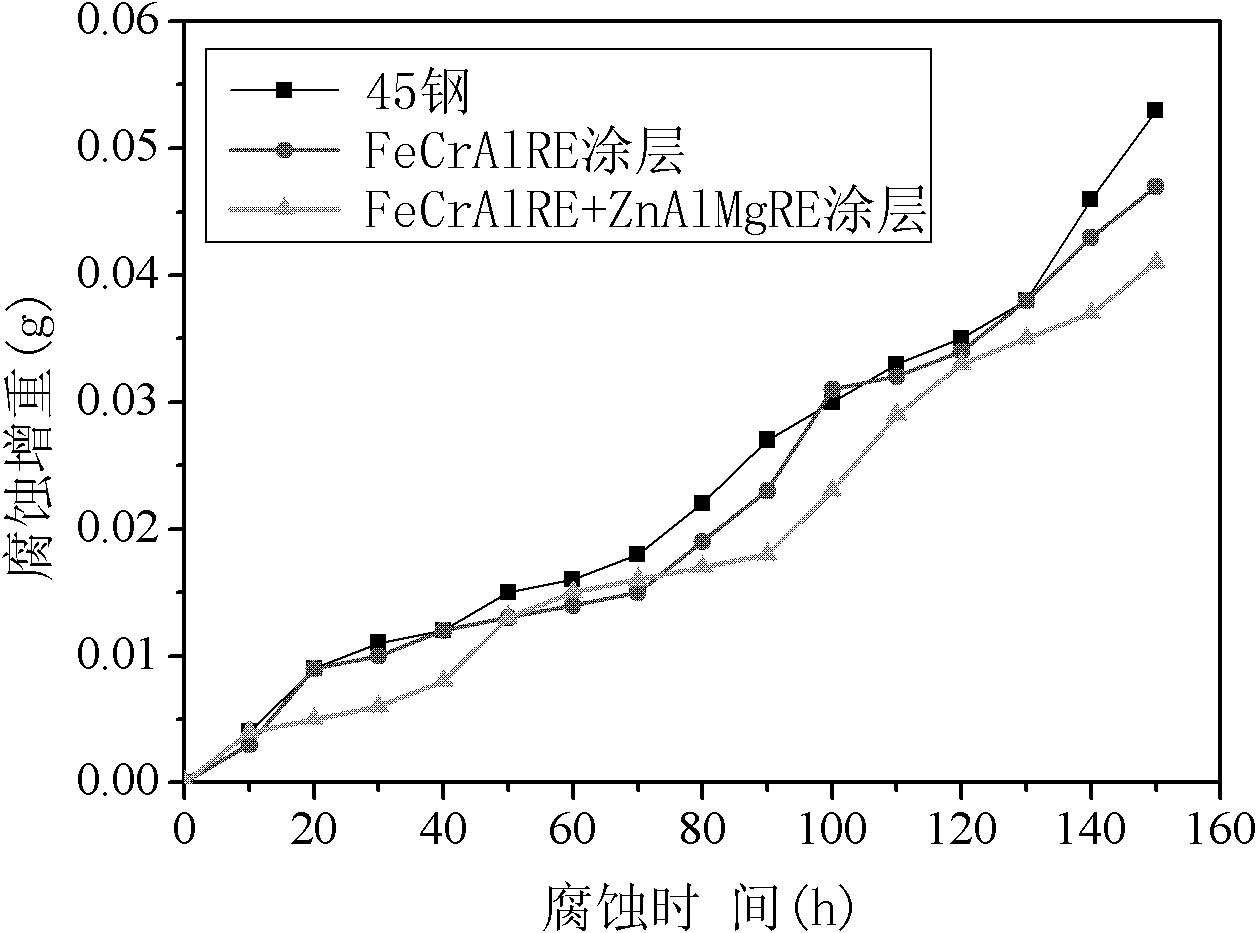

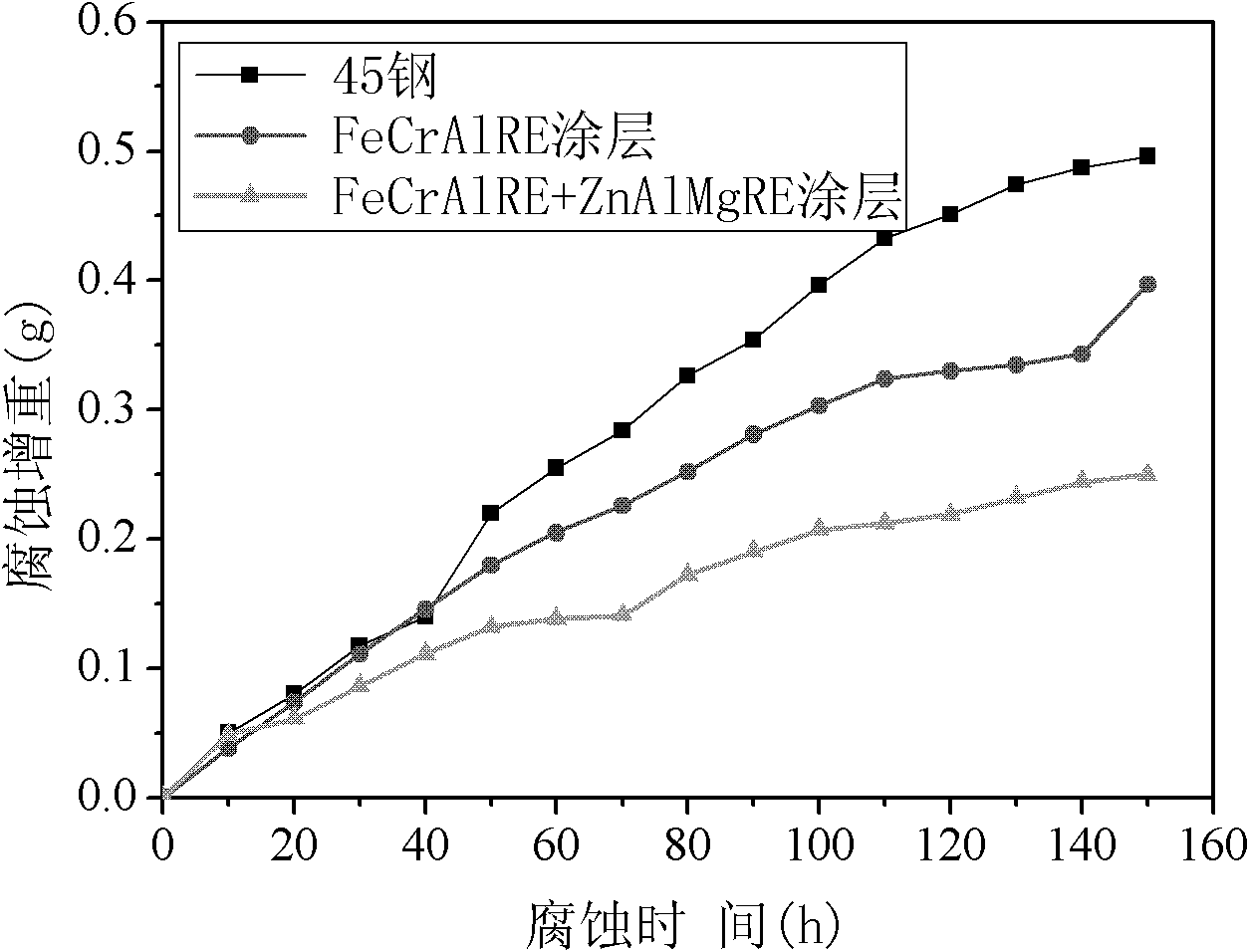

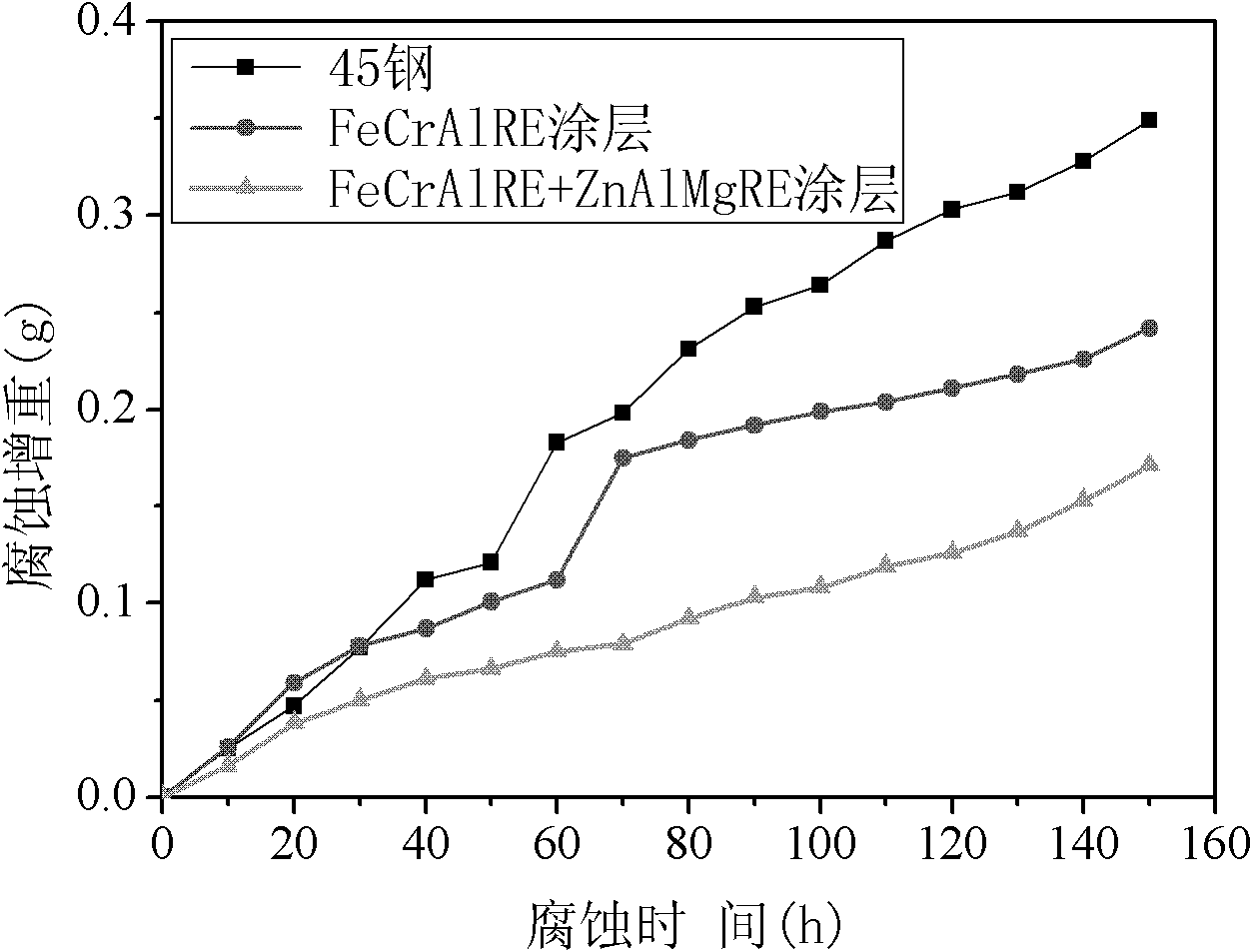

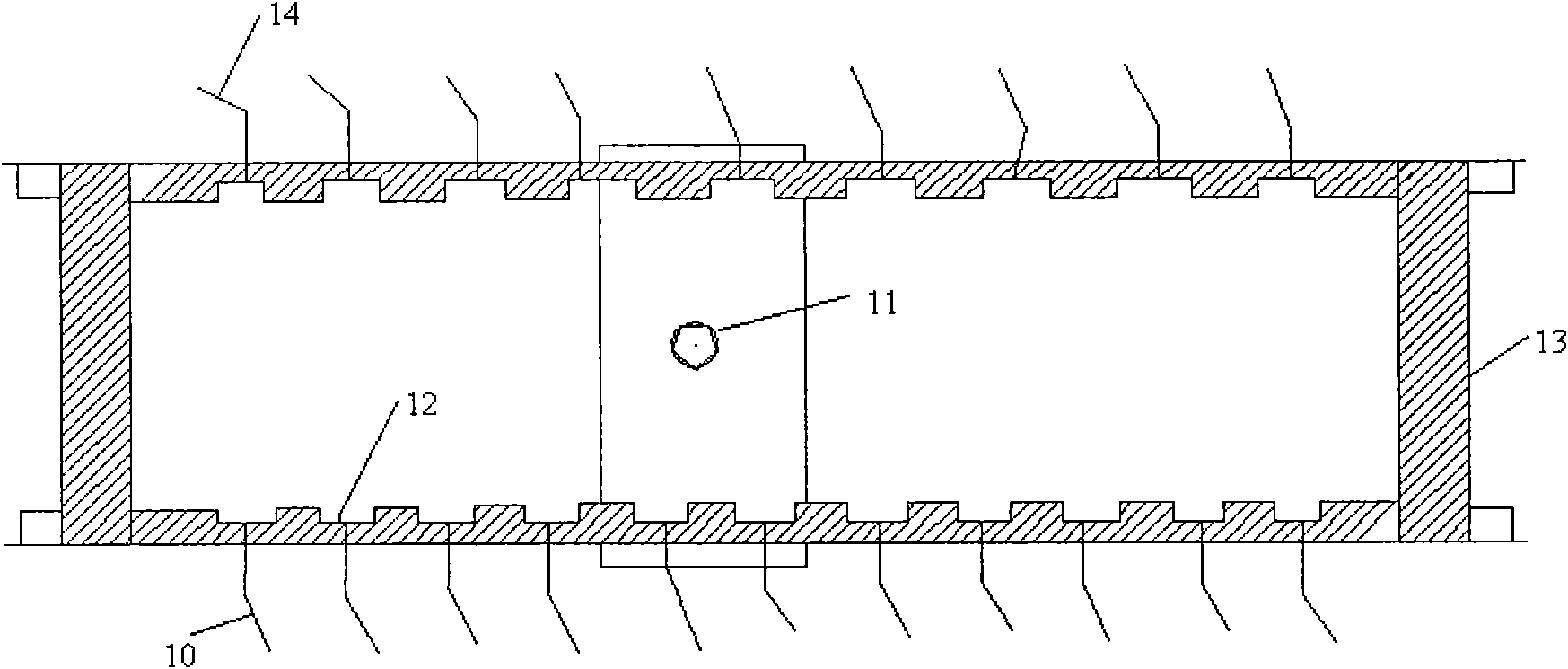

Marine-corrosion/hot-corrosion-resistant composite coating and preparation method thereof

ActiveCN102206797AGood high temperature corrosion resistanceGood self-sealingMolten spray coatingHigh humidityAlloy coating

The invention discloses a marine-corrosion / hot-corrosion-resistant composite coating and a preparation method thereof, belonging to the technical field of metal surface protection. A novel FeCrAlRe hot-corrosion-resistant powder core wire material is prepared by coating mixed powder, containing Cr powder, Al powder and the like, on a carbon steel band. A ZnAlMgRe powder core wire material is prepared by coating mixed powder, containing Al, Mg, Zn and Re, on a Zn-base alloy band. The preparation method of the composite coating comprises the following steps: spraying the FeCrAlRe powder core wire material by using a high-speed arc spraying device to form an alloy coating on a pretreated steel base surface, and spraying a ZnAlMgRe coating to form a double-layer composite structure protective coating. The prepared coating can resist hot corrosion, and has excellent corrosion resistance in a marine high-humidity high-salt-mist environment.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

High-early-strength magnesium phosphate concrete and preparation method thereof

InactiveCN101386518AQuickly restore functionalityFast setting and hardeningSolid waste managementMagnesium phosphateHazardous substance

The invention discloses a quick-hardening early strength magnesium phosphate concrete, which is mainly prepared from the following components in weight percentage: 12.7 to 30 percent of magnesia, 8.7 to 20 percent of phosphate, 1.2 to 15 percent of retarder, 10 to 25 percent of fine aggregate, 10 to 50 percent of water and the balance being water. The concrete material has the characteristics of quick coagulation and hardening, high early strength, good erosion resistance and the like, and can be widely applied to the quick repairing in projects or structures such as railways, airfields, bridges, harbors and docks and the quick solidification and closing of toxic and harmful substances, and can also be applied to the civil engineering and building construction under the sever conditions of sulfate erosion, marine corrosion, low temperature and the like. The invention has the advantages of simple preparation method, process and necessary equipment, low cost, no pungent ammonia gas generation in the construction and convenient popularization and application.

Owner:汪宏涛

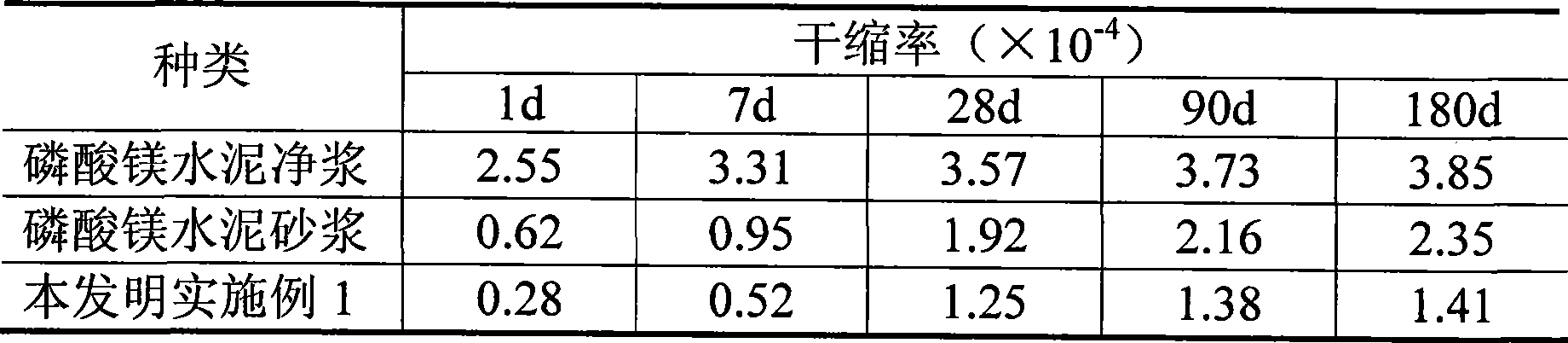

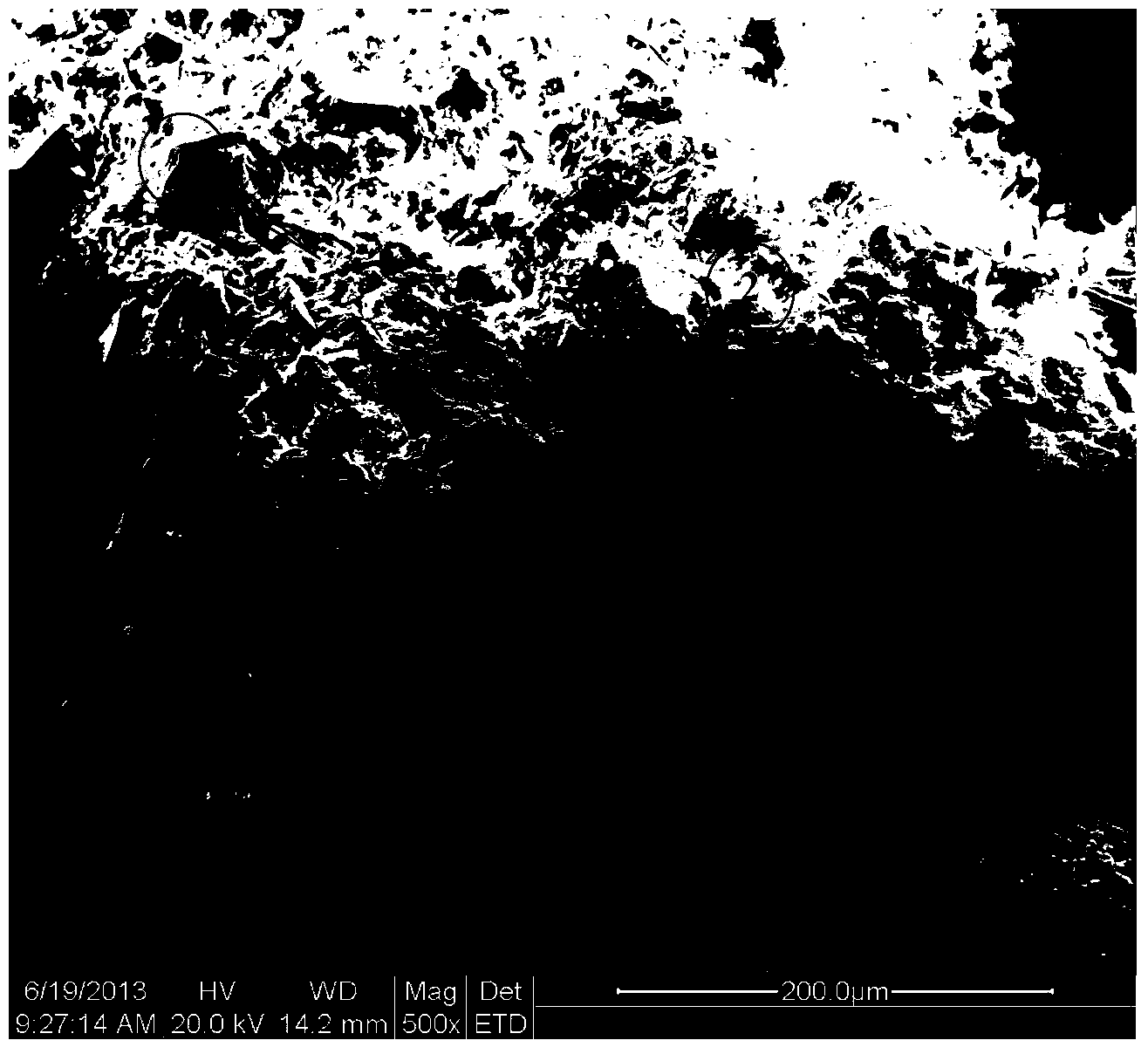

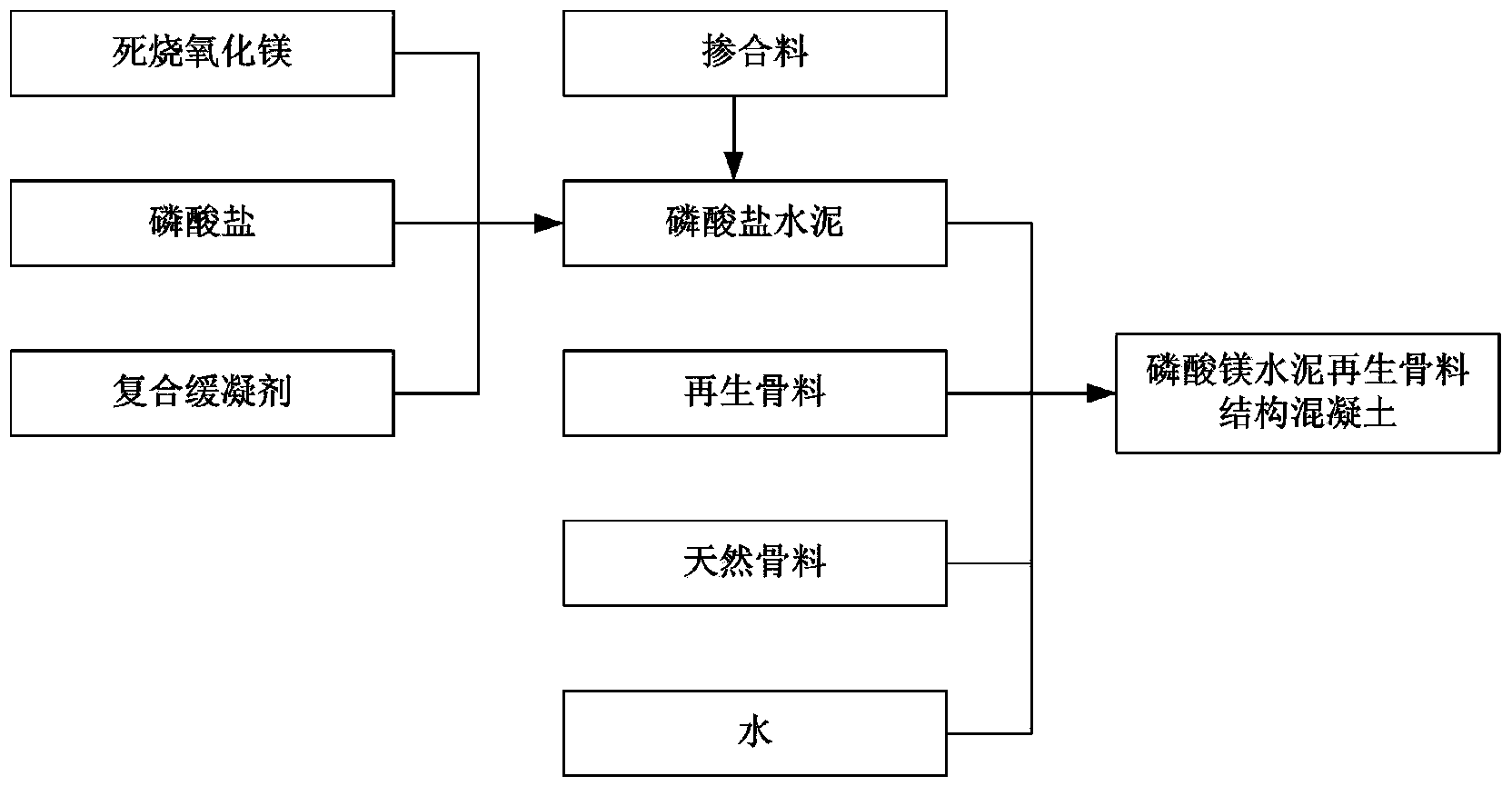

Magnesium phosphate cement recycled aggregate structure concrete and preparation method thereof

InactiveCN104072091AEarly hardening fastHigh strengthSolid waste managementAggregate (composite)Magnesium phosphate

The invention discloses magnesium phosphate cement recycled aggregate structure concrete and a preparation method thereof. The magnesium phosphate cement recycled aggregate structure concrete comprises the following components by weight percent: 12-30% of magnesium oxide, 8-20% of phosphate, 2-10% of composite retarder, 5-15% of admixture, 5-20% of recycled fine aggregate, 5-30% of recycled coarse aggregate, 0-10% of natural fine aggregate, 0-15% of natural coarse aggregate, and the balance being water. High early strength, small shrinkage rate, strong adhesive property and good corrosion resistance of the concrete are ensured by the magnesium phosphate cement; stable growth of the strength of the concrete is ensured by the admixture, and the durability and the volume stability are improved. The magnesium phosphate cement recycled aggregate structure concrete has the beneficial effects that the concrete material is applicable to the structure concrete and high-performance recycled aggregate concrete, can be applied to civil engineering in bad environments such as sulphate attack, marine corrosion, high-temperature environment and low-temperature environment, efficient utilization of the waste concrete is achieved, mining of natural gravel is reduced, the construction cost is reduced, and the targets of recycling wastes and protecting environment are achieved.

Owner:YANCHENG INST OF TECH

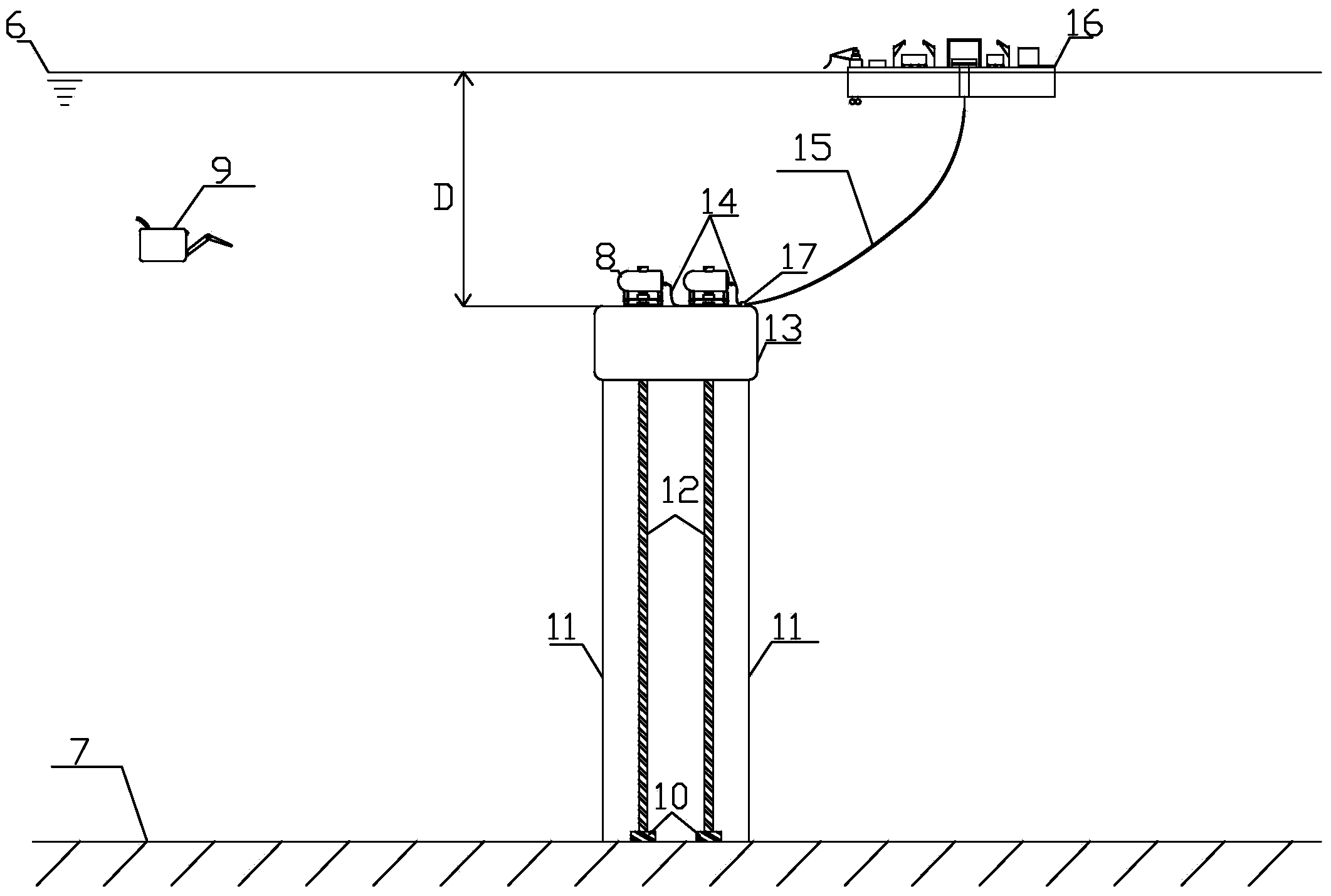

Dry-type Christmas tree based ultra-deepwater oil and gas development system and mounting method thereof

The invention discloses a dry-type Christmas tree based ultra-deepwater oil and gas development system and a mounting method thereof. The system comprises a water float, underwater wellhead chambers, dry-type Christmas trees, a water manifold device, an upper flexible stand pipe and a floating-type water surface production device, wherein the dry-type Christmas trees and related equipment are mounted in the underwater wellhead chambers; the underwater wellhead chambers are formed in a wellhead of the water float; oil outlet pipelines of the underwater wellhead chambers are connected with the inlet of the water manifold device; the water float is positioned in the position with the depth of 100-400 m under the water, and is moored to a sea bed through tension cables. According to the invention, the underwater dry-type Christmas trees are adopted, and the dry-type Christmas trees and the related equipment are separated from the sea water environment through the underwater wellhead chambers, so that compared with wet-type Christmas trees, influence of marine corrosion and pressure as well as sea bed sludge and marine creatures on the dry-type Christmas trees is avoided; the suitability is strong, the operation is convenient and safe, the maintenance cost is low, and the situation that divers are not needed to perform installation can be realized completely.

Owner:DALIAN UNIV OF TECH

Large range reinforcing steel corrosion monitoring sensor based on fiber bragg grating sensing technology

ActiveCN103411713AHigh elastic modulusChange space distanceForce measurement by measuring optical property variationFiberGrating

Owner:CCCC FOURTH HARBOR ENG INST +3

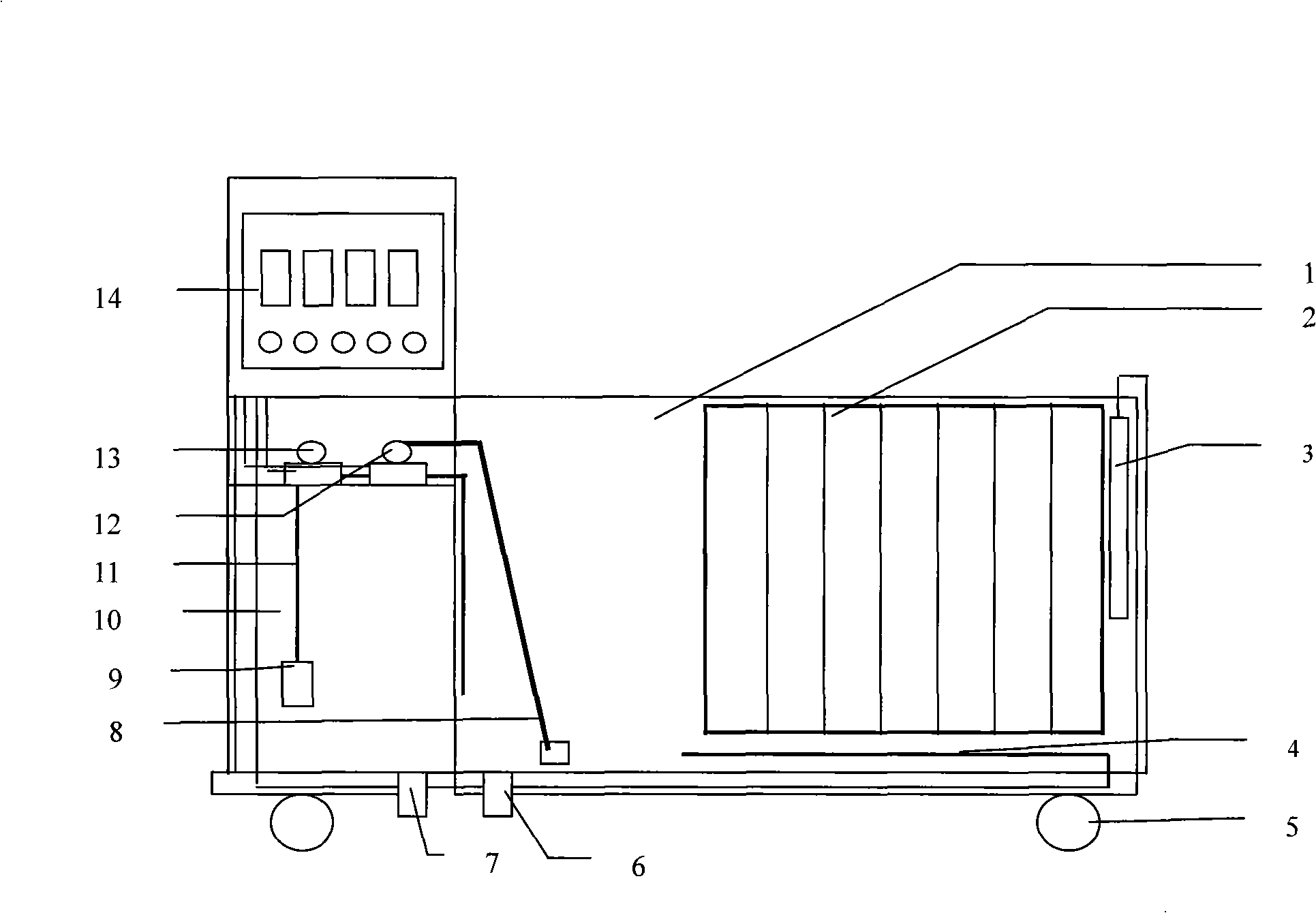

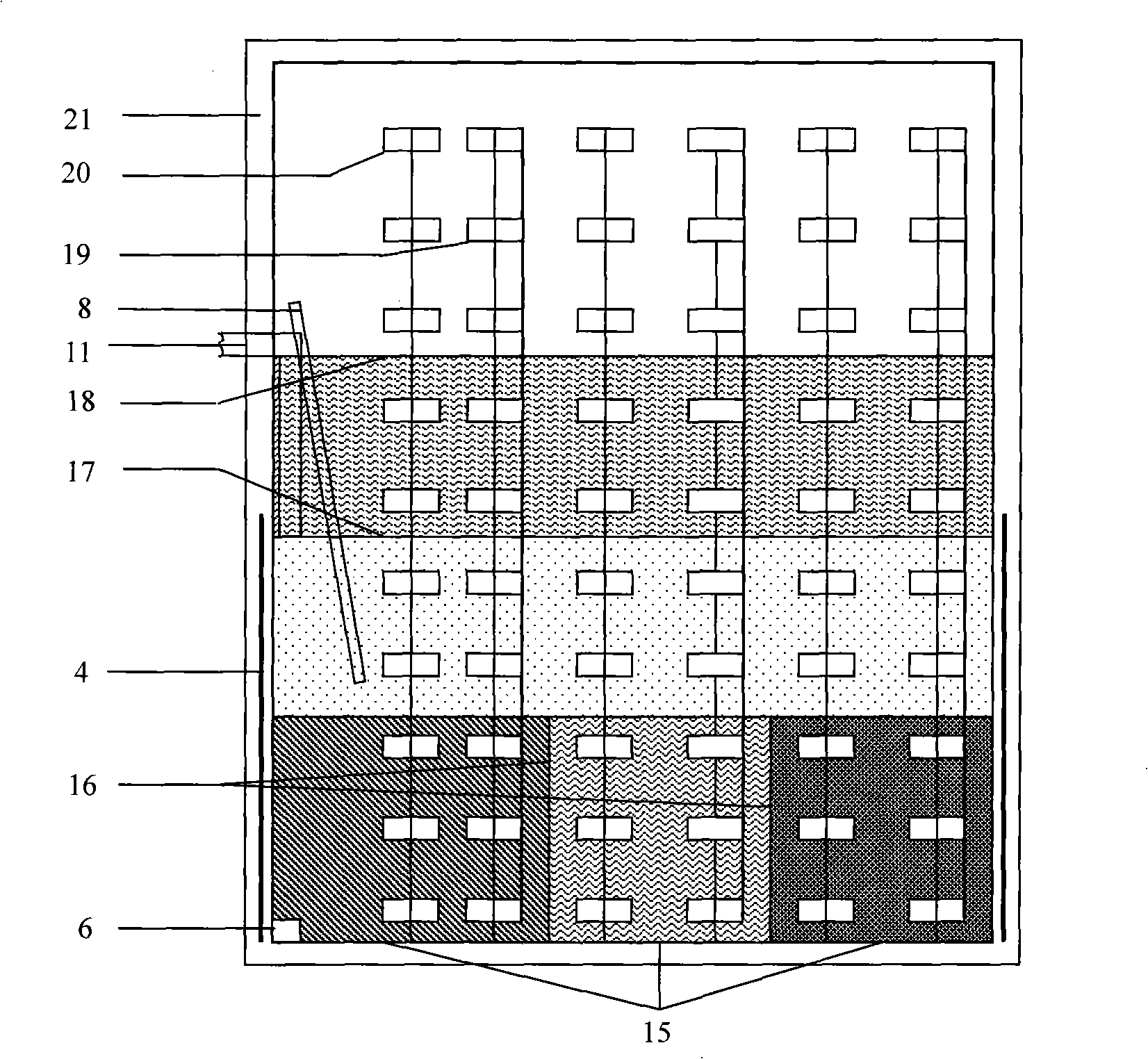

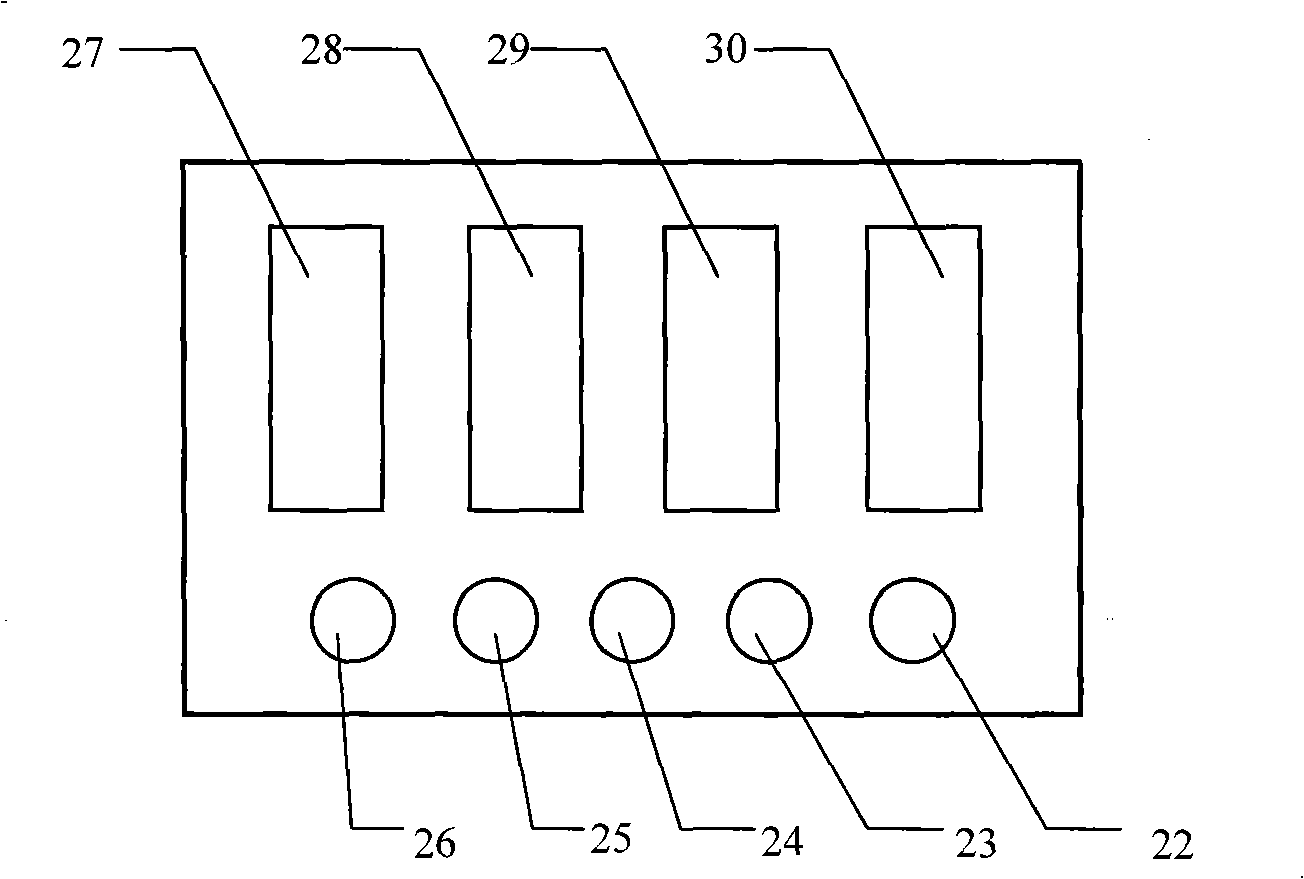

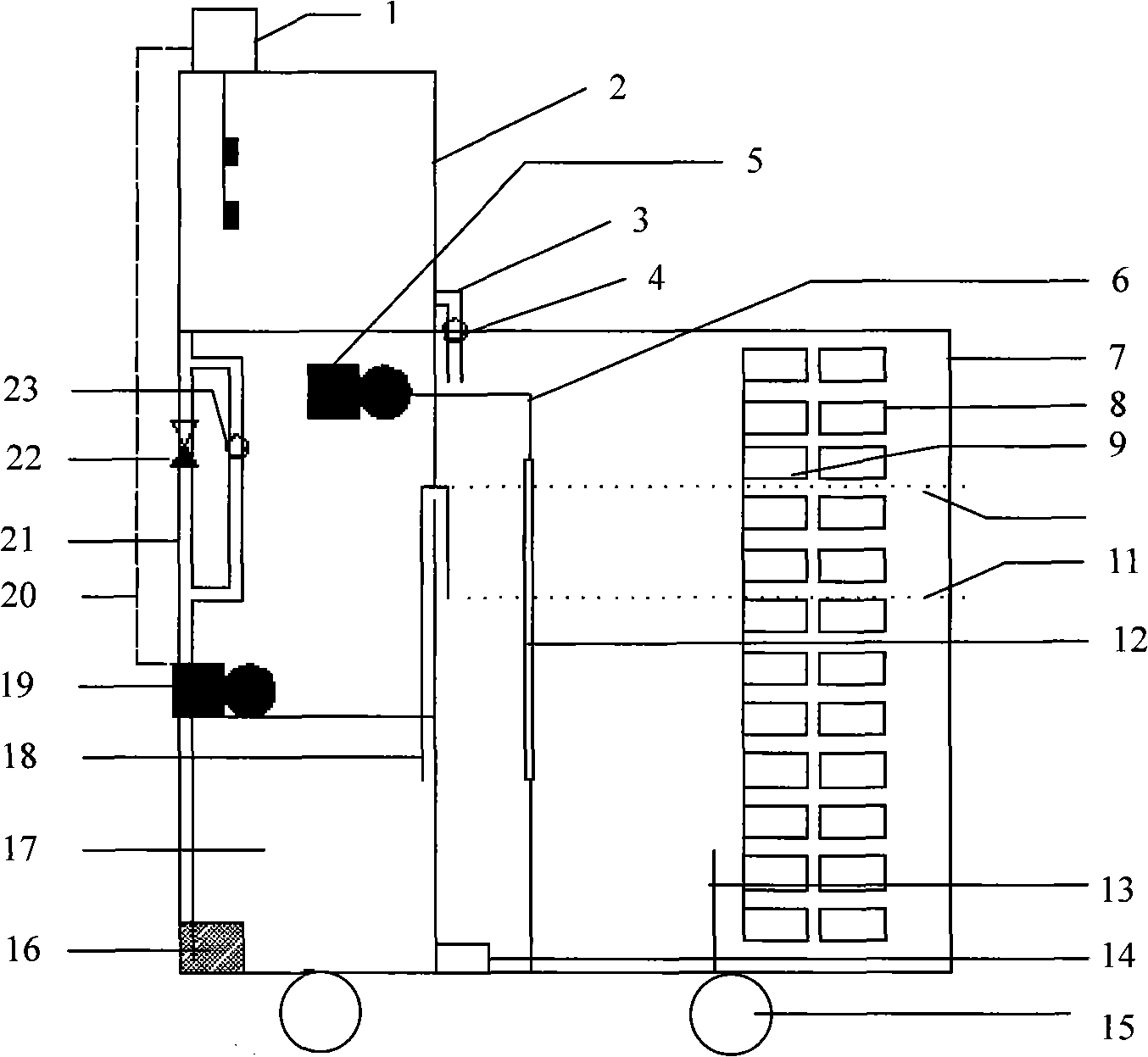

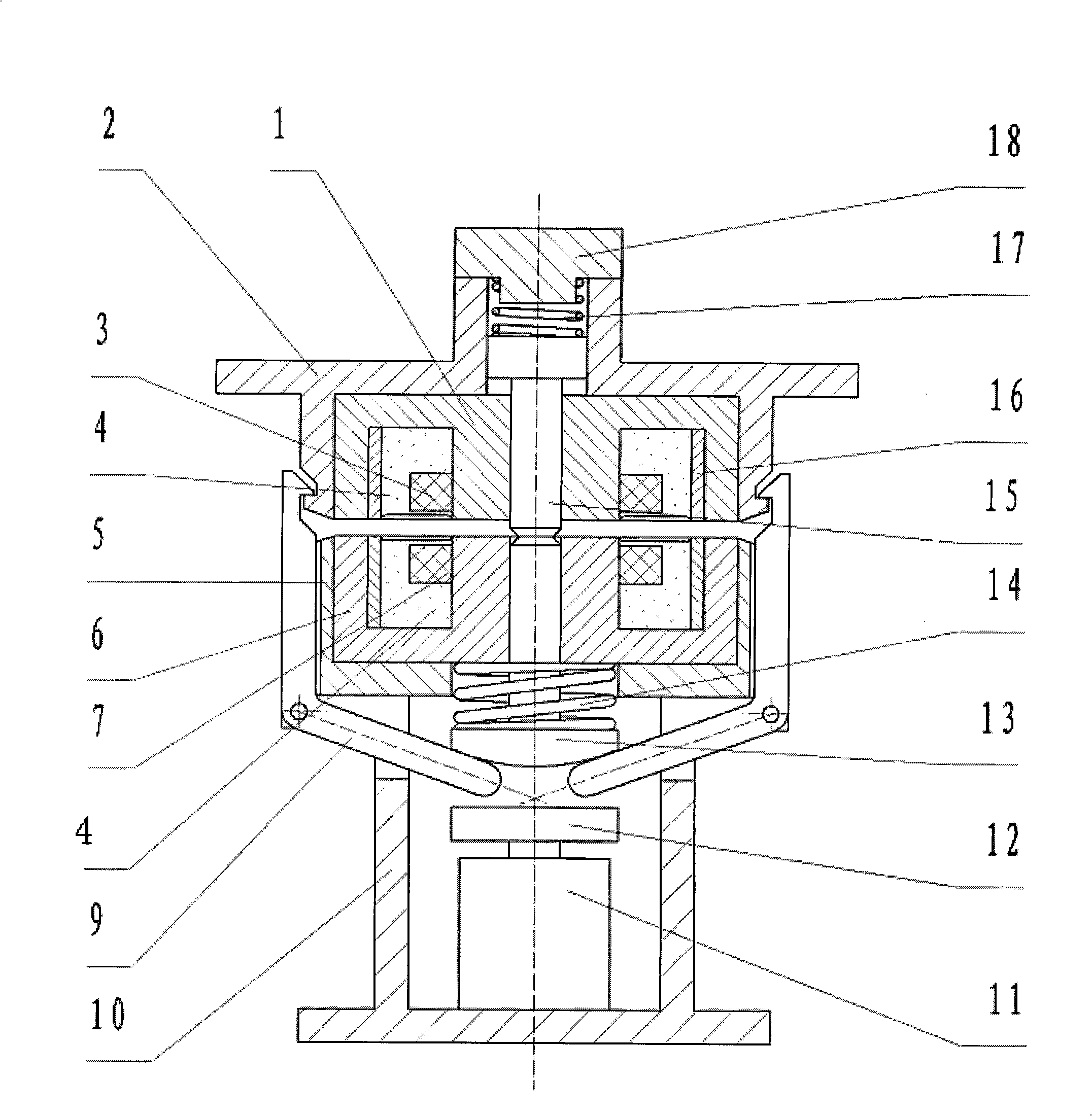

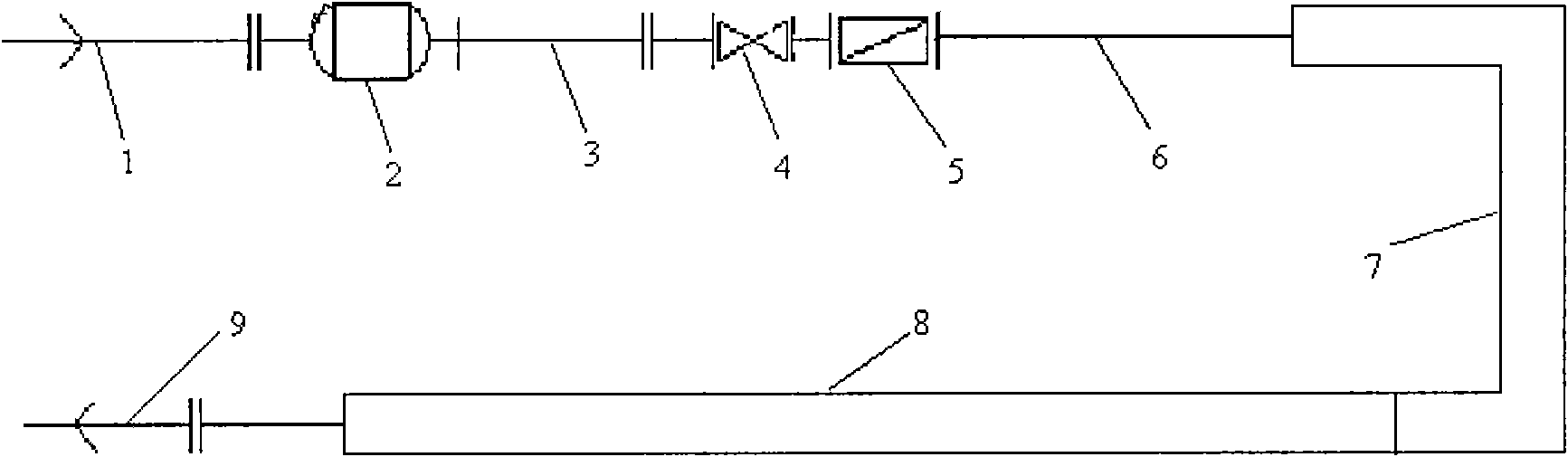

Intelligent type simulated marine corrosion test machine

InactiveCN101285756AIntegrity guaranteedGuaranteed reliabilityWeather/light/corrosion resistancePeristaltic pumpOpen sea

The invention relates to a metallic erosion experimental apparatus, in particular to an intelligent marine corrosion simulation tester for measuring erosion conditions of metals in the marine environment through computer control. The invention comprises a heatable main water tank, a water storage tank and a control panel, wherein, peristaltic pumps are arranged on the tester and respectively inserted into the main water tank and the water storage tank through peristaltic pump pipes; an electrically controlled wave generating plate and a test strip holder are arranged inside the main water tank; the control panel is positioned above the water storage tank; and the peristaltic pumps, an electric control device which is connected with the wave generating plate and a heating device on the main water tank are respectively connected with the control panel. The metallic erosion experimental apparatus can actually simulate the erosion environment of five different zones of open sea and have good correspondence with the erosion environment of the open sea, thereby not only saving a mass of labor power, physical resources and financial resources but also guaranteeing the completeness of test data and the reliability of a test structure; the operation is simple and the visualization degree is high, thereby being convenient for observation; and the simulation environment is various and true.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

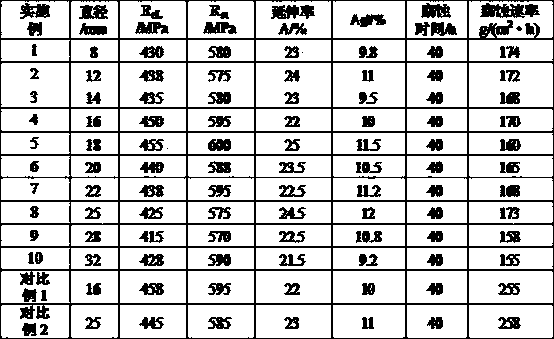

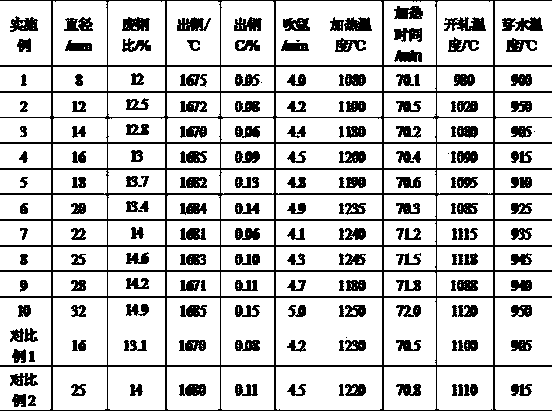

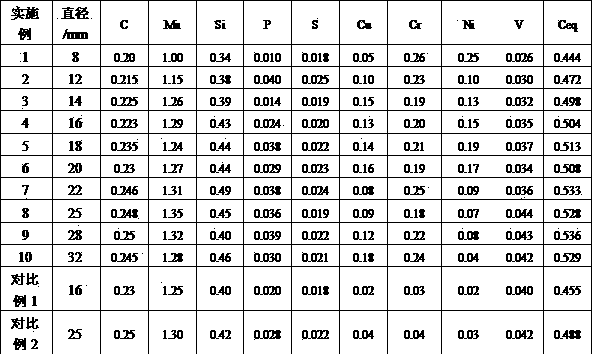

Marine-climate-corrosion-resistant steel bar

The invention relates to a marine-climate-corrosion-resistant steel bar which comprises the following components in percentage by weight: 0.2%-0.25% of C, 0.35%-0.55% of Si, 1.0%-1.35% of Mn, 0.01%-0.04% of P, 0.005-0.03% of S, 0.05%-0.3% of Cu, 0.04%-0.25% of Ni, 0.05%-0.3% of Cr, and the balance of Fe and inevitable impurities. The Ceq does not exceed 0.54%.Under the conditions that the yield strength is not lower than 400 MPa, the tensile strength is not lower than 540 MPa, the elongation percentage A is not lower than 16%, the total elongation percentage Agt / % under maximal power is not lower than 9% and the cold bending performance is qualified, the marine corrosion resistance is high and is enhanced from 1.00% to 1.43%, so that the steel bar can not crack when in use.

Owner:武钢集团有限公司

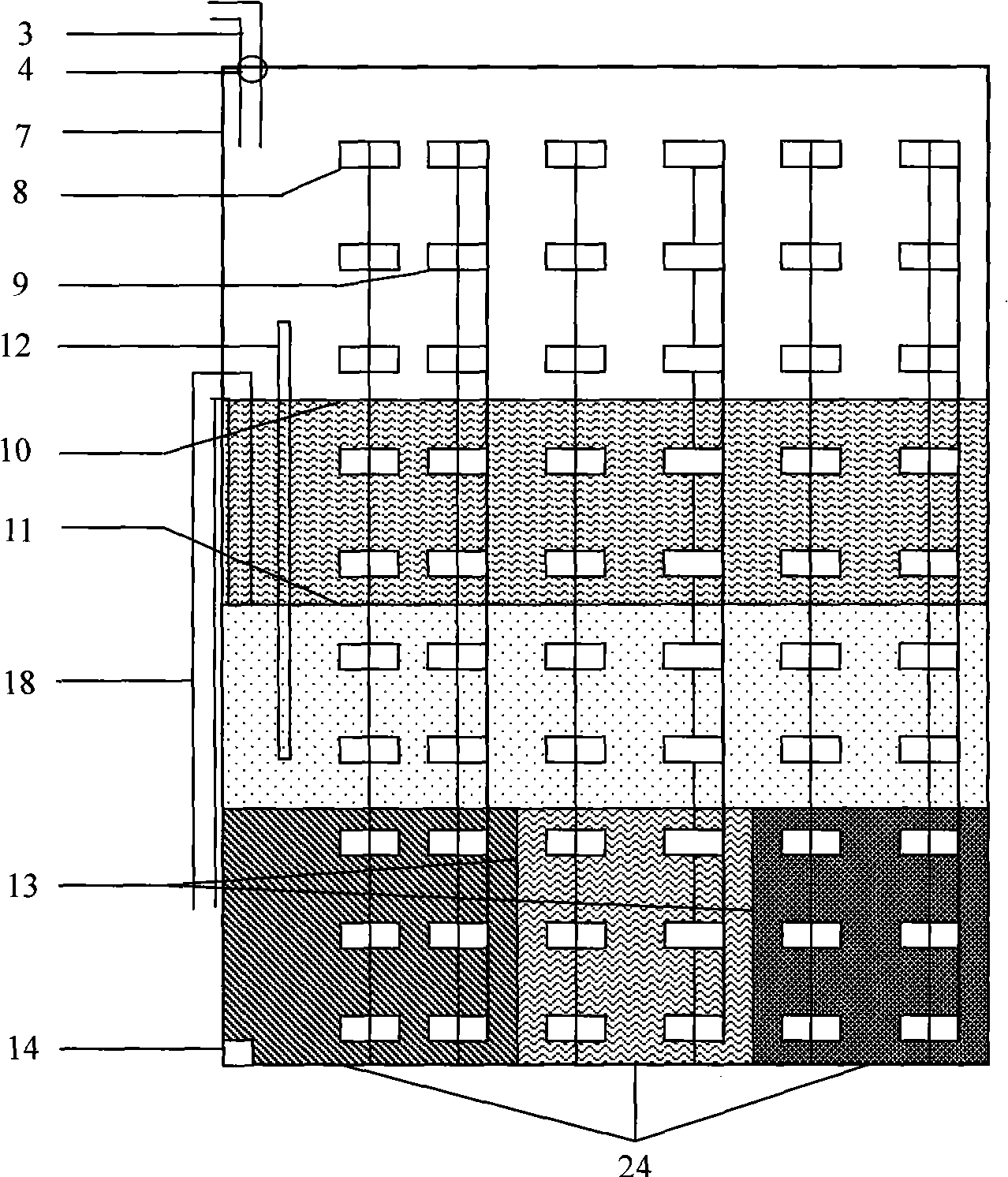

Simulated marine corrosion test machine

InactiveCN101285757AIntegrity guaranteedGuaranteed reliabilityWeather/light/corrosion resistanceSiphonWater storage tank

The invention relates to a metallic erosion experimental device, in particular to a marine erosion simulation tester for measuring erosion conditions of metals in the marine environment. The invention comprises an upper water storage tank, a lower water storage tank and a main water tank, wherein, a siphon tube is arranged between the main water tank and the lower water storage tank; one end of the siphon tube is positioned inside the main water tank and the other end of the siphon tube is inserted into the lower water storage tank; the upper water storage tank is communicated with the lower water storage tank through a water pipe capable of controlling the flow rate; a water inlet pipe capable of controlling the flow rate is arranged on the upper water storage tank and the other end of the water inlet pipe is inserted into the main water tank; an electrically controlled wave generating plate and a test strip holder are arranged inside the main water tank; a sea mud zone at the bottom is provided with a plurality of baffle plates; a liquid level controller is arranged on the upper water storage tank and connected with the water pipe through an electrical wire; a filter screen is arranged inside the lower water storage tank and water which is filtered by the filter screen passes through the water pipe and flows into the upper water storage tank; the wave generating plate is connected with a driving motor through a transmission tension rod; and the test strip holder can hang pieces respectively or hang pieces through electrical interlocking. The test result of the device is reliable and convenient for observation, and the simulation environment is various and true.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

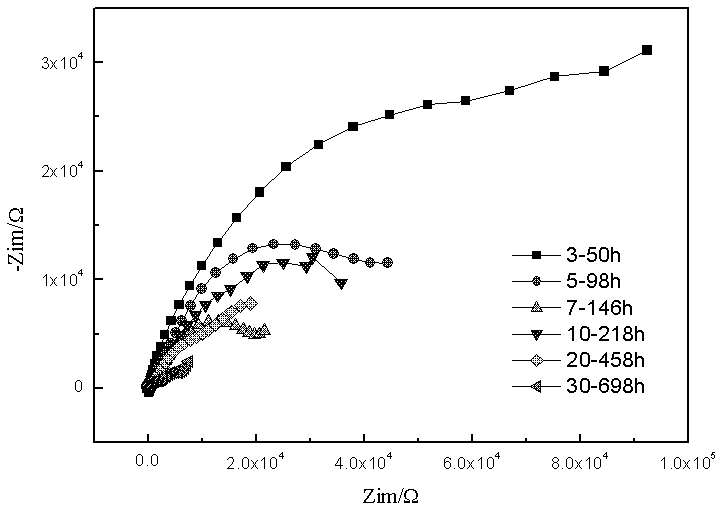

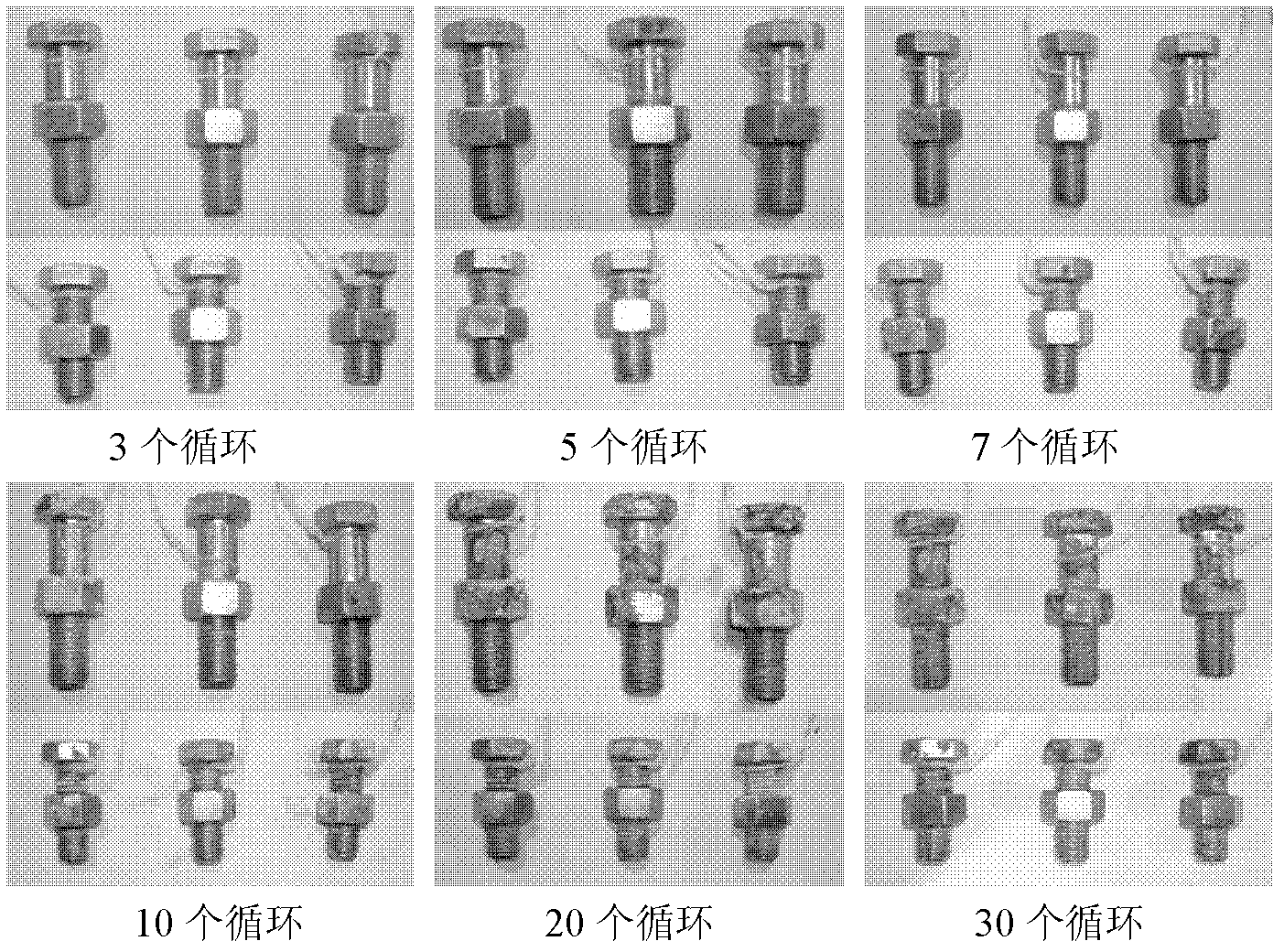

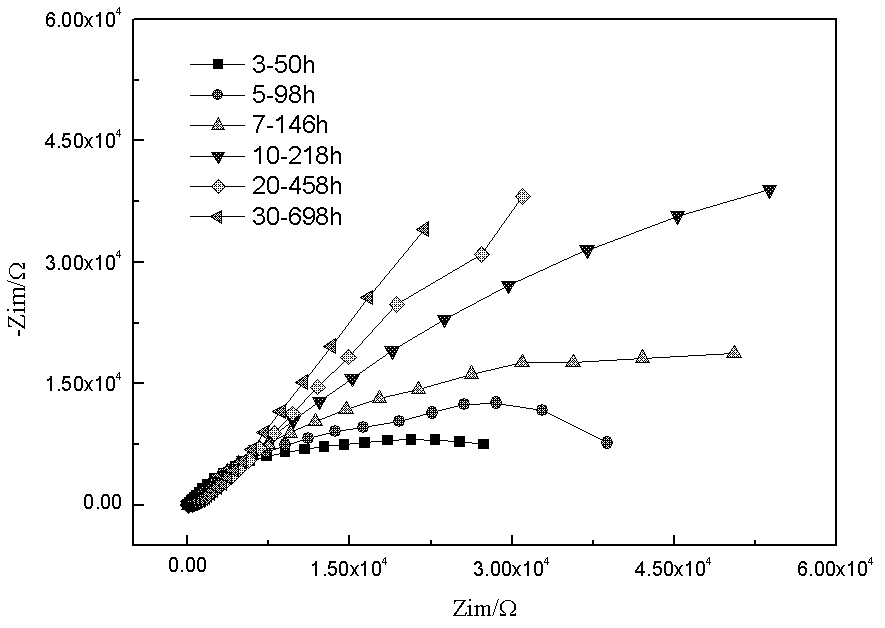

Simulated accelerated corrosion testing method of ship fastener and protective coating

InactiveCN102621058APredicting Environmental Application PerformanceThe process steps are simpleWeather/light/corrosion resistanceSalt spray testPre treatment

The invention belongs to the technical field of marine corrosion and protection and relates to a simulated accelerated corrosion testing method of a ship fastener and a protective coating. Soaking, damp and hot, drying and salt spray tests can be carried out on different specifications of fasteners and protective coatings by using natural seawater and 5% of NaCl solution as a test medium; in situ monitoring is carried out by using an electrochemical method; and process information and corrosion test result are combined with each other so as to obtain a corrosion rule of the fastener material and the protective coating; and the method comprises the specific steps of testing device selection, specimen pretreatment, corrosion experiment circulating and test result displaying; and the method provided by the invention has the advantages of simple processing steps, safe and reliable principle, friendly test environment, small test cost, mature equipment, intuitive result display and good applicability.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

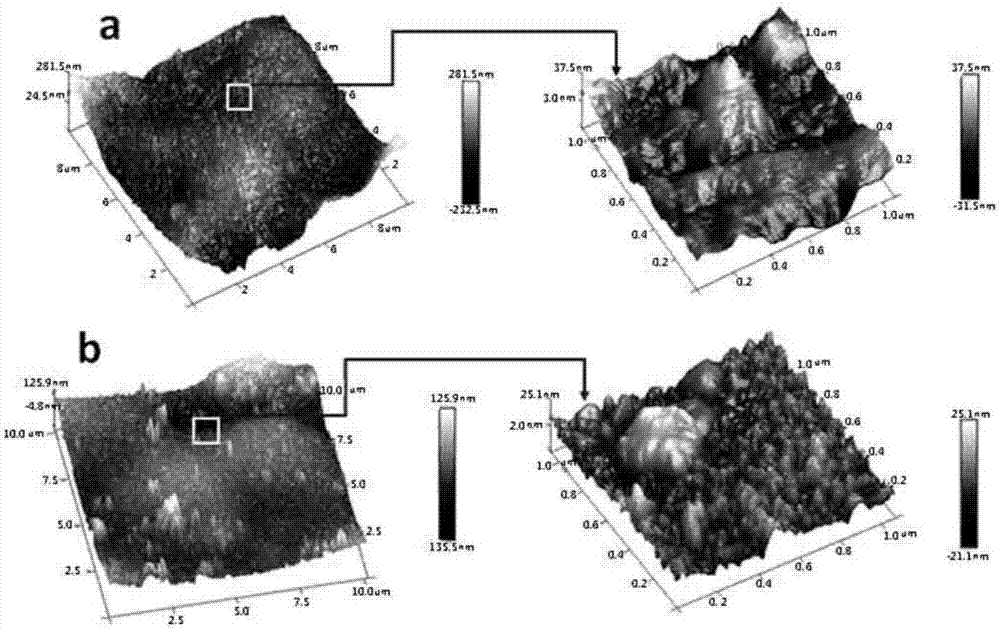

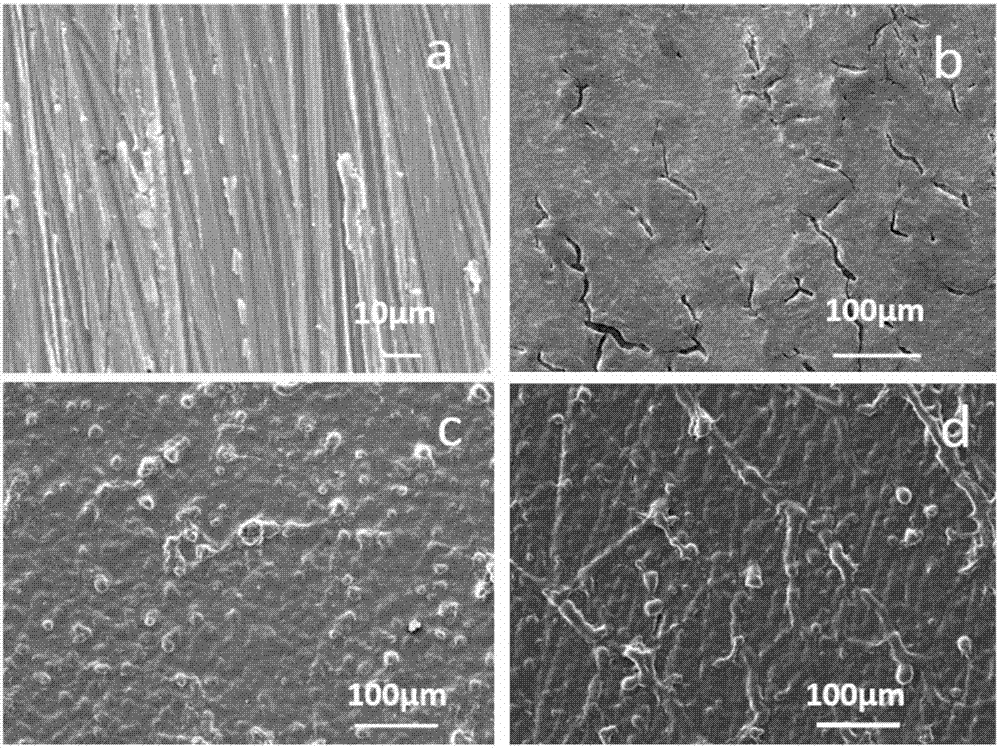

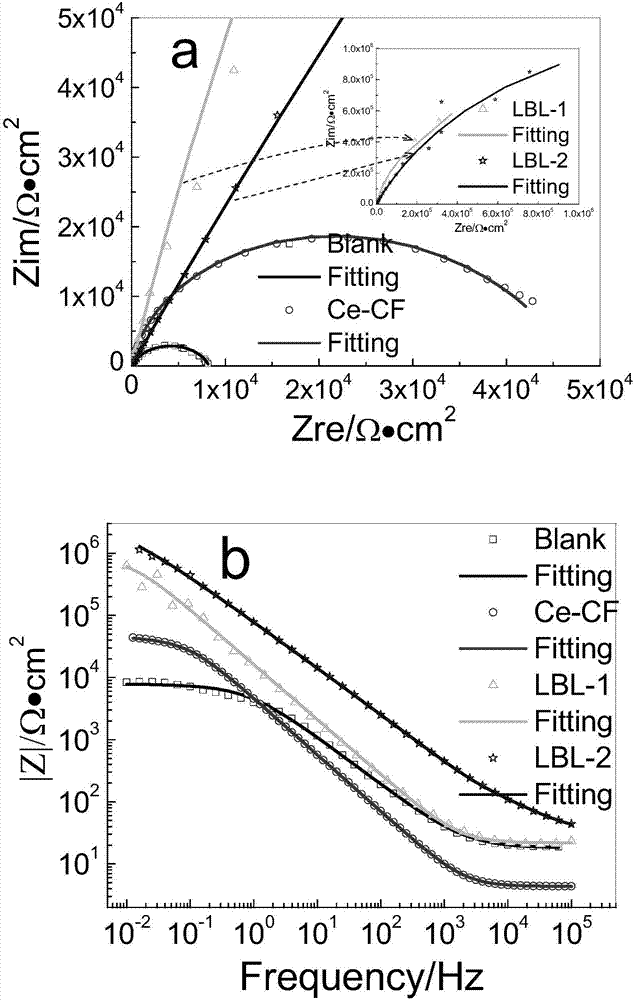

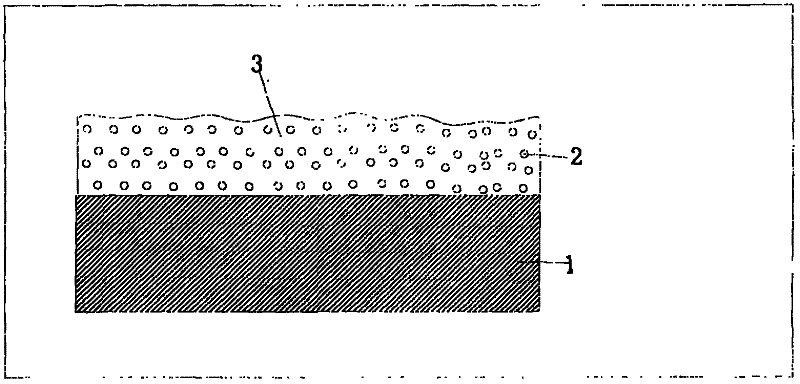

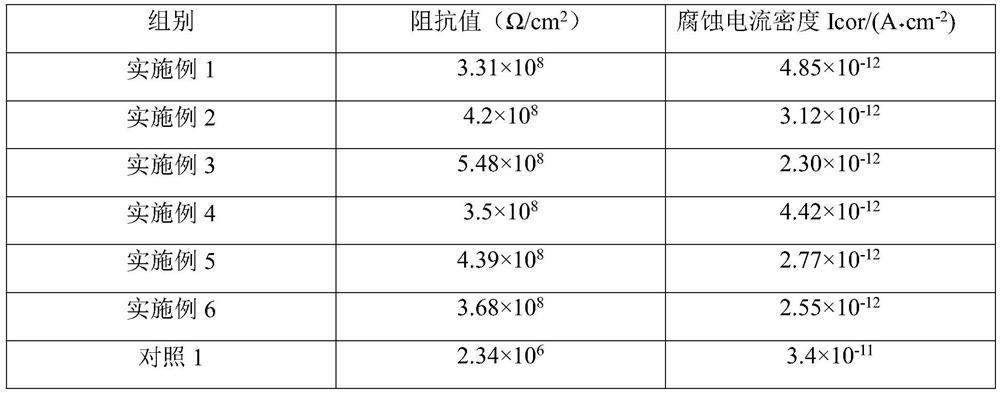

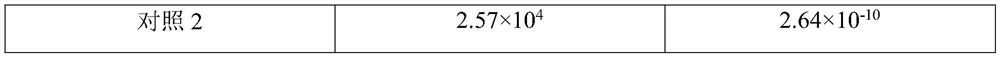

Preparation method for preparing graphene oxide anti-corrosion protective film on metal surface

The invention relates to a marine anti-corrosion protective film material, in particular to a marine anti-corrosion protective film prepared by adding graphene oxide on a metal surface by a layer-by-layer self-assembly LBL technology, and a method of the marine anti-corrosion protective film. The method comprises the following steps: soaking a pretreated aluminum alloy test sample in a cerous nitrate solution, drying at high temperature after soaking, depositing polyethyleneimine (PEI) and polyacrylic acid (PAA) layers on the test sample by the layer-by-layer self-assembly technology after drying, performing deposition of graphene oxide, and finally performing deposition of the PEI layer and the PAA layer for one time so as to realize multi-layer circulation electrochemical deposition and prepare the graphene oxide anti-corrosion protective film. The corrosion inhibition efficiency of the multi-layer self-assembly film with graphene oxide on the surface of the aluminum alloy in a 3.5 percent NaCl solution exceeds 99 percent, the corrosion inhibition efficiency of the multi-layer self-assembly film after friction is conducted by 200 mm or 400 mm exceeds 96 percent, and huge potential application is achieved in the marine anti-corrosion protection aspect.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Deep sea non-contact type electric energy transmission coupler

InactiveCN101404420AStable electrical parametersPrevent disengagementElectromagnetic wave systemTransformersElectric power transmissionElectrical connection

The invention discloses a non-contact electric energy transmission coupler in a deep ocean. The coupler comprises an upper moving magnetic core mechanism, a lower fixed magnetic core mechanism and a clamping releasing mechanism which are on a coaxial-line device. The upper moving magnetic core mechanism is provided with a first ferrite core, the lower fixed magnetic core mechanism is provided with a second ferrite core; a primary winding and a secondary winding are arranged in the first ferrite core and the second ferrite core respectively, and the relative position of the primary winding and the secondary winding is fixed by the clamping releasing mechanism in the charging process of the coupler, thus forming electromagnetic coupling to cause the electric energy to be transmitted to electric equipment; after the charging is finished, the primary winding and the secondary winding are separated, and the electric equipment can move freely. The invention can realize the electric energy transmission under water, thereby avoiding physical contact and electrical connection of interfaces of electricity transmission; fluid sealant is adopted to encapsulate and separate, thus avoiding marine corrosion and electric leakage. As the coupler has no cavity, high pressure in the deep ocean can be borne. The coupler has simple structure, is pressure resistant, has good tightness and high reliability and can effectively solve the defects of bad security of the interfaces of electricity transmission in the deep ocean and high cost.

Owner:ZHEJIANG UNIV

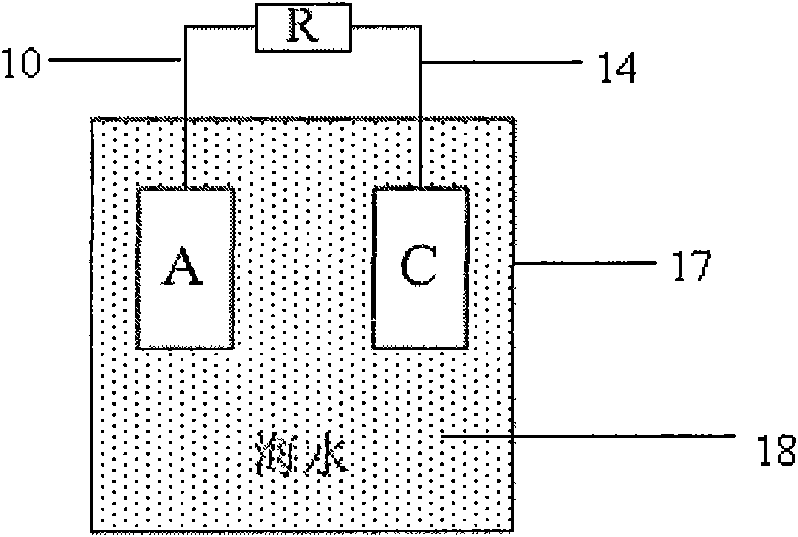

Test method for simulating couple corrosion in seawater scouring environment

InactiveCN101923042AImproved test deviceSimple processWeather/light/corrosion resistanceFrequency changerPresent method

The invention belongs to the technical field of marine corrosion tests, and relates to a novel test method for testing couple corrosion in a seawater scouring environment. The method comprises the following steps of: preprocessing test samples by using a flowing type water trough scouring corrosion experimental device, making test sample installing stages rightly opposite in pairs, and supporting the test sample installing stages with PVC supporting bars, wherein the test sample installing stages are closely attached to the walls of an experimental trough and are fixed on the two sides of the experimental trough; starting a seawater pump, regulating the flow rate of the seawater pump with a frequency converter so as to meet test requirements, and connecting each group of couple pair test samples after the water flow becomes stable; performing the experimental test of simulating an electrical insulation state under the condition of directly connecting two wires or loading a resistor; and testing and recording the numerical values of material potentials, coupling potentials and coupling currents of the test samples, photographing and washing and weighing corrosion products respectively, computing the couple corrosion rate of the materials, and drawing coupling potential-time curves. The method has the advantages of simple and reliable test theory, safe used equipment, accurate test parameters and high computability and applicability.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Chlorinated rubber coating modified by acroleic acid and method for preparing same

InactiveCN101289588AGood chemical resistanceImprove salt spray resistanceRubber derivative coatingsWax coatingsEpoxyOrganoclay

The invention relates to acrylic acid modified chlorinated rubber coating and a method for preparing the same. The coating consists of: 1 weight portion of chlorinated rubber, 0.05 to 0.4 weight portion of acrylic acid resin, 0.005 to 1.03 weight portions of chlorinated paraffin, 0.08 to 0.5 weight portion of epoxy resin, 0.05 to 3.0 weight portions of dimethylbenzene, 0.01 to 1.5 weight portions of heavy aromatic solvent, 0.005 to 0.045 weight portion of fluoro-carbon modified acrylic acid resin, 0.006 to 0.5 weight portion of titanium white powder, 0.01 to 0.8 weigh portion of talcum powder, and 0.005 to 0.05 weight portion of organoclay. The coating has the characteristics of single composition packing and drying film formation under normal temperature. A paint film of the coating has excellent physical property, chemical resistance, salt spray resistance and anti-photoaging property, and can be used for the protection and coating of the surfaces of steel structures under the environment of marine corrosion.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +1

Method for preparing metallic antifouling coating of ship sea chest

InactiveCN102225388AImprove bindingExtend the antifouling periodAntifouling/underwater paintsPretreated surfacesGratingVolumetric Mass Density

The invention belongs to the technical field of marine corrosion and fouling prevention and relates to a method for preparing a metallic antifouling coating of a ship sea chest. The method comprises the following steps: firstly, pretreating a ship sea chest or sea grating substrate, wherein the pretreatment comprises oil removing, sand blasting and dust removing; and then preparing mixed powder by uniformly mixing copper powder or copper alloy powder and cuprous oxide powder or zinc oxide powder and placing the mixed powder in a cold spraying device; and lastly, twice spraying the mixed powder carried by nitrogen, helium or air onto the ship sea chest or sea grating substrate twice under the condition of controlling the temperature of a main gas to finally a metallic compound coating which is characterized by high bonding force and long antifouling period. The preparation process is simple. The thickness of the coating and the active antifouling components are controllable. The manual maintenance is unnecessary and no hole is drilled on a ship shell. The sailing safety of the ship is high. The coating has excellent density and high hardness and bonding force.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Functional composite coating and preparing method thereof

ActiveCN105623341AOn-site construction is simpleImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyFluoropolymer

Owner:CHANGCHUN A&Z SCI CO LTD

Ultrahigh strength steel wire dip-coated with Zn-Al-Mg-Si alloy coating, preparation method thereof and application thereof

InactiveCN105331918AHigh strengthImprove toughnessHot-dipping/immersion processesHigh intensityAlloy coating

The invention relates to an ultrahigh strength coating steel wire dip-coated with a Zn-Al-Mg-Si alloy coating, a preparation method thereof and an application thereof. The alloy coating consists of the following components in percentage by mass: 30-97% of Zn, 5-80% of Al, 0.02-11% of Mg, and 0.05-5.0% of Si, based on 100% in total. The preparation method comprises the following steps: inspecting performances of an original coil rod; carrying out surface treatment; carrying out wire drawing; preparing a hot dipping Zn-Al-Mg-Si alloy coating; and carrying out stabilization treatment. The ultrahigh strength coating steel wire with the Zn-Al-Mg-Si alloy coating provided by the invention has corrosion resistance and mechanical performance superior to those of a current high-strength zinc-coated steel wire; the preparation method is easy to implement, meets needs of special environments such as a marine corrosion environment and the like on a bridge steel wire, and has a wide market prospect.

Owner:BAOSTEEL GRP NANTONG WIRE PROD

Epichlorophdrin resinous varnish and preparation method thereof

InactiveCN101294017AImprove water resistanceExcellent chemical corrosion resistanceWax coatingsParaffin waxSodium Bentonite

The invention relates to a chlorinated polyether resin coating and a production method thereof. The coating contains 1 weight part of chlorinated polyether resin, 0.025-0.5 weight parts of chlorinated paraffin wax with chlorine content of 52%, 0.008-0.5 weight parts of acrylic acid-modified fluorocarbon resin, 0.05-3.0 weight parts of dimethylbenzene, 0.01-1.2 weight parts of heavy aromatic solvent, 0.005-0.01 weight parts of dimethyl silicon oil, 0.005-0.25 weight parts of aluminum tripolyphosphate, 0.006-0.5 weight parts of titanium white powder, 0.01-0.4 weight parts of talc powder and 0.005-0.05 weight parts of organic bentonite. The coating is characterized in that: the components are packaged independently and are dried at room temperature to form coating. The coating is excellent in physical property, chemical resistance, salt spray resistance and light fastness, and can be used for the surface protection and coating of steel structure and concrete in corrosive marine environments.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +1

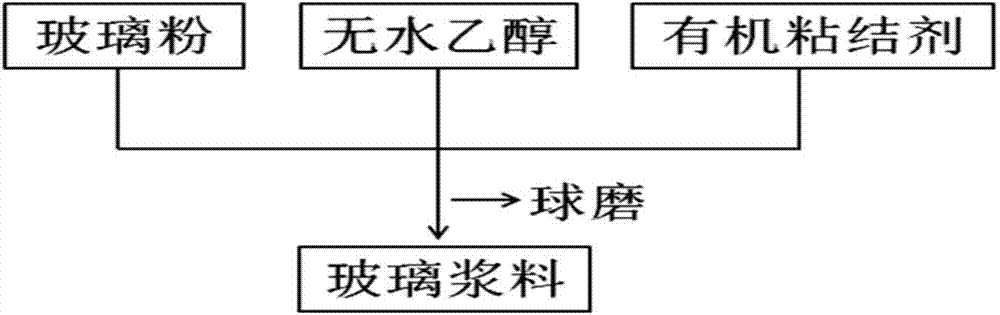

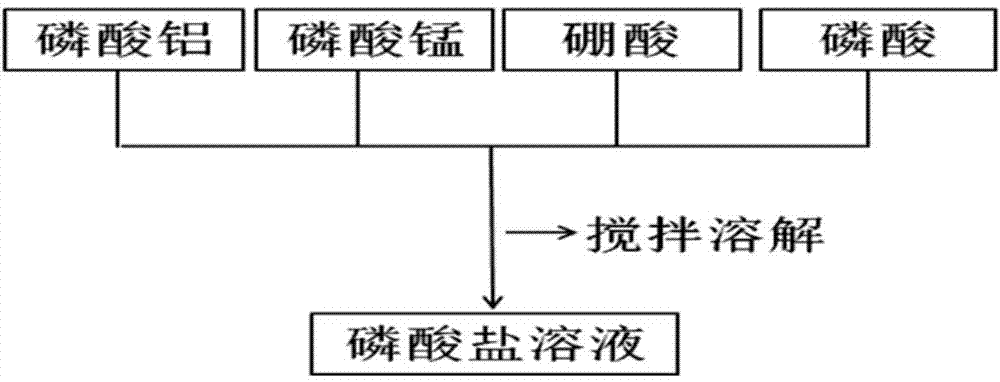

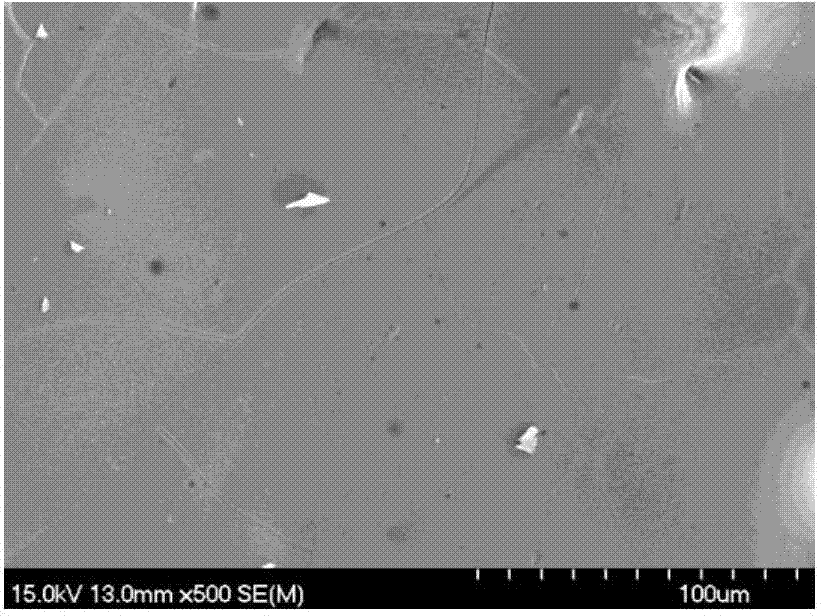

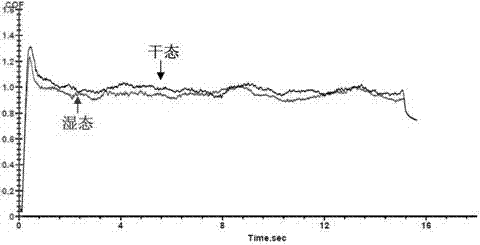

Method for preparing oxidation-resistant composite coating for carbon ceramic brake disc

InactiveCN103804030AWell bonded and denseImprove water resistanceCoatingsFriction liningAdhesiveCordierite

The invention relates to a method for preparing an oxidation-resistant composite coating for a carbon ceramic brake disc. The method comprises the following steps: preparing glass slurry to serve as a high-temperature self-healing coating by taking cordierite powder, glass powder and an organic adhesive as raw materials, preparing a solution to serve as a passivating coating by taking phosphate as a raw material, uniformly coating the glass slurry and the solution on the surface of a carbon ceramic brake material, and performing high-temperature heat treatment to obtain a dense coating which can be well combined with a matrix. The method has the beneficial effects that (1) the coating is uniform and dense and is well combined with the matrix; (2) the coating is excellent in oxidation resistance and thermal shock resistance; (3) the coating is high in marine corrosion resistance; and (4) the preparation process of the coating is simple in process, short in period, low in cost, convenient, feasible and suitable for industrial preparation.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

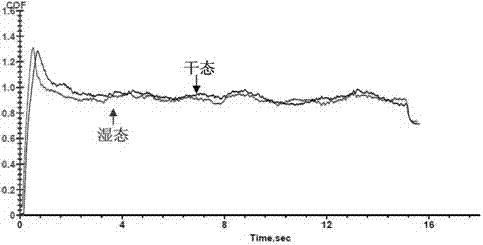

Corrosion-resistant antiskid coating with aluminum matrix composite structure and preparation process thereof

InactiveCN102732876AQuality improvementGood anti-corrosion and anti-skid performancePressure inorganic powder coatingNeopreneZinc

The invention relates to a corrosion-resistant antiskid coating with an aluminum matrix composite structure and a preparation process thereof, belonging to the technical fields of surface treatment and marine corrosion prevention, wherein the coating is capable of being rapidly repaired after damage. The corrosion-resistant antiskid coating consists of a composite structure of a zinc-aluminum corrosion-resistant bottom layer and an aluminum / ceramic antiskid top layer and is prepared through the following steps: carrying out sand-blast treating on a matrix so as to allow the surface of the matrix to be free of attached foreign materials and have roughness; spraying zinc-aluminum powder onto the matrix so as to form the zinc-aluminum corrosion-resistant bottom layer which has a bonding strength of more than 15 MPa and a thickness of 150 to 250 mu m; and spraying aluminum / ceramic powder onto the zinc-aluminum corrosion-resistant bottom layer of the matrix so as to form the corrosion-resistant antiskid coating with the aluminum matrix composite structure, wherein the coating has a bonding strength of more than 15 MPa, a thickness of more than 200 mu m and a coefficient of friction with chloroprene rubber of more than 0.85. The preparation process is simple; the quality of the coating is good; spraying is easy to carry out; and the coating has good anticorrosion and antiskid performances and a long service life and can be easily and rapidly repaired.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Rare earth-aluminium-magnesium alloy wire for thermal spraying

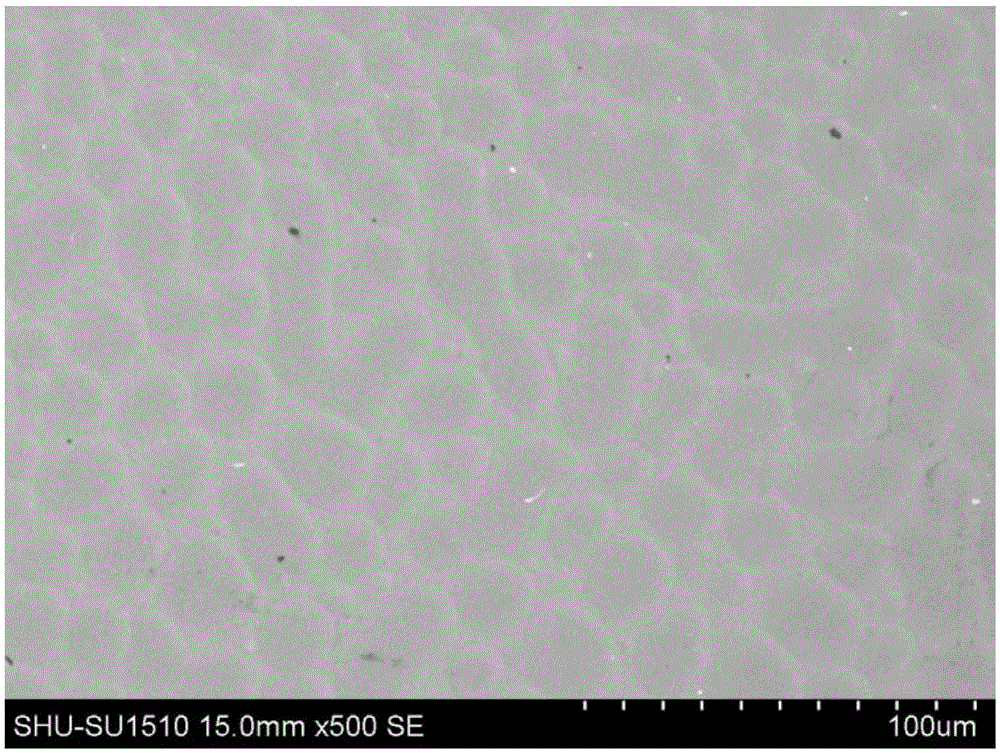

ActiveCN102352475ASolve the problem that it is difficult to draw into wireSimple preparation processMolten spray coatingPorosityThermal spraying

The invention discloses a rare earth-aluminium-magnesium alloy wire for thermal spraying, belonging to the technical field of metal alloys. The alloy wire comprises the following components by weight percent: 1%-5% of Mg, 0.1%-0.5% of RE, 0.1%-0.2% of Ti and the balance of Al. The alloy wire disclosed by the invention has the following beneficial effects: the rare earth-aluminium-magnesium alloy wire is easy to prepare and has lower cost, good comprehensive mechanical property and good corrosion resistance; the metal thermal spraying coating prepared from the alloy wire has the advantages of dense coating, low porosity, high bonding strength with the matrix and good corrosion resistance; and particularly, the metal thermal spraying coating has excellent corrosion resistance in the marine corrosion environment and can be widely used in the corrosion protection of the steel structure.

Owner:JIANGSU CUMT DAZHENG SURFACE ENG TECH

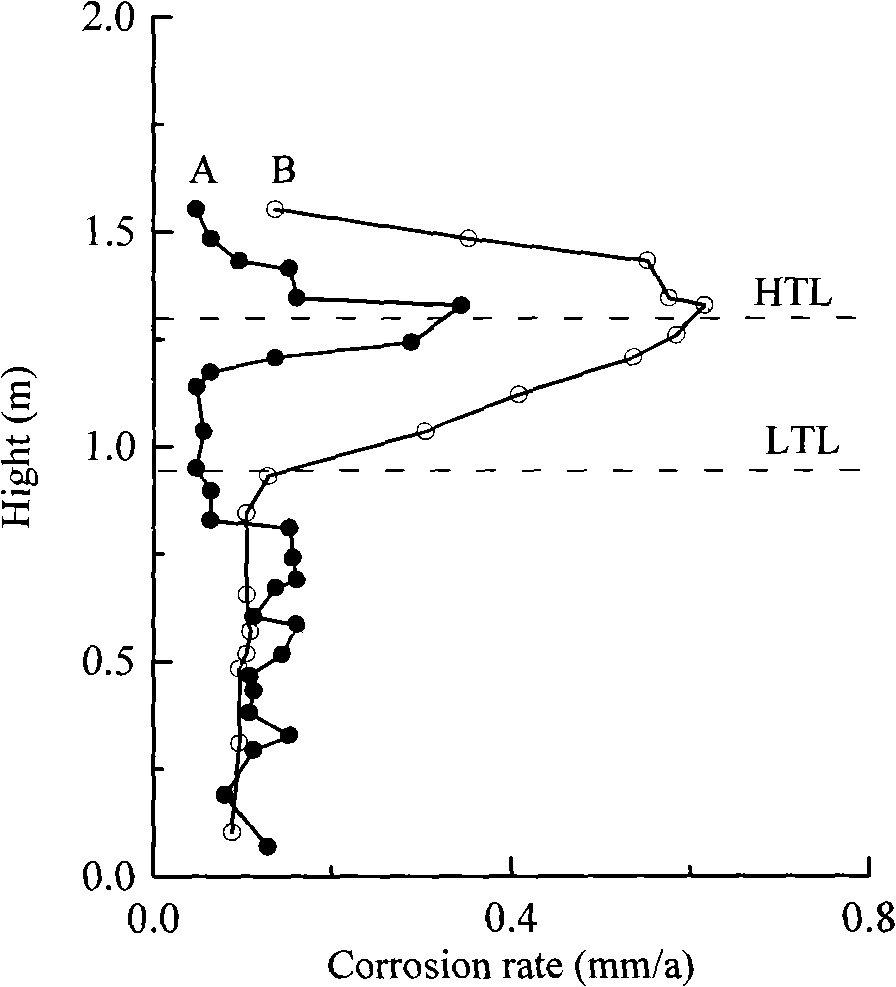

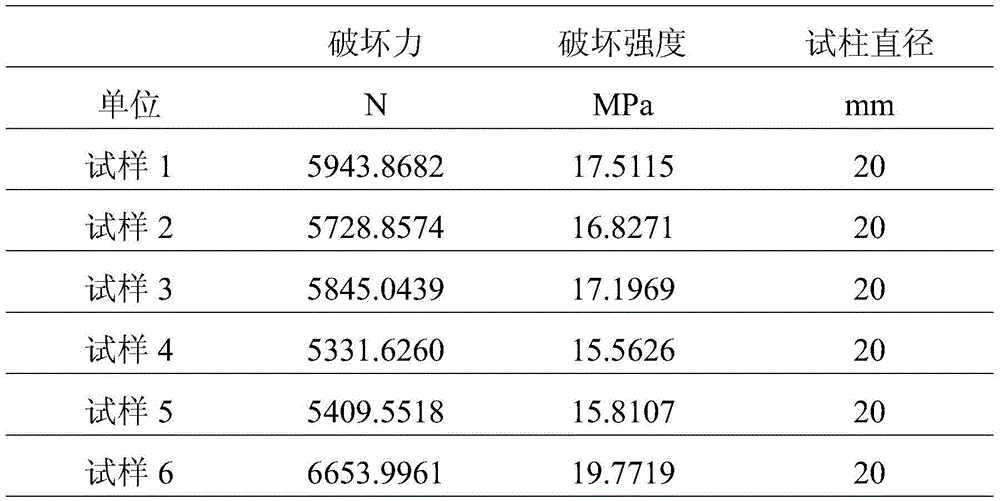

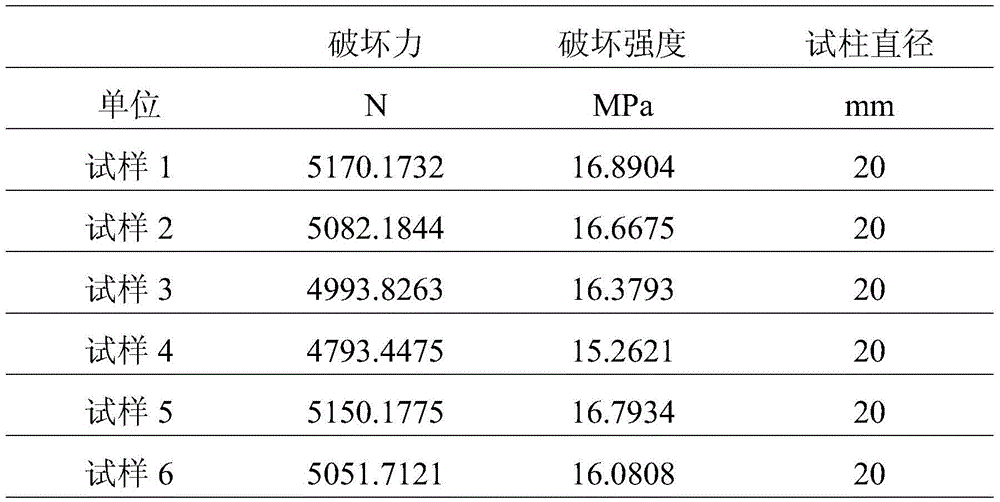

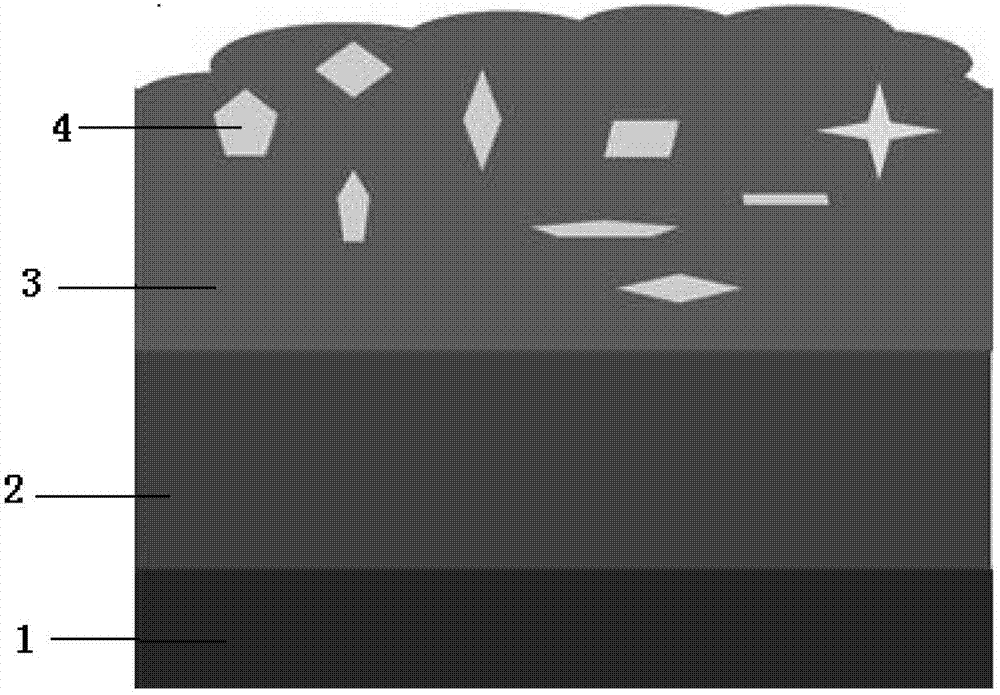

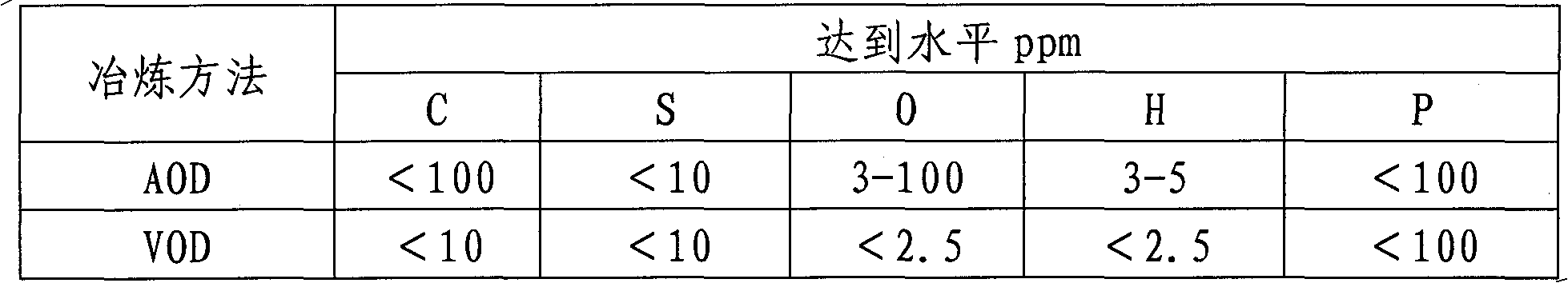

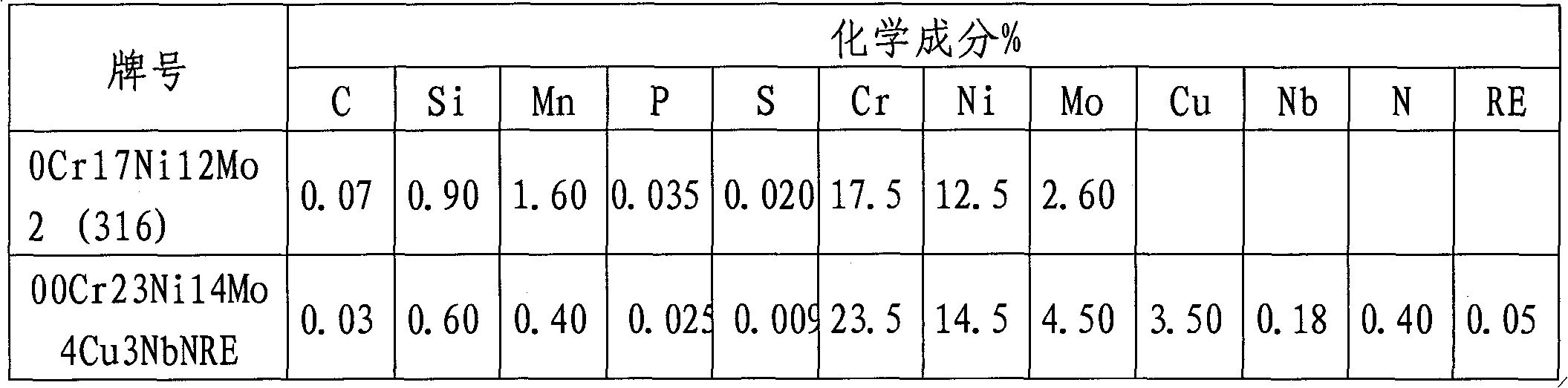

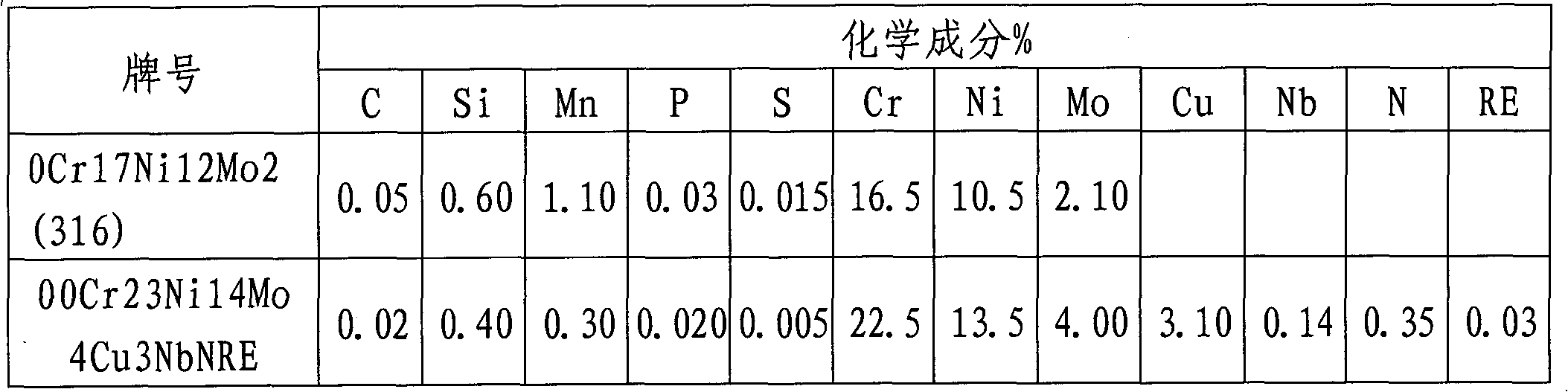

Manufacture method of novel marine corrosion resistance stainless steel and steel cable thereof

The invention provides a manufacture method of novel marine corrosion resistance stainless steel and a steel cable thereof. The marine corrosion resistance stainless steel comprises chemical compositions in the respective mixture ratio: less than 0.03 of C, less than 0.80 of Si, less than 0.50 of Mn, less than 0.03 of P, less than 0.01 of S, 22.0 to 25.0 of Cr, 13.0 to 15.0 of Ni, 3.0 to 5.0 of Mo, 2.0 to 4.0 of Cu, 0.10 to 0.20 of Nb, 0.30 to 0.45 of N, 0.03 to 0.06 of RE and the balance of Fe and unavoidable impurities. Steel wires required by the steel cable carry out electrolytic polishing processing before stranding. Compared with 316 stainless steel cables under the conditions of the same structure and the same cable diameter, the steel cable manufactured by the method of the invention has the advantages that the breaking force of the whole cable is improved by 3 to 4 KN, at the same time, the marine corrosion resistance annual corrosion speed rate in the environment such as marine atmosphere, splash zones, tidal zones, deep sea and the like is improved by more than ten times, and the maximum annual corrosion resistance depth is reduced by more than 5 times.

Owner:江苏亚盛金属制品有限公司

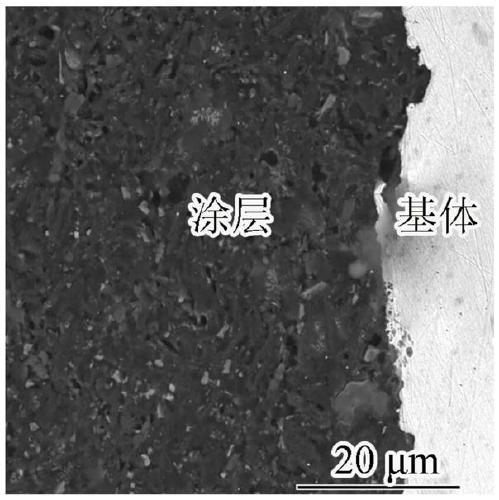

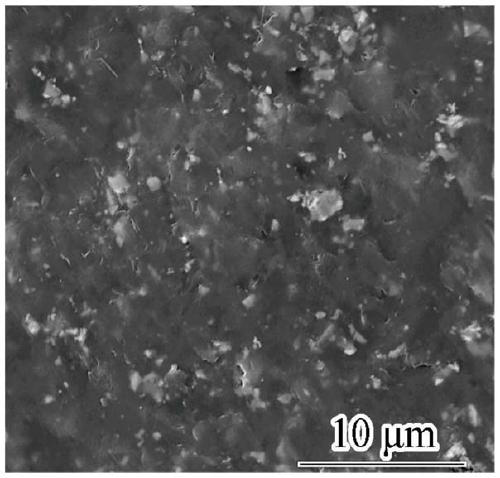

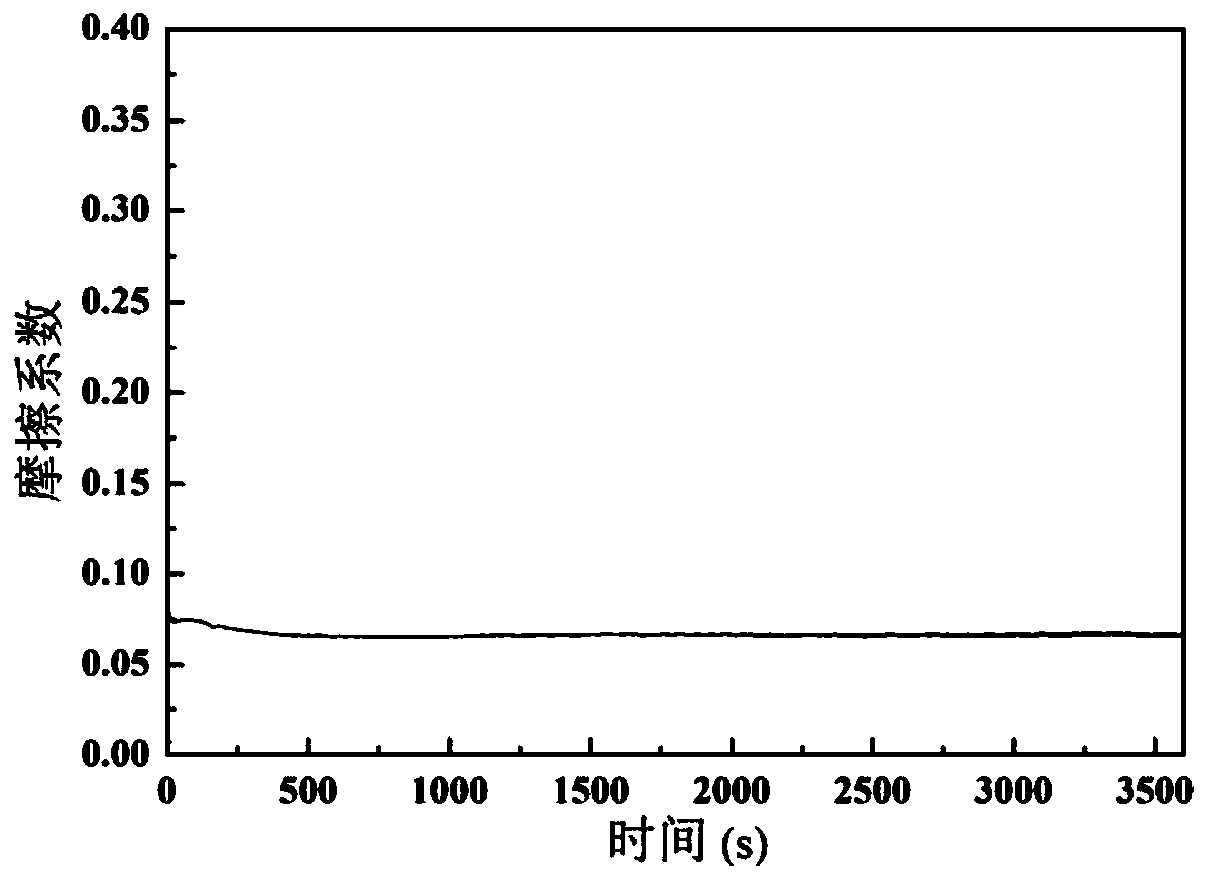

Self-lubricating composite coating with resistance to marine corrosion and wear and production technology of self-lubricating composite coating with resistance to marine corrosion and wear

ActiveCN110305558ASimple preparation processLow costPretreated surfacesAnti-corrosive paintsEpoxyAviation

The invention relates to the fields of marine corrosion and self-lubrication, and particularly provides a self-lubricating composite coating with resistance to marine corrosion and wear and a production technology of the self-lubricating composite coating with the resistance to marine corrosion and wear. The coating is composed of organic film forming matters and micron-sized filler, wherein the mass percentage of the organic film forming matters is 40%-60%, and the organic film forming matters comprise 10%-21% of epoxy resin, 15%-26% of epoxy-modified organic silicon resin, 6%-13% of polyamide resin and 4%-7% of a wetting dispersant; and the micron-sized filler is a combination of 10%-20% of graphite, 16%-30% of silicon carbide and 10%-25% of teflon. The coating is simple in production process and low in cost, the needed production raw materials can be directly bought on the market, and the coating not only can be used for marine equipment, but also is suitable for transmission partswhich serve in corrosive environments of aviation, electric power, chemical engineering and the like. On the basis of high corrosion resistance and flexibility, of the organic film forming matters, incombination with wear resistance and self-lubrication of the micron-sized filler, the composite coating has high impact toughness and excellent comprehensive performance of marine corrosion resistance, wear resistance, self-lubrication and the like.

Owner:NORTHEASTERN UNIV

Method for carrying out superhydrophobic on surface of metal

InactiveCN108315793AFast film formationOvercome operabilityElectrolytic organic material coatingInorganic saltsFatty acid

The invention relates to a preparation technology of superhydrophobic film layers, in particular to a simple method for carrying out superhydrophobic the surface of metal. A treated substrate is subjected to a one-step cathode electrodeposition method in an ethanol solution containing fatty acid and inorganic salt, and the surface of the substrate is covered with a fatty acid salt film layer, so that the superhydrophobic on the surface of the metal is realized. The method provided by the invention is environmentally friendly, simple and easy to operate and low in cost; the prepared superhydrophobic film layer is expected to be widely applied to the fields such as marine corrosion protection, microbial adhesion resistance, anti-icing and self-cleaning.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Preparation method and application of modified anti-corrosion super-hydrophobic integrated coating

InactiveCN112300697AChange the proportion of fillerReduce manufacturing costAnti-corrosive paintsAluminium chlorideTitanium oxide

The invention belongs to the technical field of preparation of anticorrosive coatings, and particularly relates to a preparation method and application of a modified anticorrosive super-hydrophobic integrated coating, the method comprises the following steps: respectively preparing a graphene titanium dioxide compound from graphene and tetrabutyl titanate, preparing a zinc-aluminum hydrotalcite anticorrosive material from sodium metavanadate, zinc chloride and aluminum chloride, preparing a PDMS organic emulsion from polydimethylsiloxane and tetrahydrofuran, then performing surface modification on the graphene titanium dioxide compound through dopamine hydrochloride and a zinc-aluminum hydrotalcite anticorrosive material to obtain a dopamine modified composite material, and finally, preparing the modified anticorrosive super-hydrophobic integrated coating from the dopamine modified composite material and a PDMS organic emulsion. Performance tests show that compared with a conventionalmarine anticorrosive coating, the coating prepared by the invention has better anticorrosive and super-hydrophobic effects, is applied to the field of marine corrosion prevention, and can effectivelyprolong the service life of the coating on a protective substrate.

Owner:SUN YAT SEN UNIV

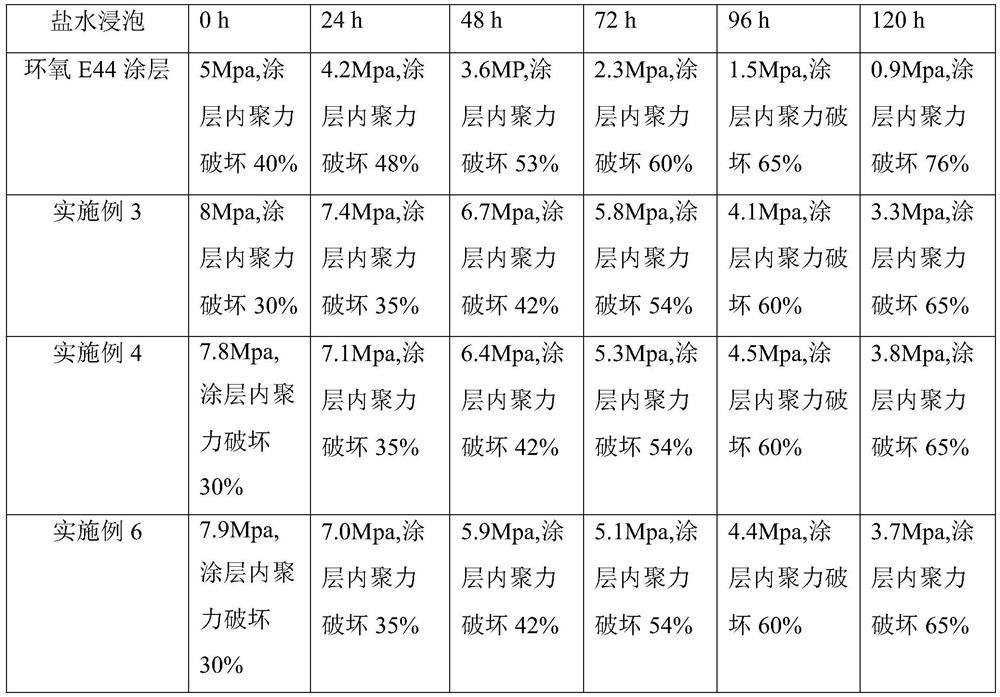

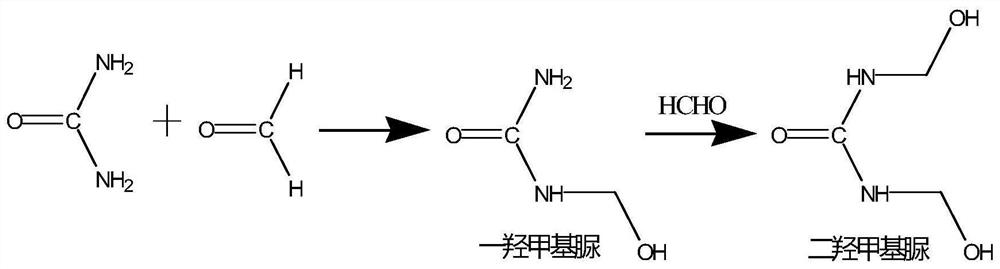

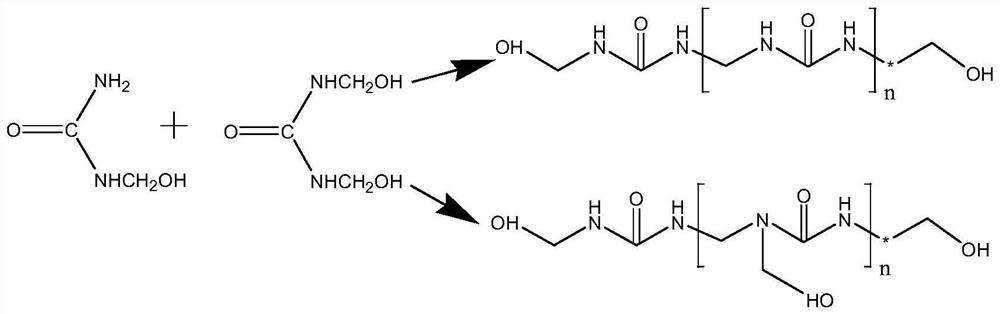

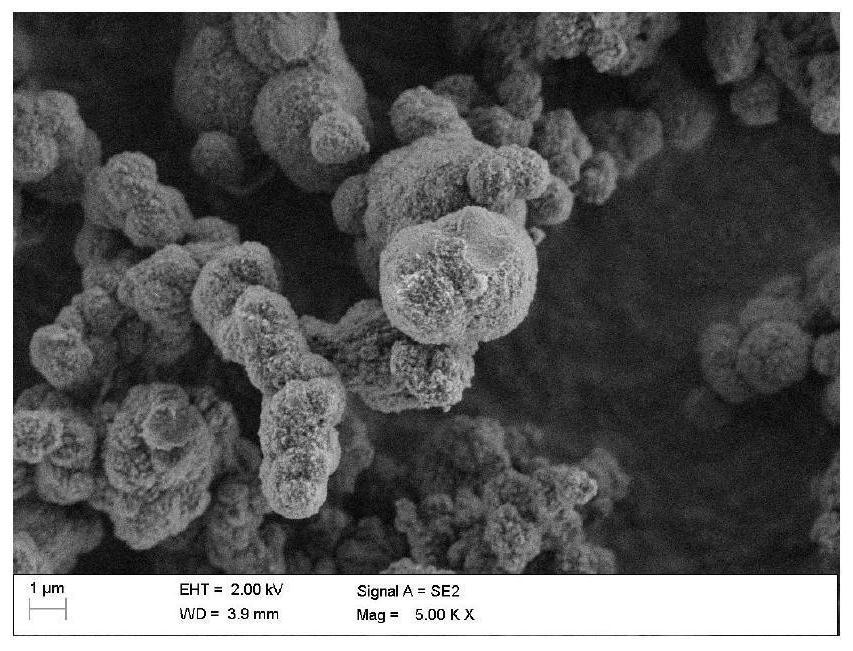

Anticorrosion and antifouling integrated self-repairing microcapsule and preparation method thereof

InactiveCN111925681AAchieve self-healingRealize functionAntifouling/underwater paintsPaints with biocidesMarine equipmentMaterials science

The invention belongs to the technical field of marine corrosion and protection. The invention relates to an anticorrosion and antifouling integrated self-repairing microcapsule and a preparation method thereof. An anticorrosive coating self-repairing agent and a biological antifouling agent are used as a two-component capsule core; urea-formaldehyde resin obtained by condensation polymerization of urea and formaldehyde is used as a capsule wall; dispersants such as emulsifiers are added, the core material is uniformly dispersed into ultrapure water to form a stable oil-in-water microemulsion;then, the urea and the formaldehyde are subjected to condensation polymerization to coat the microemulsion; thus, the anticorrosion and antifouling integrated self-repairing microcapsule with uniformparticle size and a core-shell structure is prepared. The anticorrosion and antifouling capability and the anticorrosion and antifouling service life of the organic coating can be prolonged; the operation stability of marine equipment and ships is improved, particularly, long-period corrosion protection and fouling protection can be provided for large equipment and metal structures operating in ahigh-temperature, high-salt, high-humidity and high-radiation tropical marine environment, and very high social and economic values are achieved.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

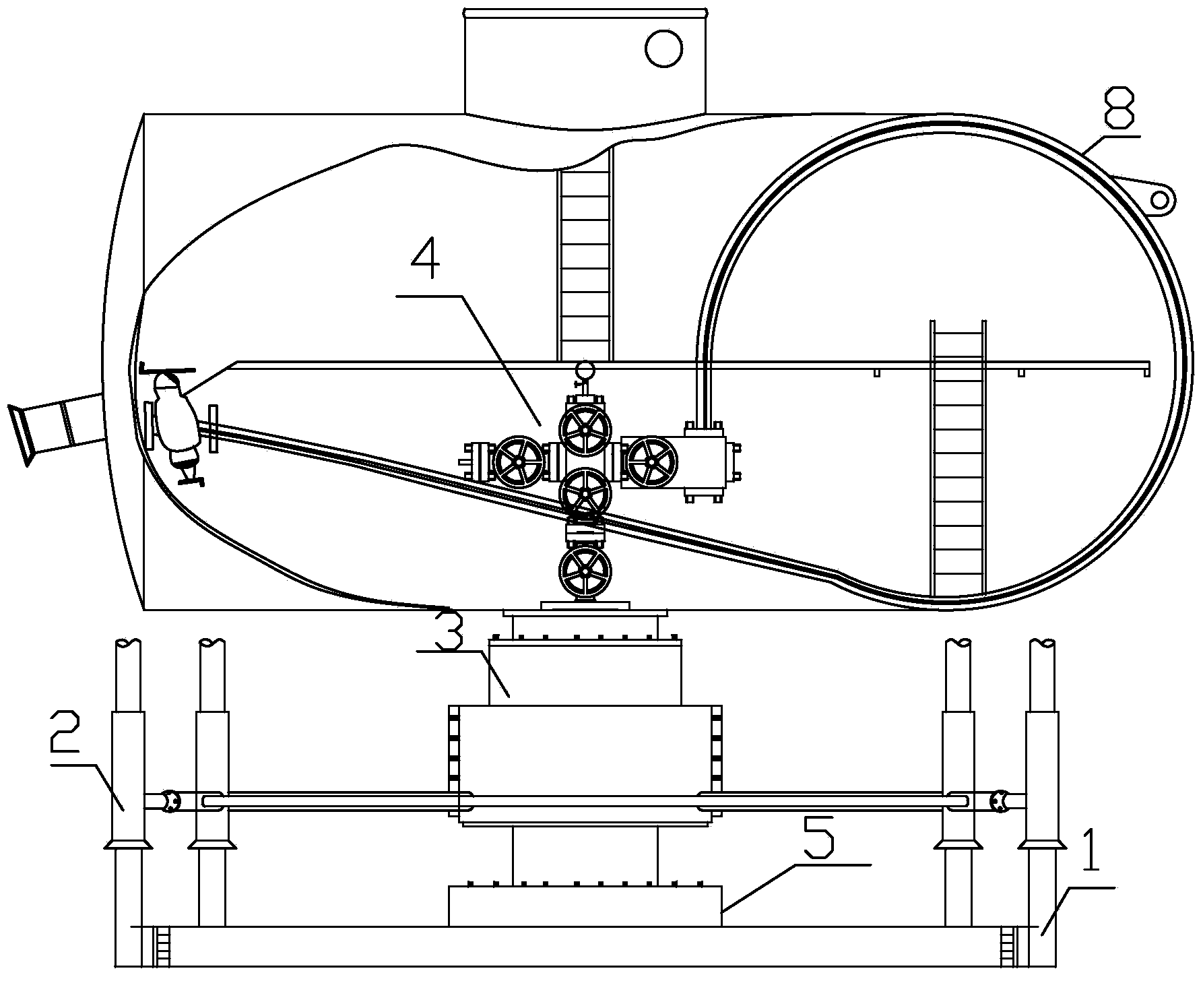

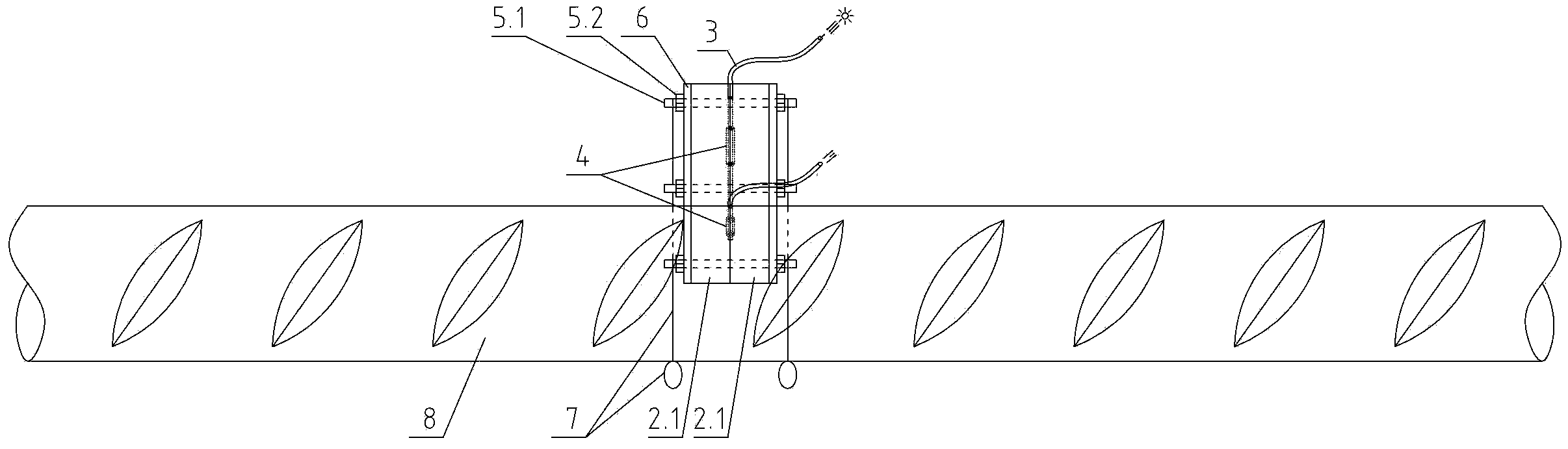

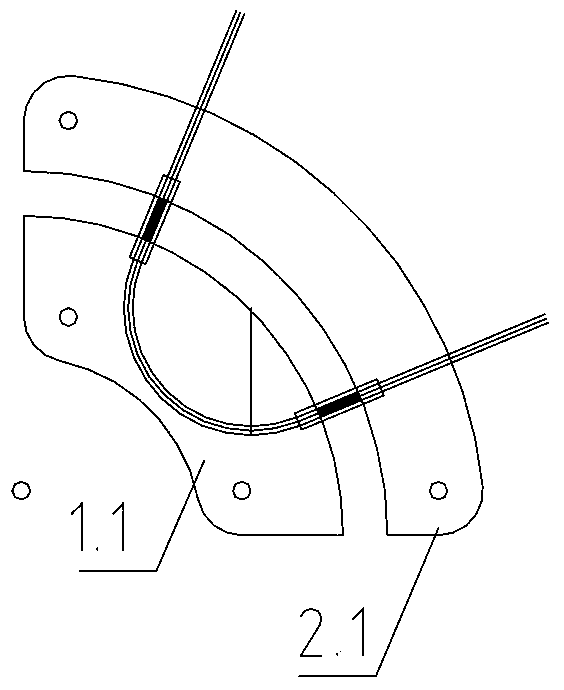

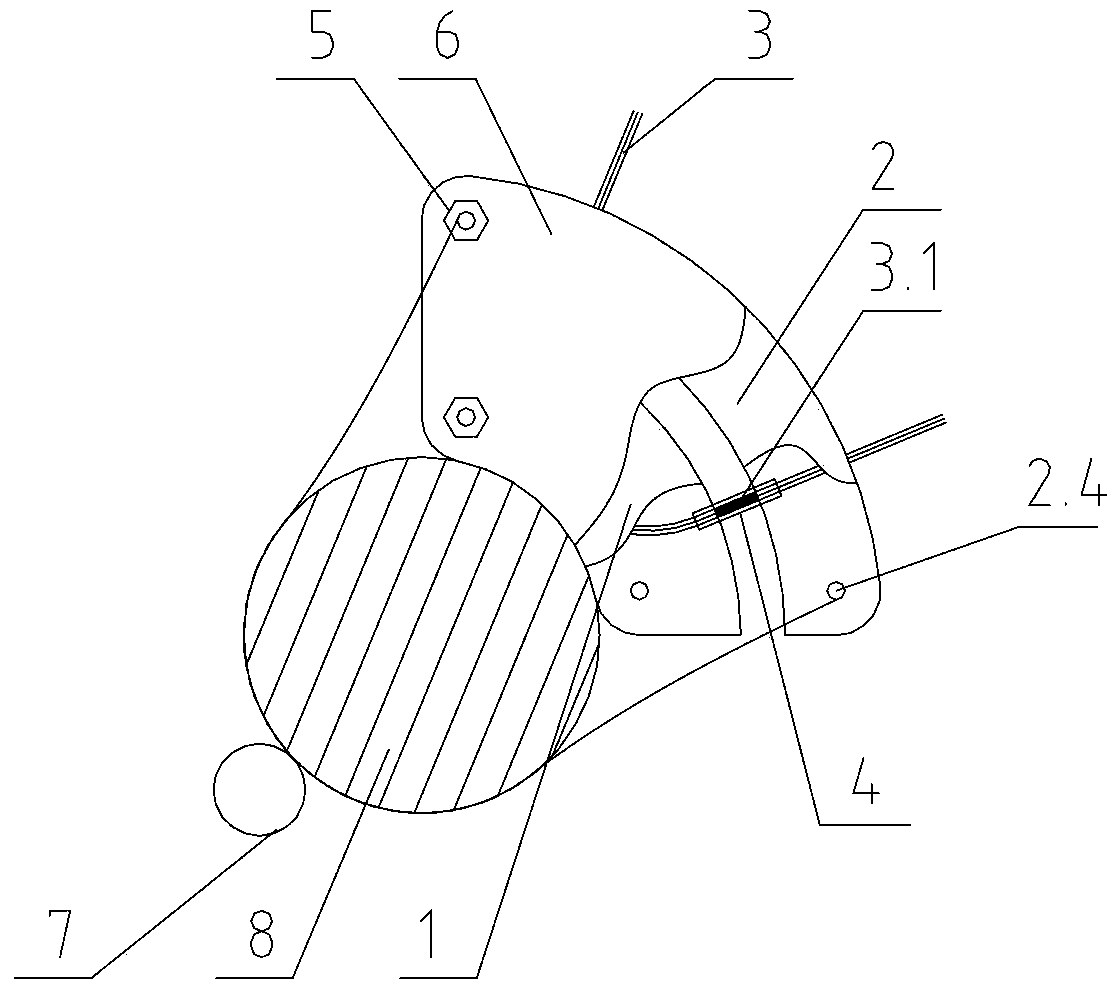

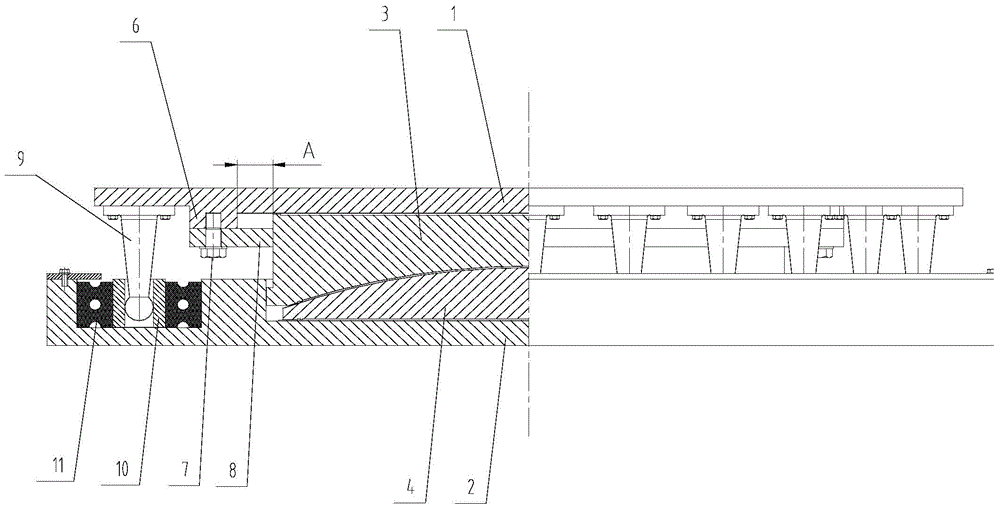

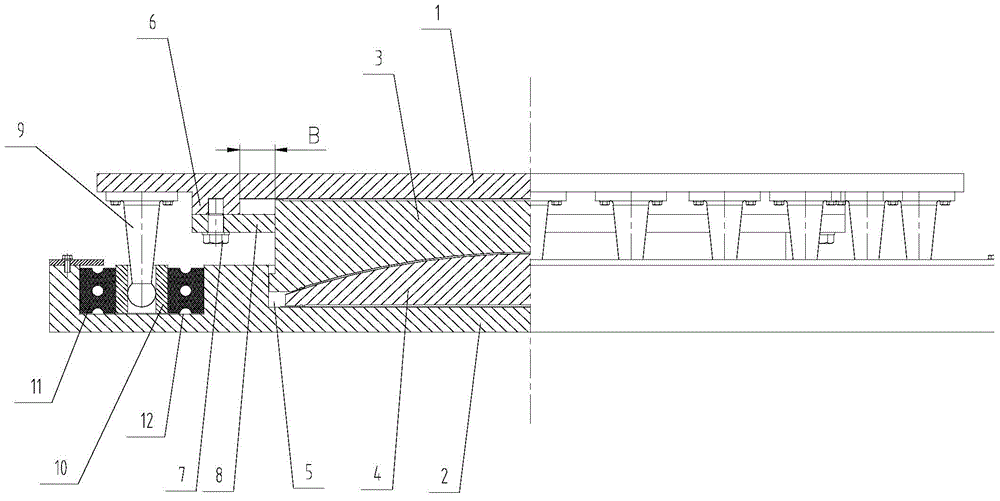

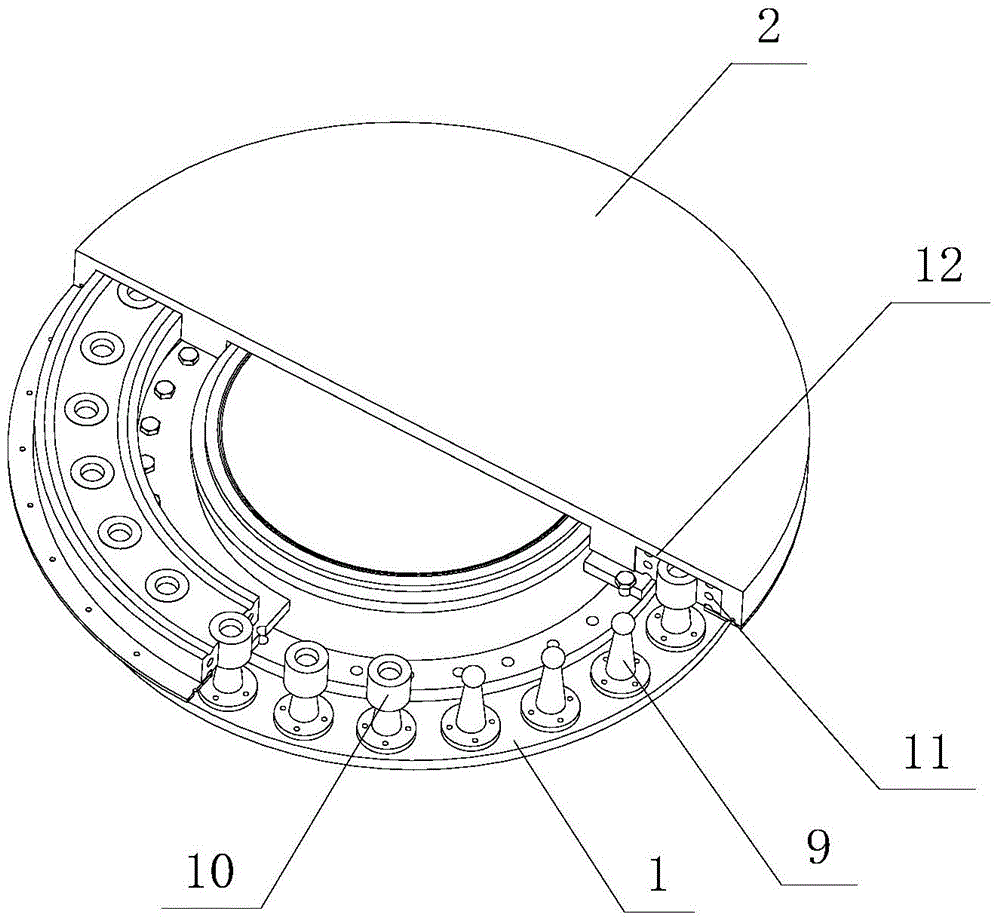

Large-tonnage marine corrosion prevention metal damping seismic mitigation and isolation steel supporting seat

ActiveCN104404870ASo as not to damageSimple structureBridge structural detailsBridge materialsEngineeringShock absorber

The invention discloses a large-tonnage marine corrosion prevention metal damping seismic mitigation and isolation steel supporting seat. The supporting seat comprises an upper supporting seat plate, a spherical crown liner plate and a lower supporting seat plate, wherein the spherical crown liner plate is mounted between the upper supporting seat plate and the lower supporting seat plate and consists of an upper liner plate and a lower liner plate; an liner plate mounting groove is formed in the lower supporting seat plate; the lower liner plate is fixed in the liner plate mounting groove; the upper liner plate is fixedly connected to the upper supporting seat plate; the outer bottom wall of the upper liner plate is in contact with the liner mounting groove; the bottom surface of the upper liner plate is in sliding fit with the top surface of the lower liner plate, and the fitting surface is a spherical crown surface; the outer side of the upper liner plate is provided with a falling-off prevention stopper fixedly connected with the upper supporting seat plate; the bottom surface of the falling-off prevention stopper is fixed with one end of an anti-seismic stopper through a shearing-resistant bolt; the other end of the anti-seismic stopper is in contact with the outer wall of the upper liner plate; a gap is reserved between the outer wall of the falling-off prevention stopper and the outer wall of the upper liner plate; and the a metal damper is mounted between the upper supporting seat plate and the lower supporting seat plate on the outer side of the falling-off prevention stopper. When an earthquake occurs, the supporting seat has a two-stage protecting structure, so that the supporting seat main body cannot be damaged, and falling off of beams can be avoided.

Owner:CHENGDU XINZHU ROAD & BRIDGE MASCH CO LTD

Marine steel structure surface antifouling and anticorrosion preparation and preparation method thereof

InactiveCN108084837AIncrease the degree of cross-linkingImprove water resistanceAntifouling/underwater paintsPaints with biocidesEpoxyComposite film

The invention discloses a marine steel structure surface antifouling and anticorrosion preparation and a preparation method thereof. The emulsion is prepared from the following raw materials in partsby mass: 1100 to 1500 parts of a polyurethane monomer, 1000 parts of polyether glycol, 200 to 400 parts of an alcohol chain extender, 100 to 250 parts of a hydrophilic chain extender, 200 to 400 partsof epoxy resin polyol, 100 to 150 parts of triethylamine, 400 to 1000 parts of an acrylic ester monomer, 1000 to 1500 parts of graphene oxide-protamine composite emulsion and 5 to 20 parts of an initiator. The solvent-free type composite film-forming resin emulsion has antifouling and anticorrosion functions, is applied to production of an environment-friendly marine coating, and can protect thesurface of the marine steel structure and prevent bioattachment and marine corrosion.

Owner:ZHEJIANG UNIV OF TECH

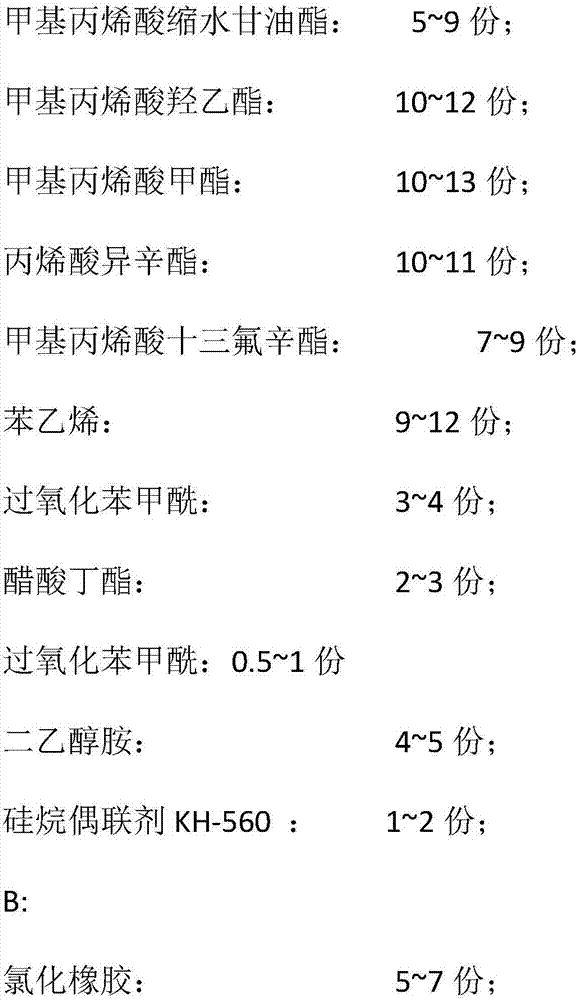

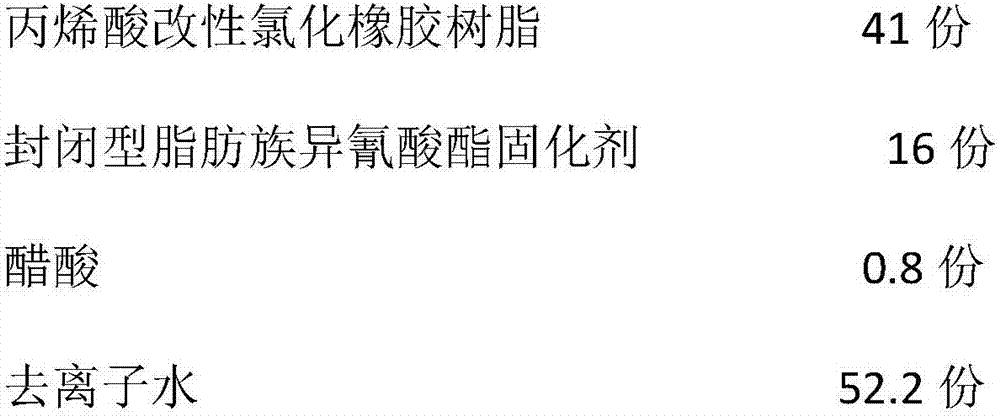

Acrylic acid modified chlorinated rubber waterborne coating suitable for marine environment and preparation method of acrylic acid modified chlorinated rubber waterborne coating

ActiveCN107245293AGood physical and mechanical propertiesGood chemical resistanceChloropene polymer coatingsAnti-corrosive paintsPolymer scienceEmulsion

The invention relates to an acrylic acid modified chlorinated rubber waterborne coating suitable for a marine environment and a preparation method of the acrylic acid modified chlorinated rubber waterborne coating. The coating composition is prepared from a modified acrylic acid modified chlorinated rubber waterborne emulsion component and a color paste component, wherein the modified acrylic acid emulsion component is prepared from the following components in parts by weight: 34-40 parts of modified acrylic acid resin, 15-17 parts of closed type aliphatic isocyanate curing agent and 44-52.2 parts of deionized water. The coating provided by the invention is a waterborne double-component coating, is convenient to coat and environmentally friendly to use and is safe; a board surface is smooth and bright and is good in decorative effect; a coating layer has the advantages of excellent mechanical performance, acid resistance performance and alkaline resistance performance, very excellent weather resistance performance and corrosion resistance performance and can be used for protecting and coating the surface of a steel structure in a marine corrosion environment; the prepared coating is simple in preparation operation technology, uniform in dispersion of various components and good in stability.

Owner:HAOLISEN COATING SHANGHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com