Method for preparing metallic antifouling coating of ship sea chest

An anti-fouling coating and submarine door technology, which is applied in the direction of anti-fouling/underwater coatings, coatings, and devices for coating liquid on the surface, can solve fouling, fail to achieve effective anti-fouling, and increase surface frictional resistance and other problems, to achieve the effect of simple preparation process, long antifouling period and good safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

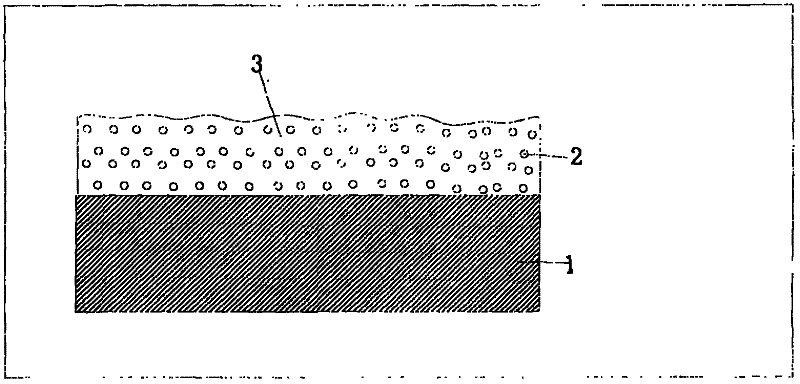

Embodiment 1

[0012] The coating in this embodiment is a metal composite coating prepared by a spraying process. The composite coating contains an antifouling agent that can inhibit marine organisms. According to the different requirements of the substrate and protection life, the composition of the coating can be changed. content; first, degreasing, sandblasting and dust pretreatment are carried out on the substrate of the ship's submarine door, and then the copper powder or copper alloy with a particle size of 5-50 μm and cuprous oxide powder or zinc oxide powder are mixed evenly into powder and placed in the In the cold spraying equipment, use nitrogen, helium or air to carry the powder on the substrate at a spraying speed of 10cm-20cm / min and a pressure of 0.7-3.5MPa and control the temperature of the main gas at 300-550°C. A metal composite coating with a thickness of 100-300 microns is formed in one pass, the mass percentage of copper in the coating is 70-95%, and the mass percentage o...

Embodiment 2

[0019] Embodiment 2: According to the process steps of Embodiment 1, select the substrate of the sea bottom door of a ship, adjust the mass percentages of copper and zinc oxide in the coating to 70% and 30%, and prepare a coating with a coating thickness of 100 microns.

Embodiment 3

[0020] Embodiment 3: According to the process steps of Embodiment 1, select the base body of the ship's seabed door, adjust the mass percentages of copper or copper-nickel or copper-aluminum alloy and zinc oxide in the coating to 95% and 5%, and prepare the coating. The thickness of the prepared coating is 300 microns, and the mass percentage of copper in the copper-nickel or copper-aluminum alloy powder is 95%-99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com