Simulated accelerated corrosion testing method of ship fastener and protective coating

A protective coating, corrosion test technology, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of indistinguishability, large differences in corrosion behavior, long test period, etc., to achieve simple process steps, Test environment friendly, principle safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

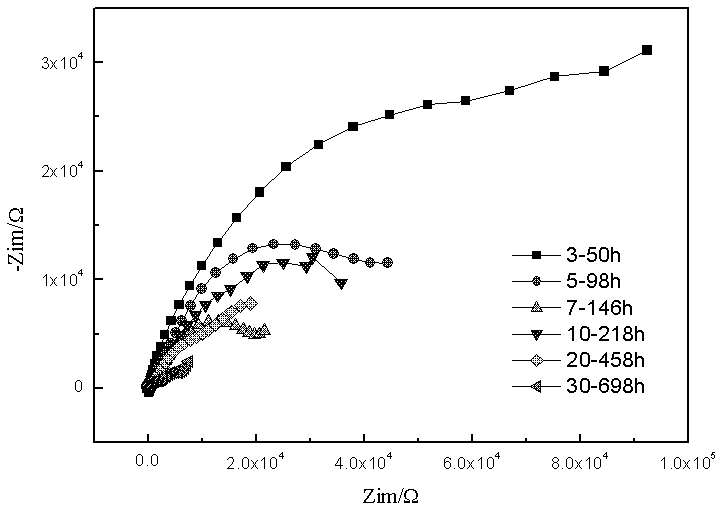

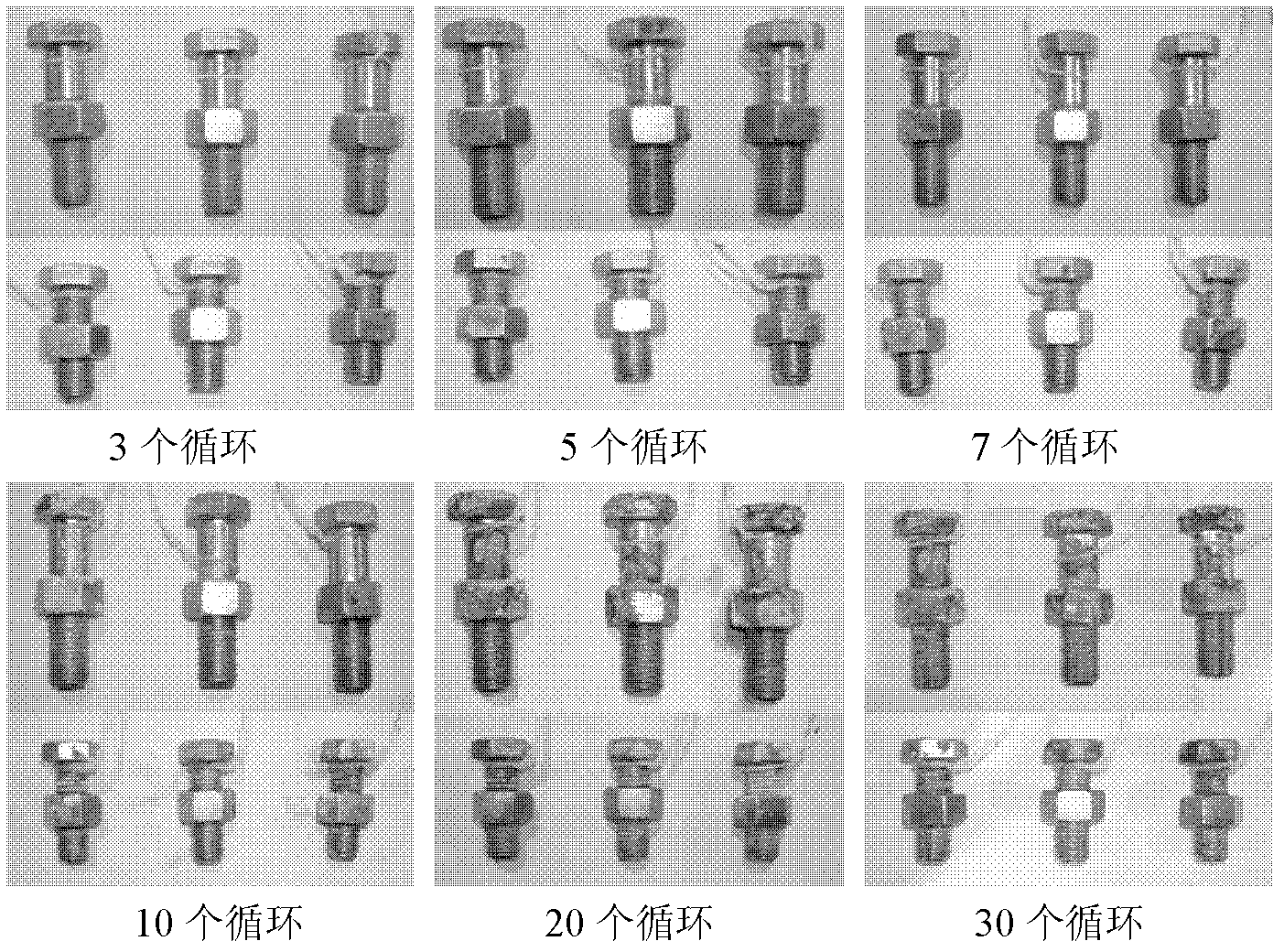

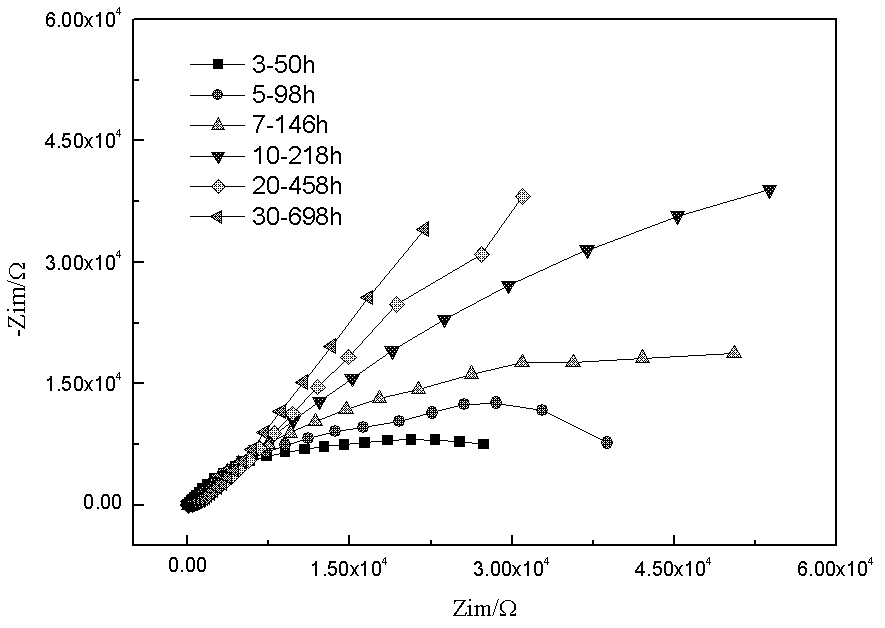

[0023] In this embodiment, natural seawater and 5% NaCl solution are used as the test medium, and the immersion, damp heat, drying and salt spray tests of fasteners of different specifications and their protective coatings can be carried out, and in-situ monitoring is carried out in combination with electrochemical methods. The information is combined with the corrosion test results to obtain the corrosion law of the fastener material and its protective coating. The specific steps include four parts: test device selection, sample pretreatment, cyclic corrosion test and display test results:

[0024] (1) Test device selection: The test device used is composed of a multi-functional cyclic corrosion test box and a customized electrochemical test electrolytic cell. The multi-functional cyclic corrosion test box realizes the simulation control of various environmental factors, such as temperature and humidity , spray, water immersion, etc.; the test electrolytic cell is made of corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com