Preparation method for nanocrystals cellulose/white carbon black/rubber composite material

A nano-crystal and composite material technology, applied in the rubber field, can solve the problems of light damage to polymer materials, increased density of vulcanized rubber, serious processing pollution, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

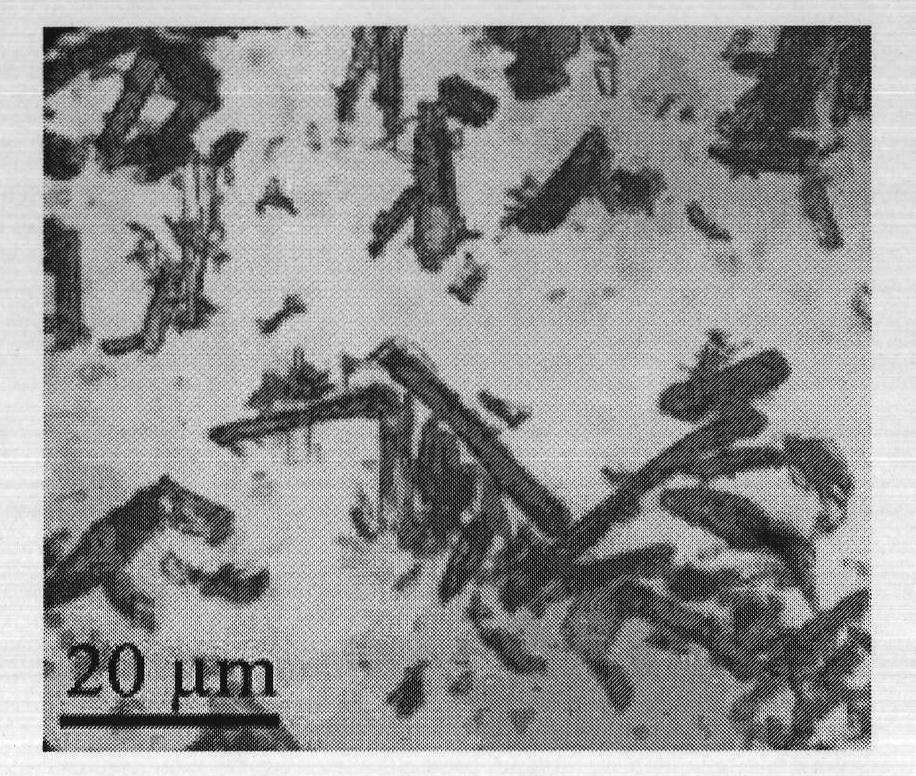

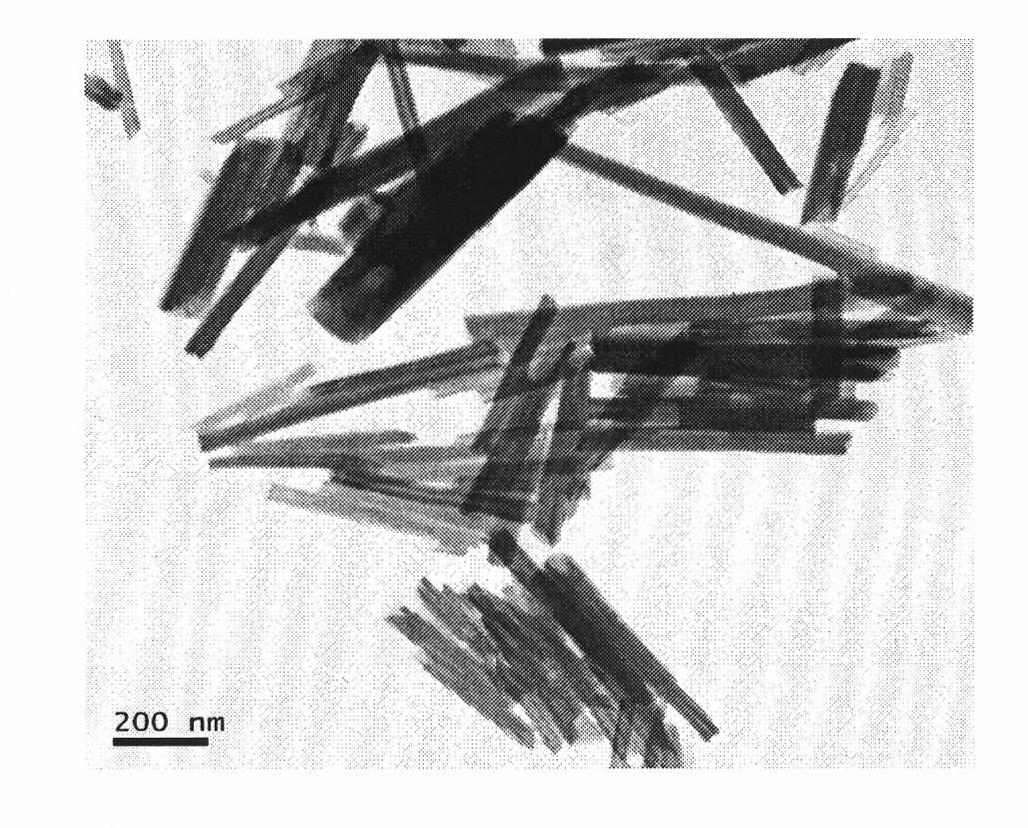

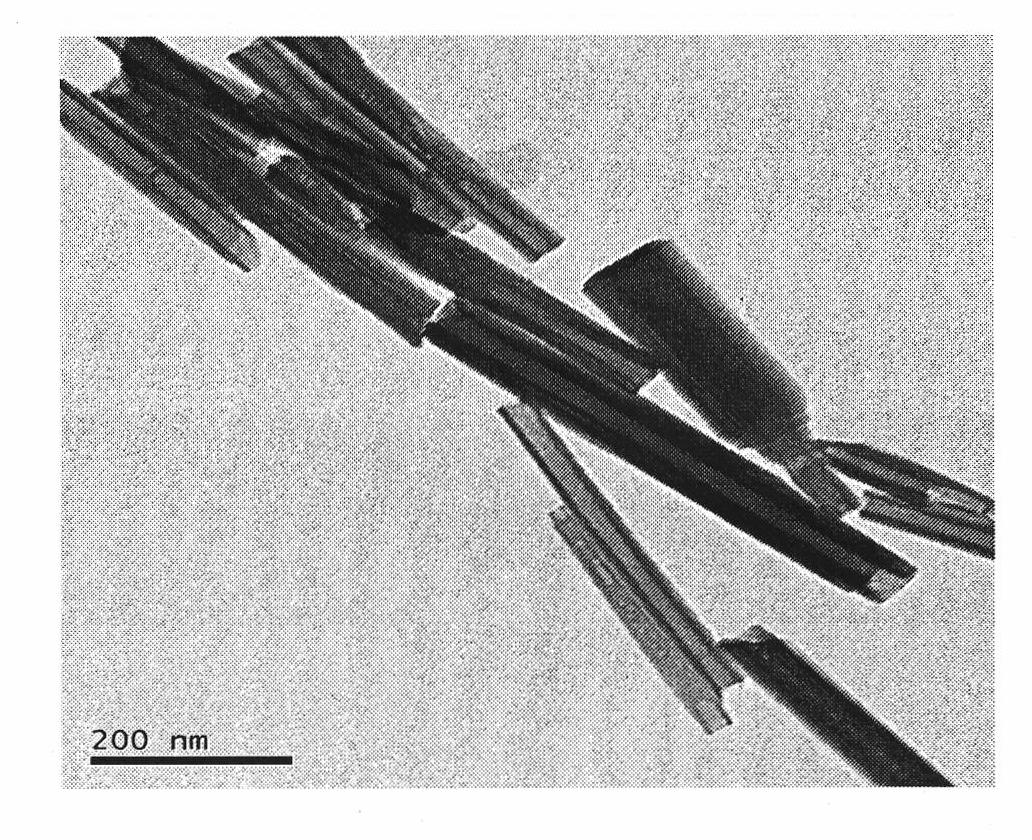

Image

Examples

Embodiment 1

[0061] In the first step, 169.5g mass fraction of 59% natural rubber latex (equivalent to 100g dry rubber) is placed in a 1L beaker, and stirred for 5min at room temperature;

[0062] In the second step, at 20°C, add 10g of nanocrystalline cellulose to 100g of ethanol solution with a mass fraction of 95%, adjust the pH to 9.5 with sodium bicarbonate, add 0.5g of coupling agent KH-550, and stir for 30 minutes ;

[0063] The third step is to add nano-microcrystalline cellulose to the evenly stirred natural rubber latex, and stir and mix at room temperature for 15 minutes;

[0064] The fourth step is to pour the evenly stirred nano-microcrystalline cellulose / natural rubber mixture into the tray, and spray 10% CaCl in mass fraction 2 The solution was demulsified, co-precipitated, washed for 12 hours, and dried in a blast drying oven at 40°C to a constant weight to obtain a solid nanocrystalline cellulose / natural rubber mixture;

[0065] The 5th step carries out mixing with the o...

Embodiment 2

[0068] In the first step, 169.5g mass fraction of 59% natural rubber latex (equivalent to 100g dry rubber) is placed in a 1L beaker, and stirred for 5min at room temperature;

[0069] In the second step, at 40° C., 0 g, 2 g, 4 g, 6 g, and 8 g of nanocrystalline cellulose (NCC) are added to a mass fraction of 95% ethanol solution (the quality of NCC is 10% of the ethanol solution quality), Adjust the pH to 7, add 1g RH, and stir for 30 minutes;

[0070] The third step is to add nano-microcrystalline cellulose to the evenly stirred natural rubber latex, and stir and mix at room temperature for 15 minutes;

[0071] The fourth step is to pour the evenly stirred nano-microcrystalline cellulose / natural rubber mixture into the tray, and spray 10% CaCl in mass fraction 2 The solution was demulsified, co-precipitated, washed for 12 hours, and dried in a blast drying oven at 40°C to a constant weight to obtain a solid nanocrystalline cellulose / natural rubber mixture;

[0072] The 5th ...

Embodiment 3

[0074] In the first step, 169.5g mass fraction of 59% natural rubber latex (equivalent to 100g dry rubber) is placed in a 1L beaker, and stirred at room temperature for 10min;

[0075] The second step is at 50 DEG C, the nanocrystalline cellulose that quality is respectively 0g, 5g, 10g, 15g, 20g, 25g is added to the ethanol solution that mass fraction is 95% (the quality of NCC is 10% of ethanol solution quality ), adjust the pH at 5 with acetic acid, add 1g modifier KH-570, and stir for 60 minutes;

[0076] The third step is to add the modified nano-microcrystalline cellulose with uniform stirring reaction to the evenly stirred natural rubber latex, and stir and mix at room temperature for 30 minutes;

[0077] The fourth step is to pour the evenly stirred nano-microcrystalline cellulose / natural rubber mixture into the tray, and spray 10% CaCl 2 The solution was demulsified, co-precipitated, washed for 16 hours, and dried in a blast drying oven at 50°C to a constant weight t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com