Corrosion-resistant antiskid coating with aluminum matrix composite structure and preparation process thereof

An aluminum-based composite, anti-slip coating technology, applied in the direction of pressure inorganic powder coating, etc., can solve the problems of high construction requirements, poor coating quality stability, large deposition area, etc., and achieve good anti-corrosion and anti-skid performance of the coating The effect of reliable quality and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

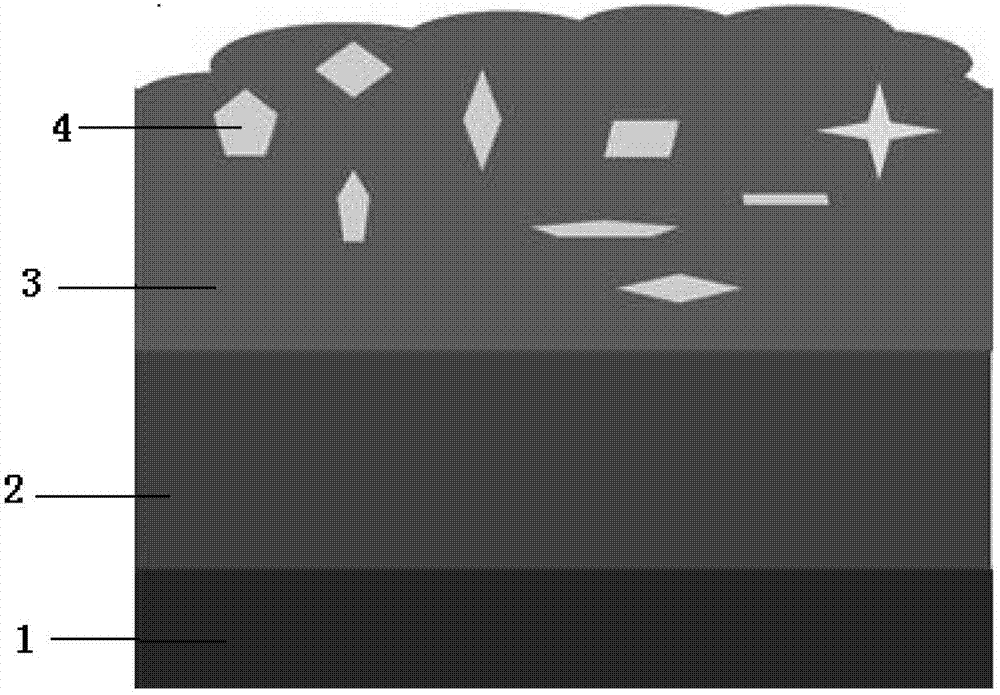

Embodiment 1

[0017] In this embodiment, the powder of the zinc-aluminum corrosion-resistant bottom layer 2 is selected as zinc-aluminum powder with a zinc content of 10% by weight and a particle size distribution of 0 to 50 μm; first, brown corundum sandblasting is used for the ship substrate, and then the cold spraying conditions are controlled. The cold spraying equipment is used for spraying, the air pressure of cold spraying is 1.0Mpa, the preheating temperature is 400°C, the spraying distance is 20mm, and the spraying angle is 90°, and the zinc-aluminum corrosion-resistant bottom layer 2 with uniform layer thickness is sprayed; then choose aluminum / ceramic The powder of the anti-slip top layer 3 is aluminum powder 0~40μm, alumina powder 0~30μm, aluminum / ceramic powder with a volume ratio of alumina of 40%. Conventional cold spraying equipment is used to control the spraying conditions. The cold spraying pressure is 0.6Mpa. The preheating temperature is 400°C, the spraying distance is 2...

Embodiment 2

[0021] In this example, the composite structure corrosion-resistant and anti-slip coating in Example 1 is first destroyed, and then the corrosion-resistant and anti-slip coating is repaired by spraying. The materials and parameters used are as follows:

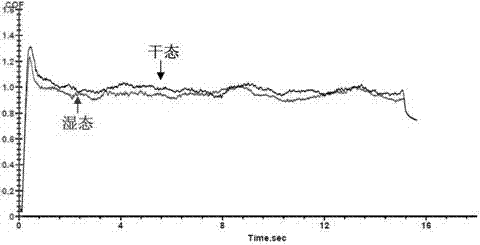

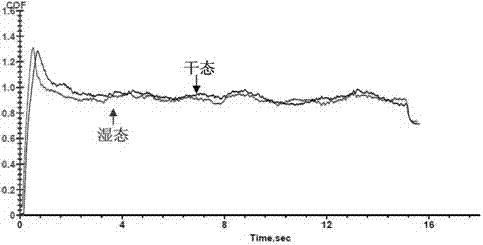

[0022] The coating powder is a mixed powder of aluminum powder less than 40 μm and alumina powder with a diameter of less than μm, wherein the volume ratio of aluminum oxide is 60%; using conventional portable cold spray equipment, the cold spray pressure is 0.8 MPa, and the preheating temperature is 400 ℃, the spraying distance is 20mm, and the spraying angle is 70-90 degrees; the friction coefficient test is carried out on the coating prepared by spraying repair and the neoprene plate in the dry state and wet state, and the average friction coefficient in the dry state after stabilization is 0.9316, wet state is 0.9115.

[0023] The smelting and crushing described in this embodiment is to heat and melt the raw materials to b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com