Functional composite coating and preparing method thereof

A composite coating and functional technology, applied in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of large thickness of corrosion-resistant coatings, poor seawater corrosion resistance, and short service life, and achieve a small coating thickness. , Excellent corrosion resistance, high elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of the above-mentioned functional composite coating comprises the following steps:

[0031] Step 1. After mixing the zinc yellow primer and the zinc yellow primer curing agent according to the above ratio evenly, paint or spray on the metal substrate to a thickness of 35-65 μm, and cure at room temperature for more than 5 hours to obtain a primer.

[0032]Wherein, according to techniques well known to those skilled in the art, before preparing the coating on the metal substrate, the surface of the metal substrate needs to be roughened and cleaned. For roughening treatment, 60# corundum can be used as sandblasting, and the workpiece can be sandblasted to the standard of sa2.5 or above; for parts that cannot be disassembled and need to be painted online, use an angle grinder or other equipment to roughen the surface of the substrate processed to the appropriate level. The cleaning treatment can use n-hexane or other suitable organic solvents to rep...

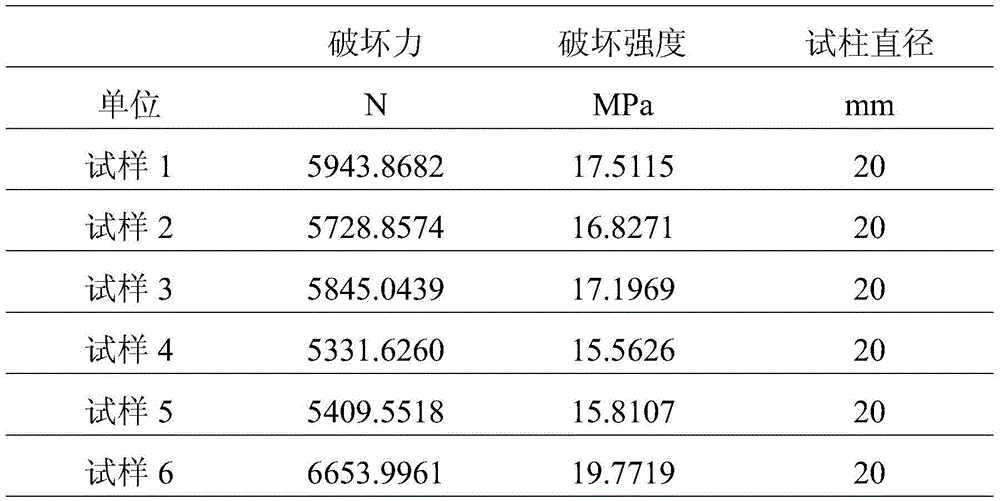

Embodiment 1

[0041] The functional composite coating is composed of primer, middle coat and top coat. The primer is composed of zinc yellow primer FXH02-7 with a mass ratio of 8:1 and cardanol modified amine curing agent ZY-2015, with a thickness of 45 μm. The coating is composed of epoxy resin E-44, epoxy resin 830, epoxy resin curing agent 651, toughening agent JHZ-403 and glass hollow microspheres with a mass ratio of 15:33:48:5:30, with a thickness of 0.3 mm, the surface coating consists of fluoroolefin-vinyl ether copolymer resin TFE-PPVE with a mass ratio of 77:7:60:24, fluoroolefin-vinyl ether copolymer resin TFE-PPVE curing agent, and solvent-based polyurethane resin S06- 0215 and solvent-based polyurethane resin S06-0215 curing agent, the thickness is 0.7mm.

[0042] The preparation method of the above-mentioned functional composite coating:

[0043] Step 1. Mix zinc yellow primer FXH02-7 and cardanol-modified amine curing agent ZY-2015 in a mass ratio of 8:1, spray on the meta...

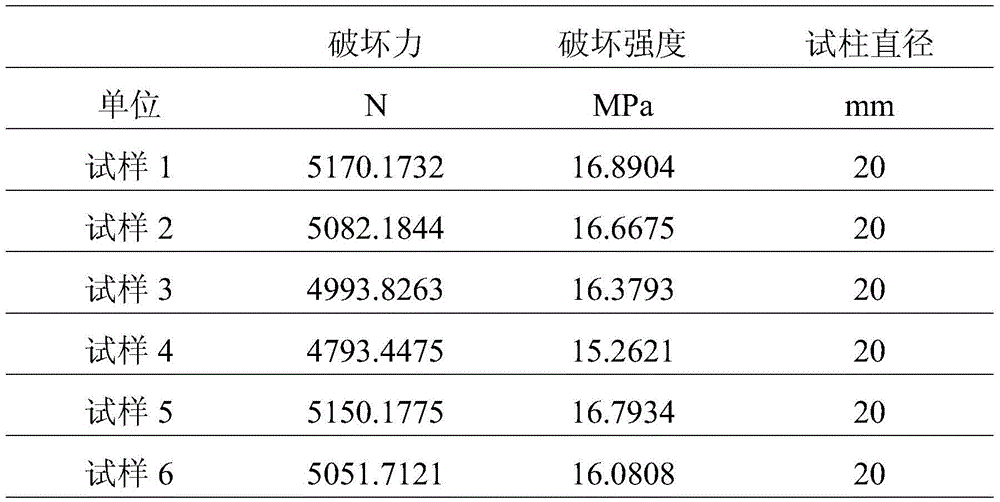

Embodiment 2

[0054] The functional composite coating consists of primer, middle coat and top coat. The primer is composed of zinc yellow primer FXH02-7 with a mass ratio of 8:1 and cardanol modified amine curing agent ZY-2015, with a thickness of 35 μm. The coating is composed of epoxy resin E-20 with a mass ratio of 55:30:2.55:25.5, epoxy resin curing agent polyamide resin 651, butadiene acrylonitrile copolymerized nitrile rubber and lamellar ferrite, with a thickness of 0.25mm, the surface coating consists of fluoroolefin-vinyl ether copolymer resin (DuPont 340BK in the United States) with a mass ratio of 12:1:10:3, fluoroolefin-vinyl ether copolymer resin (DuPont 340BK in the United States) curing agent, and solvent Type polyurethane resin S04-950H.YH, solvent type polyurethane resin S04-950H.YH curing agent, thickness 0.8mm.

[0055] The preparation method of the above-mentioned functional composite coating:

[0056] Step 1. Mix zinc yellow primer FXH02-7 and cardanol-modified amine c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com